A bolt-connected assembleable anti-crack and anti-seepage permanent beam formwork

A connection type, beam formwork technology, applied in the direction of joists, girders, trusses, etc., can solve the problems of affecting durability and service life, common concrete is easy to crack, affecting the safe operation of structures, etc., to improve durability and service life. , High tensile ductility and crack control ability, the effect of shortening construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

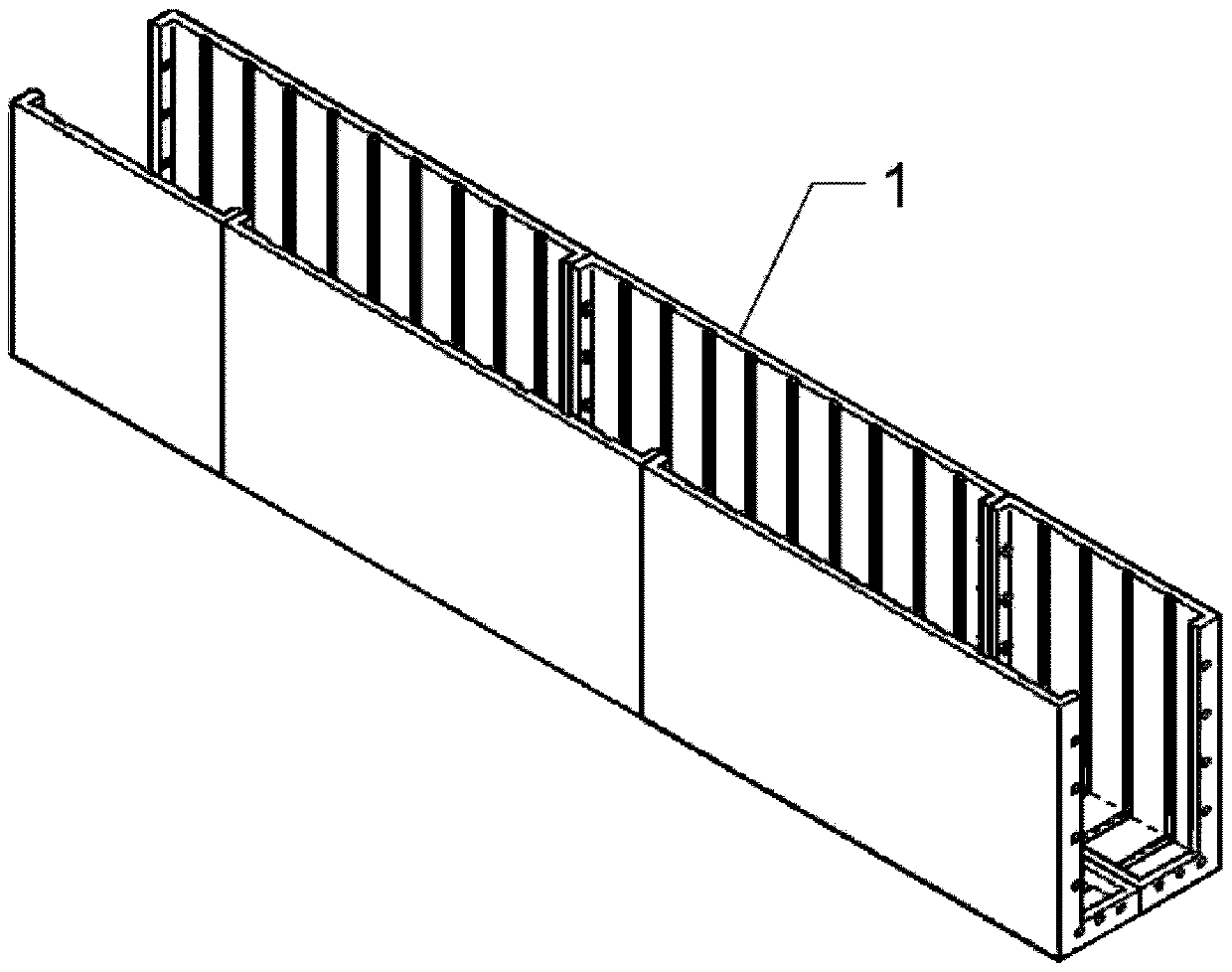

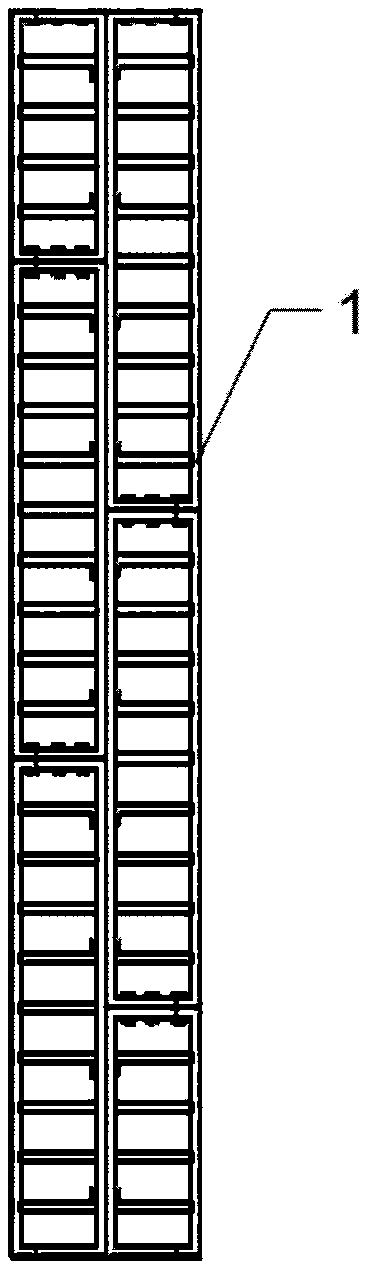

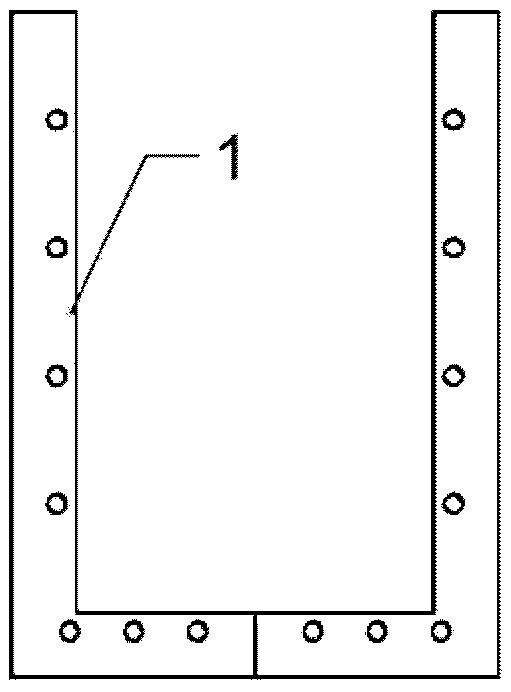

[0043] The specific implementation of the bolt-connected assembled anti-crack and anti-seepage permanent beam formwork provided by the present invention will be further described below in conjunction with the accompanying drawings. This implementation example is an illustration of the present invention, rather than limiting the present invention.

[0044] A bolt-connected permanent anti-cracking and anti-seepage permanent beam formwork of this embodiment is composed of three left corner panels 1 and three right corner panels; the left corner panel 1 is composed of a vertical first panel 14 and The second panel 15 constitutes the main body, the first panel 14 corresponds to the side of the beam, the second panel 15 corresponds to the bottom of the beam, the right corner panel forms the main body with the third and fourth panels perpendicular to each other, the third panel corresponds to the side of the beam, The fourth panel corresponds to the bottom of the beam; the side of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com