An all-in-one machine for leveling and texture of ultra-high toughness cement-based composite materials for road engineering and its working method

A technology of ultra-high toughness and composite materials, applied in road repair, roads, roads, etc., can solve problems such as material surface damage, uneven potholes, improper leveling methods, etc., and achieve improved friction coefficient, neat edges, and leveling effects Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

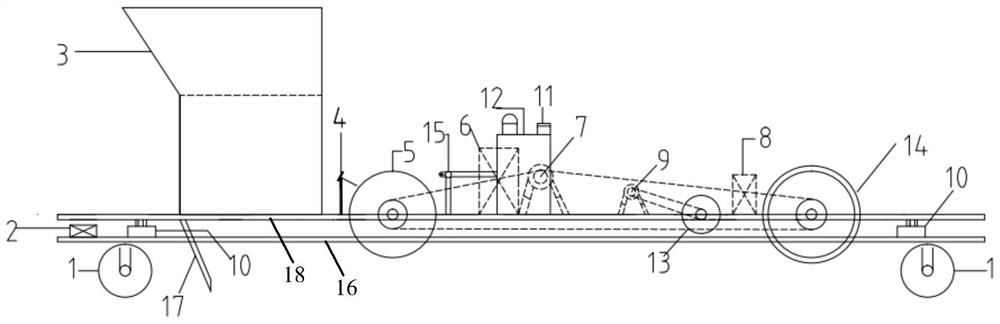

[0073] An all-in-one machine for leveling and texture of ultra-high toughness cement-based composite materials for road engineering, such as Figure 1~6 As shown, a bottom frame 16 and a main body frame 18 located on the bottom frame 16 are included, and the height of the main body frame 18 can be adjusted up and down relative to the bottom frame 16;

[0074] The four corners of the bottom frame 16 are provided with steel wheels 1, the steel wheel 1 at the front end is driven by the first motor 2, the bottom frame 16 is moved by four steel wheels 1, the two steel wheels at the front end of the all-in-one machine are driving wheels, and the rear end The two steel wheels are driven wheels, and the rotation of the steel wheels driven by the first motor 2 is a prior art, which will not be repeated here;

[0075] A hopper 3, a leveling roller shaft 5 and an embossing roller shaft 14 are sequentially arranged on the main frame 18 along the advancing direction, and an ultra-high toug...

Embodiment 2

[0077] An all-in-one machine for leveling and textured ultra-high-toughness cement-based composite materials for road engineering, the structure of which is shown in Example 1, the difference is that due to the existence of fibers in the ultra-high-toughness cement-based composite materials, after leveling, both sides The spilled material is difficult to clean up, therefore, the main frame 18 is provided with a cutting circular knife system between the leveling roller shaft 5 and the embossing roller shaft 14, and the cutting circular knife system includes two cutting circles arranged on both sides of the main frame 18 The knives 13 are all driven to rotate by the second motor 9. When the all-in-one machine is working forward, the cutting circular knife 13 rotates under the drive of the second motor 9, and is used for cutting and leveling roller shafts to overflow after compacting and leveling. of excess material.

[0078] Such as Figure 7 As shown, a connecting shaft A 19 i...

Embodiment 3

[0081] An all-in-one machine for smoothing and textured ultra-high toughness cement-based composite materials for road engineering, the structure of which is shown in Example 1, the difference is that both the leveling roller shaft 5 and the embossing roller shaft 14 are driven to rotate by the third motor 7 , the size of the leveling roller 5 and the embossing roller 14 are the same, and the maximum linear speeds of the leveling roller 5, the embossing roller 14 and the steel wheel 1 are the same, that is, the leveling roller 5, the embossing roller 14 It is consistent with the distance traveled by the steel wheel 1 in the same time to ensure that the steel wheel, the leveling roller shaft and the embossing roller shaft move synchronously;

[0082]The third motor 7 is fixed on the main body frame 18. Both sides of the leveling roller shaft 5 and the embossing roller shaft 14 are connected with a belt pulley B 22 through a connecting shaft B21. The connecting shafts B 21 are a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com