Method and heater for improving quality of monocrystal silicon grown by Czochralski method

A technology of growing single crystal silicon and Czochralski method, which is applied in the directions of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of black core inefficiency, decrease of minority carrier lifetime, device scrapping, etc., and achieve the reduction of temperature gradient and transformation Low-cost, easy-to-match effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The heater of this embodiment is applied on a 20-inch quartz crucible, the height of the 20-inch quartz crucible is 380mm, the feeding amount is 135KG, and the N-type, crystal orientation, resistivity 0.8-4.5Ω·cm, and 6.5-inch diameter silicon single crystal.

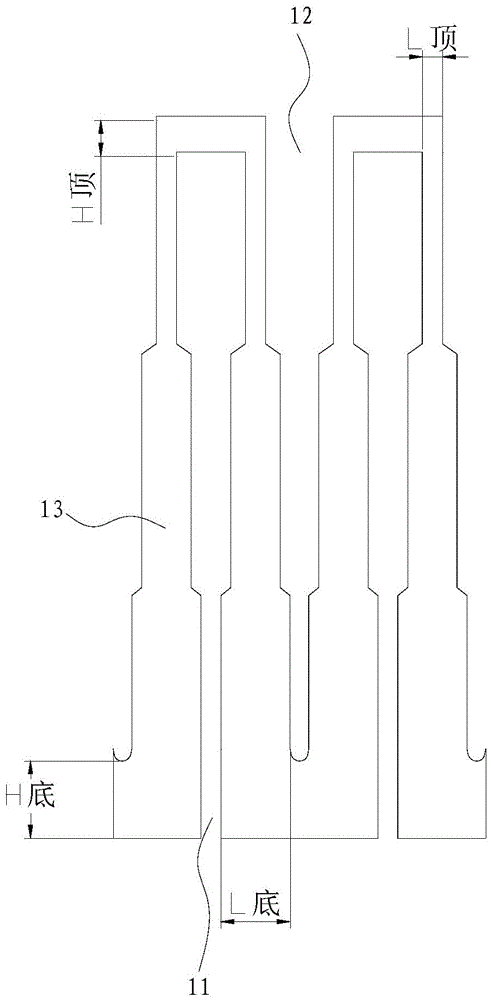

[0048] Such as image 3 As shown, the top of the heating strip 13 in this embodiment is 1 / 3 of the width of the bottom, the middle broadband is twice that of the top, and the bottom broadband is 3 times that of the top. Change, the height of the heating body 1 is 380mm, the groove depth of the upper groove 11 and the lower groove 12 satisfies H bottom = L bottom = 3L top = 3H top, and the distance between the groove bottom of the upper groove and the top edge of the heating body The distance between the bottom of the groove and the bottom edge of the heating body is H bottom. The above structure makes the heating value of the upper part of the heating body 1 greater than that of the lower part, combined with th...

Embodiment 2

[0052] The heater of this embodiment is applied to an 18-inch quartz crucible, the height of the 18-inch quartz crucible is 350mm, the feeding amount is 90KG, the N-type is drawn, the crystal orientation is pulled multiple times, the first three are 6 inches, and the target resistance The resistivity is 45-30Ω·cm, and the last drawing is 5 inches, and the remaining material is drawn, and the target resistivity is 45-15Ω·cm.

[0053] The lower part of the heating strip 13 of the present embodiment is thickened while the lower part is widened, such as Figure 4 As shown, the wall thickness of the heating body 1 gradually increases from top to bottom, and the top thickness is 3 / 4 of the bottom thickness, such as Figure 5 As shown, by adjusting the upper slot and the lower slot, the width of the heating strip 13 at the top is 3 / 4 of the bottom, the ratio of the cross-sectional area of the top of the heating body 1 to the bottom is 9:16, and the height of the heater is 350 mm. ...

Embodiment 3

[0057] The heater of this embodiment is applied to a 22-inch quartz crucible, the height of the 22-inch quartz crucible is 420mm, the feeding amount is 200KG, the drawn P-type, crystal orientation, the resistivity is 1-3Ω·cm, and the solar silicon single cell with a diameter of 8 inches crystal.

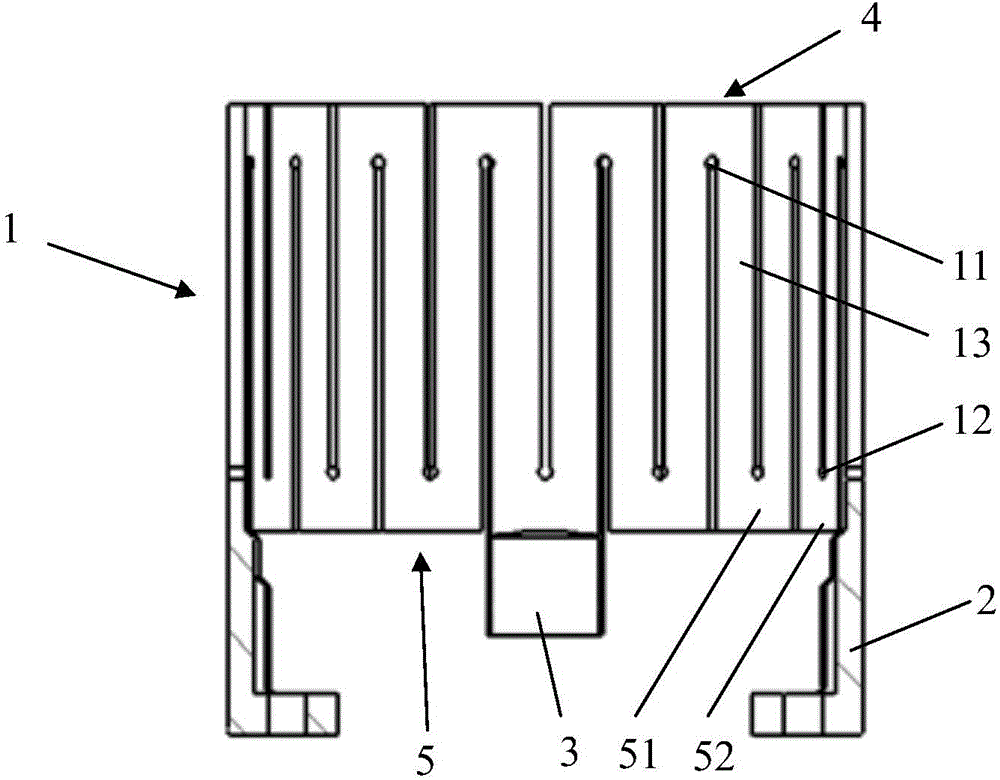

[0058] Such as figure 1As shown, any pair of adjacent heating strips of the heater form a U-shaped heating strip, wherein the upper U-shaped heating strip 4 with the upper slot is the lower U-shaped heating strip 5 with the lower slot. Counting from the electrode foot of the device, start counting the lower U-shaped heating strips clockwise or counterclockwise. The ones separated from the electrode feet 2 are the odd-numbered lower U-shaped heating strips 51, and the rest are the even-numbered lower U-shaped heating strips 52. .

[0059] The heater of this embodiment, such as Figure 6 As shown, among the figure, L even=280mm, L odd=420mm, H even=2H odd=2L, L is the wide band of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com