Patents

Literature

142 results about "Oxygen precipitates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The oxygen precipitates in silicon substrates were formed by a low–high two-step annealing. With the increase of oxygen precipitation, the minority carrier diffusion length of CZ silicon solar cells decreases and, meanwhile, the leakage currents due to the carrier recombination at the defect states get increased.

Silicon wafer and epitaxial silicon wafer

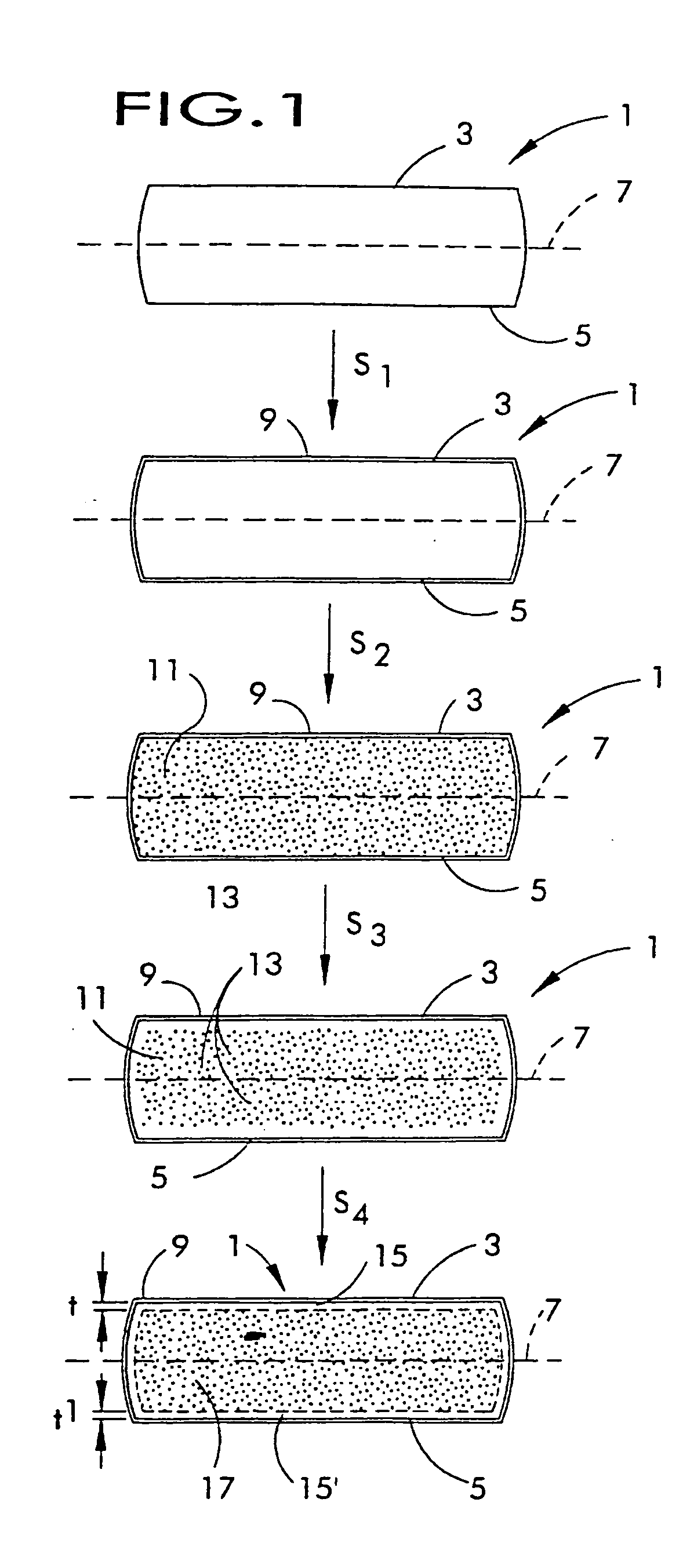

InactiveUS20030104222A1Polycrystalline material growthSemiconductor/solid-state device manufacturingHigh concentrationDopant

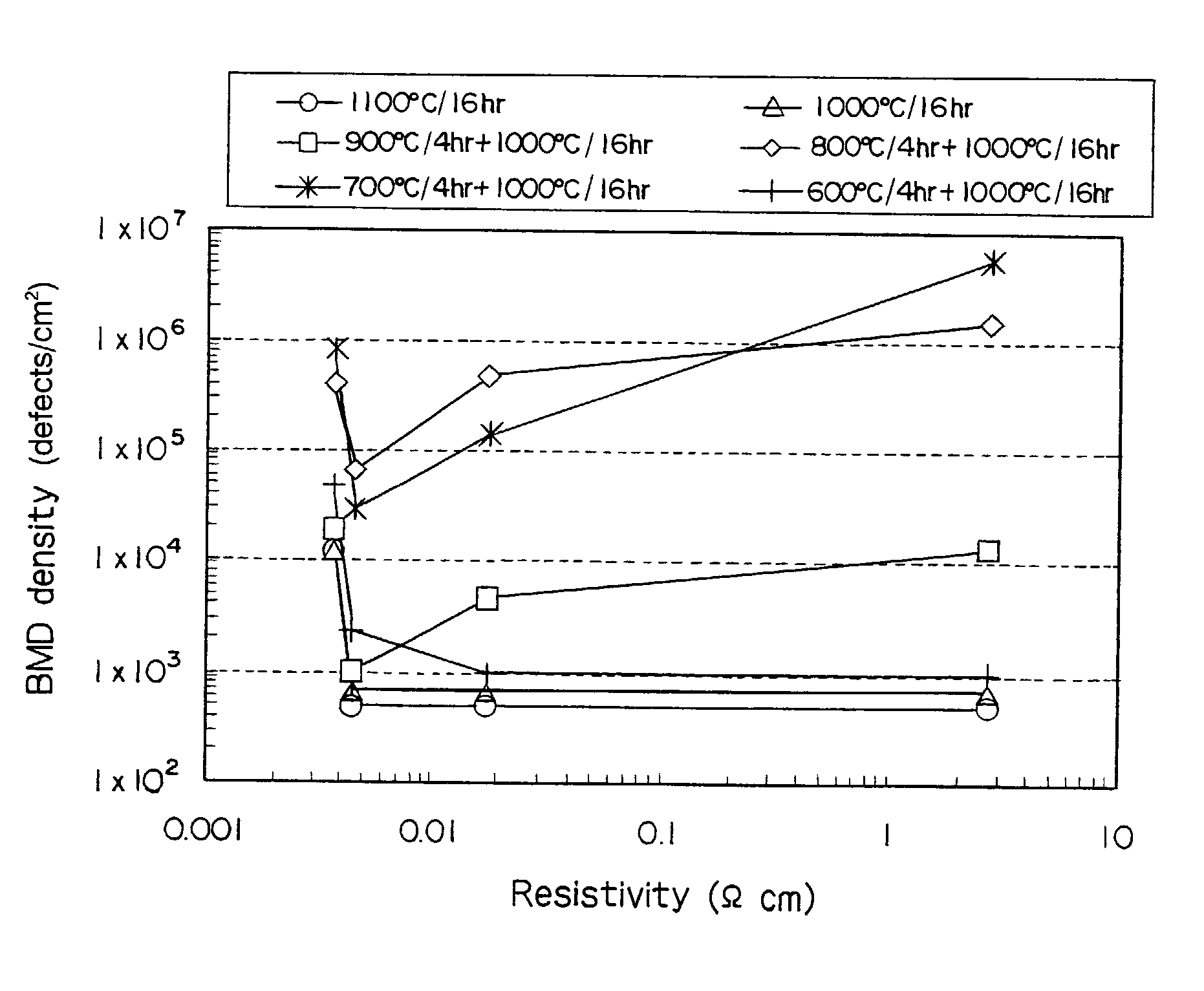

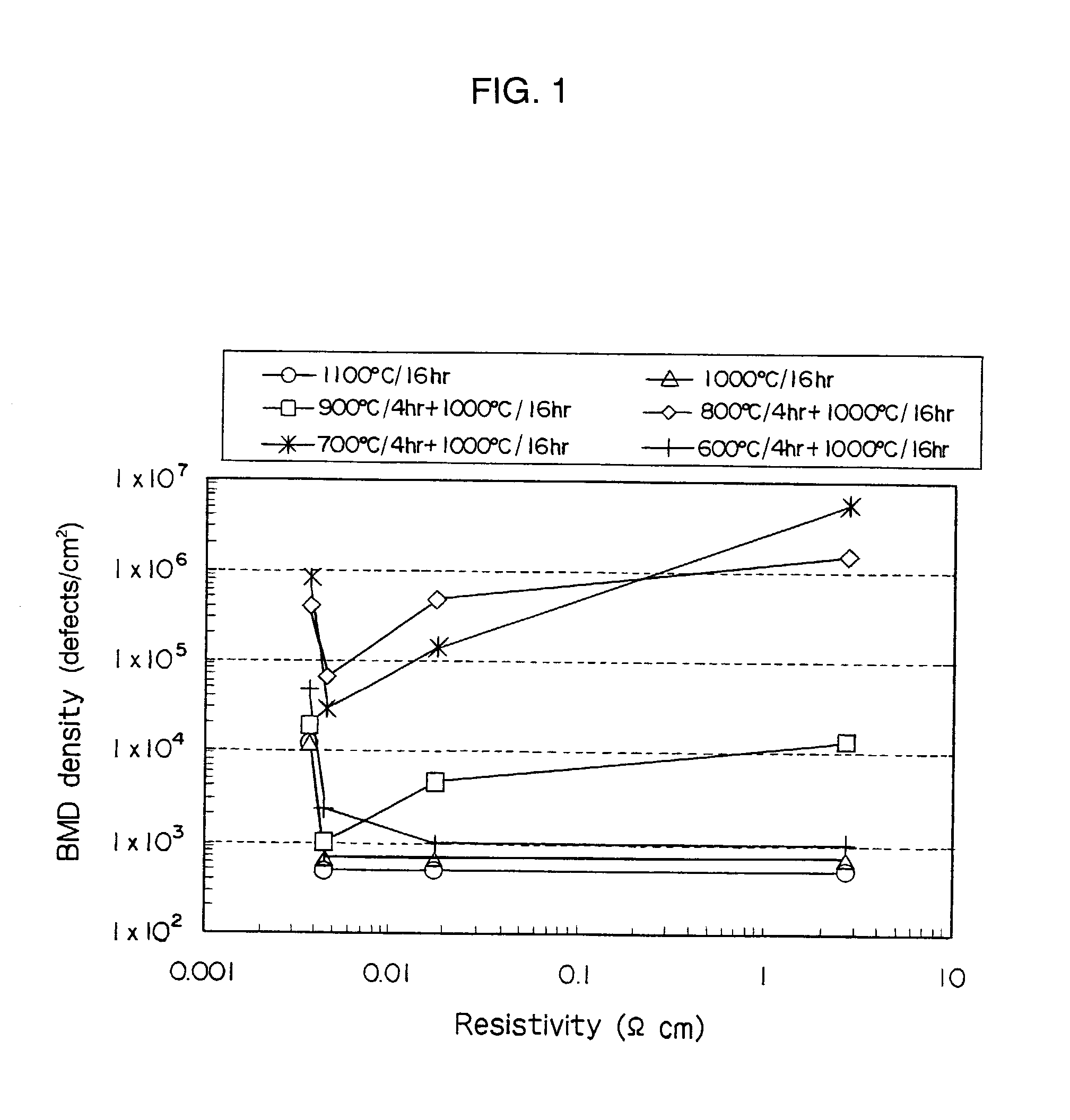

The invention relates to a silicon wafer and an epitaxial silicon wafer, which are doped with arsenic (As) as an n-type dopant and are excellent in gettering characteristics. A first silicon wafer has a resistivity of 10 OMEGAcm to 0.001 OMEGAcm as a result of addition of arsenic and has a nitrogen concentration of 1x1013 to 1x1015 atoms / cm3. A second silicon wafer has a resistivity of 0.1 OMEGAcm to 0.005 OMEGAcm and a nitrogen concentration of 1x1014 to 1x1015 atoms / cm3. A third silicon wafer has a resistivity of 0.005 OMEGAcm to 0.001 OMEGAcm and a nitrogen concentration of 1x1013 to 3x1014 atoms / cm3. An epitaxial silicon wafer derived from any of the first to third silicon wafers by forming an epitaxial layer in the surface layer portion is provided. In producing this epitaxial silicon wafer, epitaxial layer formation is desirably carried out after subjecting the silicon wafer to heat treatment for forming oxygen precipitates under conditions of a temperature not lower than 700° C. but lower than 900° C. and a period of 30 minutes to 4 hours. By these, an oxygen precipitate density can be secured and a sufficient gettering effect can be produced in the device producing process in spite of their being n-type silicon wafers doped with a high concentration of arsenic.

