Continuous drying device used for automatic circuit board production line

A technology for automated production lines and drying equipment, applied in drying, drying machines, lighting and heating equipment, etc., can solve the problems of difficult temperature and humidity control, low drying efficiency, affecting circuit board processing, etc., to improve thermal energy. utilization rate, improve drying efficiency, and realize the effect of intelligent control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

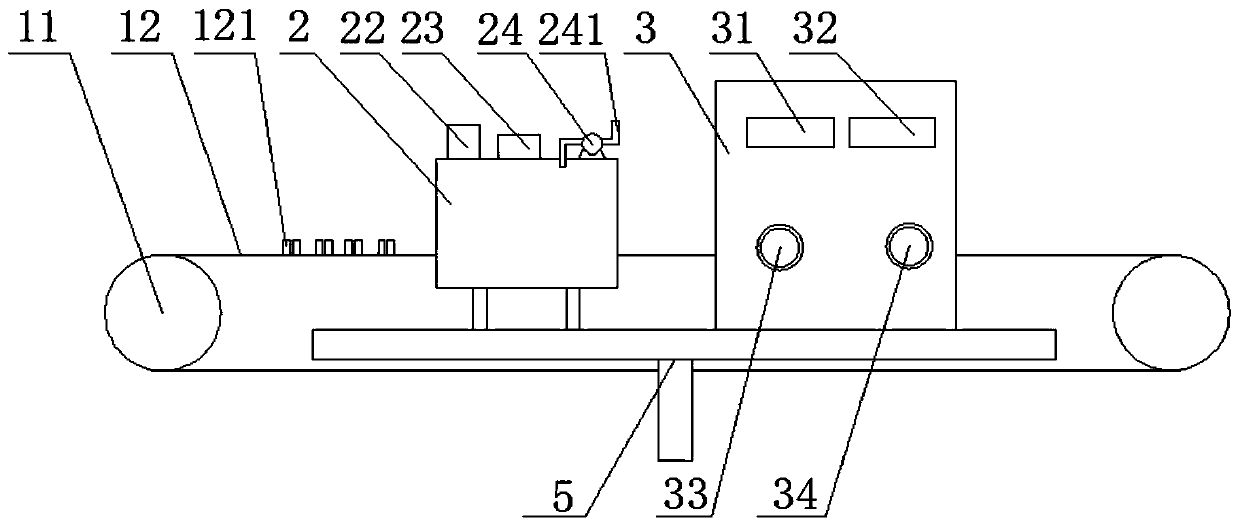

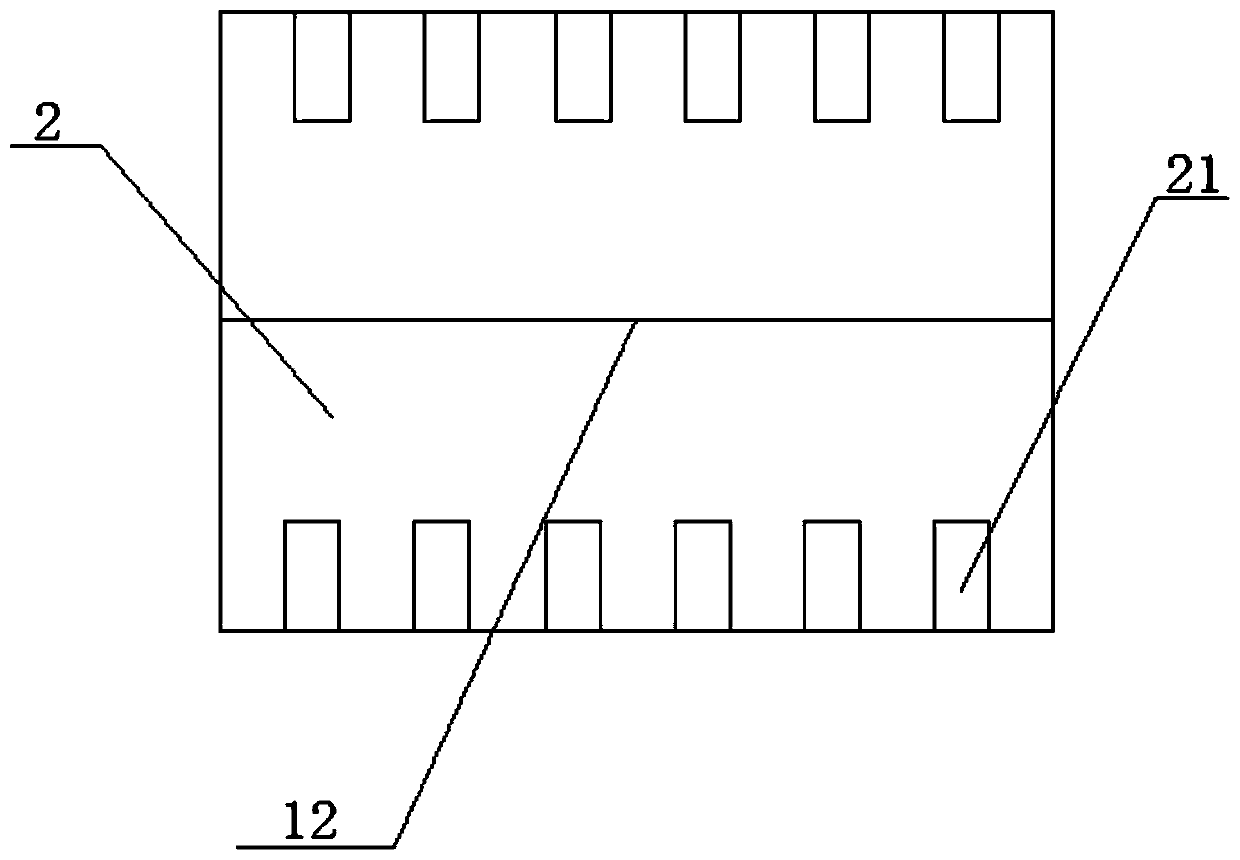

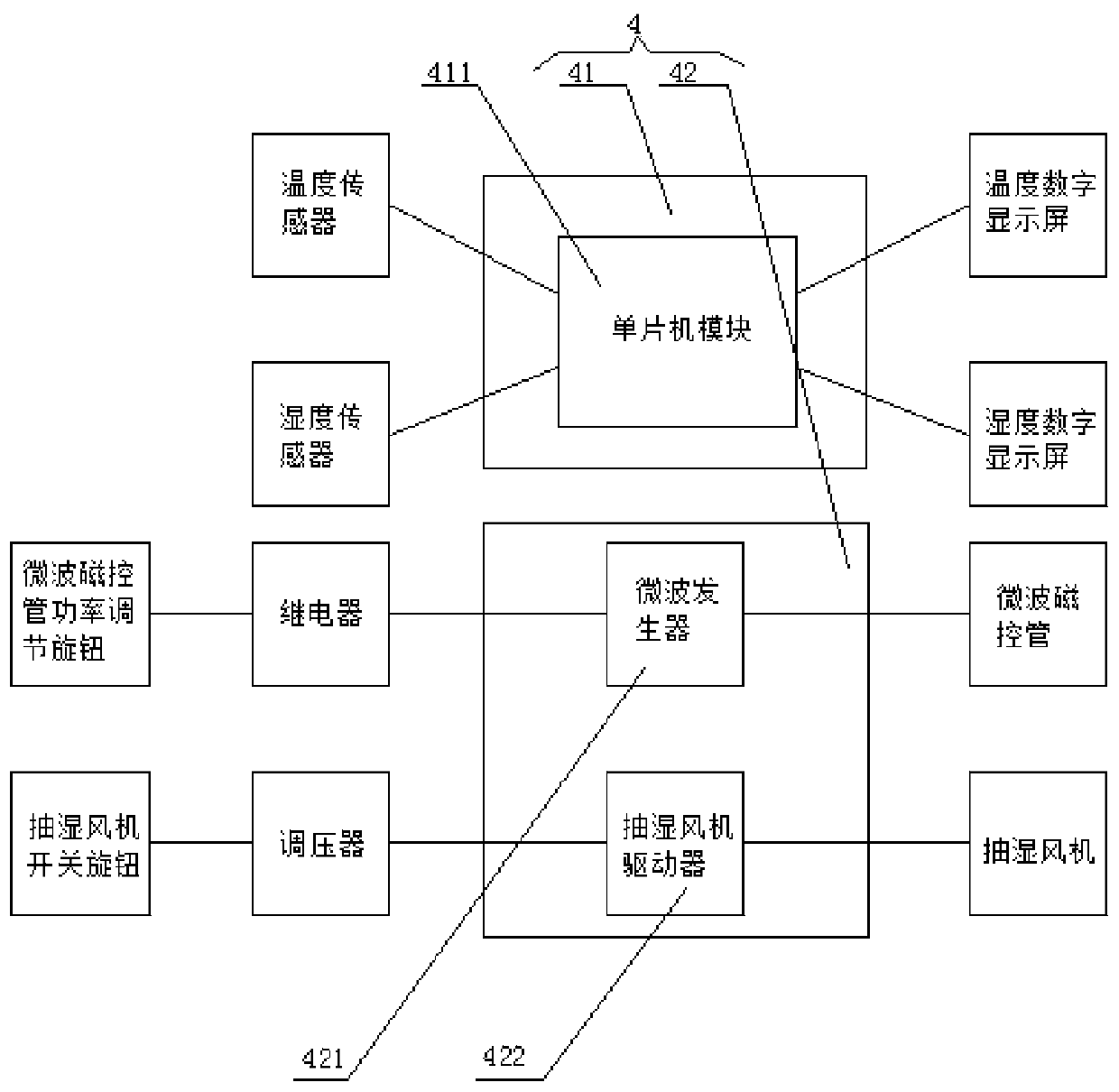

[0023] Such as figure 1 As shown, one embodiment of the present invention discloses a continuous drying equipment for an automatic circuit board production line, including a conveying device and a drying device, the drying device is arranged on the conveying device, and the conveying device It includes two pulleys 11, and a conveyor belt surrounding the two pulleys is arranged outside the two pulleys; the drying device includes a drying box 2, and a plurality of microwave magnets are arranged in the drying box 2. Control pipe 21; the upper end of the drying box 2 is sequentially provided with a temperature sensor 22, a humidity sensor 23 and a dehumidifying fan 24; The air outlet of the dehumidifying fan 24 is connected with an air outlet duct 241; the conveyor belt 12 passes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com