Device and method for heating and drying household garbage through steam with gas circulation

A domestic garbage and gas circulation technology, applied in the direction of heating devices, drying gas layout, combustion methods, etc., can solve the problems of unfavorable continuous large-scale production, multi-energy, intermittent, etc., to reduce the cost of tail gas treatment, reduce emissions, reduce The effect of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

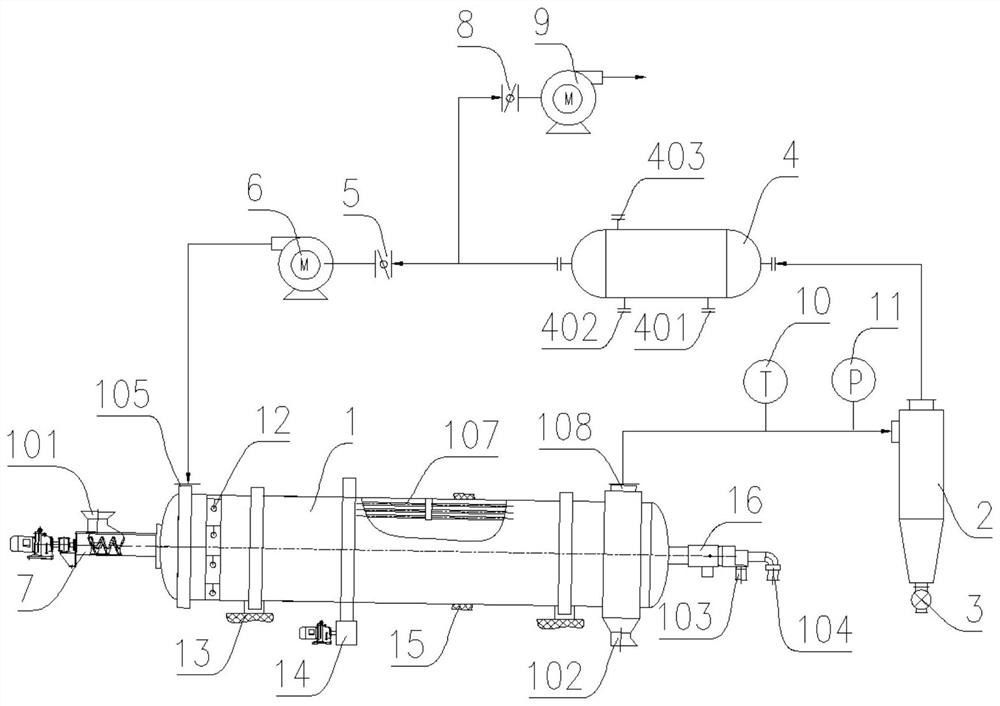

[0028] A steam-heated drying device with gas circulation, comprising a steam-heated tubular rotary cylinder dryer 1, the steam-heated tubular rotary cylinder dryer 1 is in the shape of a cylinder, the left end is the feed end, and the right end is the outlet At the feed end, a feed device 7 is installed at the feed end, and the steam heating tubular rotary cylinder dryer 1 is installed obliquely with a certain angle (<10 degrees) with the horizontal plane, and the side of the feed end is higher. One end of the material is lower; 101 garbage feeding ports are arranged on the feeding device 7 . A circulating gas inlet 105 is also provided on the steam-heated tubular rotary cylinder dryer 1, and a hammer 12 is provided outside the cylinder body of the steam-heated tubular rotary cylinder dryer 1 for vibrating the cylinder wall surface, Vibrate the rubbish stuck on the inner surface; arrange several heating tubes 107 in concentric circles inside the cylinder, and the circumference...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com