Basalt fiber grid reinforced lining structure for high ground temperature high-pressure hydraulic tunnel

A technology of basalt fiber and hydraulic tunnels, which is applied in water conservancy projects, hydropower, hydropower stations, etc., can solve problems such as cracking and endangering the stability of surrounding rocks, and achieve low construction cost, low engineering cost, and good crack resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

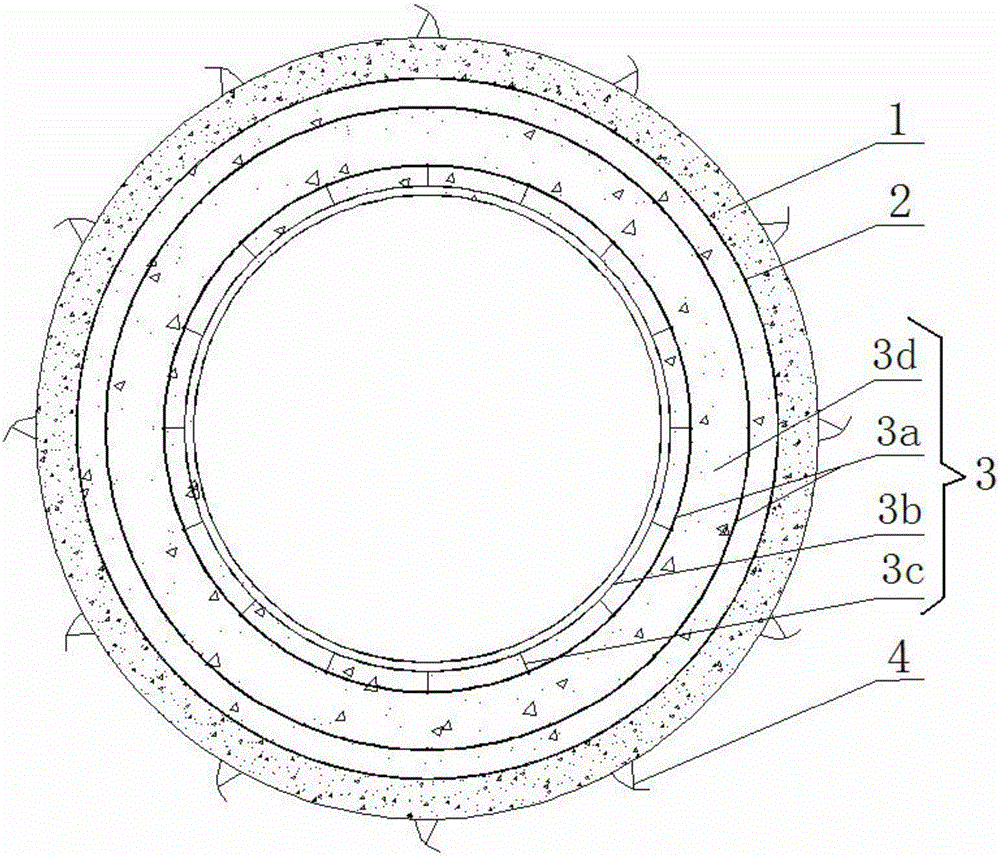

[0037] The basalt fiber mesh reinforced lining structure used in high-temperature and high-pressure hydraulic tunnels consists of primary lining, water-resisting layer and secondary lining in sequence from the surface of the surrounding rock of the tunnel to the tunnel wall.

[0038] The initial lining is a reinforced concrete layer;

[0039] The water-proof layer includes a concrete sealing primer layer on the surface of the initial lining outer wall and a polyurea elastomer layer on the outer surface of the concrete sealing primer layer;

[0040] The secondary lining is a reinforced concrete layer embedded with basalt fiber grids.

