Purification method of graphite in waste residues of artificial diamond production, graphite anode material for lithium ion battery and preparation method of graphite anode material

A synthetic diamond, lithium-ion battery technology, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of serious equipment corrosion, high reaction temperature, increased production costs, etc., to achieve reduced corrosion degree, high recovery rate, Energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of graphite negative electrode material for lithium ion battery of the present invention comprises the following steps: 1) mixing artificial diamond production waste slag with inorganic acid, and reacting at 80-120°C for 24-36h; the inorganic acid is concentrated sulfuric acid, concentrated nitric acid , at least one of concentrated hydrochloric acid; 2) the solid-liquid separation of the system after the reaction in step 1), washing and drying, to obtain purified graphite; 3) the purified graphite obtained in step 2) is mixed with a pyrolytic carbon source, impregnated, Carbonization, that is.

[0036] Step 1) The concentration of hydrogen ions in the inorganic acid is 12-36.8 mol / L.

[0037] The washing in step 2) is to wash the solid after solid-liquid separation until the filtrate is neutral. In step 2), the drying temperature is 110-300° C., and the drying time is 2-4 hours.

[0038] The pyrolysis carbon source in step 3) is pitch, and the ...

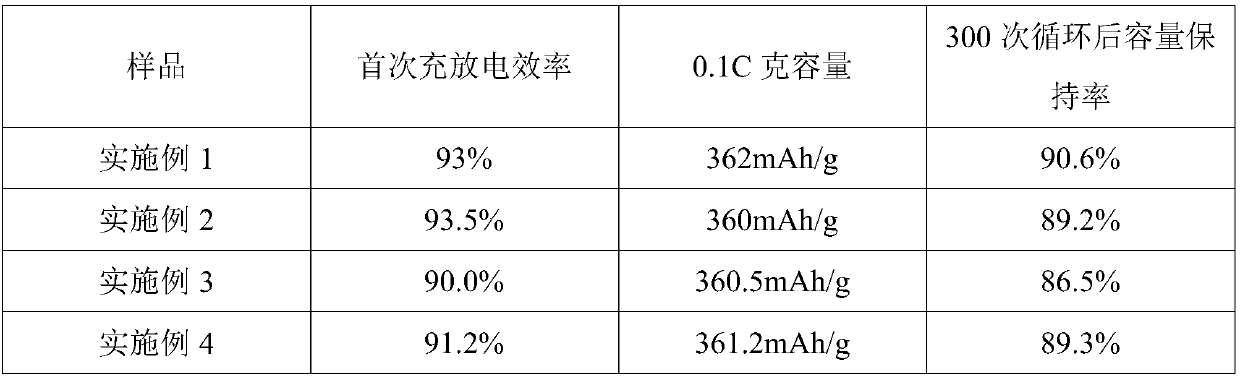

Embodiment 1

[0043] The purification method of the present embodiment comprises the following steps:

[0044] (1) Put 20kg of artificial diamond production waste residue (water content 50%) into a ball mill for ball milling, then pass through a 120-groove bed shaker, remove most of the artificial diamond and metal, repeat suction filtration twice, and wash with deionized water , and then baked at 150°C for 3 hours to obtain a total of 9.5kg of graphite powder;

[0045] (2) the graphite powder that step (1) is obtained is put into crushing spheroidization equipment (FNMZ-4122 type crushing spheroidization production line) and carries out spheroidization process, obtains D50 and is 5.7kg of spherical graphite of 16.09 μ m;

[0046] (3) Get the spherical graphite 2.7kg that step (2) obtains and add in the reactor, add 10L concentrated hydrochloric acid (mass fraction is 37.5%, density is 1.179g / cm 3 , the hydrogen ion concentration is 12mol / L), stirred and reacted at 120°C for 24h, and the sti...

Embodiment 2

[0048] The purification method of the present embodiment comprises the following steps:

[0049] (1) Put 20kg of artificial diamond production waste residue (water content 50%) into a ball mill for ball milling, then pass through a 120-groove bed shaker, remove most of the artificial diamond and metal, repeat suction filtration twice, and wash with deionized water , and then baked at 150°C for 3 hours to obtain a total of 9.4kg of graphite powder;

[0050] (2) the graphite powder that step (1) obtains is put into crushing spheroidization equipment (FNMZ-4122 type crushing spheroidization production line) and carries out spheroidization process, obtains D50 and is 5.9kg of spherical graphite of 16.28 μ m;

[0051] (3) Get 3kg of spherical graphite obtained in step (2) and add in the reactor, add 3L of concentrated sulfuric acid, 1.5L of concentrated hydrochloric acid and 0.5L of concentrated nitric acid, stir and react at 120°C for 24h, and the stirring rate is 200 rpm; After ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com