A temperature control method of a dry clothes treatment device and a dry clothes treatment device

A technology of a clothes processing device and a temperature control method, which is applied to the temperature control of a clothes drying device and the field of a clothes drying device, and can solve problems such as damage to clothes, affecting the temperature rise rate in a drying cylinder, and prolonging drying time, etc. Achieve the effect of leveling clothes, ensuring long drying time and reducing work burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

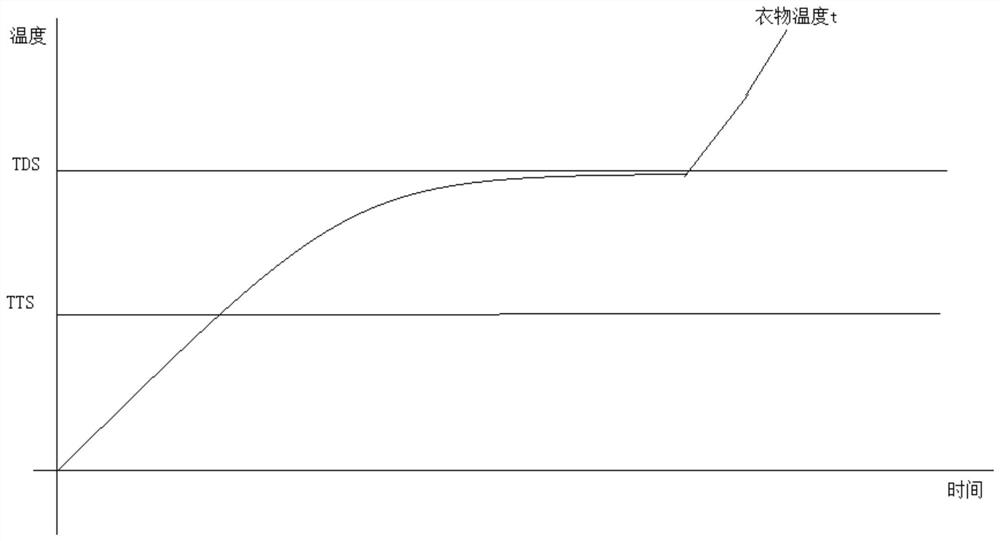

[0048] like figure 2 As shown, this embodiment discloses a method for controlling the temperature of a dry clothes treatment device. The dry clothes treatment device in this embodiment is a clothes dryer, and the dry clothes treatment device is provided with a heating device, a temperature measuring device and a control device electrically connected to each other. The heating device is used to heat the dry clothes treatment device, so as to increase the temperature inside the dry clothes treatment device, accelerate the gasification process of the liquid on the surface of the clothes, and achieve the effect of drying clothes to realize the drying of clothes. At the same time, a temperature measurement device is provided in the dry clothes treatment device, and the temperature measurement device is used to measure the temperature information of the dry clothes treatment device, and send the measured temperature information to the control device; the control device receives the...