Owner:SUMITOMO MITSUBISHI SILICON CORP

Silicon wafers and method of fabricating the same

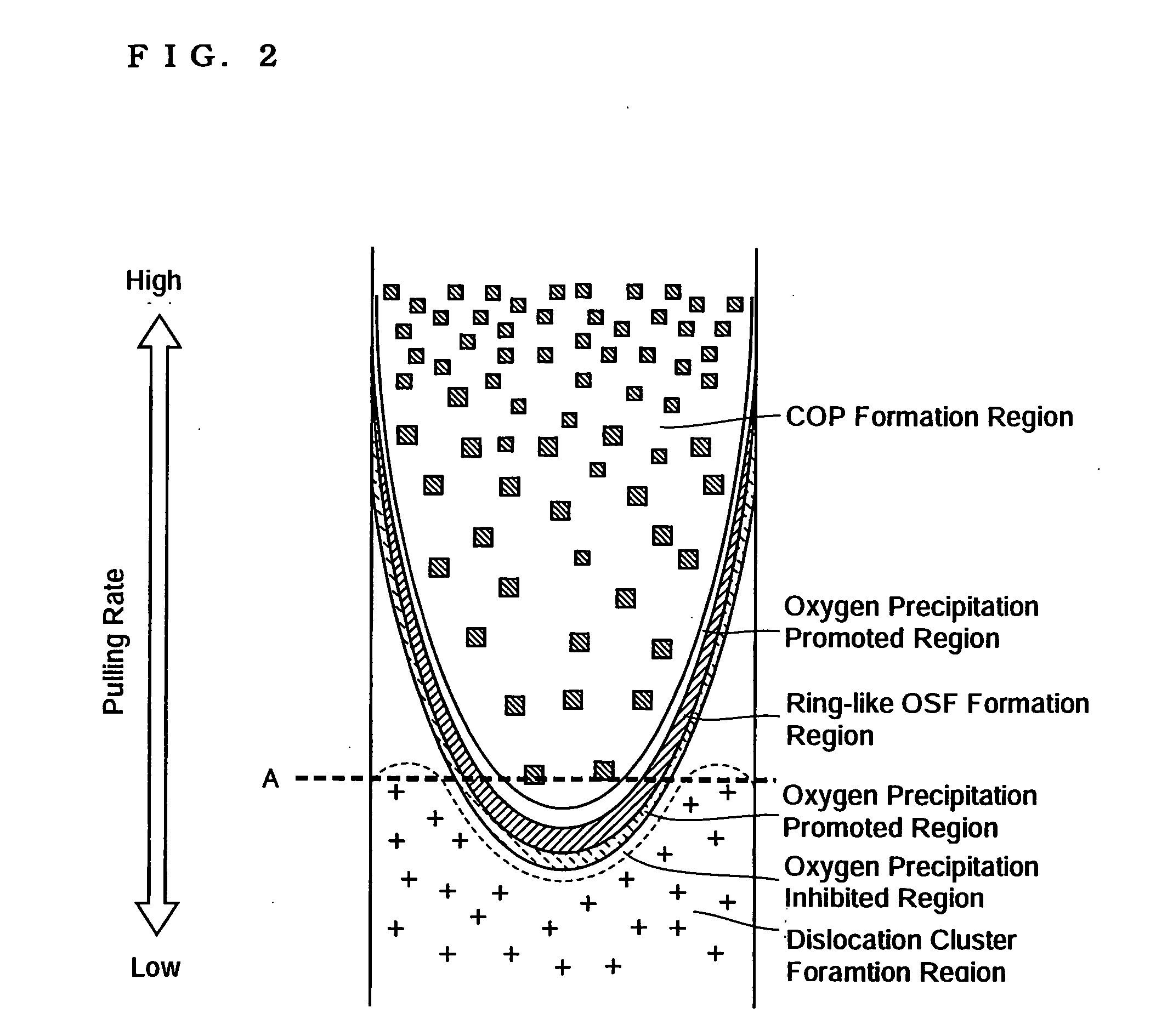

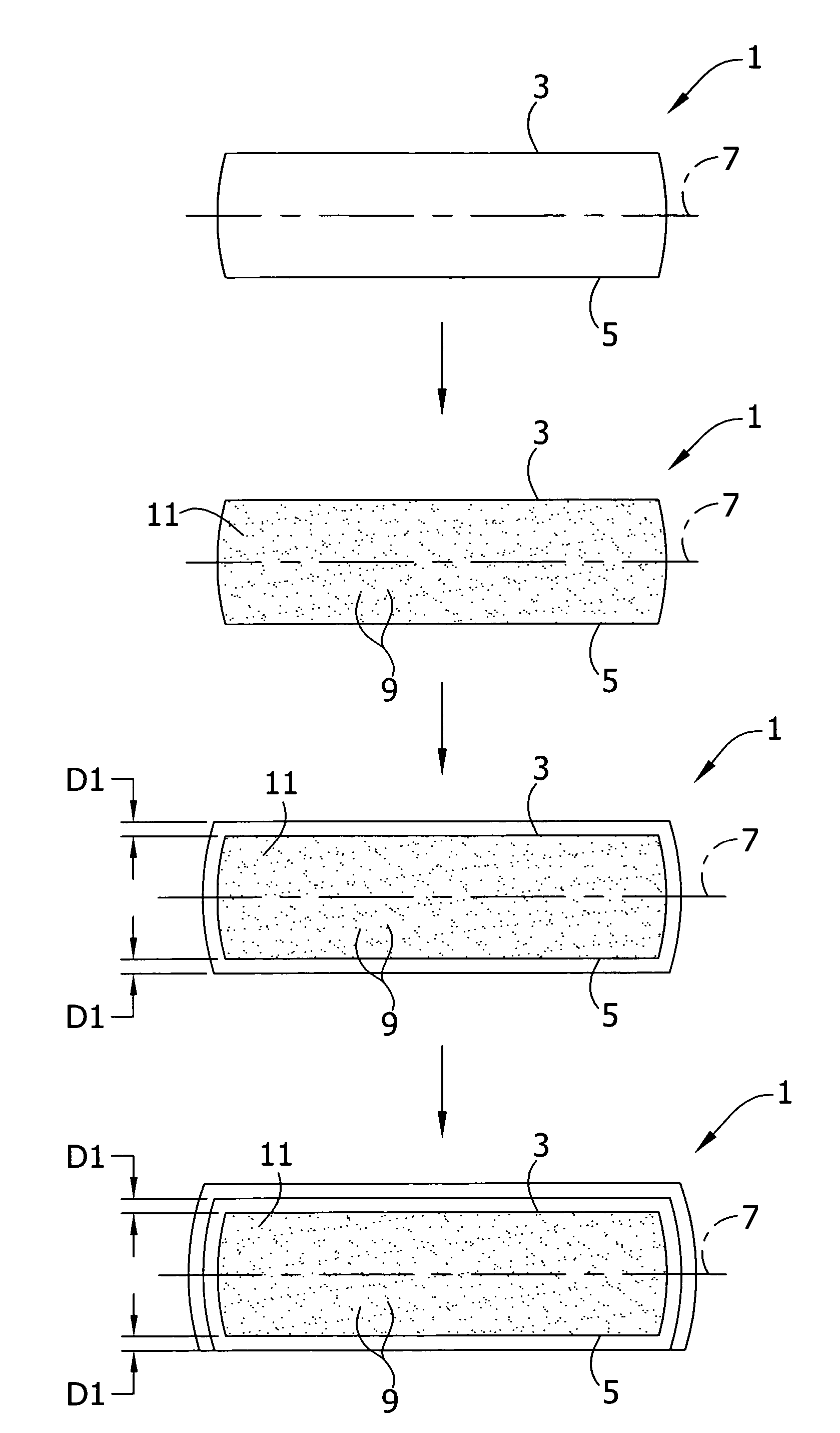

ActiveUS20050054124A1Increased formationPolycrystalline material growthSemiconductor/solid-state device manufacturingStacking faultOxygen precipitates

