Seed crystal for seeding during manufacturing of silicon single crystal rod and manufacturing method of silicon single crystal rod

A production method and technology of single crystal silicon rods, which are applied in chemical instruments and methods, single crystal growth, single crystal growth, etc., can solve the problems that the quality of single crystal silicon rods cannot be effectively improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

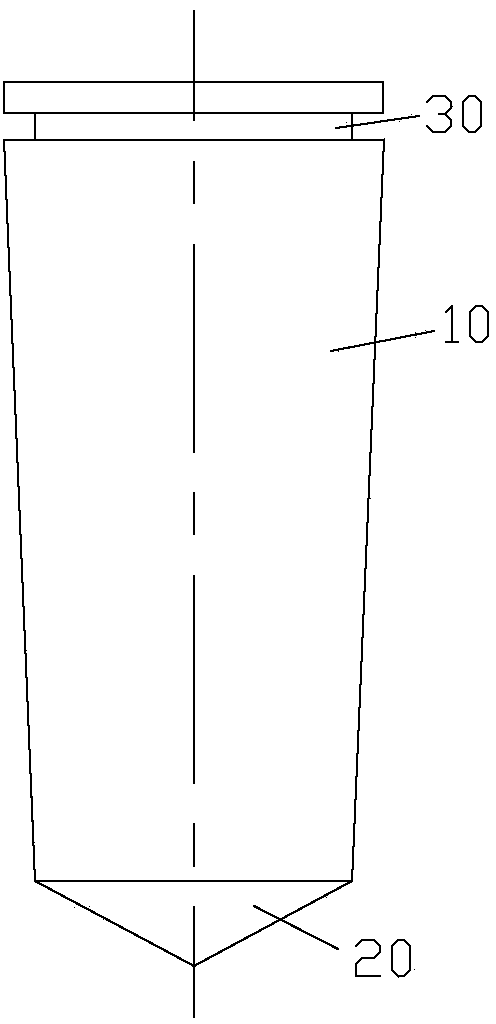

[0021] According to one aspect of the present invention, there is provided a seed crystal used for seeding when making a single crystal silicon rod, such as figure 1 As shown, the seed crystal is conical.

[0022] The seed crystals in the prior art are cylindrical, and some are stepped cylindrical. The seed crystal provided by the present invention has a conical shape. When the seed crystal contacts the surface of the molten silicon for seeding, the conical shape can increase the adsorption force between the molten silicon and the seed crystal, so that the seeding process is not easy to cause disconnection Condition. The impact of thermal convection in molten silicon on the crystal is the main factor causing the breaking. In the prior art, the cru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com