Pharmaceutical drier

A dryer and drying chamber technology, applied in the direction of dryers, drying, drying solid materials, etc., can solve the problems of increased drying costs, decomposition of active ingredients, and errors in temperature control, so as to improve the drying effect , reduce thermal decomposition, improve the quality of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

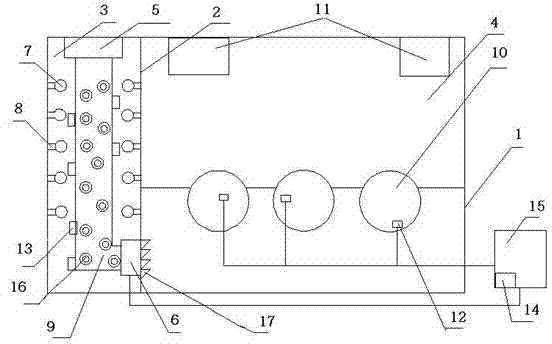

[0020] The dryer includes a shell 1, the partition 2 divides the shell 1 into a hot air chamber 3 and a drying chamber 4, and a hot air blower 5 is installed below the air inlet of the hot air chamber 3 to blow hot air from the hot air chamber 3 to the drying chamber 4. An air intake fan 6 is provided on the partition plate 2 between the hot air chamber 3 and the drying chamber 4, and an air intake regulating valve 17 is provided on the air intake fan 6. The inner wall of the hot air chamber 3 is evenly distributed with metal pendants 7, and the metal pendants 7 are suspended and fixed with electric heating tubes 8 that are uniformly distributed and heated facing the material delivery tank. A power regulating device 14 is used for adjustment. A material conveying trough 9 and two temperature sensors 13 arranged beside the material conveying trough 9 are arranged in the hot air chamber 3 . The temperature sensors 13 are connected with the control cabinet 15 . The bottom of the ...

Embodiment 2

[0022] The dryer includes a shell 1, the partition 2 divides the shell 1 into a hot air chamber 3 and a drying chamber 4, and a hot air blower 5 is installed below the air inlet of the hot air chamber 3 to blow hot air from the hot air chamber 3 to the drying chamber 4. The partition plate 2 between the hot air chamber 3 and the drying chamber 4 is provided with an air inlet fan 6, and the air inlet fan 6 is provided with an air inlet regulating valve 17, which can adjust the direction and angle of the air outlet. The inner wall of the hot air chamber 3 is evenly distributed with metal pendants 7, and the metal pendants 7 are suspended and fixed with electric heating tubes 8 that are uniformly distributed and heated facing the material delivery tank. The power adjustment device 14 is used for adjustment. The hot air chamber 3 is provided with two material conveying troughs 9 and two temperature sensors 13 arranged beside the material conveying troughs 9 . The bottom of the mat...

Embodiment 3

[0024] The dryer includes a shell 1, the partition 2 divides the shell 1 into a hot air chamber 3 and a drying chamber 4, and a hot air blower 5 is installed below the air inlet of the hot air chamber 3 to blow hot air from the hot air chamber 3 to the drying chamber 4. The partition plate 2 between the hot air chamber 3 and the drying chamber 4 is provided with an air inlet fan 6, and the air inlet fan 6 is provided with an air inlet regulating valve 17, which can adjust the direction and angle of the air outlet. The inner wall of the hot air chamber 3 is evenly distributed with metal pendants 7, and the metal pendants 7 are suspended and fixed with electric heating tubes 8 that are uniformly distributed and heated facing the material delivery tank. The power adjustment device 14 is used for adjustment. The hot air chamber 3 is provided with three material conveying troughs 9 and eight temperature sensors 13 arranged beside the material conveying troughs 9 . The bottom of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com