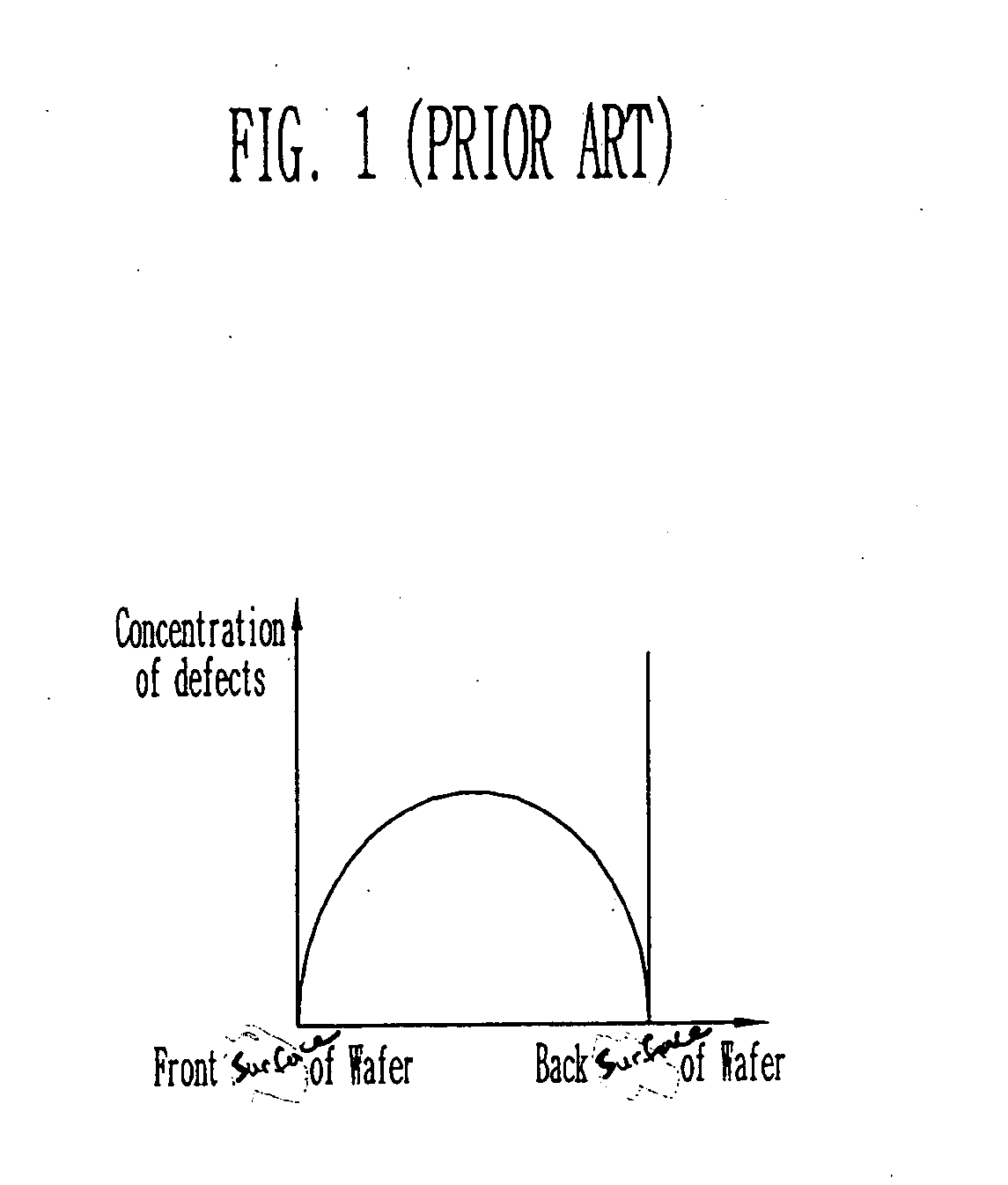

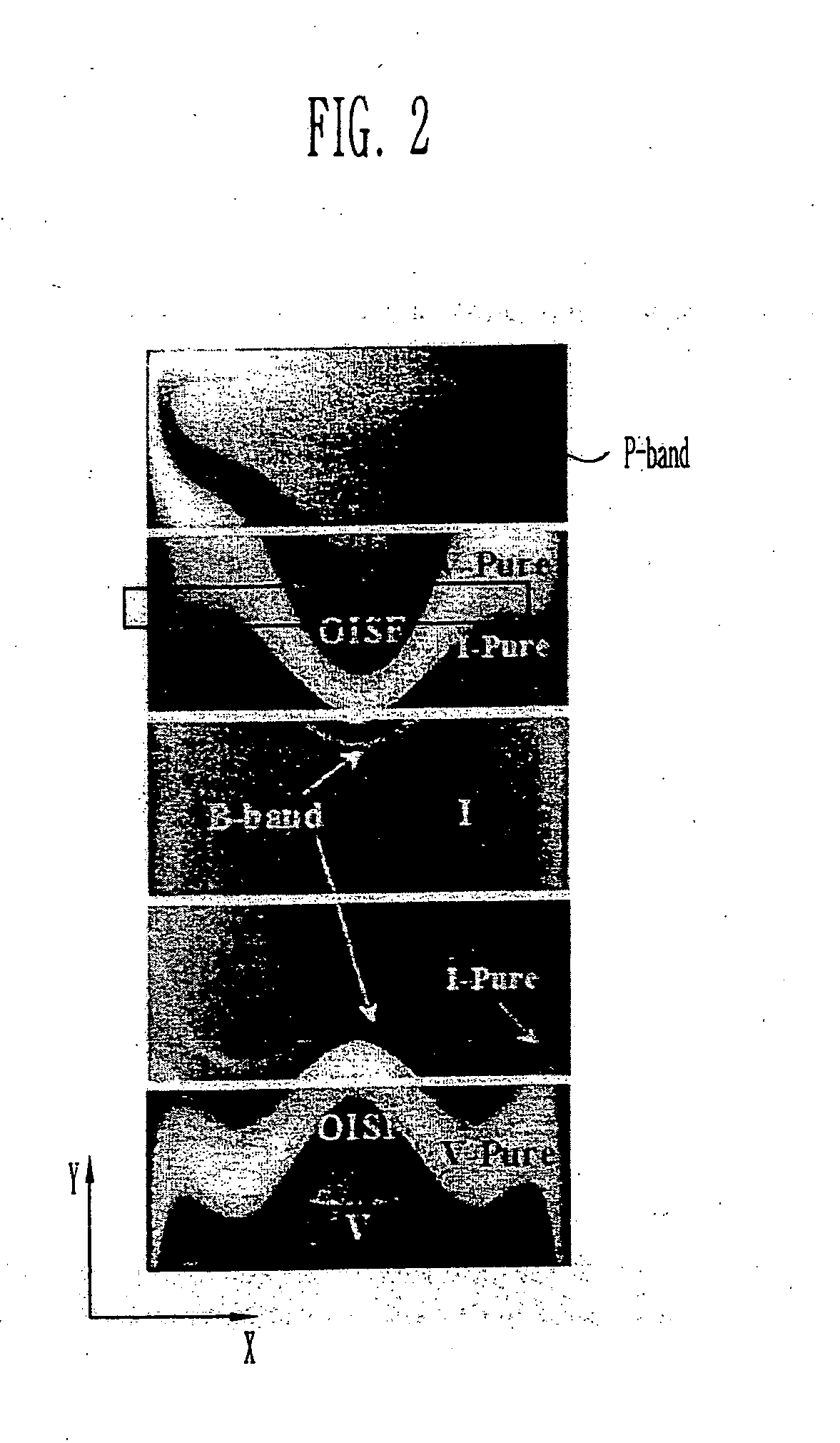

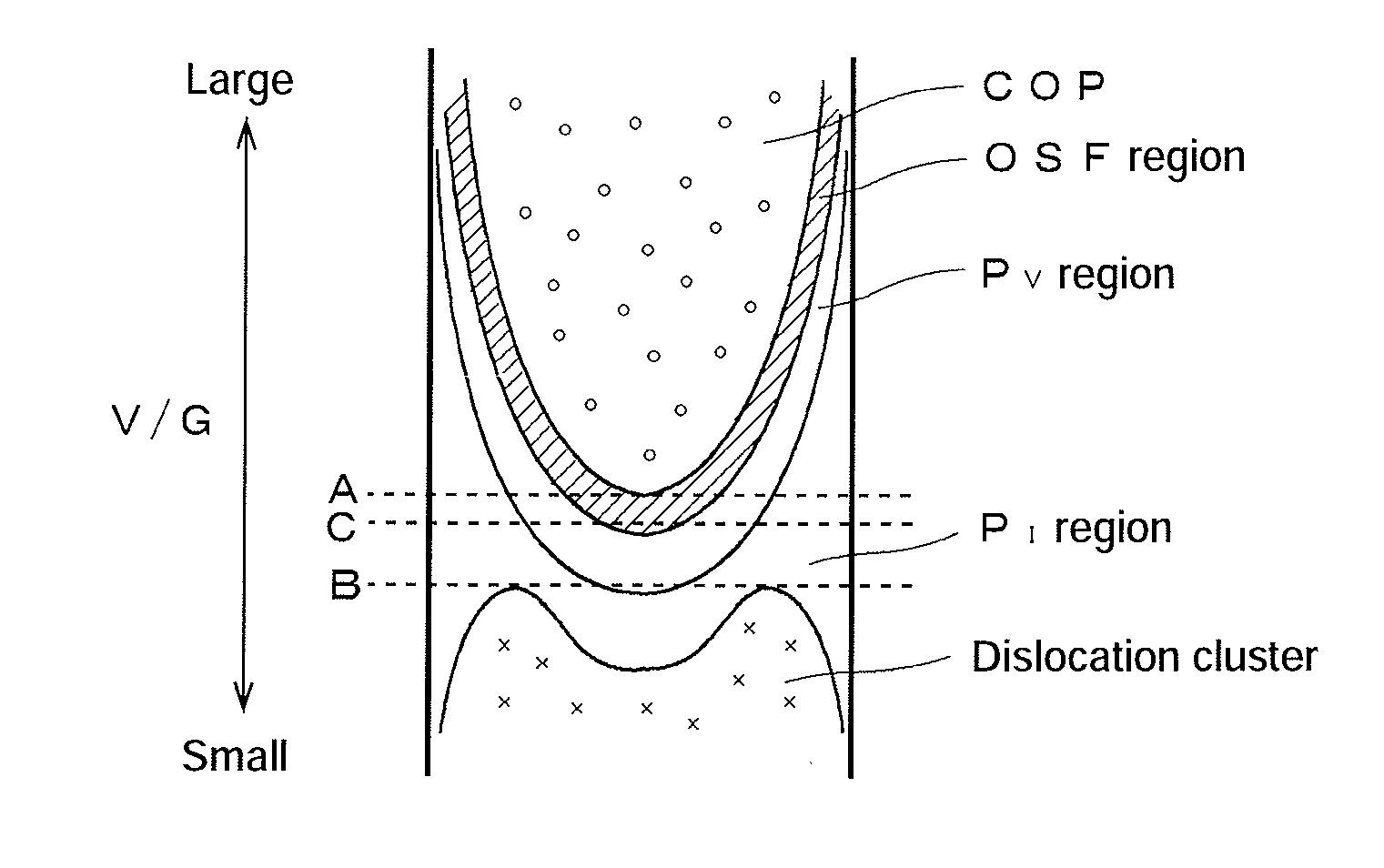

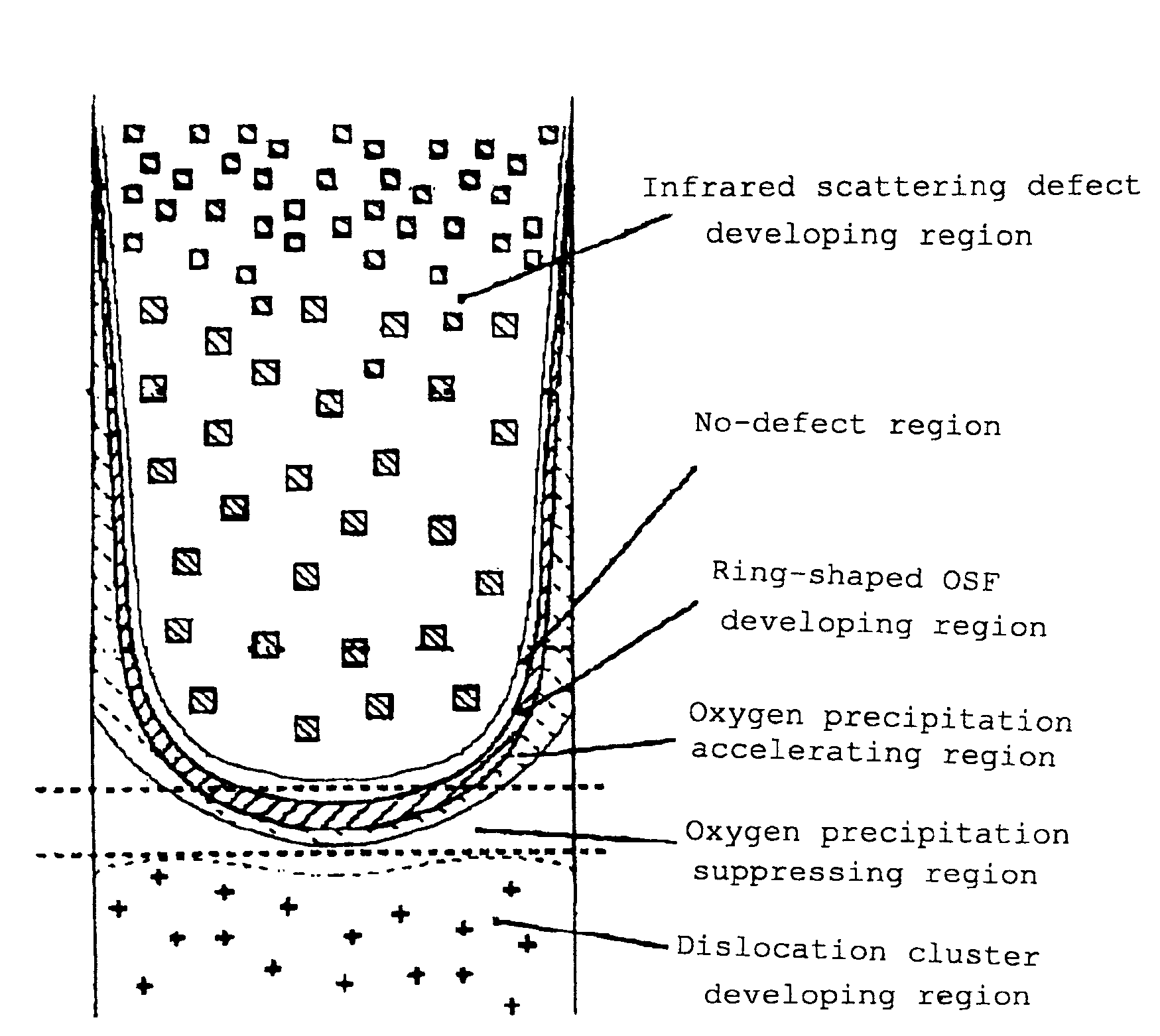

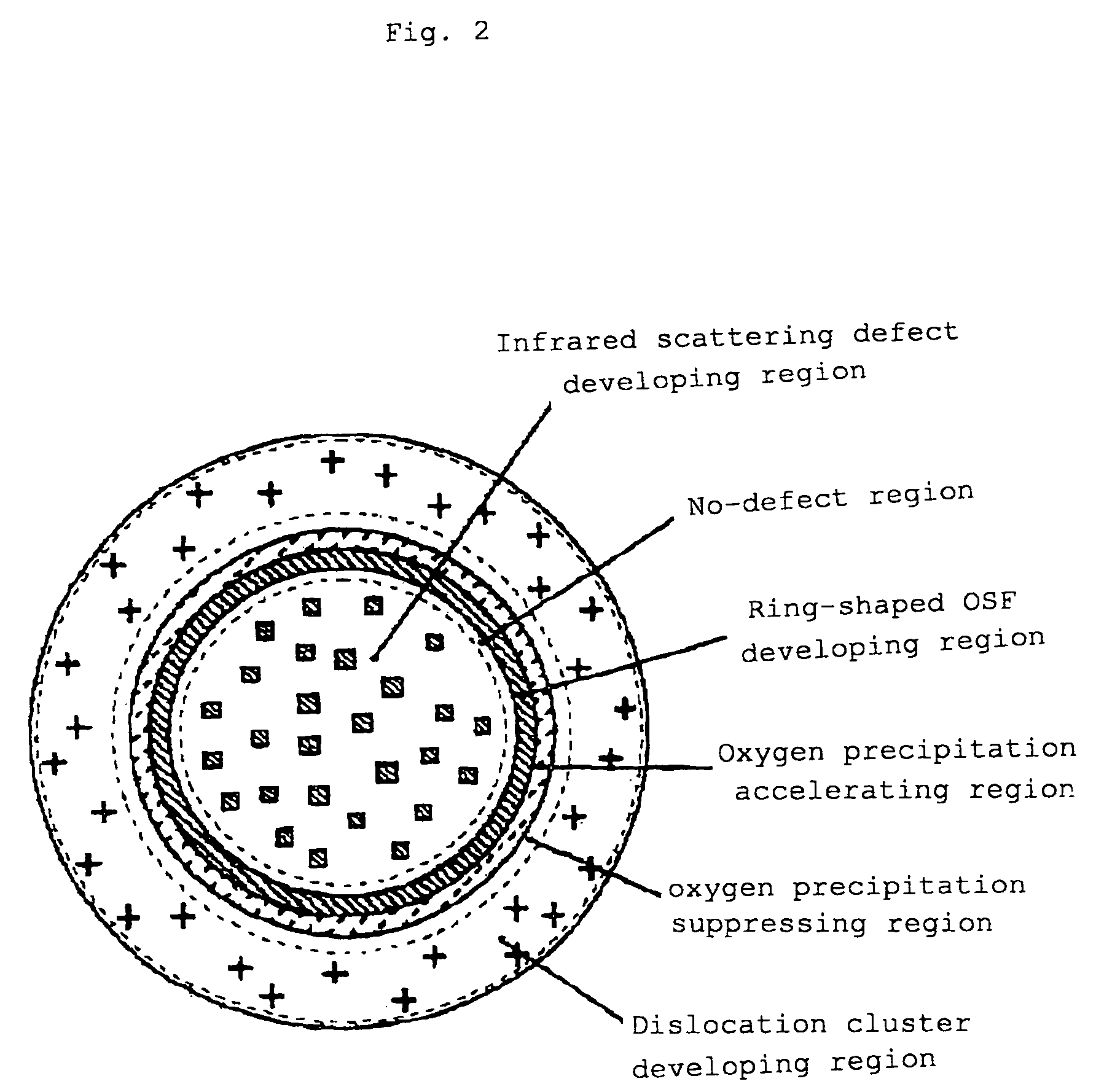

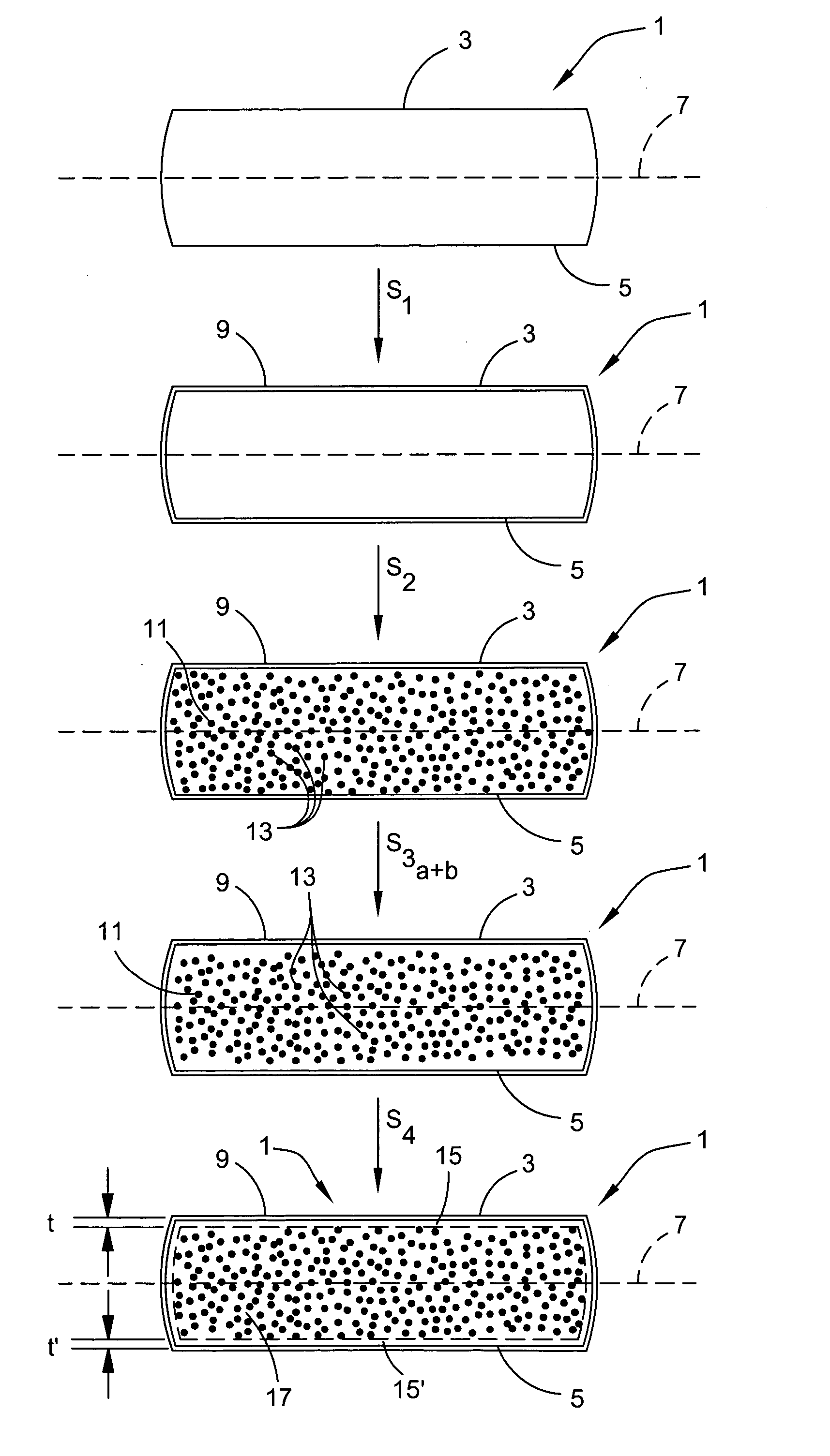

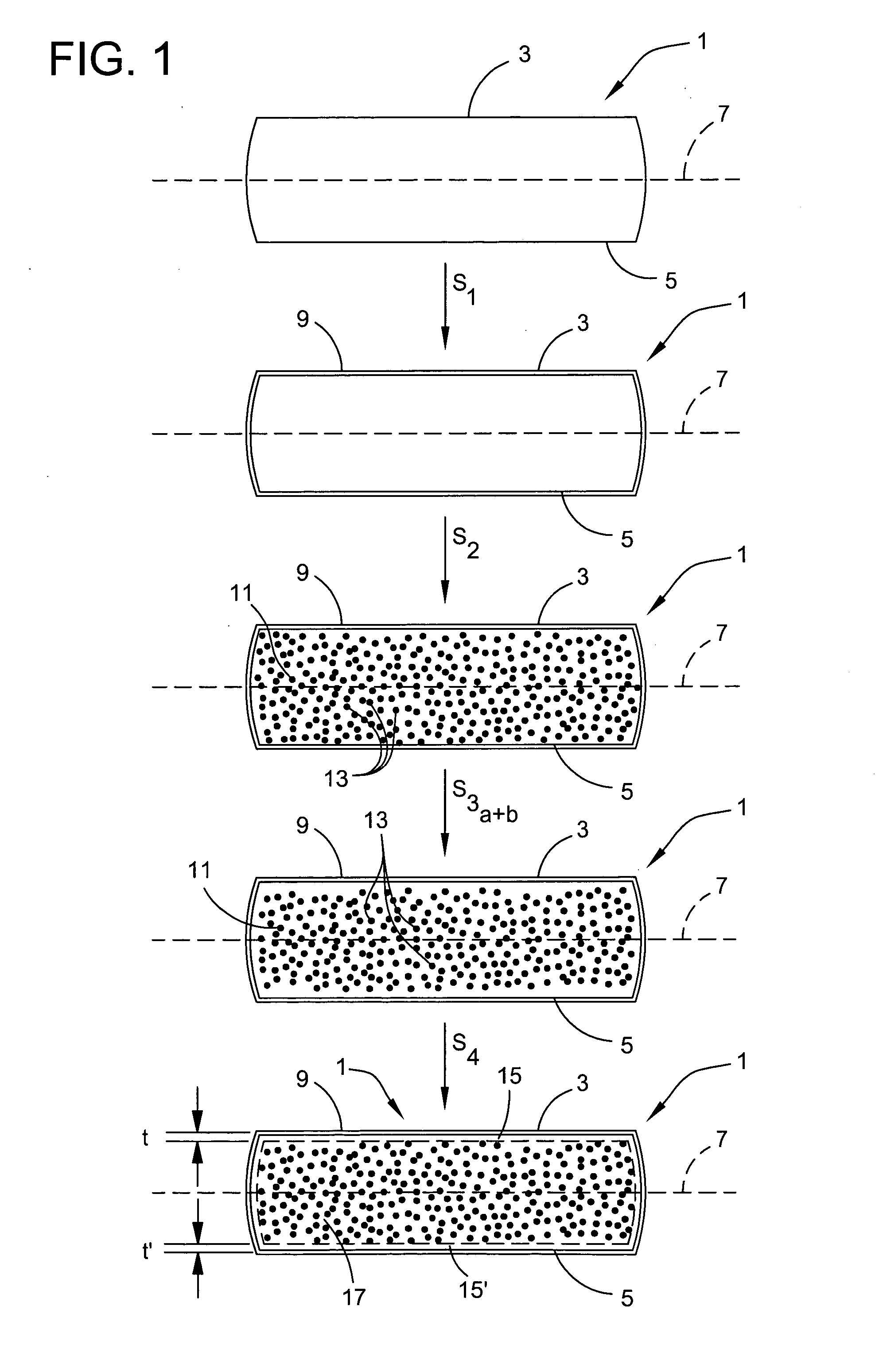

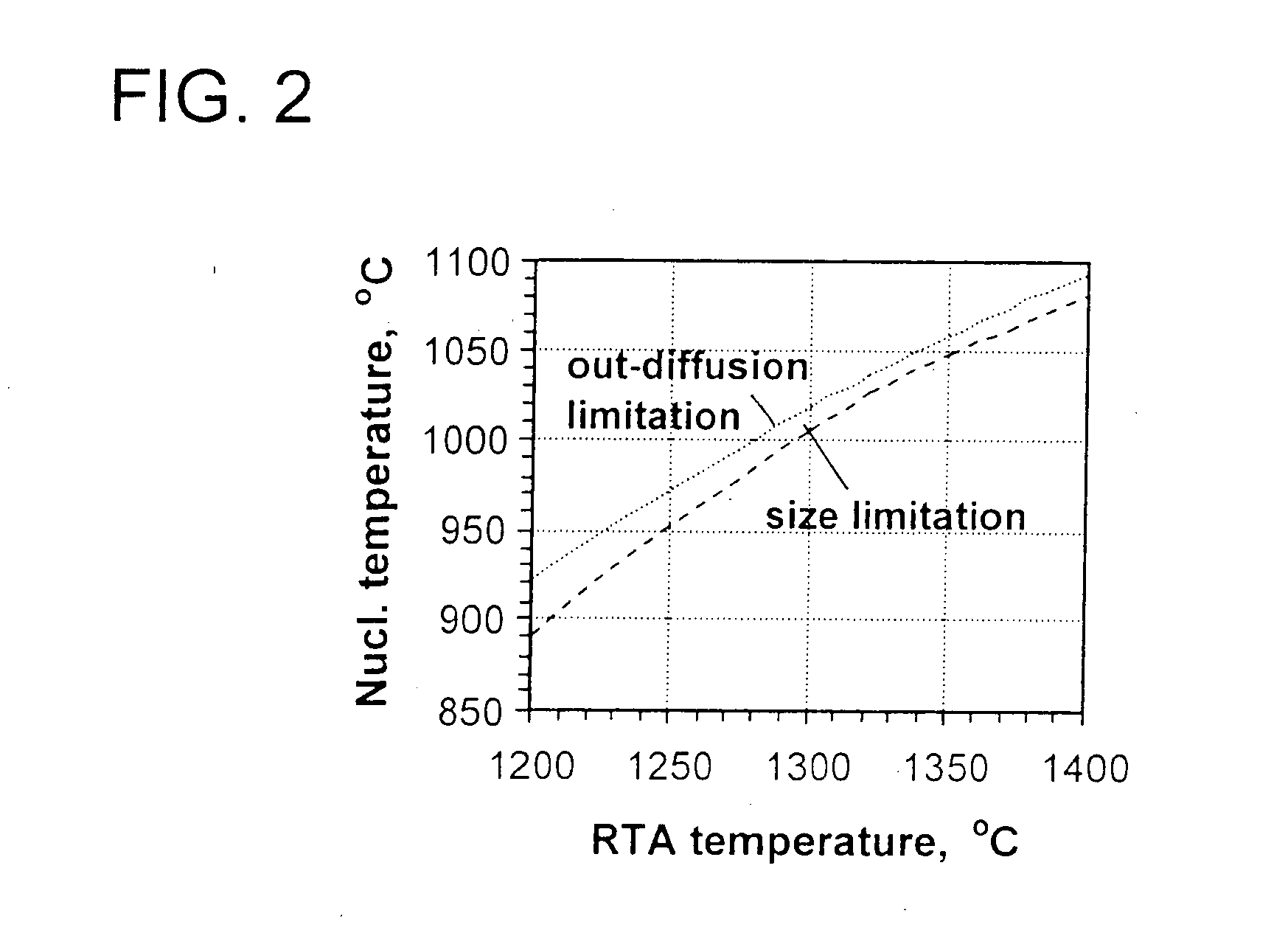

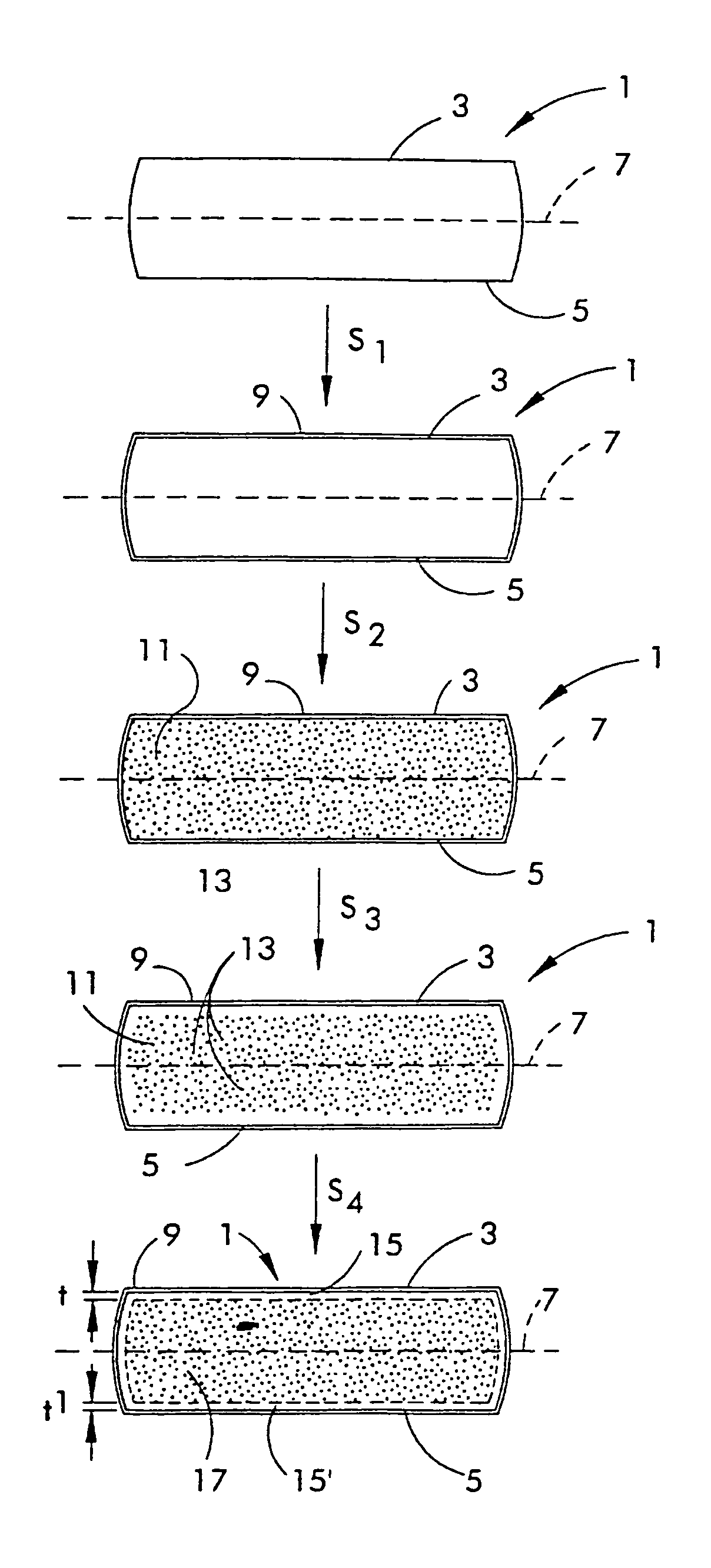

By using a two-step RTP (rapid thermal processing) process, the wafer is provided which has an ideal semiconductor device region secured by controlling fine oxygen precipitates and OiSFs (Oxidation Induced Stacking Fault) located on the surface region of the wafer. By performing the disclosed two-step rapid thermal process, the distribution of defects can be accurately controlled and an ideal device active zone can be formed up to a certain distance from the surfaces of the wafer. In addition, it is possible to maximize the internal gettering (IG) efficiency by enabling the oxygen precipitates and the bulk stacking faults to have constant densities in the depth direction in an internal region of the wafer, that is, the bulk region. In order to obtain the constant concentration profile of the oxygen precipitates and the bulk stacking faults in the bulk region, the wafer is subjected to the aforementioned two-step rapid thermal process in a predetermined mixed gas atmosphere.

Owner:SK HYNIX INC +1

Control of oxygen precipitate formation in high resistivity CZ silicon

InactiveUS6897084B2Layer is highHigh resistivityAfter-treatment detailsSolid-state devicesSurface layerHigh resistivity

