Low-dew-point PSA nitrogen generation system

A low dew point, nitrogen technology, applied in nitrogen compounds, refrigeration and liquefaction, nitrogen purification/separation, etc., can solve the problems of inability to lower the dew point and high water content of nitrogen, achieve good air dispersion effect, improve dryness, and reduce sound Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

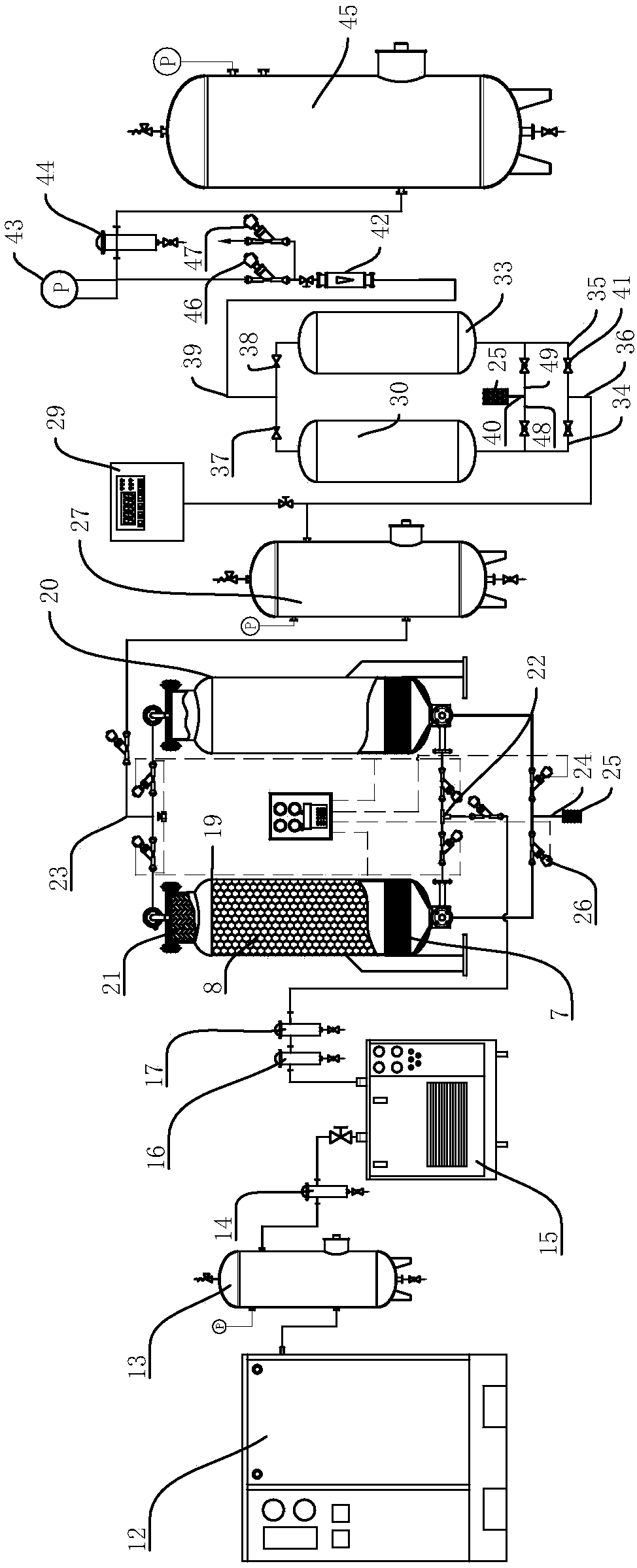

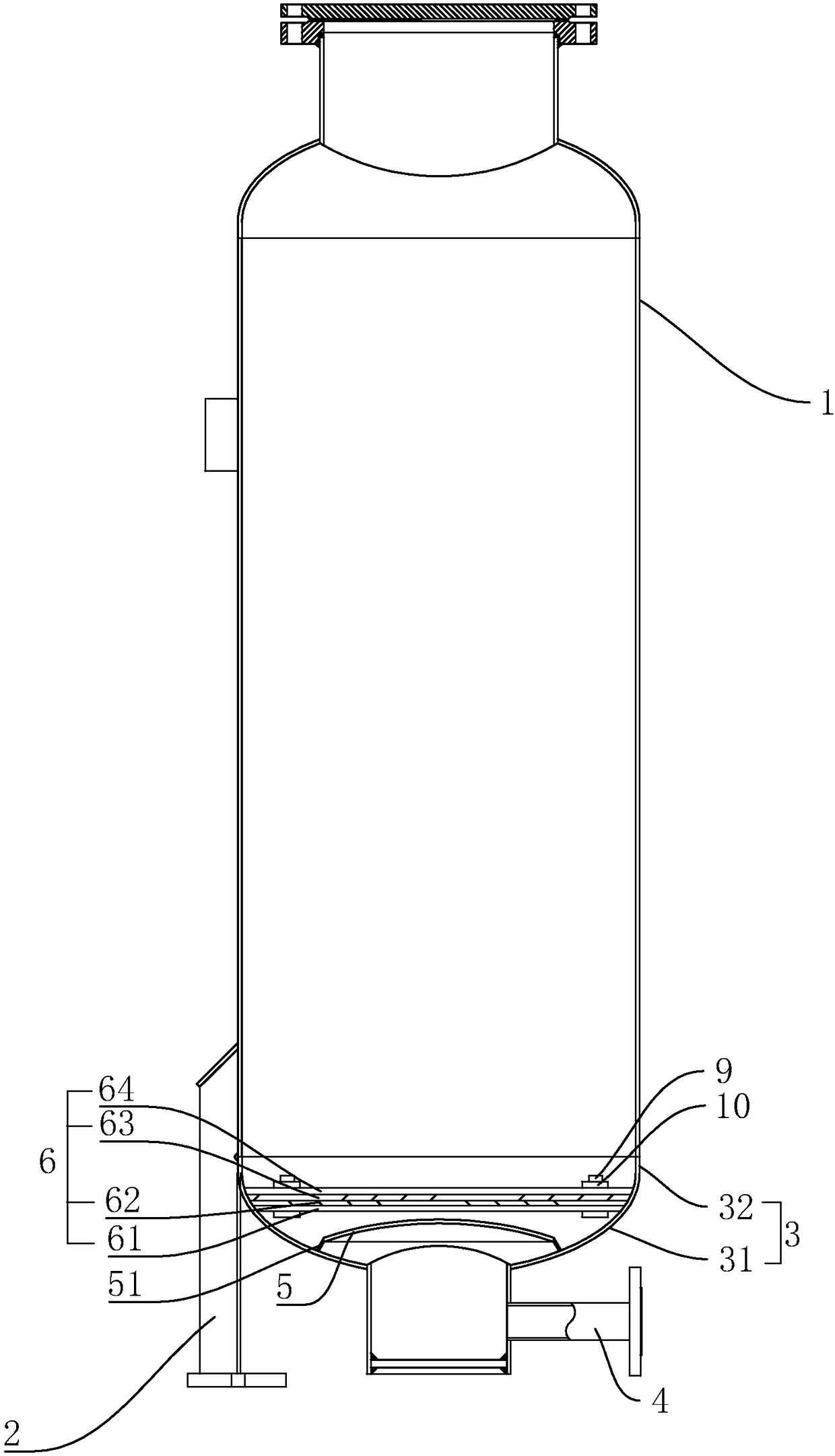

[0037] Embodiment: a kind of low dew point PSA nitrogen production system, such as figure 1 , 2 As shown, it includes an air compressor 12, an air buffer tank 13, a C-level filter 14, a cold dryer 15, a T-level filter 16, an A-level filter 17, a nitrogen generating device, and a nitrogen buffer tank 27 connected in sequence through pipelines. , heatless adsorption dryer 28 and nitrogen storage tank 45. The air compressor 12 is used to extract air, and the air buffer tank 13 is used to store the air extracted by the air compressor 12 and release it slowly. The C-level filter 14 is used to filter moisture and impurities of larger particles in the air. The cold dryer 15 is used for cooling and compressing air. The T-level filter 16 and the A-level filter 17 are used to filter the impurities of smaller particles in the air. The nitrogen generator can separate the nitrogen and oxygen in the air to produce nitrogen. The nitrogen buffer tank 27 can reduce the nitrogen flow rate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com