Multi-heat-source tobacco drying system

A drying system and multi-heat source technology, which is applied in drying, tobacco, dryer, etc., can solve the problem of continuous drying of tobacco and achieve the effects of prolonging the effective time, saving energy, and improving precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

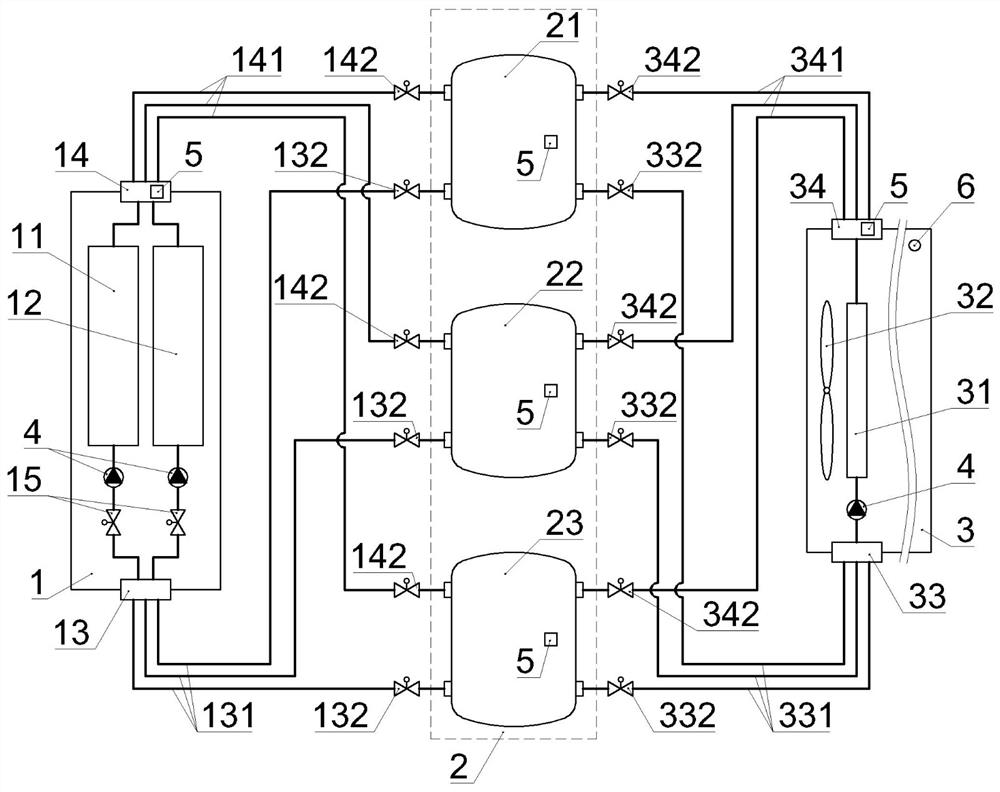

[0032] Such as figure 1 As shown, a multi-heat source tobacco drying system includes a multi-heat source heating device 1 , a heat storage tank 2 and a drying room 3 .

[0033] There can be one or more hot water storage tanks 2, and they can be divided into high temperature water tank 21, medium temperature water tank 22 and low temperature water tank 23 according to the temperature range of stored energy storage water. There can also be one or more high-temperature water tanks 21, medium-temperature water tanks 22 and low-temperature water tanks 23. The heat storage tank 2 is wrapped with thermal insulation material to prevent the heat of the energy storage water inside the heat storage tank 2 from being lost to the environment.

[0034] Preferably, the heat storage tank 2 in this embodiment includes a high-temperature water tank 21 , a medium-temperature water tank 22 and a low-temperature water tank 23 .

[0035] The multi-heat source heating device 1 includes a heating w...

Embodiment 2

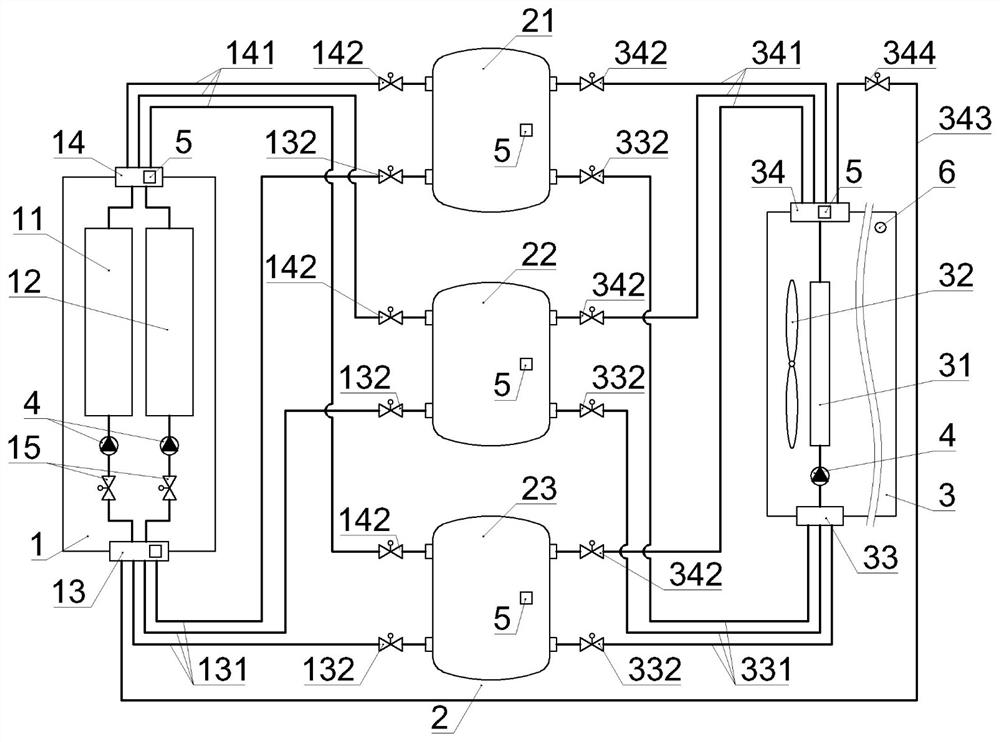

[0057] Different from Embodiment 1, this embodiment is also provided with a temperature replenishing branch 343 connected to the heating water inlet 13 of the multi-heat source heating device 1 at the heat dissipation return water end 34 of the drying room 3, and the heat replenishment branch 343 There is a supplementary heat valve 344 on it. According to the actual situation, the energy storage water after cooling can be directly entered into the multi-heat source heating device 1 for heating without returning to the hot water storage tank 2 .

Embodiment 3

[0059] The difference from the second embodiment is that this embodiment is provided with three drying rooms 3, each drying room 3 is connected to the hot water storage tank 2 and the multi-heat source heating device 1 in the same way as the second embodiment, and different The energy-saving drying of tobacco in the drying stage makes full use of the energy storage water inside the heat storage tank 2 in different temperature ranges, further improving the overall heat utilization rate of the system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com