The present invention is directed to a single crystal Czochralski-type silicon wafer, and a process for the preparation thereof, which has at least a surface layer of high resistivity, the layer having an interstitial oxygen content which renders it incapable of forming thermal donors in an amount sufficient to affect resistivity upon being subjected to a conventional semiconductor device manufacturing process. The present invention further directed to a silicon on insulator structure derived from such a wafer.

Owner:GLOBALWAFERS CO LTD

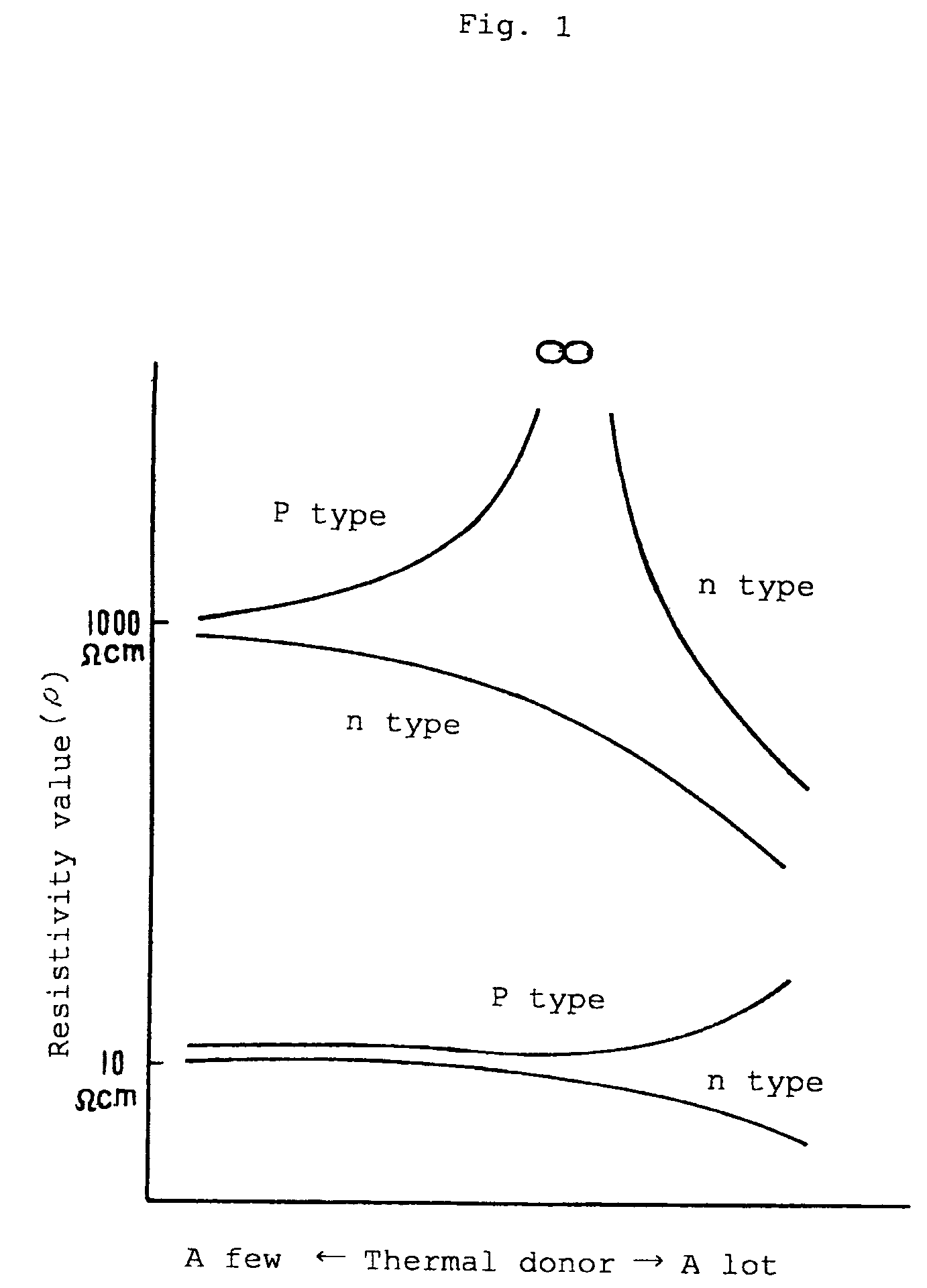

High resistance silicon wafer and method for production thereof

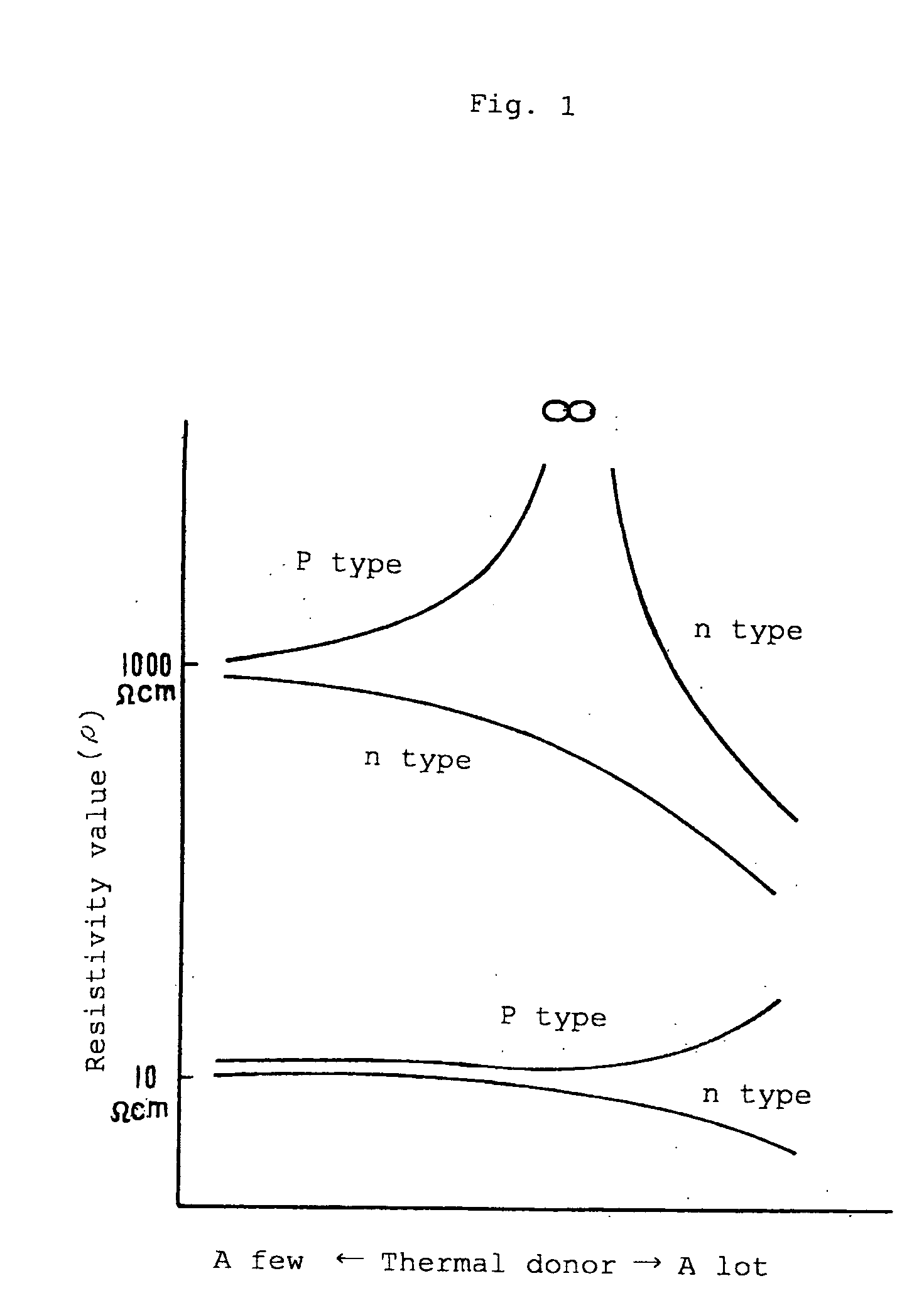

ActiveUS20050253221A1Promote formationUniform gettering abilitySemiconductor/solid-state device manufacturingSemiconductor devicesHigh resistanceHigh density

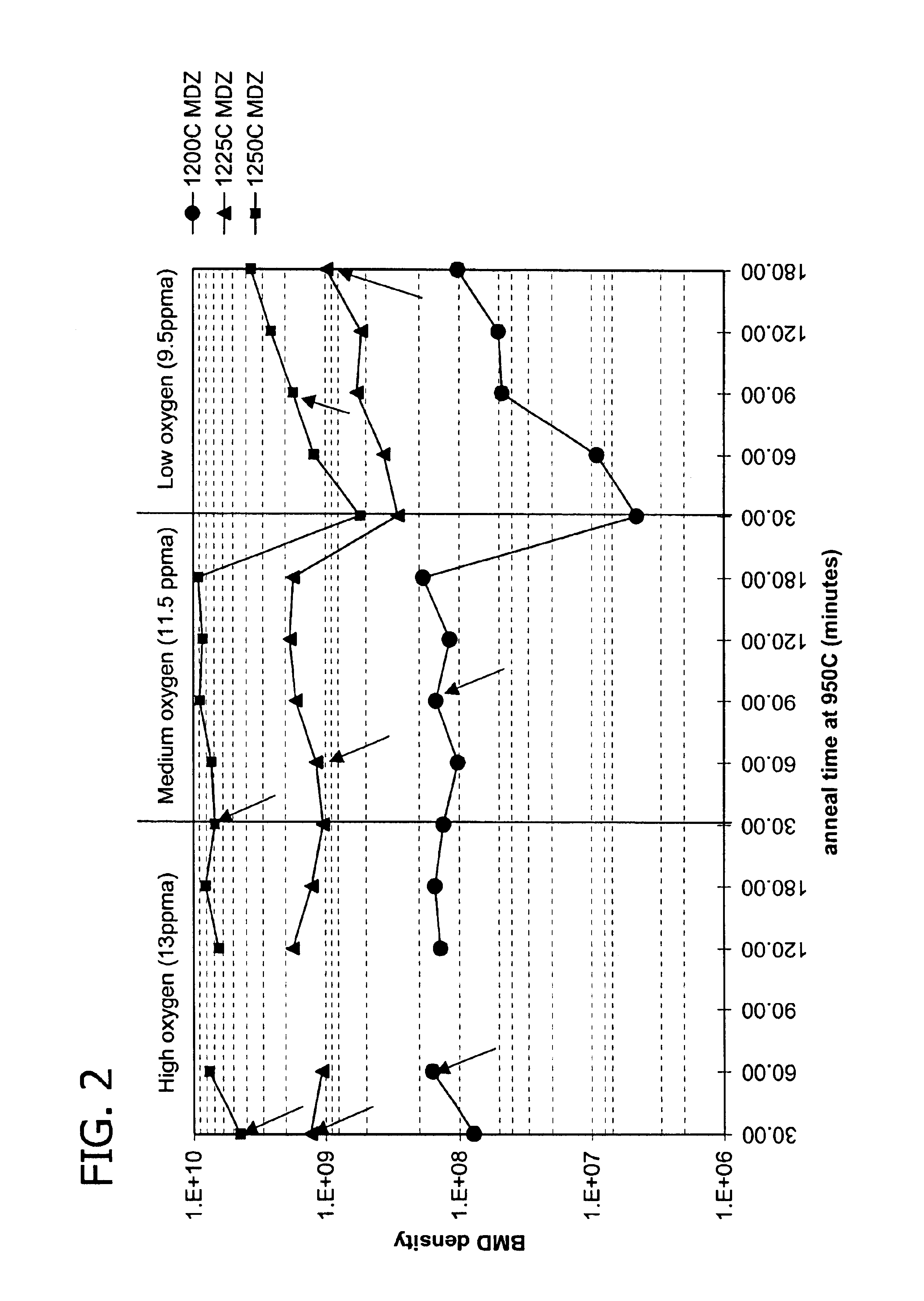

A high-resistance silicon wafer is manufactured in which a gettering ability, mechanical strength, and economical efficiency are excellent and an oxygen thermal donor is effectively prevented from being generated in a heat treatment for forming a circuit, which is implemented on the side of a device maker. A heat treatment for forming an oxygen precipitate nucleus is performed at 500 to 900° C. for 5 hours or more in a non-oxidizing atmosphere and a heat treatment for growing an oxygen precipitate is performed at 950 to 1050° C. for 10 hours or more on a high-oxygen and carbon-doped high-resistance silicon wafer in which resistivity is 100 Ωcm or more, an oxygen concentration is 14×1017 atoms / cm3 (ASTM F-121, 1979) or more and a carbon concentration is 0.5×1016 atoms / cm3 or more. By these heat treatments, a remaining oxygen concentration in the wafer is controlled to be 12×1017 atoms / cm3 (ASTM F-121, 1979) or less. Thus, there is provided a high-resistance, low-oxygen and high-strength silicon wafer in which resistivity is 100 Ωcm or more and an oxygen precipitate (BMD) having a size of 0.2 μm is formed so as to have high density of 1×104 / cm2 or more.

