Multiple-tower continuous dryer

A dryer and drying tower technology, applied in the direction of drying and saving seeds, can solve the problems of increasing the burden on enterprises and farmers, not being able to dry grain, and increasing costs, so as to save heat energy, have sufficient drying time, The effect of reducing the purchase cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

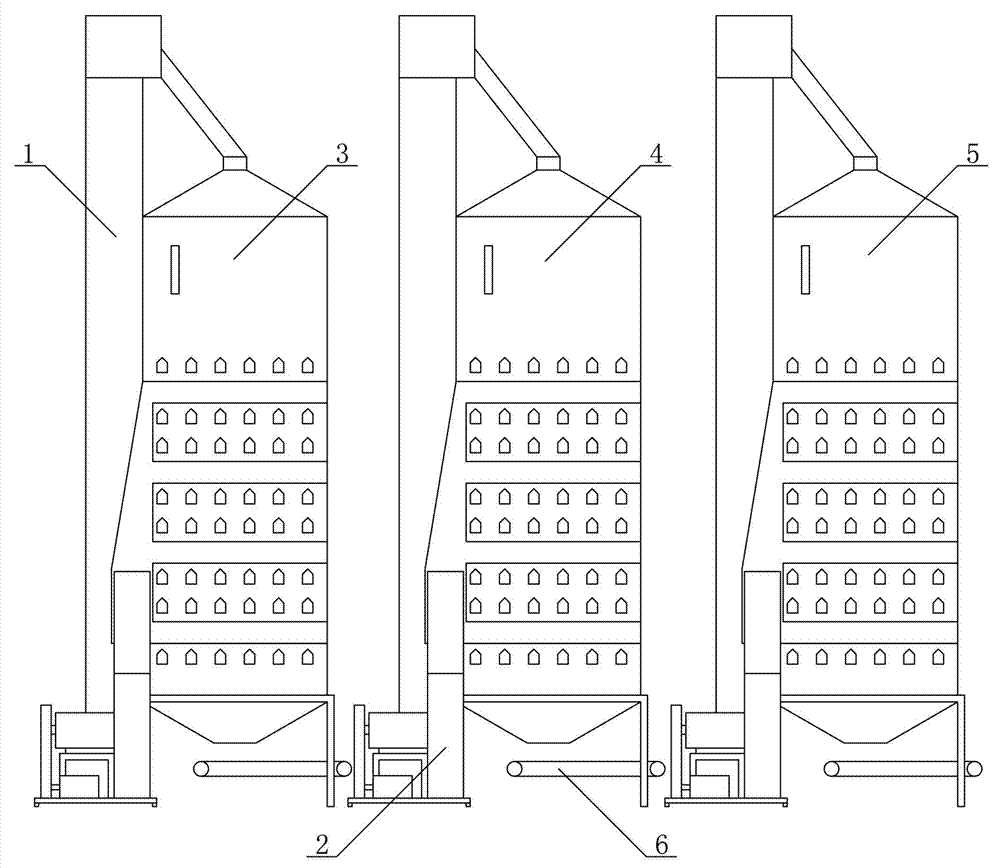

[0013] Such as figure 1 As shown, a multi-tower continuous dryer includes at least two stages of drying tower mechanisms and a hot air generating and conveying mechanism that provides drying gas for each drying tower mechanism, and each stage of drying tower mechanism includes a drying tower And for the hoist 1 that transports grain to the corresponding drying tower, the grain input end of the hoist 1 of the next level is set correspondingly to the grain output end of the drying tower described in the upper level so that the drying capacity of the upper level is The dried grain in the drying tower is transported to the next drying tower.

[0014] There are three advantages of this design:

[0015] 1. Due to the limited volume of a single drying tower, the moisture content of the once-dried grain has not yet dropped to the storage standard, and it needs to be dried continuously. Therefore, the grain that has been dried by the previous stage passes through the elevator 1 It is...

Embodiment 2

[0021] The difference between Embodiment 2 and Embodiment 1 is that the hot air generating and conveying mechanism includes at least two hot air blowers 2, and each of the hot air blowers 2 is connected to the corresponding drying tower through an air duct so as to transport the drying air for the drying tower. dry gas. The advantage of this design is that multiple hot air blowers can be used to replace a total hot air blower, so that each of the hot air blowers 2 corresponds to each of the drying towers, so as to realize the supply of different hot air blowers 2. The temperature of the drying gas is also different, so that each drying tower can carry out targeted temperature-controlled drying according to the drying degree of the grain in it. The drying gas is the gas heated by the hot air blower 2 .

Embodiment 3

[0023] The difference between embodiment 3 and embodiment 2 is that: the grain output end of the drying tower includes a discharge port and a conveyor belt mechanism 6 located below the discharge port, and the conveyor belt mechanism 6 is connected to the lifting mechanism of the next stage. The grain input end of machine 1 is correspondingly set. Due to the large volume of the drying tower, the conveyor belt mechanism 6 is provided to facilitate the grain transmission between adjacent two-stage drying equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com