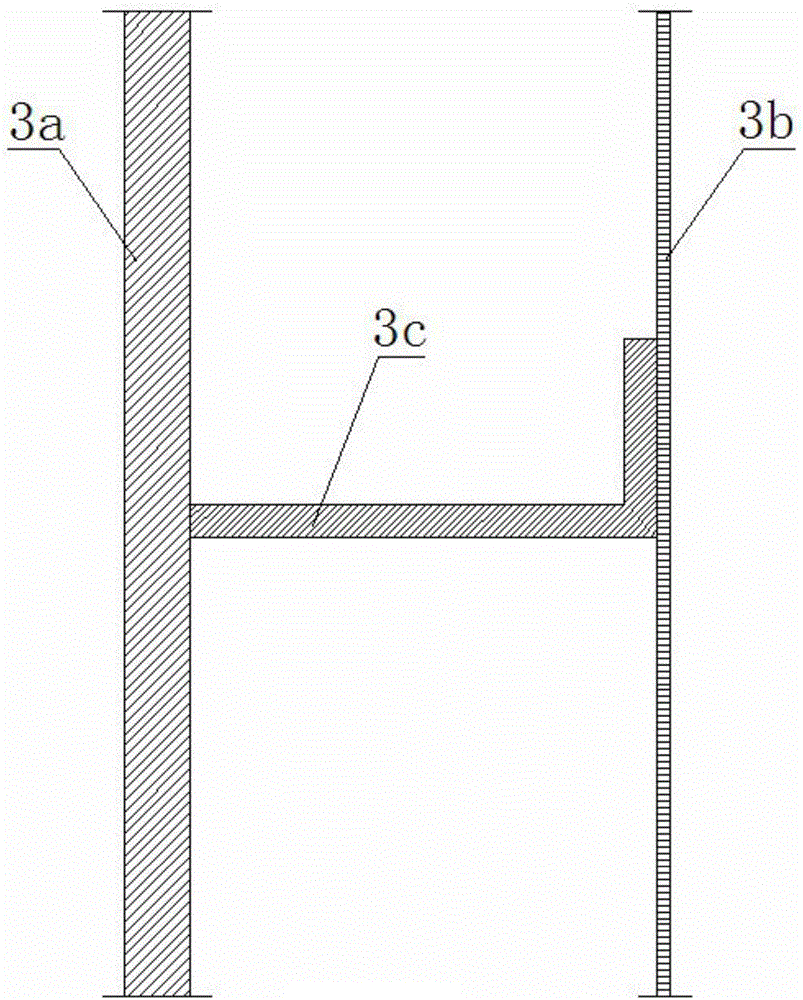

[0041] The basalt fiber grid is fixed with the hoop stress reinforcement in the secondary lining through the limit support.

Embodiment 2

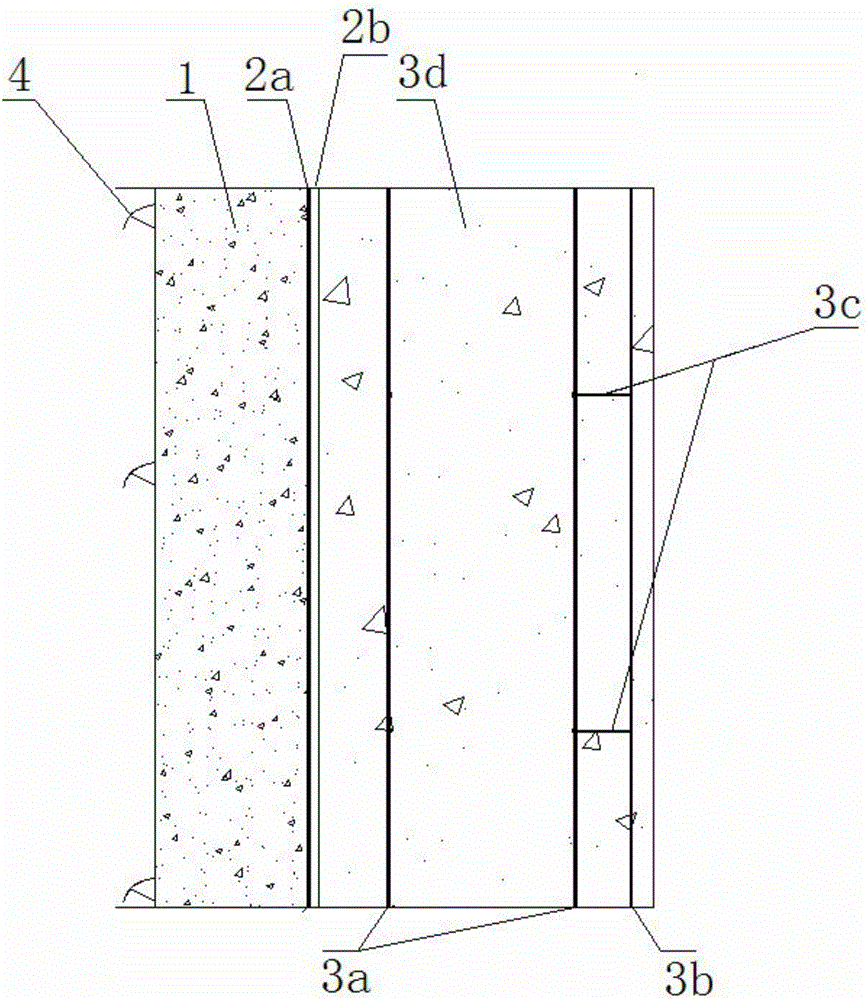

[0043] The basalt fiber grid reinforced lining structure used in high-temperature and high-pressure hydraulic tunnels, from the surface of the surrounding rock of the tunnel to the tunnel wall, is the primary lining 1, the water-resisting layer 2 and the secondary lining 3,

[0044] The initial lining 1 is the initial lining of shotcrete, which is composed of shotcrete and steel mesh;

[0045] The water-proof layer 2 is a polyurea elastomer water-proof spray layer, which is composed of a roller-coated concrete sealing primer layer 2a and a spray-coated polyurea elastomer 2b on the outer wall surface of the initial lining;

[0046] The secondary lining 3 is a basalt fiber grid reinforced reinforced concrete secondary lining, which is composed of circumferential steel bars 3a, basalt fiber grid 3b for distribution network on the inner wall of the secondary lining, limit support 3c and concrete poured by formwork. 3d composition.

[0047] Wherein, the primary lining of sprayed c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com