Owner:SUMITOMO MITSUBISHI SILICON CORP

Silicon wafer and method for producing the same

ActiveUS20100290971A1Improve solubilityReduce heatPolycrystalline material growthAfter-treatment detailsWaferingSurface layer

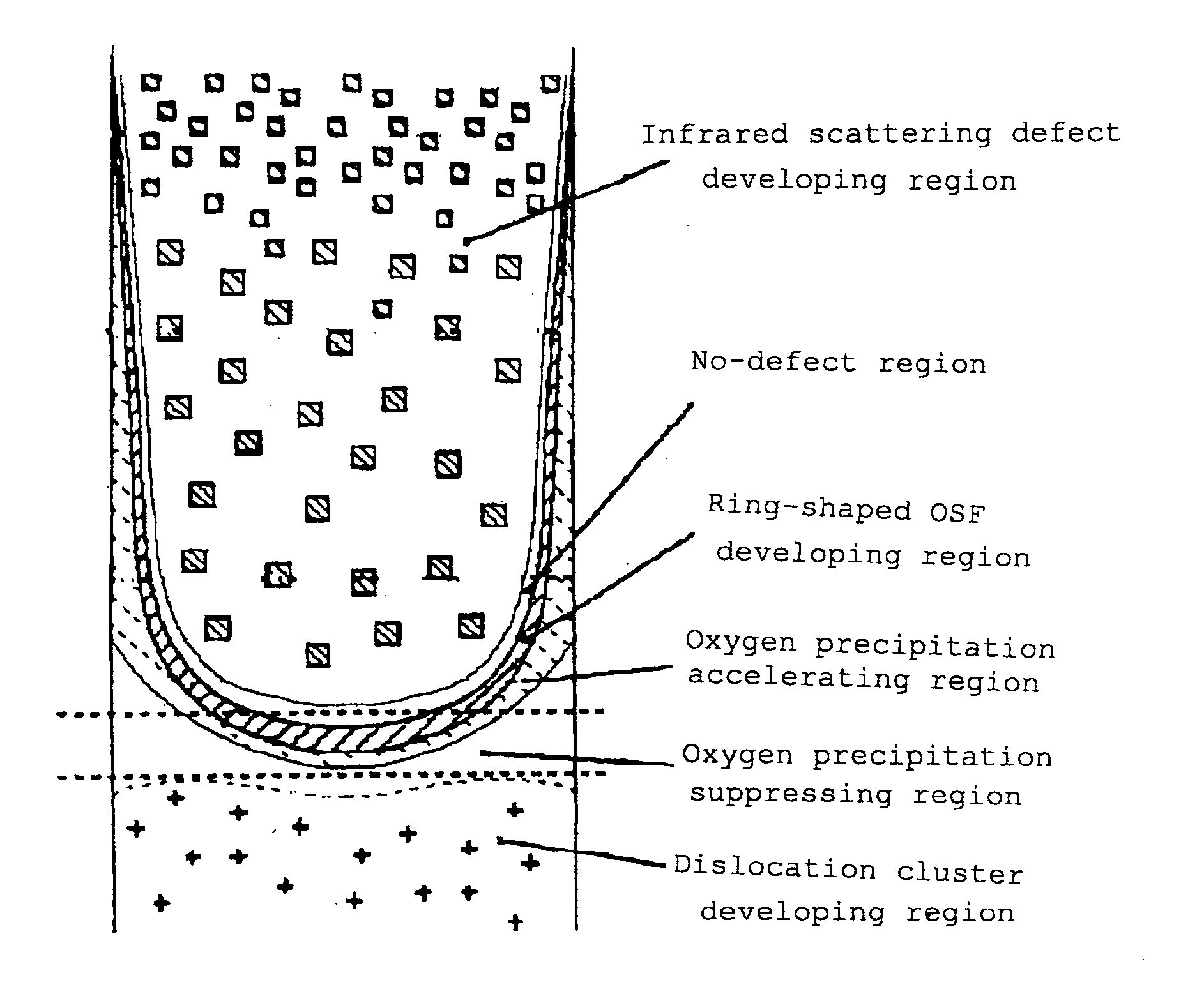

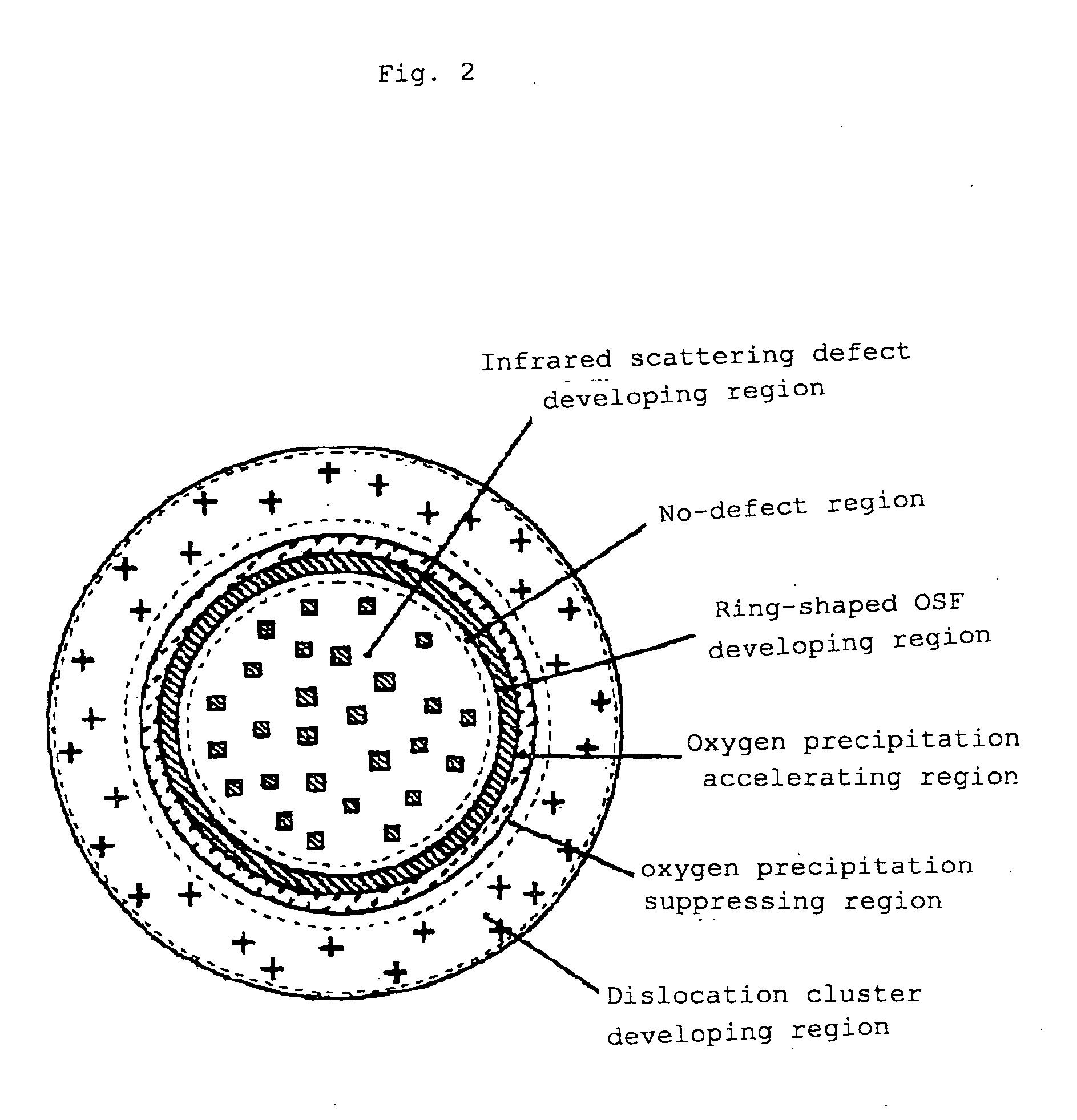

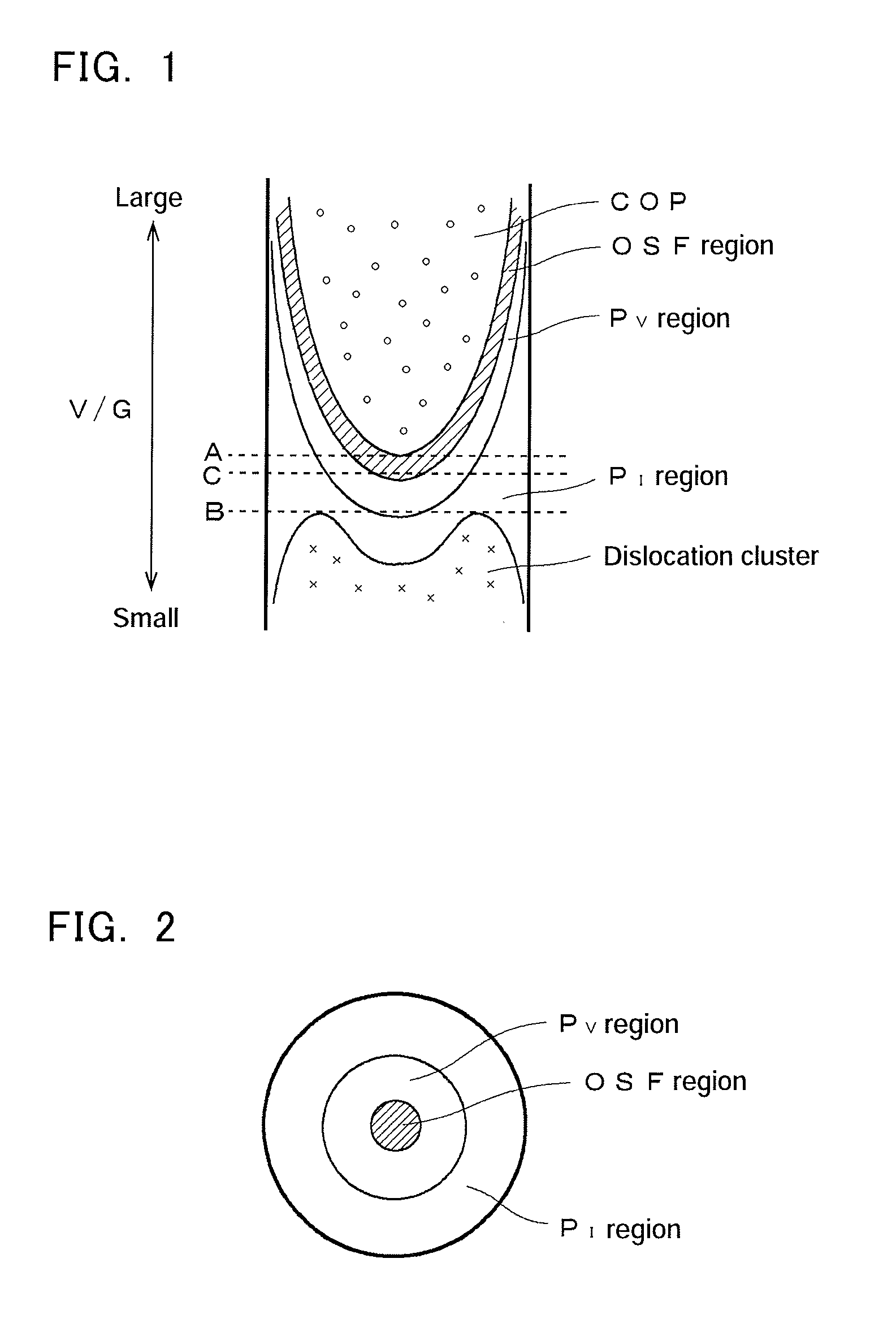

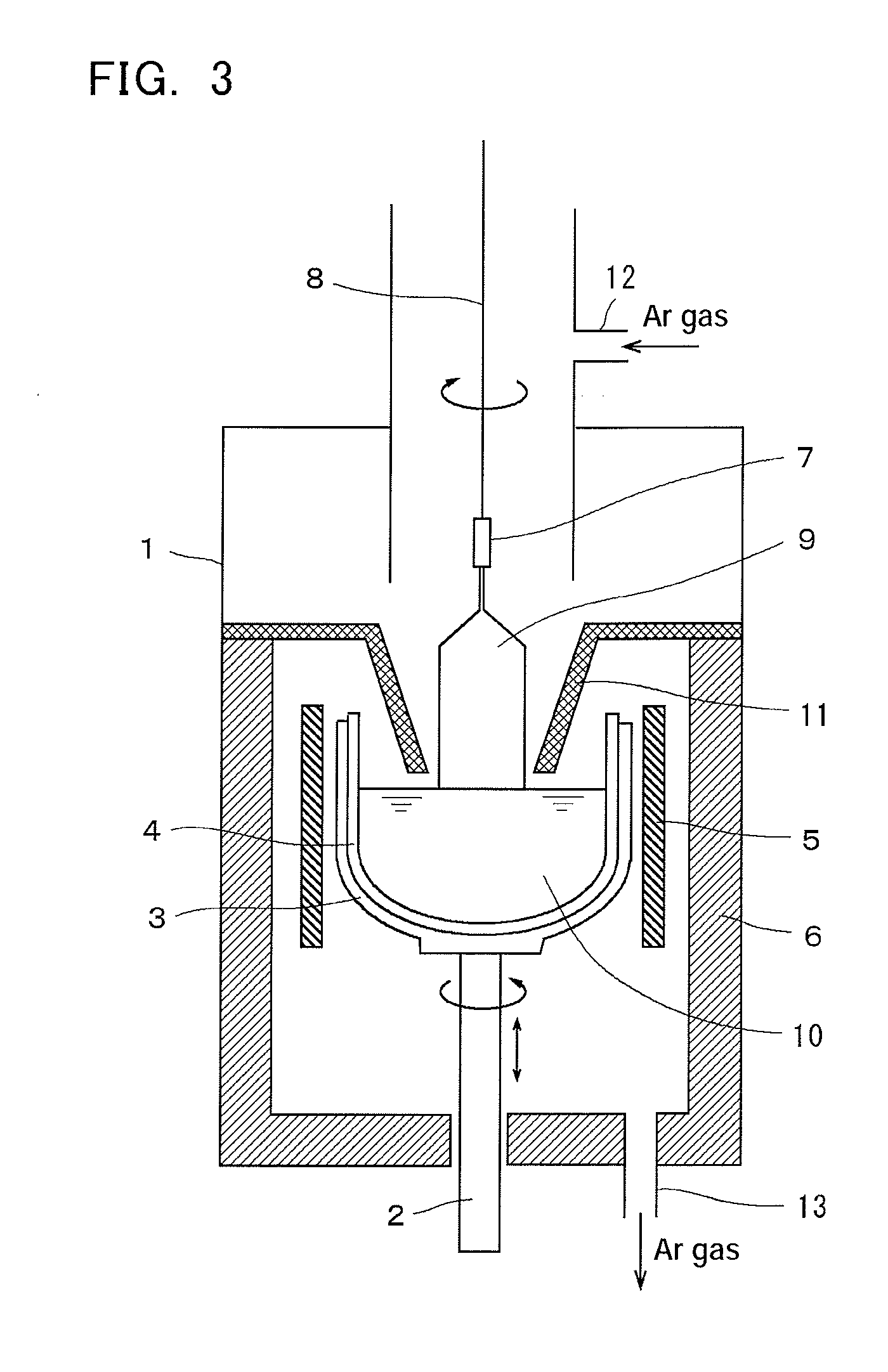

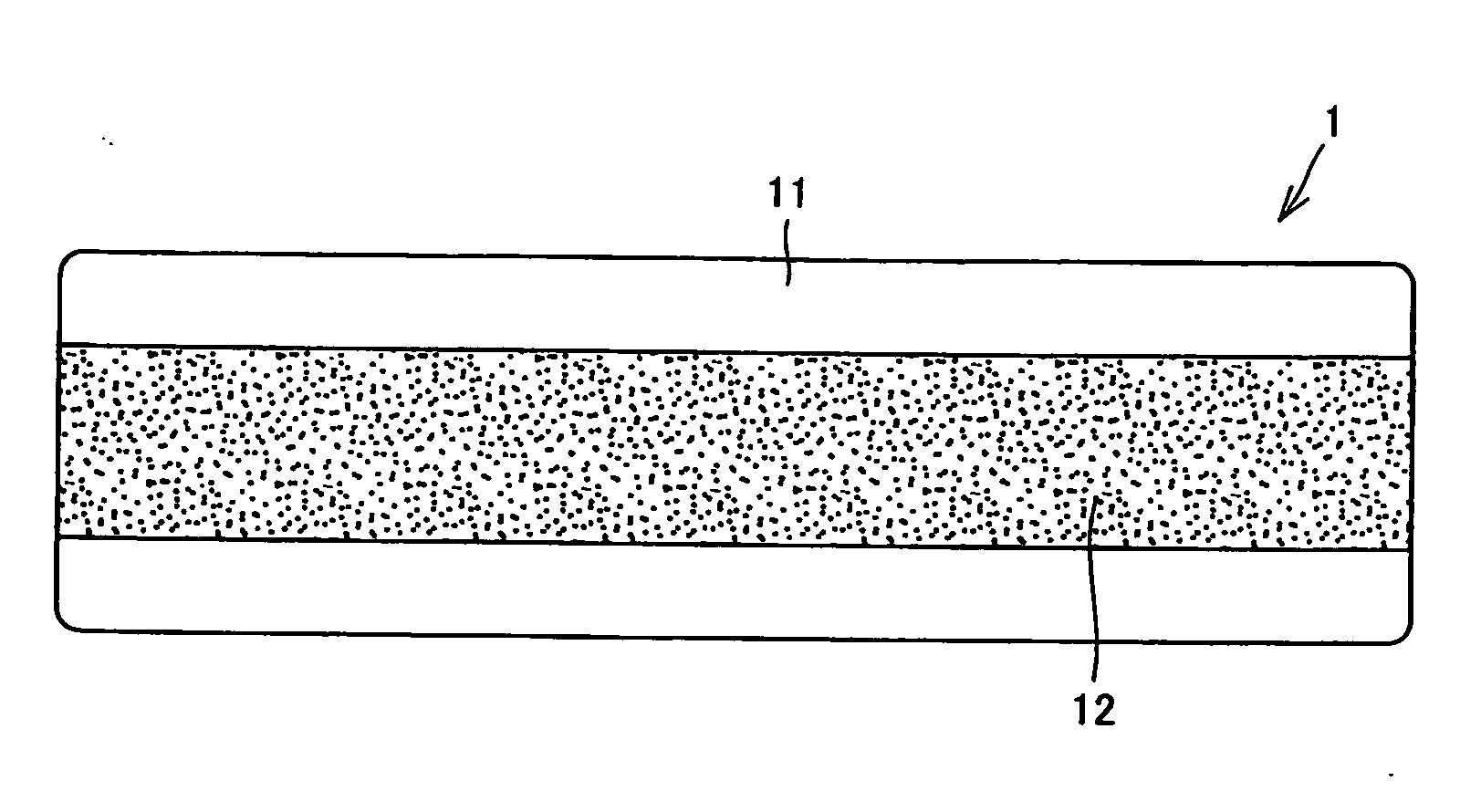

It is possible to provide a silicon wafer that as well as being free of COPs and dislocation clusters, has defects (grown-in defects including silicon oxides), which are not overt in an as-grown state, such as OSF nuclei and oxygen precipitate nuclei existing in the PV region, to be vanished or reduced, by adopting a method for producing a silicon wafer, the method comprising the steps of: growing a single crystal silicon ingot by the Czochralski method; cutting a silicon wafer out of the ingot; subjecting the wafer to an RTP at 1,250° C. or more for 10 seconds or more in an oxidizing atmosphere; and removing a grown-in defect region including silicon oxides in the vicinity of wafer surface layer after the RTP.

Owner:SUMCO CORP

Method for heat treatment of silicon wafers

InactiveUS20060189169A1Promote formationStable formationSemiconductor/solid-state device manufacturingHigh densityOxygen ions

A method is provided for the heat treatment of low oxygen concentration silicon wafers obtained from a silicon single crystal produced by the Czochralski process. The method comprises high-temperature oxidation heat treatment for the formation of a high oxygen concentration region under the wafer surface and the subsequent oxygen precipitation heat treatment. The high-temperature oxidation heat treatment can cause inward diffusion of oxygen from the wafer surface to form a region increased in oxygen concentration under the wafer surface, and the subsequent oxygen precipitation heat treatment can form a DZ layer on the wafer surface and stably form oxygen precipitates optimal in size within the wafer at a high density, so that excellent gettering effects can be produced. Further, in case of using as SOI substrates formed by SIMOX, too, the same effects as mentioned above can be produced by carrying out the high-temperature oxidation heat treatment after oxygen ion implantation in the SIMOX process and then carrying out the oxygen precipitation heat treatment.

