Fiber woven mesh reinforced cement-based composite material permanent beam formwork and manufacturing method thereof

A technology of fiber woven mesh and reinforced cement, which is applied in the direction of formwork/formwork/work frame, manufacturing tools, and on-site preparation of building components. Cracking and other problems, to achieve the effect of improving durability and service life, inhibiting crack development, and high crack control ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and a specific embodiment of a fiber braided mesh reinforced cement-based composite permanent beam formwork and its manufacturing method. This implementation example is an illustration of the present invention, rather than making any limitation to the present invention.

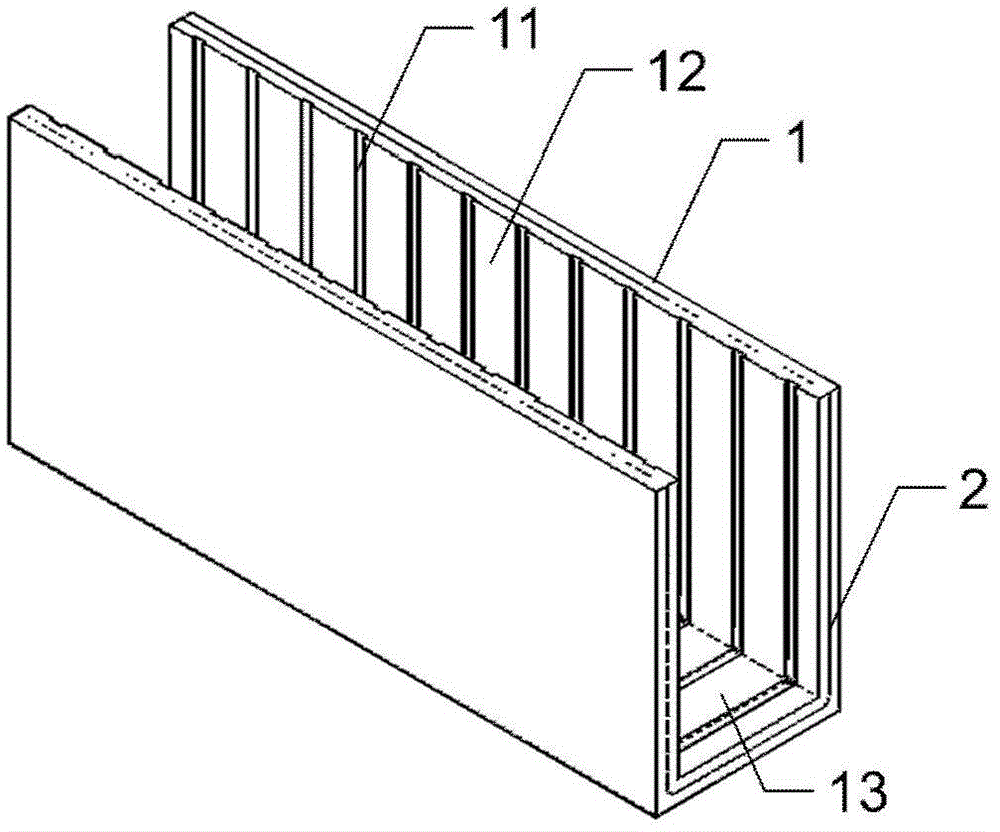

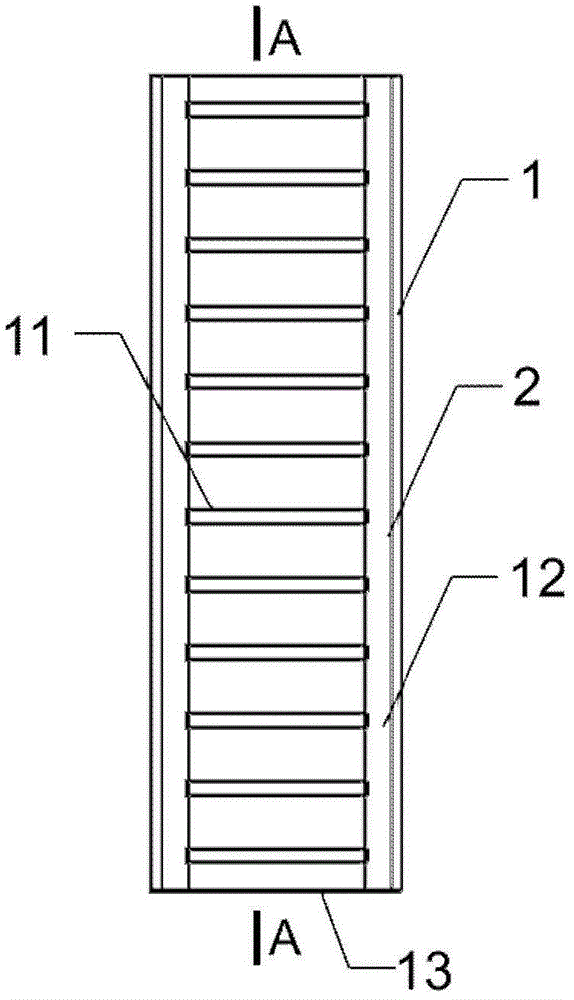

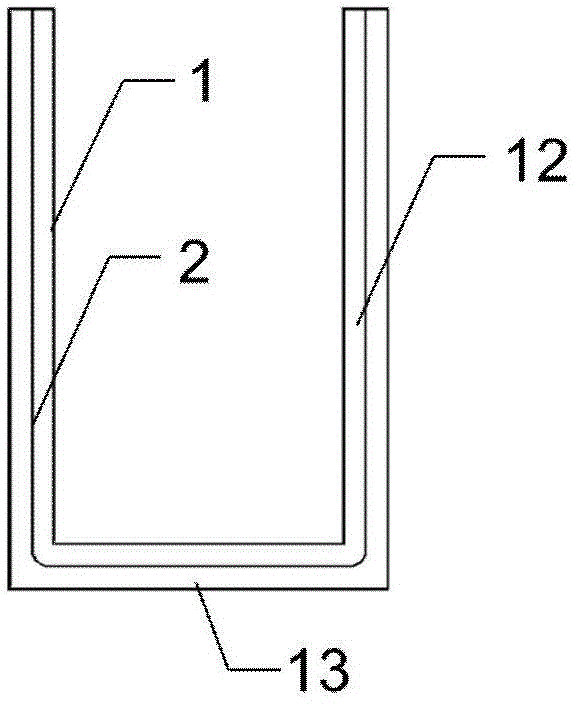

[0044] An interlocking anti-crack and anti-seepage permanent beam formwork of this embodiment is shown in Figure 1 (a) (b) (c) (d). The permanent beam formwork is composed of panels 1. The beam formwork is described. The cross section of the panel is in concave shape, and grooves 11 are distributed on the inner surface.

[0045] The cement-based composite material reinforced by non-metal fiber braided mesh is composed of non-metallic fiber mesh and cement-based matrix. The non-metallic fiber braided mesh includes: carbon fiber braided mesh, aramid fiber braided mesh, alkali-resistant glass fiber braided m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com