Pin shaft mistake proofing device used on automatic production line

An automated production line and pin shaft technology, which is applied to conveyor control devices, transportation and packaging, mechanical conveyors, etc., can solve problems such as leaf spring pin model inconsistencies, reduce labor intensity, ensure accuracy, and ensure stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

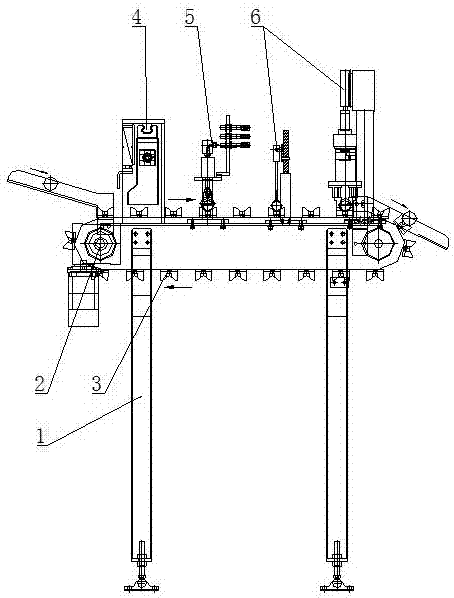

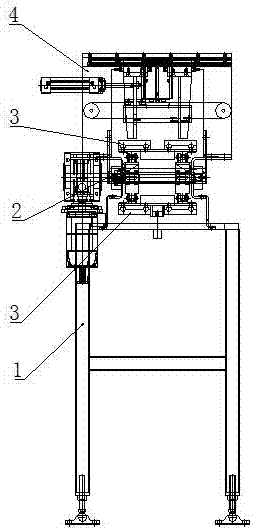

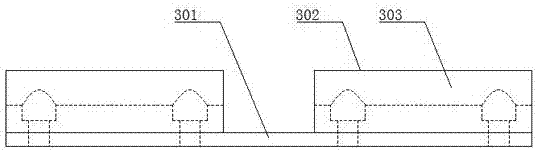

[0031] Such as figure 1 and figure 2As shown, a pin-type error-proofing device used on an automated production line includes a frame 1, a workpiece conveying device 2 is arranged in the frame, and a plurality of accompanying tooling 3 evenly spaced is arranged on the workpiece conveying device. The frame is provided with an axial centering positioning mechanism 4, a diameter detection mechanism 5, and a ring groove position detection and correction mechanism 6 in sequence from the head end to the tail end. and the ring groove position detection and correction mechanism through the cavity; the axial centering positioning mechanism can clamp and center the workpiece on the accompanying tooling, and identify the type of workpiece according to the length and size; the diameter detection mechanism can check the workpiece on the accompanying tooling Carry out diameter detection and identify the workpiece type according to the diameter size; the ring groove position detection and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com