An interlocking formwork for an anti-crack and anti-seepage permanent column

A column formwork and permanent technology, applied in the direction of formwork/formwork/work frame, column, pier column, etc., can solve the problems of affecting durability and service life, easy cracking of ordinary concrete, affecting the safe operation of the structure, etc. Durability and service life, high tensile ductility and crack control, effect of reduced construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The specific implementation of the interlocking, crack-proof and seepage-proof permanent column formwork provided by the present invention will be further described below in conjunction with the accompanying drawings. This implementation example is an illustration of the present invention, rather than limiting the present invention.

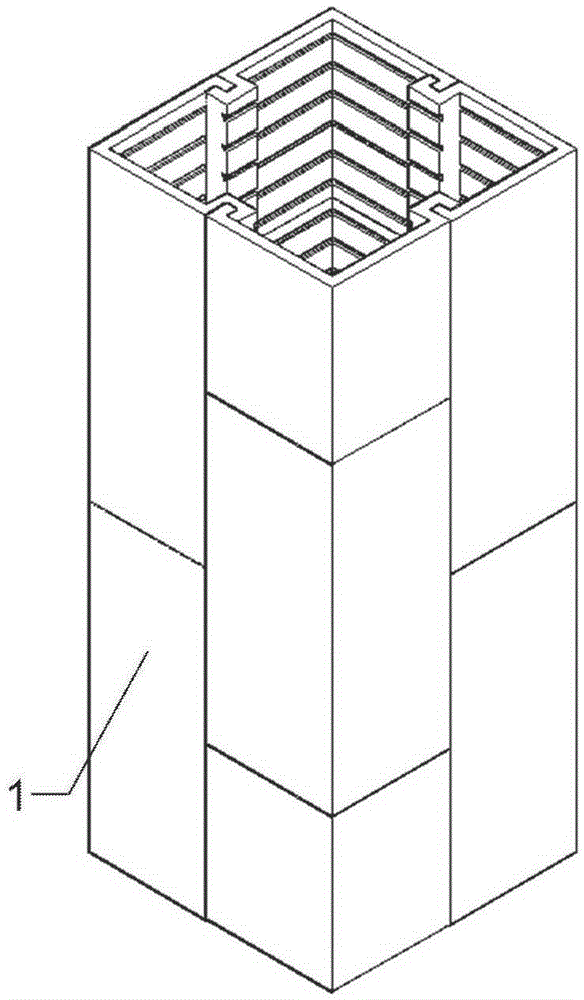

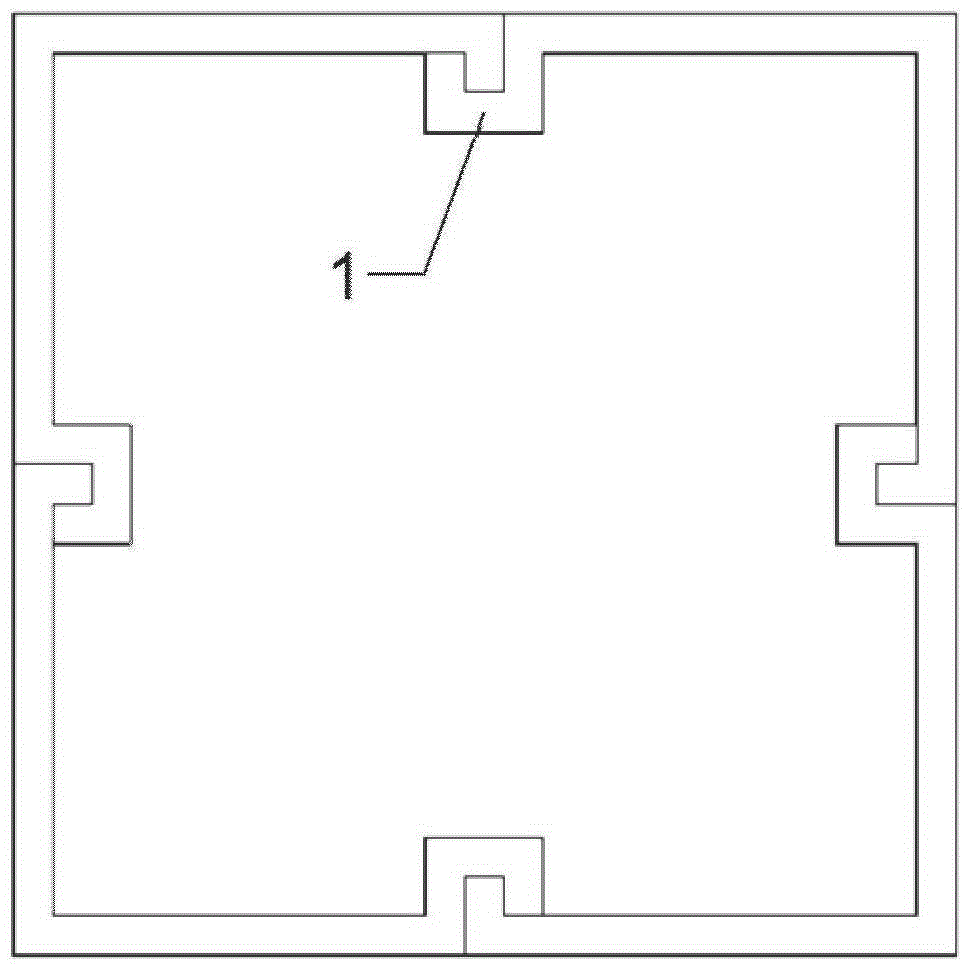

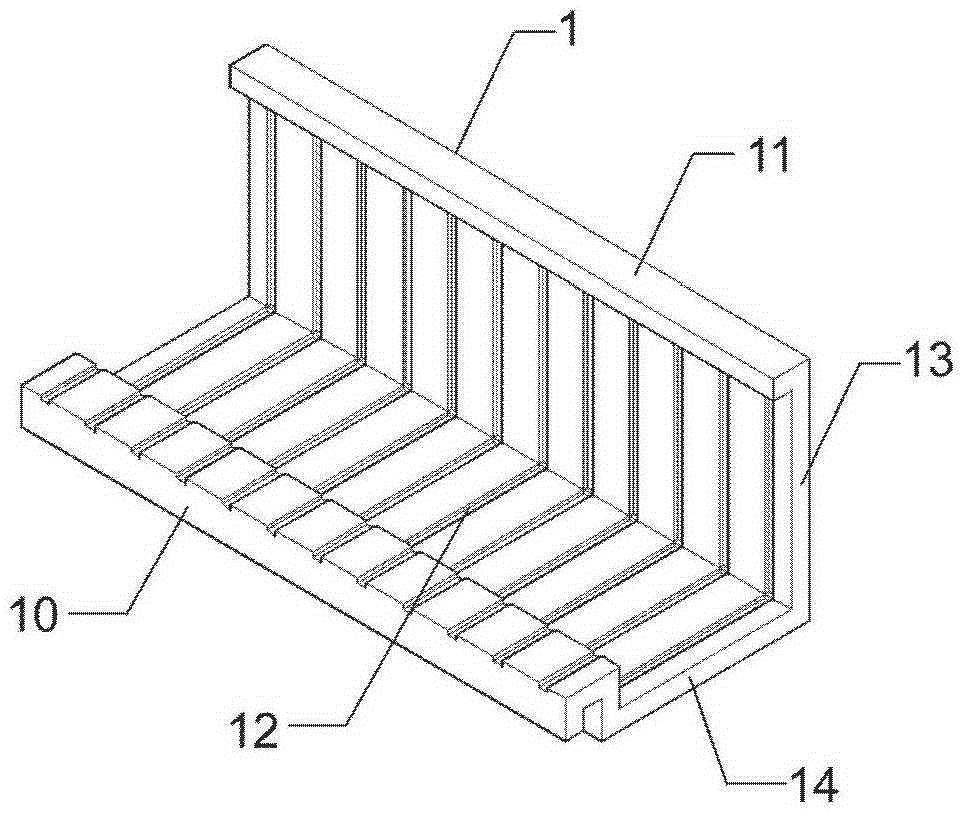

[0045] An interlocking, crack-proof and anti-seepage permanent column formwork of this embodiment has 10 corner panels connected through the connection configuration and connection grooves of adjacent corner panels, and the transverse joints between the corner panels are staggered from each other And the connection constitutes the column formwork. The corner panel 1 is composed of a vertical first panel 13 and a second panel 14; the inner side of one side of the corner panel has a raised connection structure 11, and the other side of the corner panel has its An outwardly opening connection groove 10 whose size can be plugged and matched wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com