Sludge comprehensive treatment system and method

A comprehensive sludge treatment technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problem of affecting the economic benefits of enterprises and restricting the application of sludge drying and incineration projects Prospects, increased costs and other issues, to achieve the effect of reasonable fluidity and particle size distribution, good engineering application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

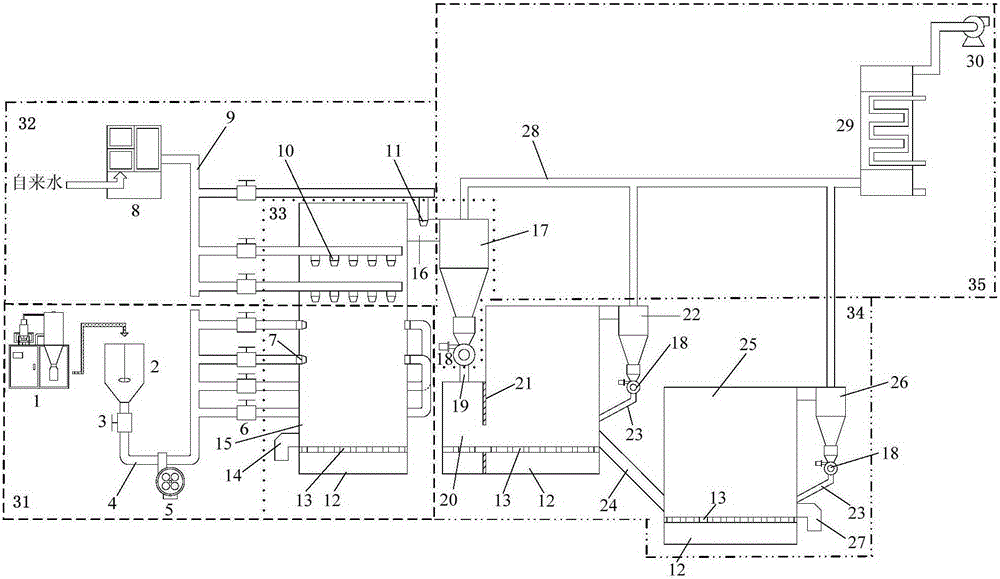

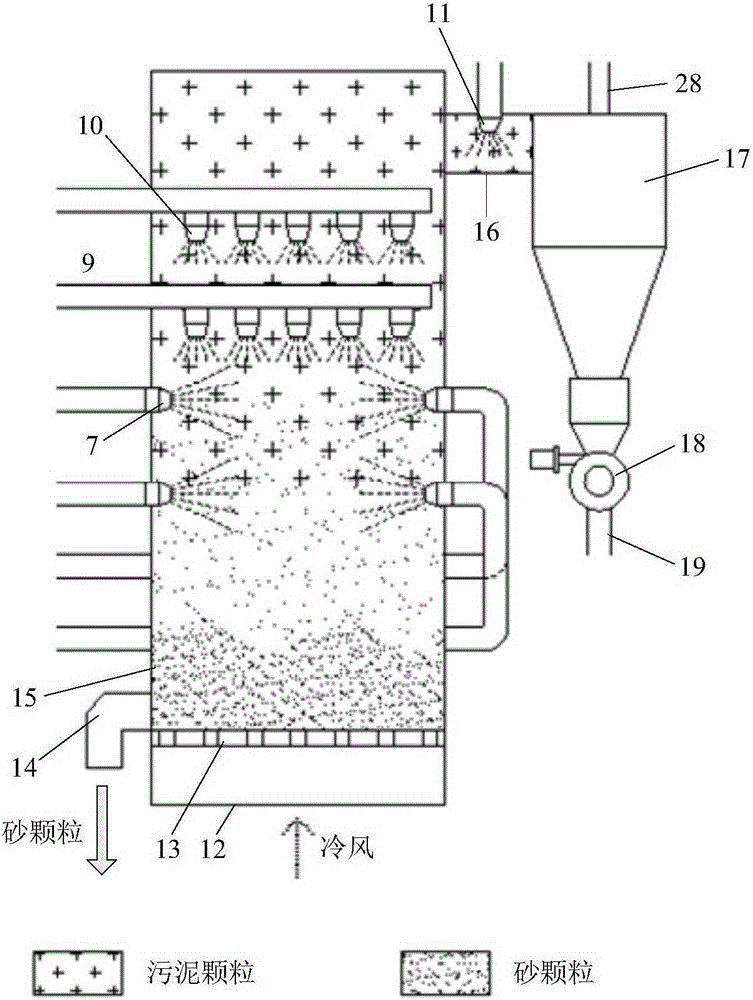

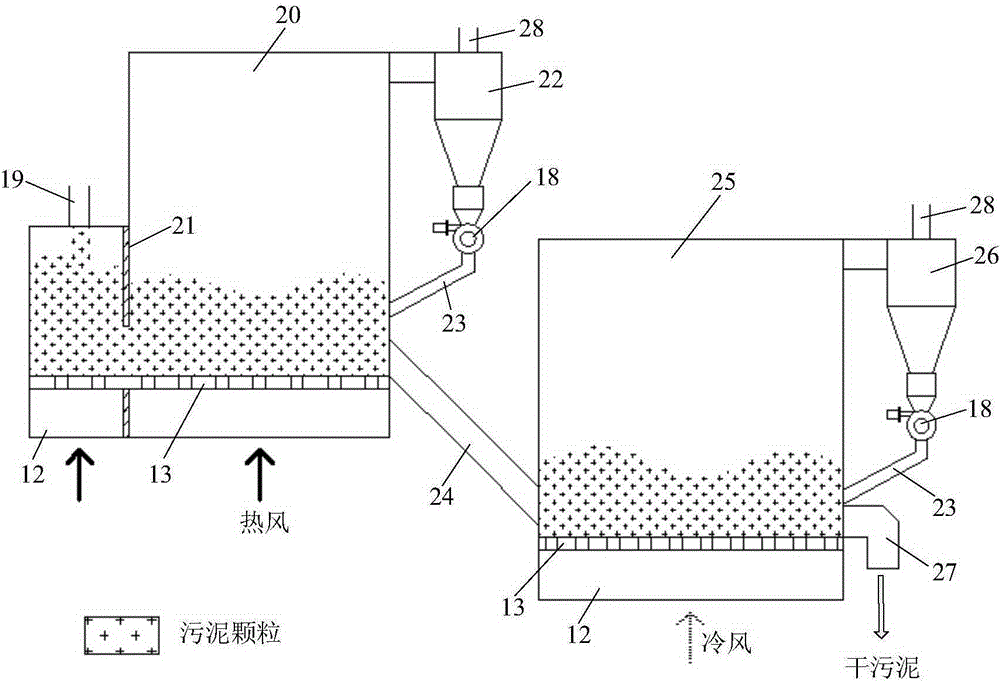

[0022] The structure, principle and working process of the present invention will be further described below in conjunction with the accompanying drawings.

[0023] see figure 1 , figure 2 and image 3, The system provided by the present invention is mainly composed of a sludge crushing and conveying spraying device 31, a plant liquid conveying and spraying device 32, a fluidized bed sand particle removal and deodorizing device 33, a fluidized bed drying and cooling device 34 and an exhaust gas treatment device 35. The sand particle removal and deodorization device contains a main fluidized bed 15 and a main cyclone separator 17, and an inlet pipe plant liquid atomizing nozzle 11 is provided in the inlet pipeline 16 of the main cyclone separator; Horizontally and vertically arrange several pairs of horizontally hedged wet sludge atomizing nozzles 7 along the front and rear walls, and the wet sludge atomizing nozzles are connected with the sludge crushing and conveying spray...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com