Embodiment 2

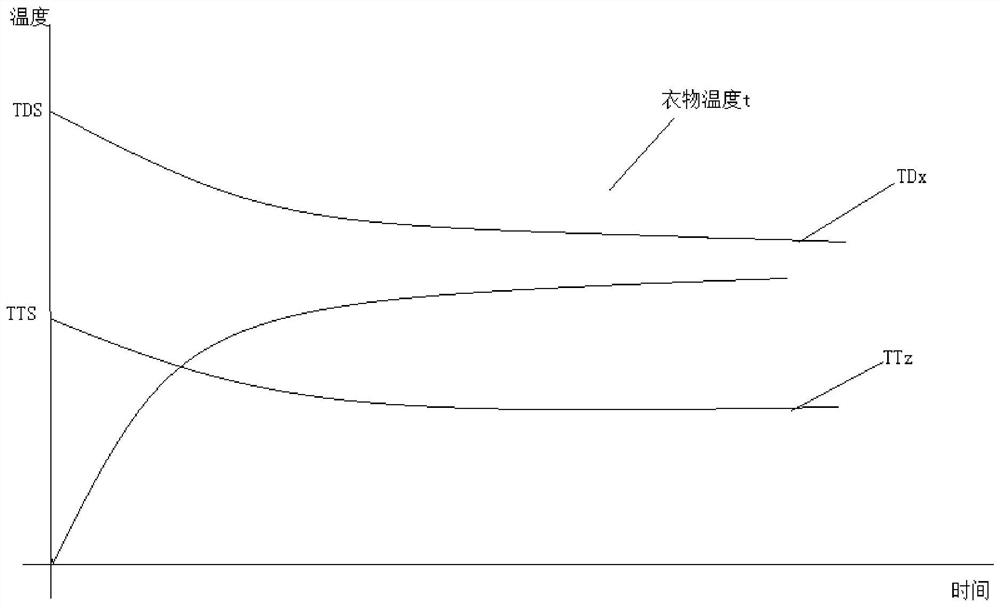

[0066] like image 3 As shown, this implementation is a supplement to Example 1. The difference between this embodiment and Embodiment 1 is that in this embodiment, when the temperature in the cylinder of the heating device of the drying clothes processing device drops to the lower limit value TTz of the temperature range for the zth time, the drying clothes processing device turns on the heating device. The heating device is used for heating; the lower limit value TTz of the temperature range decreases as the number z of the heating device is switched on. The dry clothes treatment device is provided with a system switch-on temperature TT0, TT0 is a set value, and the value of TTz is infinitely close to TT0 as the number of times z of the heating device is switched on increases. TT0 is determined by the liquid point temperature of the liquid on the clothes in the dry clothes treatment device, and the TT0 is greater than the liquid point temperature.

[0067] The dry clothes tr...

Embodiment 3

[0071] A dry clothes treatment device applying the method for controlling the temperature of a dry clothes treatment device according to any one of the above embodiments is provided with a heating device, a temperature measuring device and a control device electrically connected to each other. The heating device is used to heat the drying clothes processing device to realize the drying of clothes; the temperature measuring device is used to measure the temperature information of the drying clothes processing device, and send the measured temperature information to the control device; The control device receives the temperature information, and controls the heating device to perform an on / off operation within a temperature range according to the temperature information.

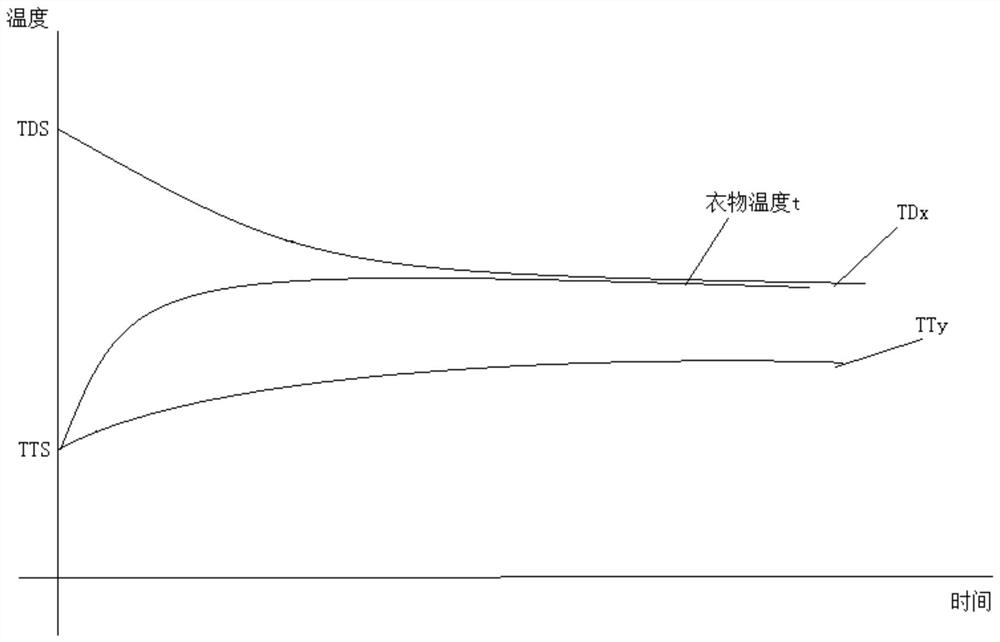

[0072] In this embodiment, when the temperature inside the cylinder reaches the upper limit value TDx of the temperature range under the action of the heating device, the drying clothes treatment device disconn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com