Heat exchanger panel and method for manufacturing thereof

A heat exchanger and panel technology, which is applied in the directions of heat exchanger fixing, heat exchanger sealing device, heat exchange equipment, etc., can solve the problem that polycarbonate heat exchanger panels are not widely used, low cost, complicated manufacturing cost, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

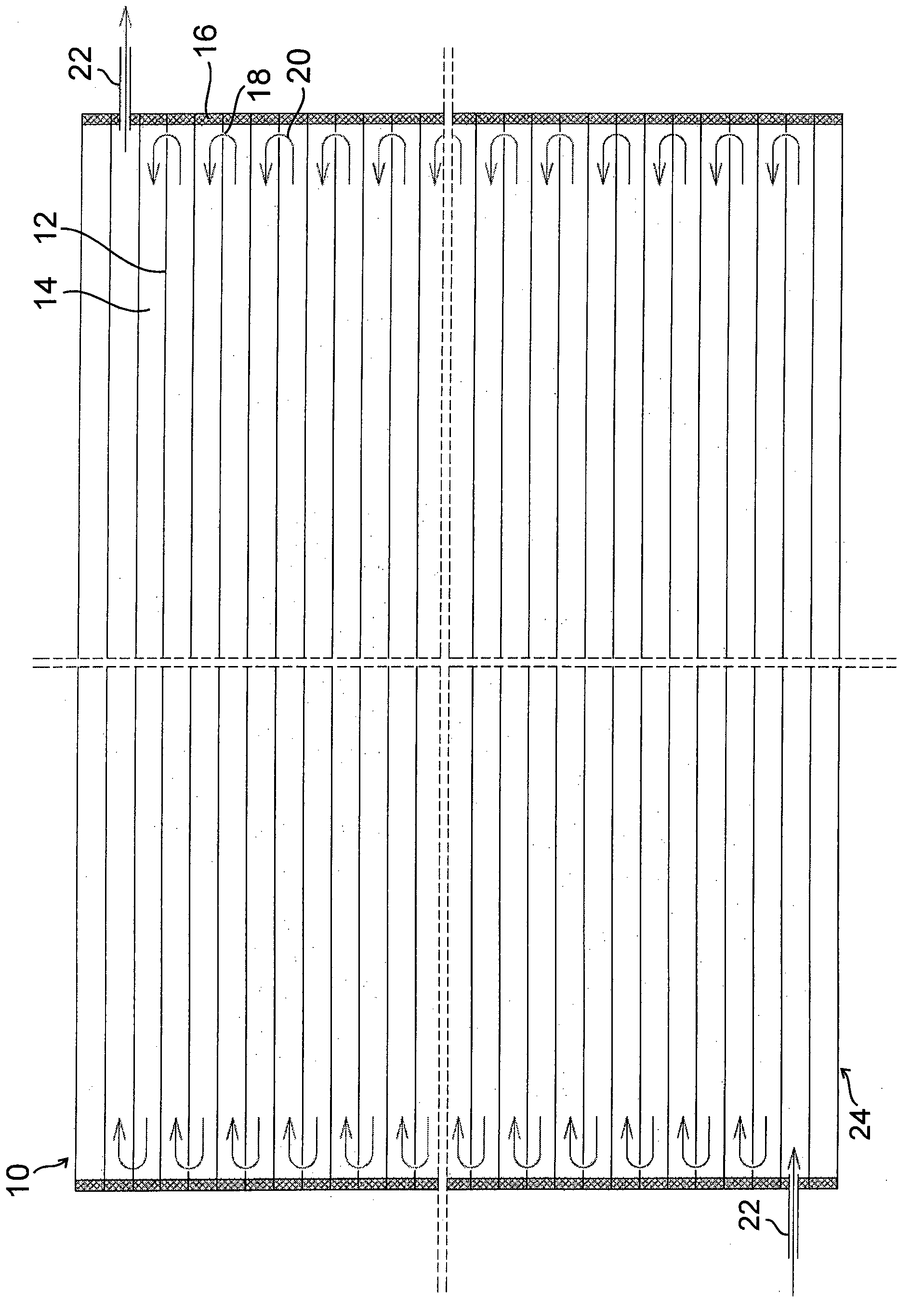

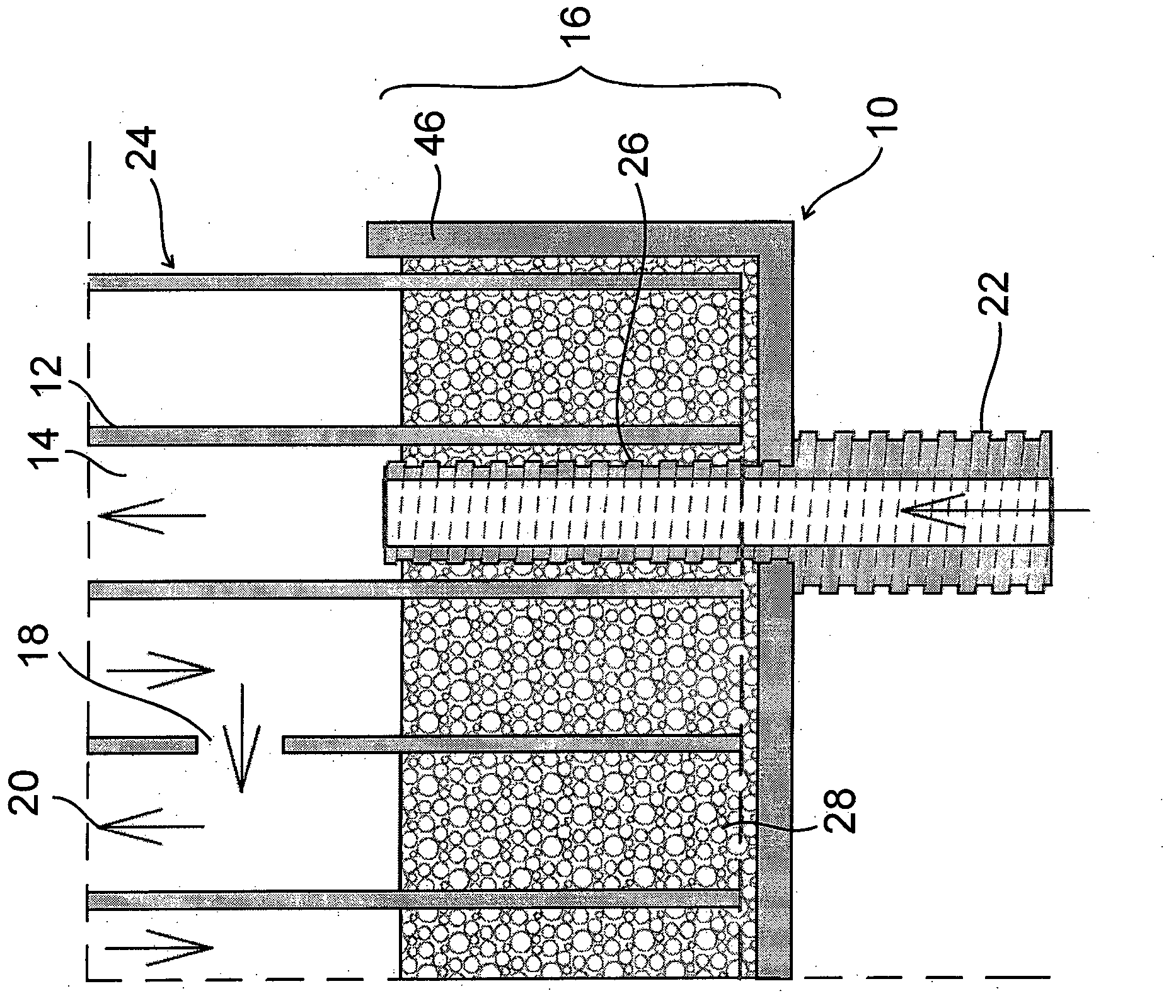

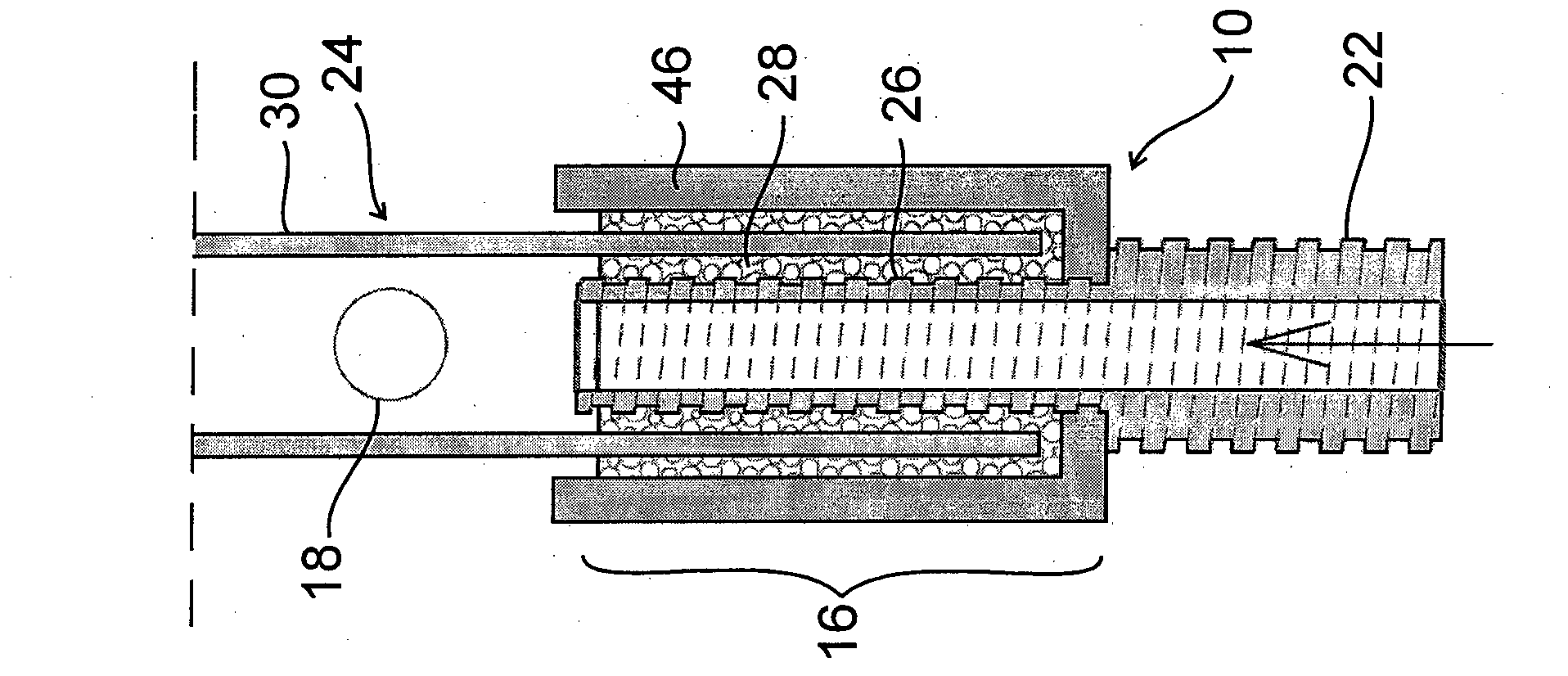

[0047] The purpose of developing the heat exchanger panel according to the invention is to provide a durable and extremely efficient heat exchange by using commercially available multilayer polycarbonate plates and by sealing its channels in a long-term reliable manner at these sealing points heat exchanger panels that have a substantially lower primary cost than currently available heat exchanger panels.

[0048] When forming a seal, the most important requirement is that the sealing unit has a joint that is thermally expansion compatible with the rest of the panel. The various daily repeated expansion and contraction tendencies of the sealant material compared to the material of the panel lead to contact failure between the sealing unit and the panel, panel defects, loss of panel pressure resistance and consequent overall damage.

[0049] In the heat exchanger panel according to the invention, in order to avoid damages caused by differences in thermal expansion, thermal expa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com