Production method and product of lithium-ion power battery rate cathode material

A technology of power battery and manufacturing method, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve problems such as difficulty in ensuring quality uniformity, lengthy manufacturing process, and increased cost, and achieve large-scale production and cost control with abundant sources , The effect of simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

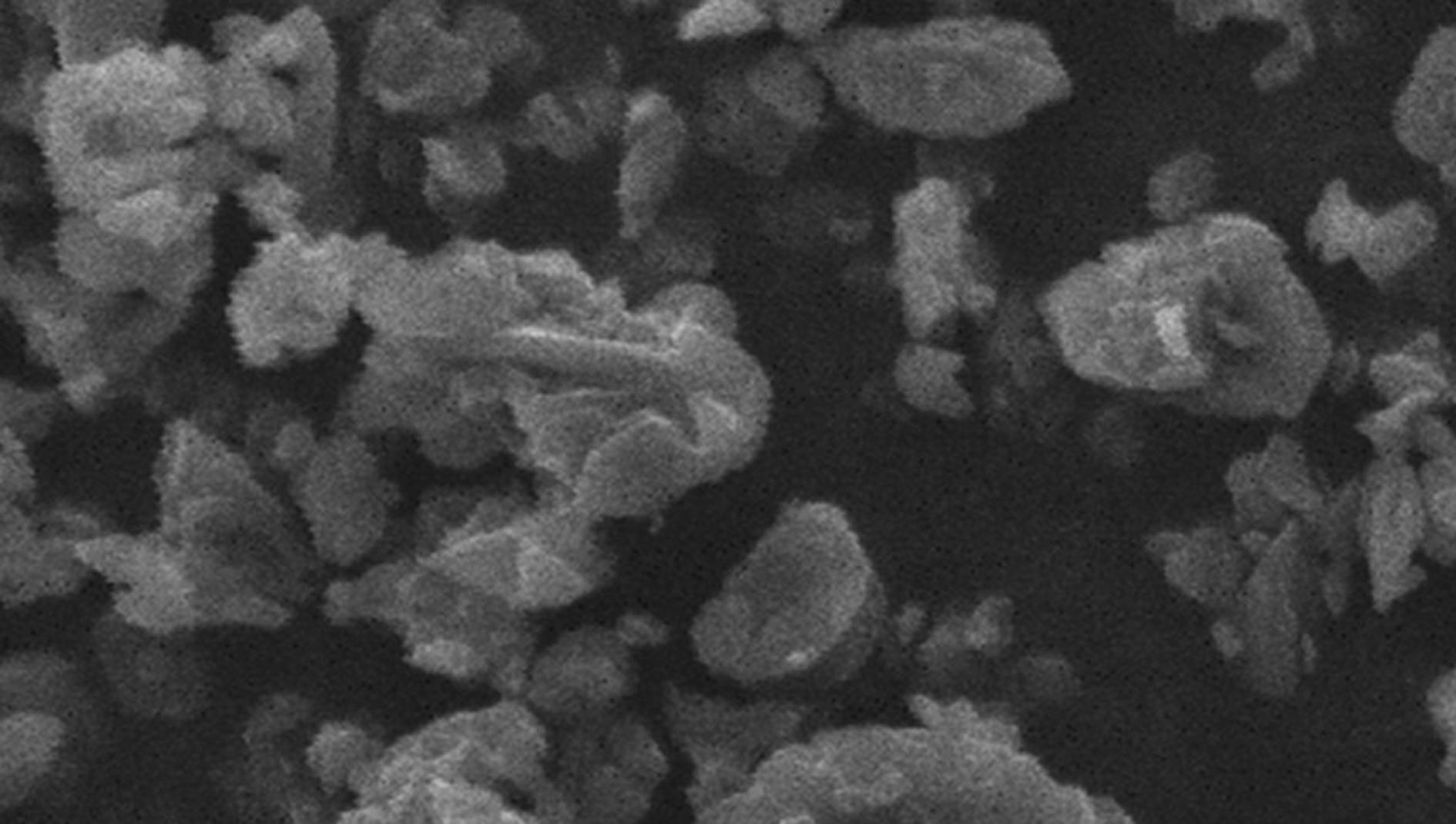

Image

Examples

Embodiment 1

[0050] In a 50-liter small reaction kettle, heavy products of petroleum processing, heavy products of coal processing and carbon nanotubes are sequentially added, and the weights added are 9.0 kg, 1.0 kg and 0.05 kg respectively. Then, the temperature of the reactor was raised from room temperature to 590° C. at a temperature increase rate of 0-2.0° C. / min. The whole heating process was carried out under the inert gas N 2 Down, the pressure is maintained at 0-0.02MPa. Under the final temperature condition, keep it for 0-3 hours, then cool the material and take it out. Then graphitization treatment is performed to obtain the negative electrode material of the lithium ion battery, and the temperature of the carbonization treatment is 1280°C.

[0051] The particle size of the above-mentioned heavy product of coal tar processing is D50=3.0-50.0 μm, the particle size of the low-temperature carbonization product of the heavy residue of hydrocarbon polycondensation reaction is D50=...

Embodiment 2

[0053] In a 50-liter small reaction kettle, heavy products of petroleum processing, heavy products of coal tar processing and carbon microspheres were sequentially added, and the added weights were 9.0 kg, 1.0 kg and 0.05 kg respectively. Then, the temperature of the reactor was raised from room temperature to 590° C. at a temperature increase rate of 0-2.0° C. / min. The whole heating process was carried out under the inert gas N 2 Down, the pressure is maintained at 0-0.02MPa. Under the final temperature condition, keep it for 0-3 hours, then cool the material and take it out. Then, graphitization treatment is performed to obtain the negative electrode material of the lithium ion battery, and the temperature of the graphitization treatment is 2400°C.

[0054] The particle size of the above-mentioned coal tar processed heavy product is D50=3.0-50.0 μm, and the particle size of the petroleum processed heavy product is D50=4.0-20.0 μm.

Embodiment 3

[0056] In a 50-liter small reaction kettle, heavy products of petroleum processing, heavy products of coal tar processing, and vapor-phase deposited carbon fibers were sequentially added, and the added weights were 9.0 kg, 1.0 kg, and 0.05 kg, respectively. Then, the temperature of the reactor was raised from room temperature to 590° C. at a temperature increase rate of 0-2.0° C. / min. The whole heating process was carried out under the inert gas N 2 Down, the pressure is maintained at 0-0.02MPa. Under the final temperature condition, keep it for 0-3 hours, then cool the material and take it out. The material is crushed and classified to keep the particle size of the material at D50=4.0-12.0μm, and then carbonized to obtain the negative electrode material of lithium ion battery. The temperature of carbonization is 1000°C.

[0057] The particle size of the above-mentioned coal tar processed heavy product is D50=3.0-50.0 μm, and the particle size of the petroleum processed heav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size distribution | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com