Owner:SUMCO CORP

Methods for manufacturing compound-material wafers and for recycling used donor substrates

ActiveUS7405136B2Quality improvementLow costSolid-state devicesSemiconductor/solid-state device manufacturingOxygen precipitatesThermal treatment

This invention provides methods for manufacturing compound-material wafers and methods for recycling donor substrates that results from manufacturing compound-material wafers. The provided methods includes at least one further thermal treatment step configured to at least partially reduce oxygen precipitates and / or nuclei. Reduction of oxygen precipitates and / or nuclei, improves the recycling rate of the donor substrate.

Owner:SOITEC SA

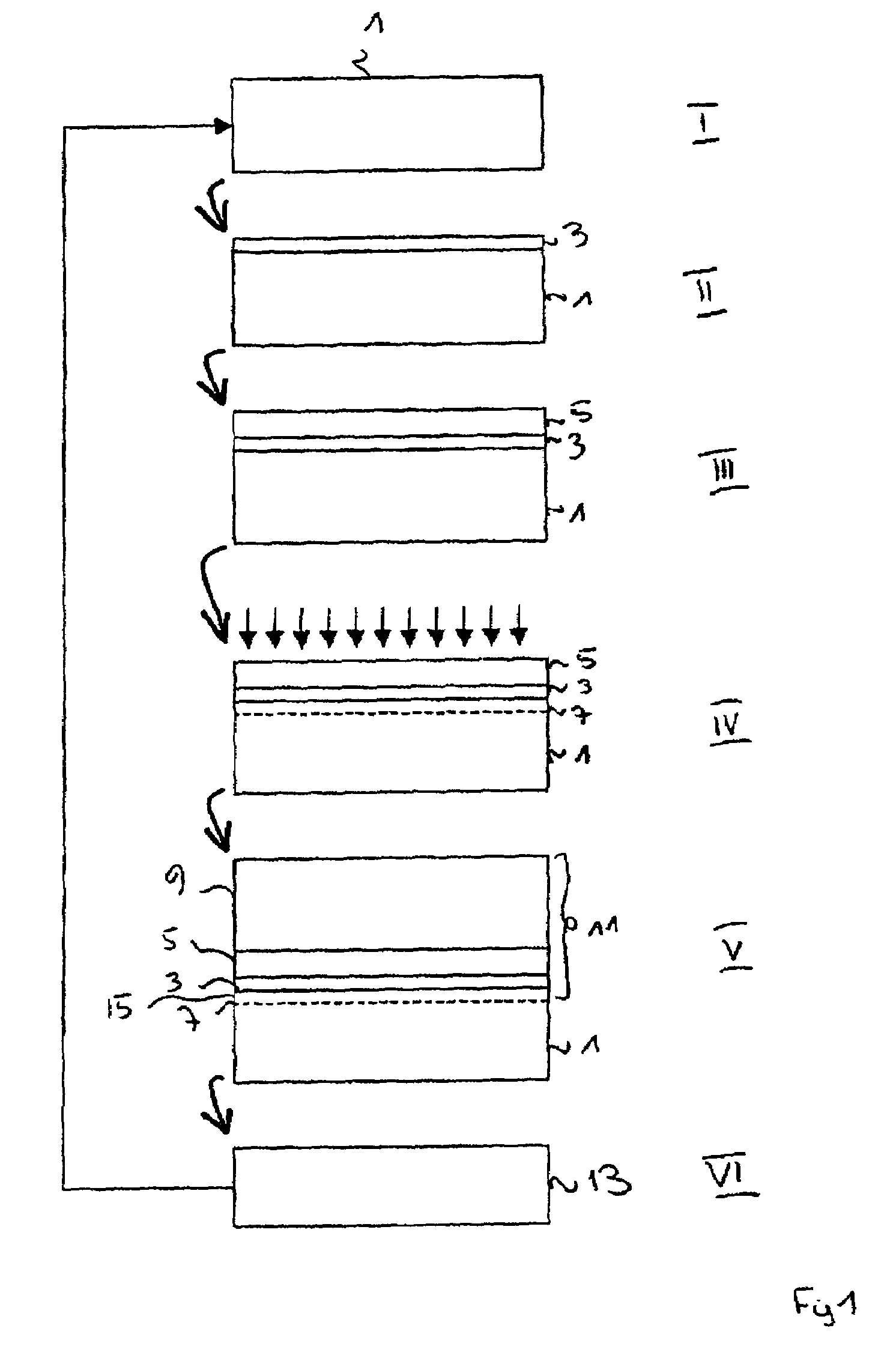

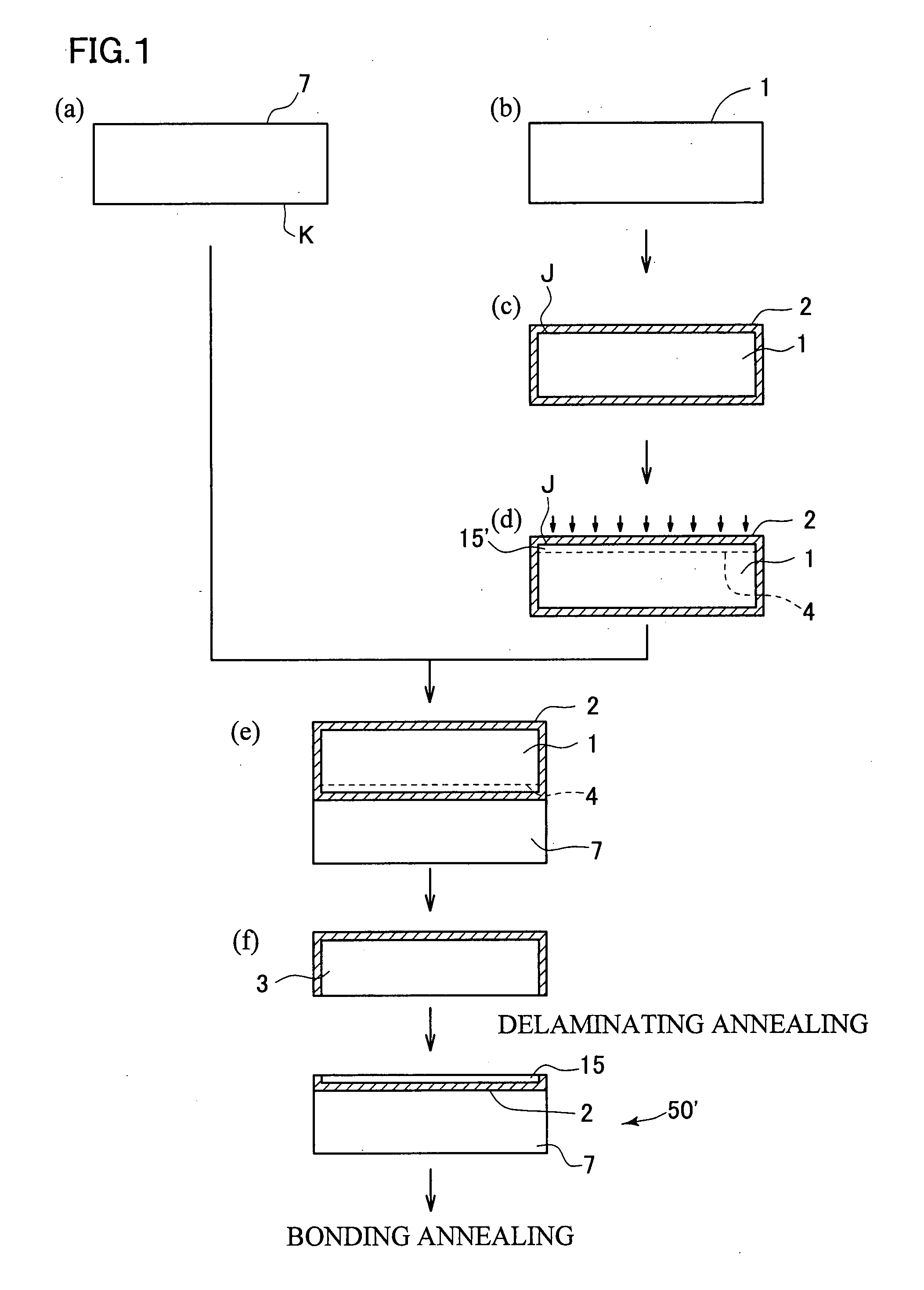

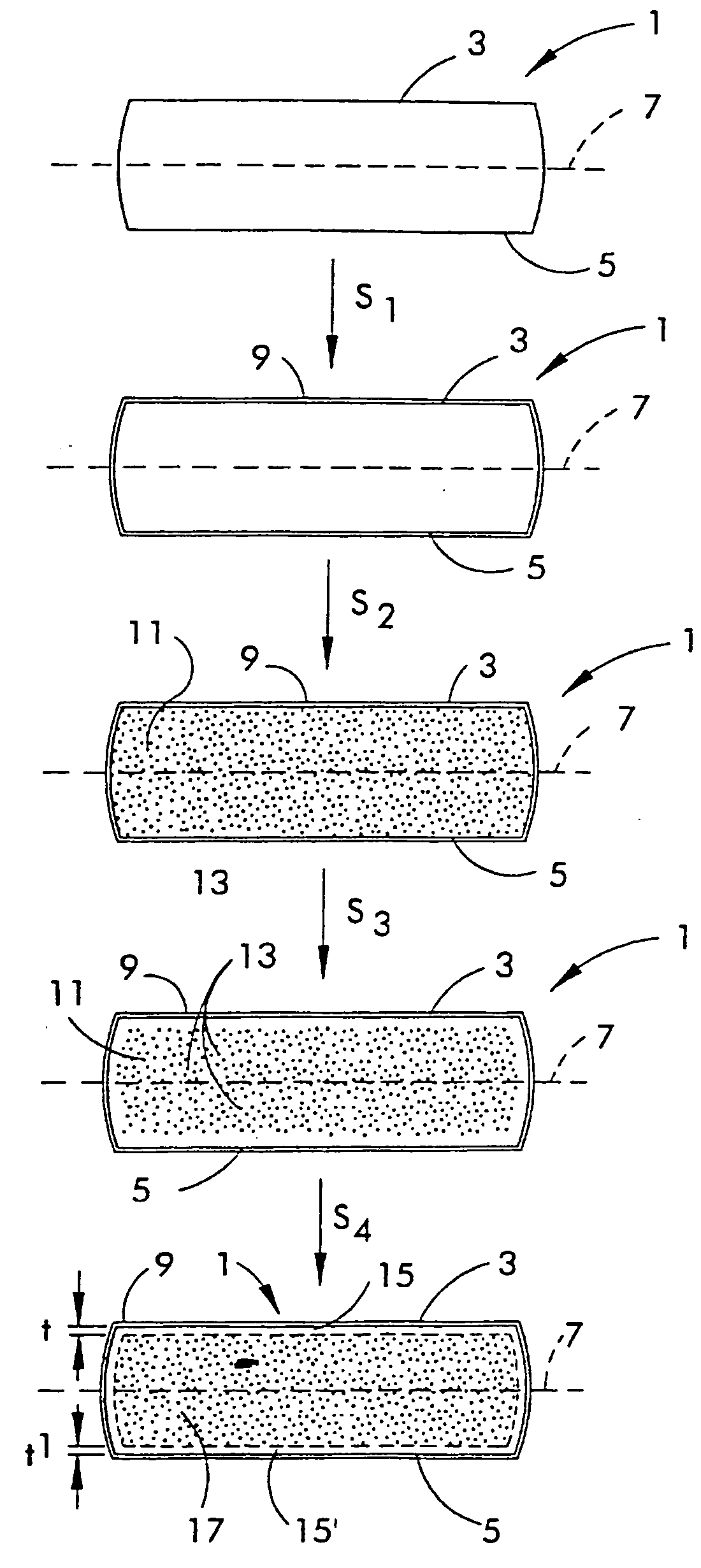

Method Of Manufacturing Soi Wafer And Thus-Manufactured Soi Wafer

ActiveUS20080128851A1Suppress density of formationReduce in quantitySolid-state devicesSemiconductor/solid-state device manufacturingRefractive indexSilicon oxide

A method of manufacturing an SOI wafer includes a bonding step, a thinning and a bonding annealing step. Assuming refractive index n1 of SiO2 as 1.5, refractive index n2 of Si as 3.5, and optical thickness tOP of the silicon oxide film 2 and the SOI layer 15 in the infrared wavelength region as tOP=n1×t1+n2×t2, the thickness t1 of the silicon oxide film 2 and thickness t2 of the SOI layer so as to satisfy a relation of 0.1λ<tOP<2λ, and so as to make (t1×n1) / (t2×n2) fall within 0.2 to 3. By nuclei killer annealing carried out before the bonding annealing, density of formation of oxygen precipitate in the base wafer after the bonding annealing is adjusted to less than 1×109 / cm3. This configuration successfully provides a method of manufacturing the SOI wafer having the thin silicon oxide film and the SOI layer, and being less likely to cause warping.

