A high-strength heat-resistant rare earth magnesium alloy ingot electromagnetic semi-continuous casting preparation method

A rare-earth magnesium and alloy ingot technology, applied in the field of light alloy casting, can solve the problems of high-quality ingots, such as difficulty, and achieve the effects of improving internal metallurgical quality and surface quality, inhibiting macro segregation, and changing the shape of liquid pockets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

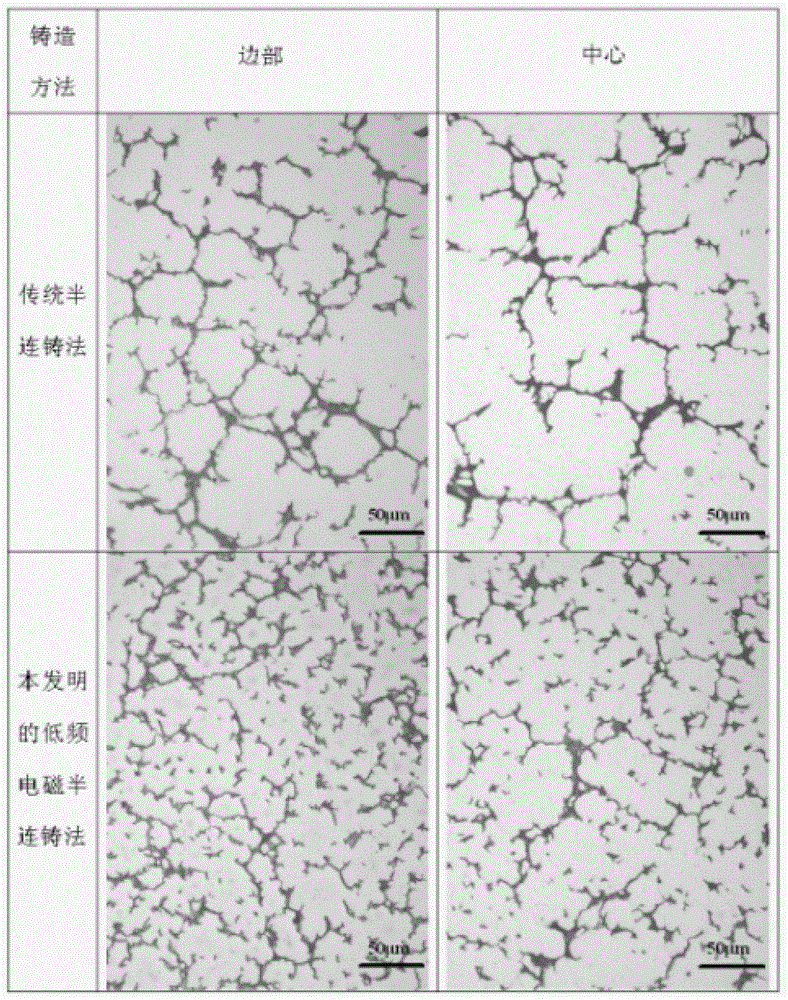

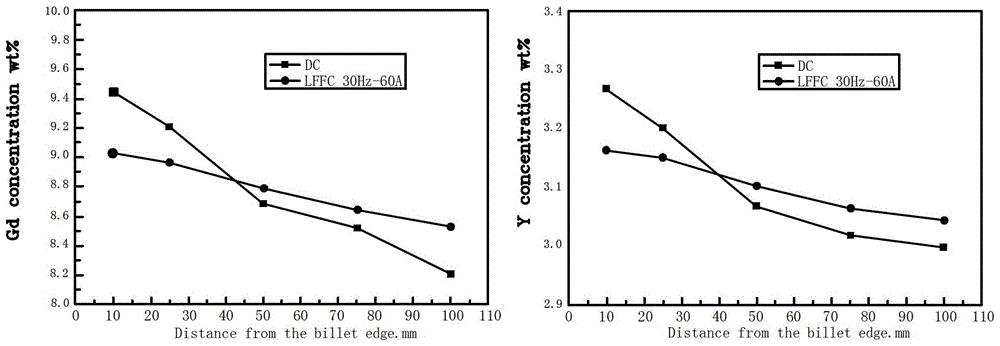

[0026] Vertical Semi-continuous Casting of Mg-Gd-Y-Zn-Zr Magnesium Alloy φ200mm Ingot

[0027] The technical solution of the present invention will be described in detail below by taking the vertical semi-continuous casting of a φ200 mm ingot of Mg-Gd-Y-Zn-Zr magnesium alloy as an example.

[0028] 1) Smelting Mg-9Gd-3Y-1.5Zn-0.6Zr magnesium alloy according to the ratio, the materials are pure Mg ingot, Mg-25% Gd master alloy, Mg-25% Y master alloy, pure Zn ingot and Mg-30% Zr master alloy;

[0029] 2) Melting the proportioned materials: A. Preheat the crucible to dark red 400-500°C, sprinkle appropriate flux on the crucible wall and bottom, add preheated Mg ingot, heat up and melt, and then put Sprinkle flux on top; B. Add Zn ingots when the molten magnesium temperature rises to 720°C, and stir for 8 minutes after it is completely melted; C. Add Mg-Gd master alloy in batches when the temperature rises to 755-765°C, adding Stir while stirring; add Mg-Zr and Mg-Y intermediate...

Embodiment 2

[0035] Vertical Semi-continuous Casting of Mg-Gd-Y-Zn-Zr Magnesium Alloy φ280mm Ingot

[0036] The technical solution of the present invention will be described in detail below by taking the vertical semi-continuous casting of a φ280 mm ingot of Mg-Gd-Y-Zn-Zr magnesium alloy as an example.

[0037] The Mg-12Gd-5Y-2Zn-0.5Zr magnesium alloy is smelted according to the ratio; the crystallizer is a hot-top metal mold inlaid with graphite rings and heat preservation caps; the melt is applied with a low-frequency electromagnetic field in the crystallizer.

[0038] The casting process conditions are: casting speed 50mm / min; casting temperature 740°C; cooling water intensity 140L / min; magnetic field AC frequency 15Hz, strength 9000AT.

[0039] Tests show that under the above casting speed and casting temperature, the liquid cavity depths of the two casting methods are significantly different, the traditional semi-continuous casting is about 158mm, and the low-frequency electromagnetic...

Embodiment 3

[0041] Vertical semi-continuous casting of Mg-Y-Zn-Zr magnesium alloy φ130mm billet

[0042] The technical solution of the present invention will be described in detail below by taking the vertical semi-continuous casting of a φ130 mm billet of Mg-11Y-7Zn-0.5Zr magnesium alloy as an example.

[0043] The Mg-11Y-7Zn-0.5Zr magnesium alloy is smelted according to the ratio; the crystallizer is a hot-top metal mold inlaid with graphite rings and heat preservation caps; the melt is applied with a low-frequency electromagnetic oscillation field in the crystallizer.

[0044] The casting process conditions are: casting speed 90mm / min; casting temperature 740°C; AC frequency 30Hz, intensity 4000AT; DC intensity 4000AT.

[0045] Tests show that under the above casting speed and casting temperature, the liquid cavity depths of the two casting methods are significantly different, the traditional semi-continuous casting is about 75mm, and the low-frequency electromagnetic casting method of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com