Combined oven used in printing and dyeing industry

A combined type and oven technology, which is applied in drying, drying machines, progressive drying machines, etc., can solve the problems of small-capacity ovens being eliminated and moved, and achieves convenient disassembly, reduced floor space, and strong applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below, the present invention is described in detail with reference to accompanying drawing and embodiment:

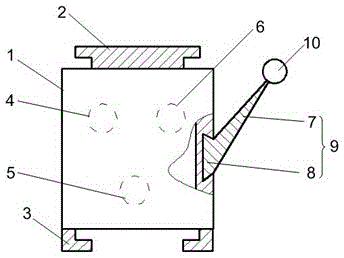

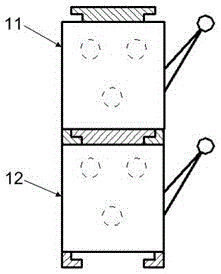

[0025] Such as figure 1 As shown, a combined oven in the printing and dyeing industry includes a box body 1 with a feed inlet and a discharge port on two opposite sides. The top of the box body 1 forms a T-shaped slider 2, and the bottom forms a T-shaped slider. The matching guide groove 4, the first guide roller 4, the second guide roller 5, and the third guide roller 6 inside are distributed in a triangle, and the side wall where the feeding port of the box body 1 is located is provided with an auxiliary frame 9, and the auxiliary frame 9 is free An auxiliary guide roller 10 is provided at the end.

[0026] The auxiliary frame 9 includes an assembly block 8 and a pole 7 inserted into the side wall of the box body 1 .

[0027] The cross-section of the assembly block 8 is trapezoidal, and the side wall of the box body 1 forms a corresponding assembly groove wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com