Owner:SHIN-ETSU HANDOTAI CO LTD

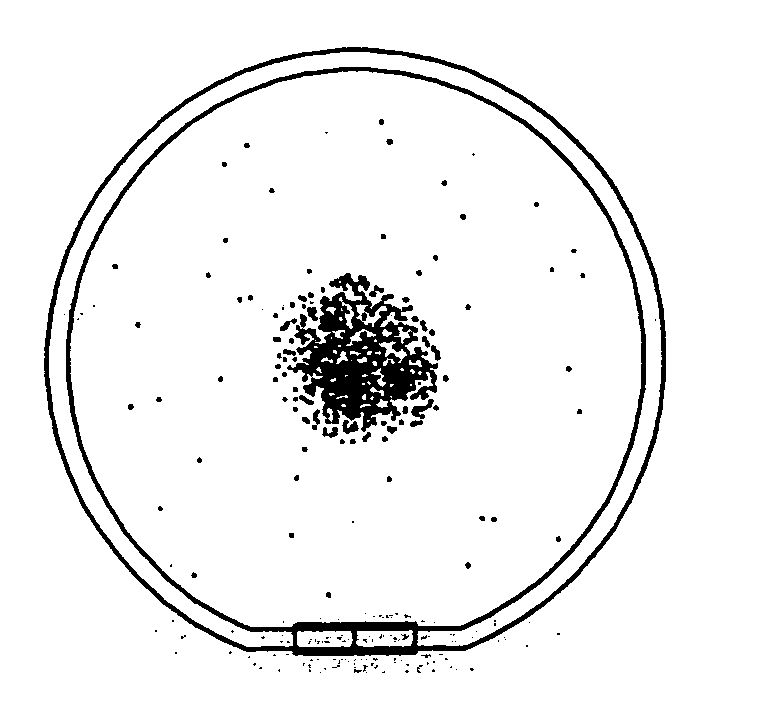

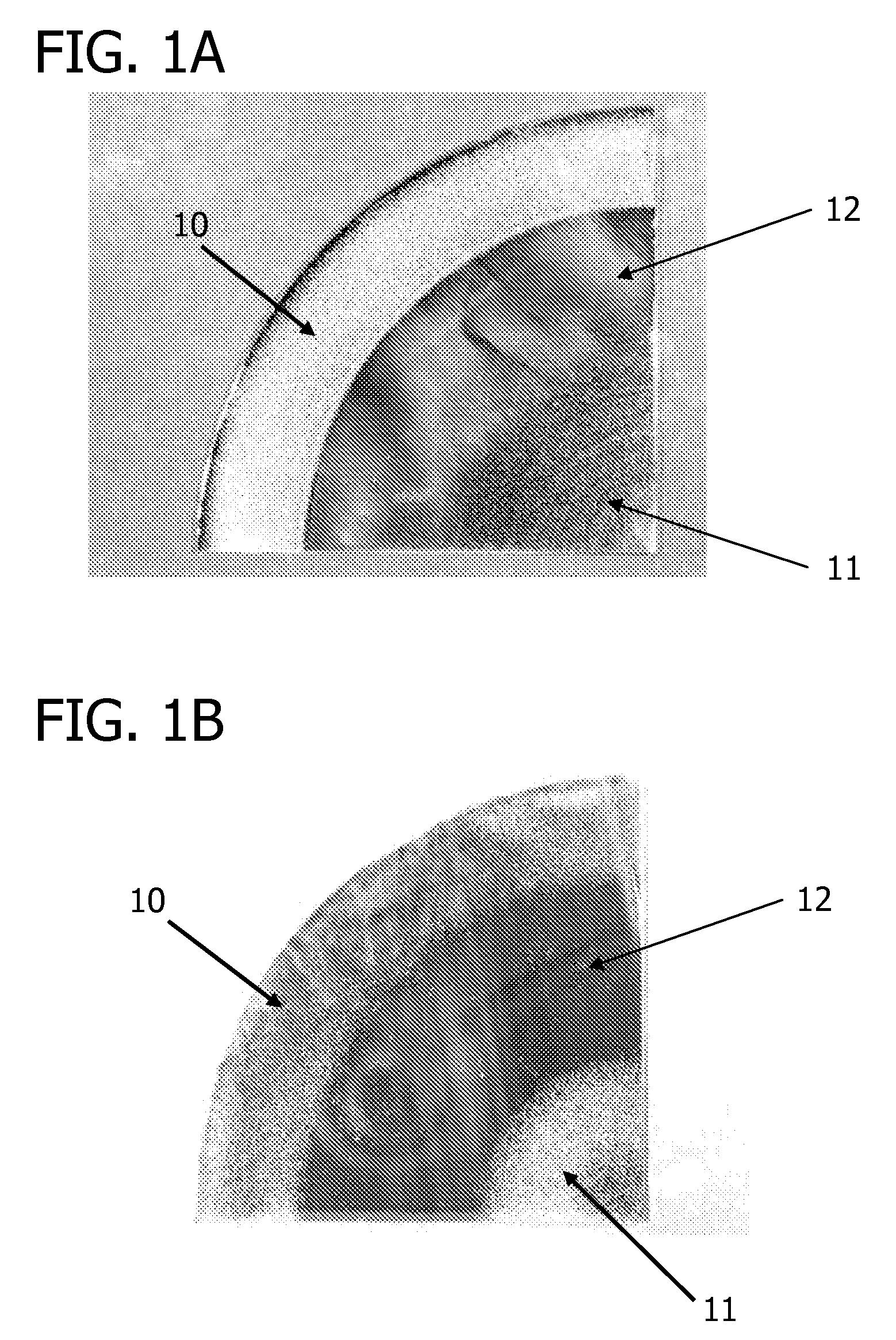

Silicon material with controlled agglomerated point defects and oxygen clusters induced by the lateral surface

The present invention relates to a single crystal silicon ingot or wafer wherein the lateral incorporation effect of intrinsic point defects has been manipulated such that the formation of agglomerated intrinsic point defects and / or oxygen precipitate clusters in a ring extending radially inward from about the lateral surface of the ingot segment is limited.

Owner:GLOBALWAFERS CO LTD

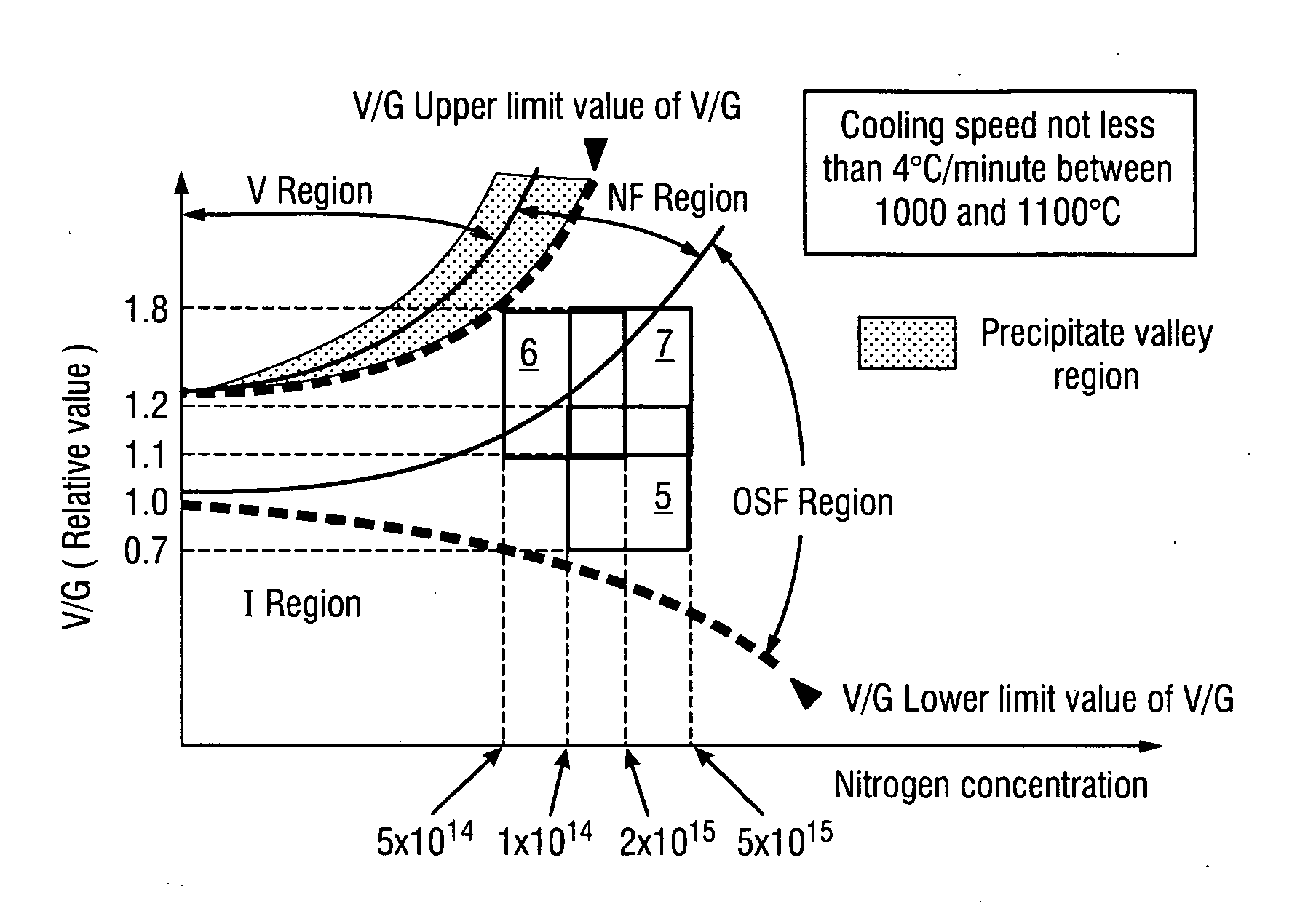

Nitorgen doped silicon wafer and manufacturing method thereof

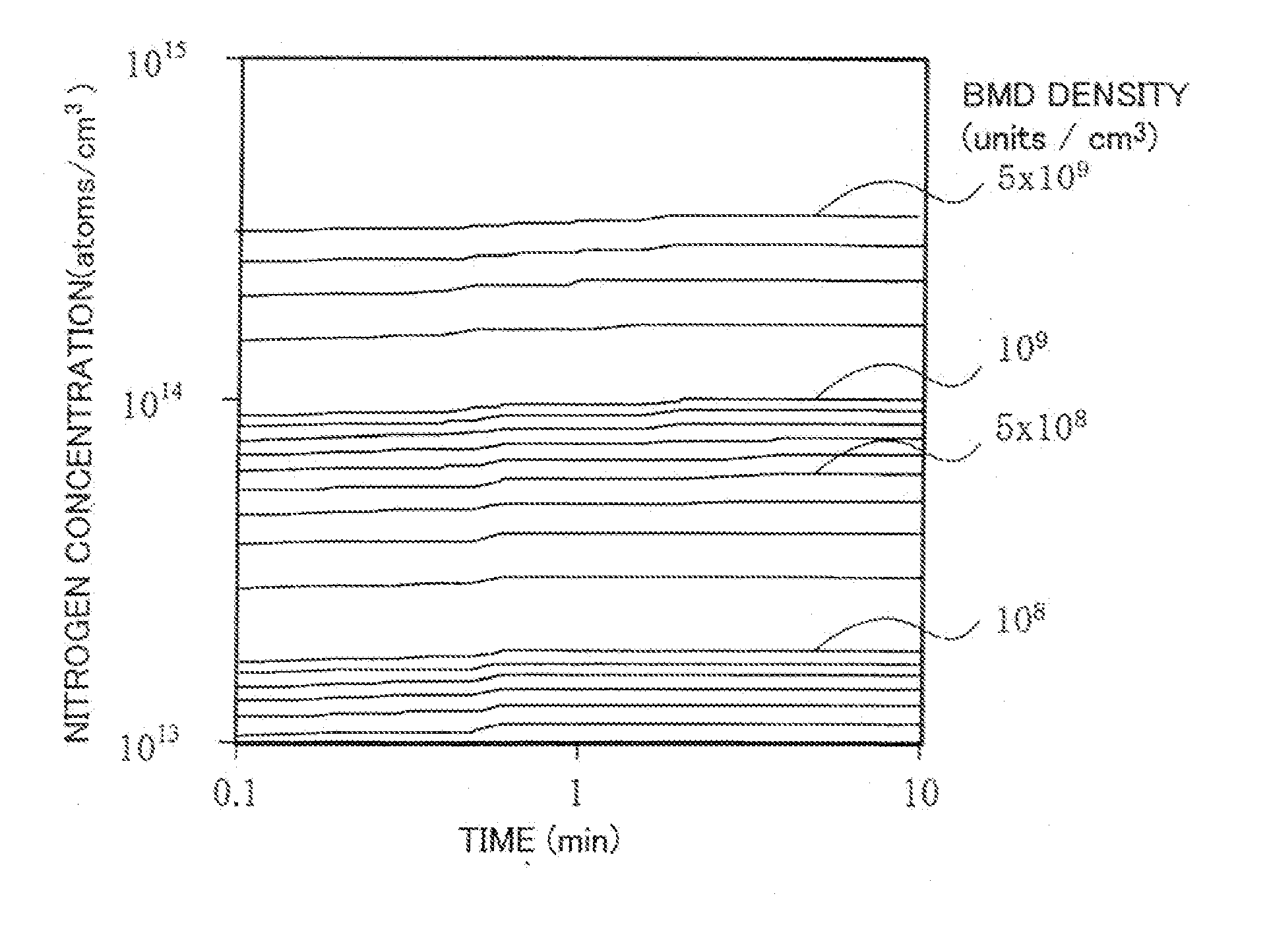

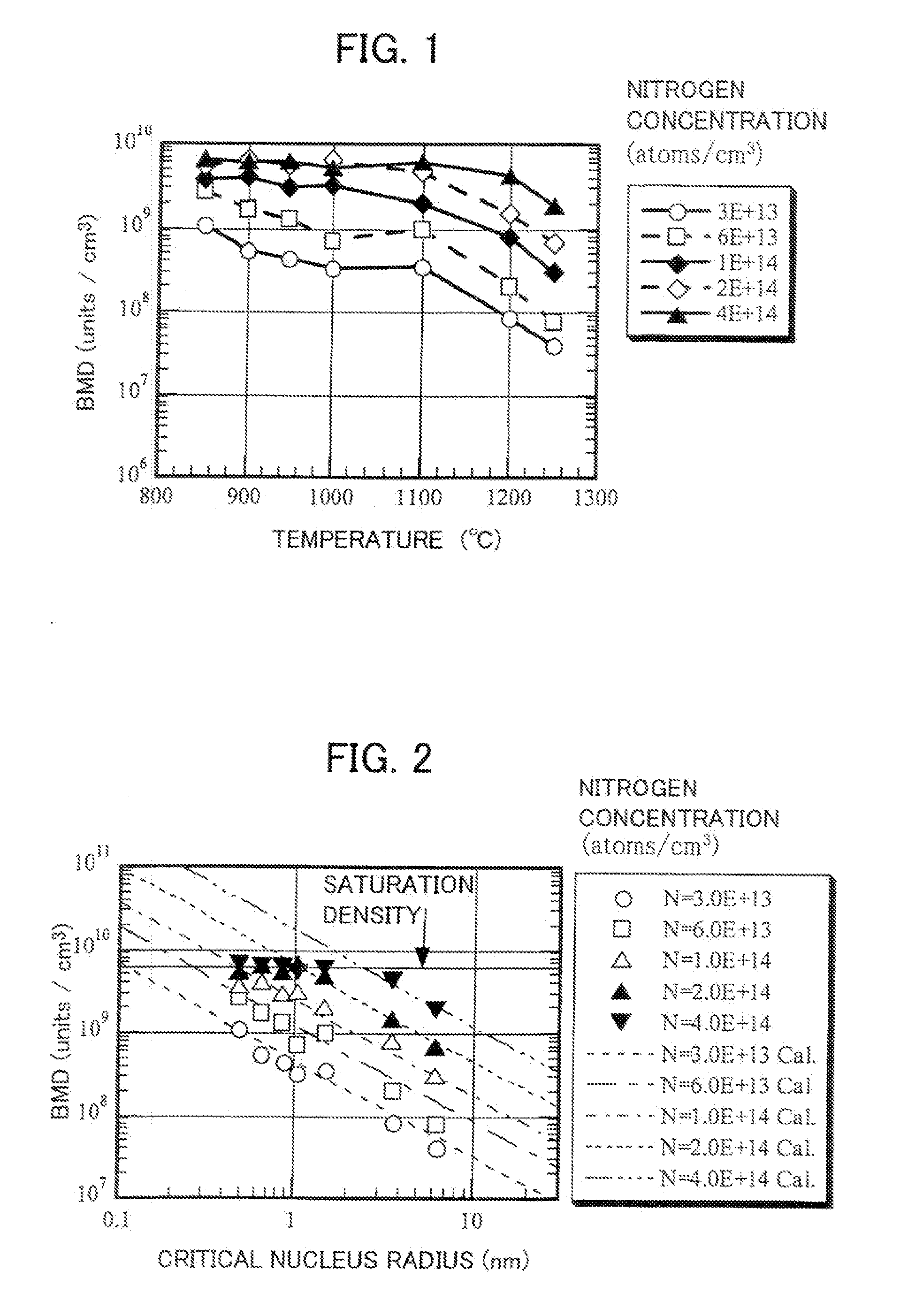

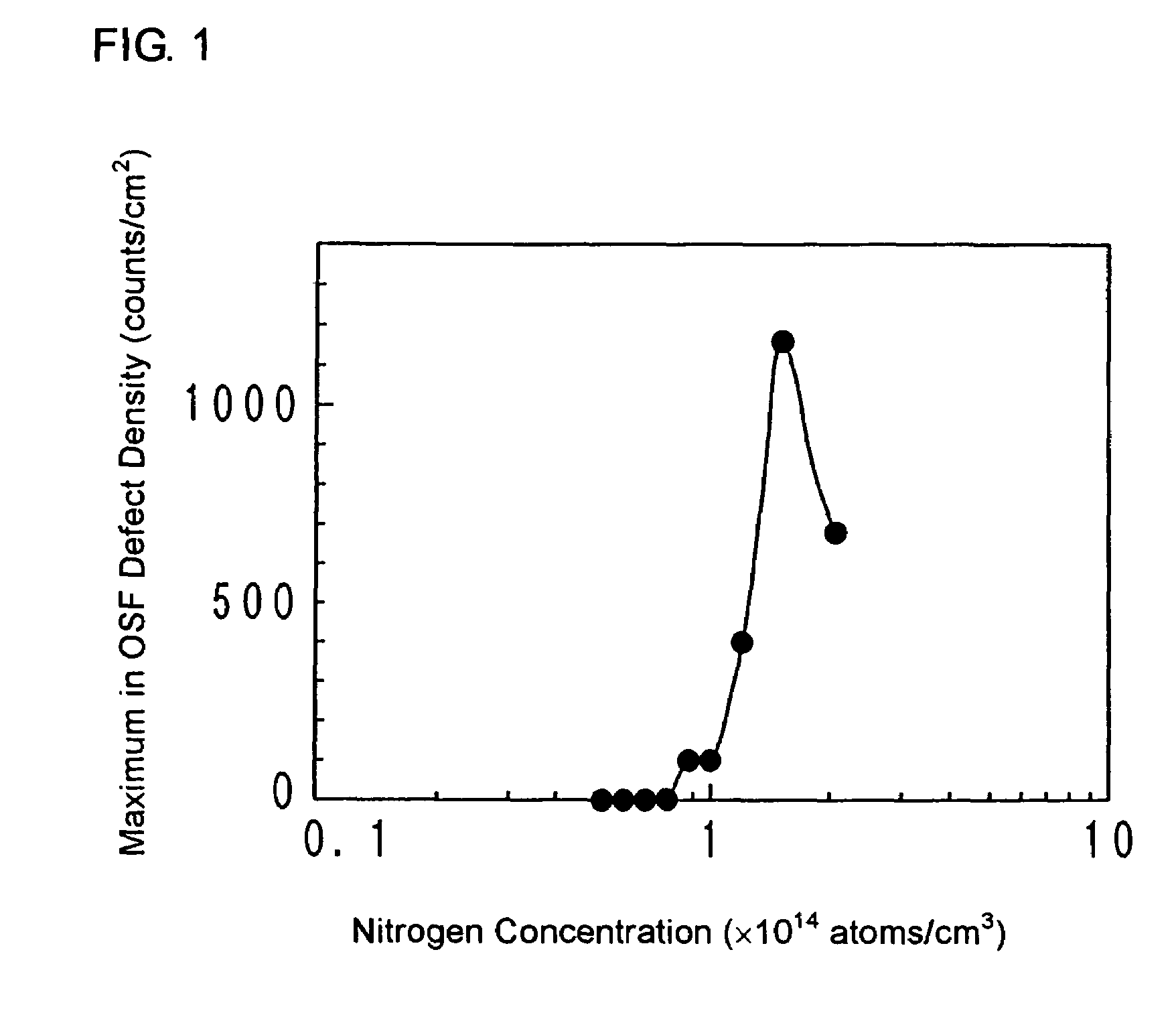

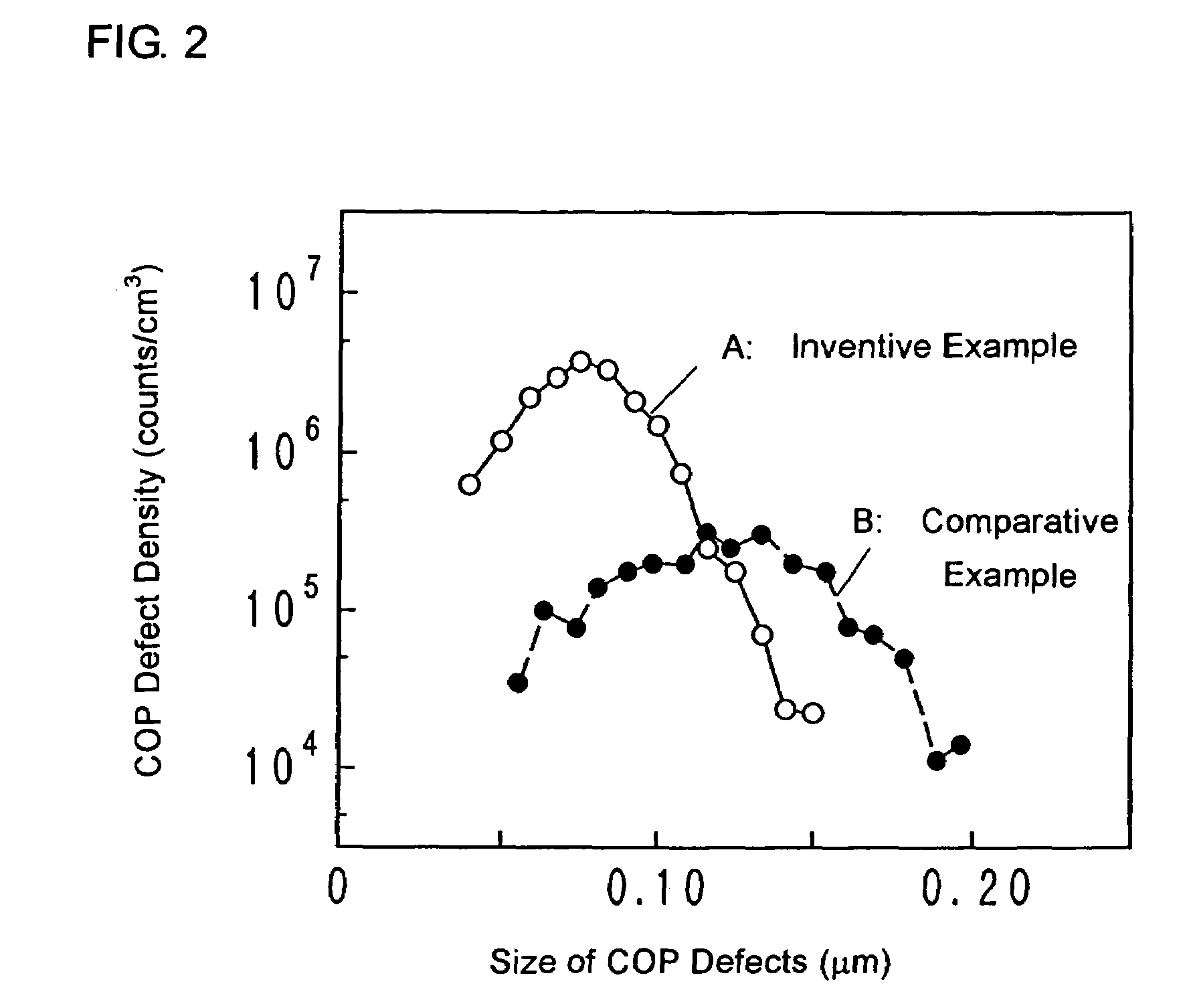

ActiveUS20070218570A1Sufficient gettering capabilityEasy selectionPolycrystalline material growthSemiconductor/solid-state device testing/measurementOxygen precipitatesNitrogen

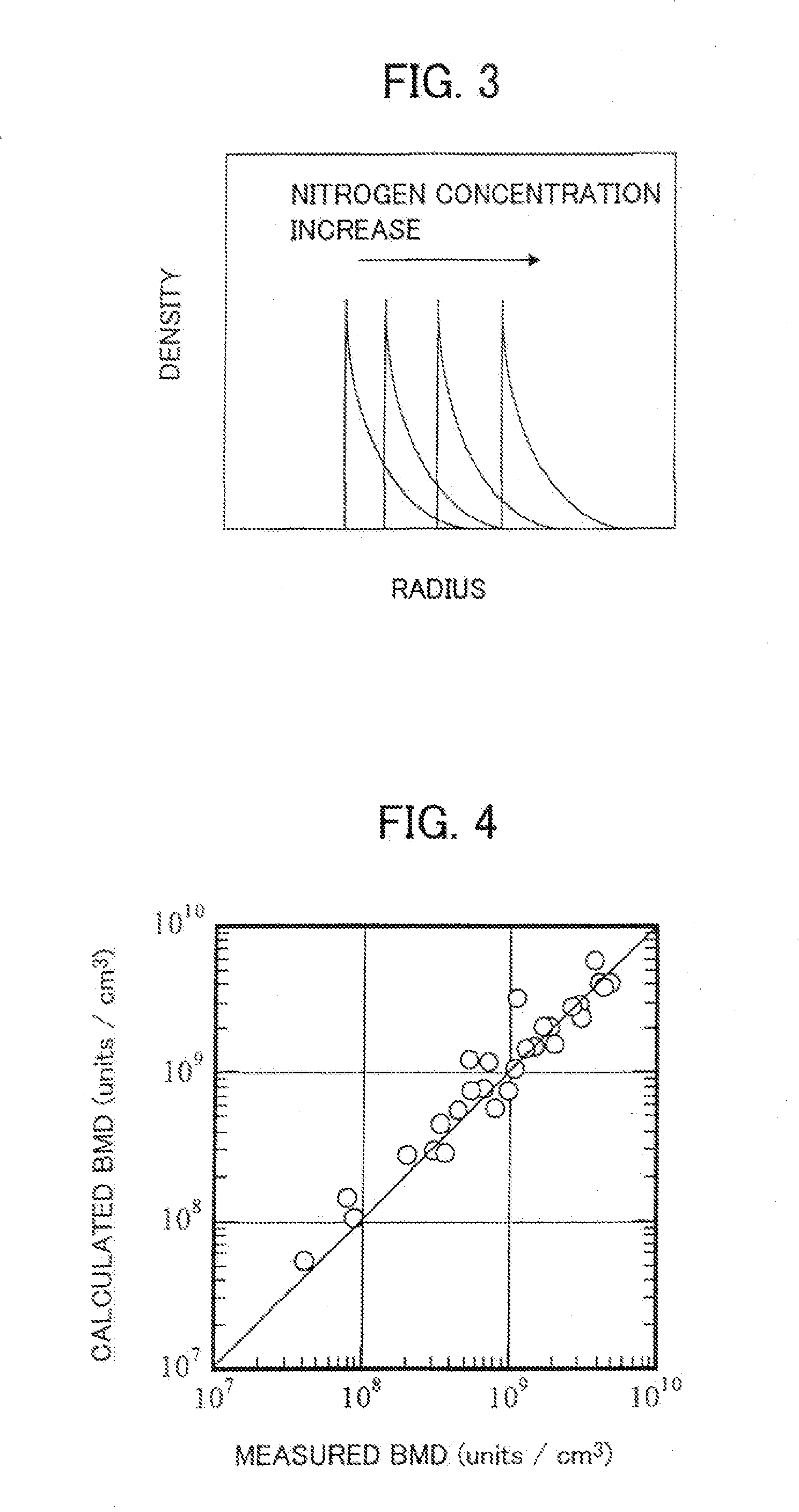

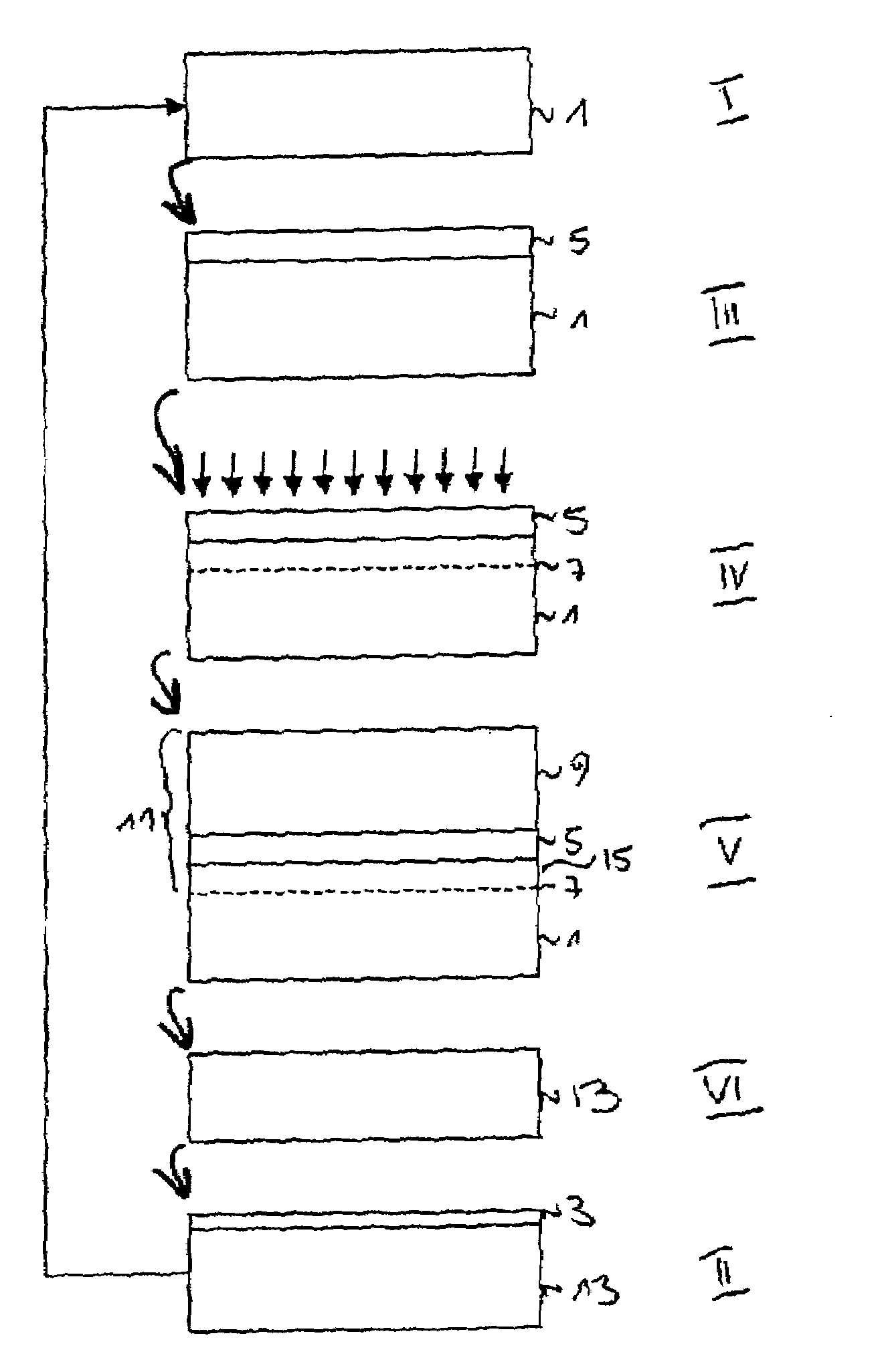

An epitaxial wafer and a high-temperature heat treatment wafer having an excellent gettering capability are obtained by performing epitaxial growth or a high-temperature heat treatment. A relational equation relating the density to the radius of an oxygen precipitate introduced in a silicon crystal doped with nitrogen at the time of crystal growth can be derived from the nitrogen concentration and the cooling rate around 1100° C. during crystal growth, and the oxygen precipitate density to be obtained after a heat treatment can be predicted from the derived relational equation relating the oxygen precipitate density to the radius, the oxygen concentration, and the wafer heat treatment process. Also, an epitaxially grown wafer and a high-temperature annealed wafer whose oxygen precipitate density has been controlled to an appropriate density are obtained, using conditions predicted by the method.

Owner:SUMCO TECHXIV

Methods for manufacturing compound-material wafers and for recycling used donor substrates

ActiveUS20070216042A1Quality improvementLow costSolid-state devicesSemiconductor/solid-state device manufacturingOxygen precipitatesThermal treatment

This invention provides methods for manufacturing compound-material wafers and methods for recycling donor substrates that results from manufacturing compound-material wafers. The provided methods includes at least one further thermal treatment step configured to at least partially reduce oxygen precipitates and / or nuclei. Reduction of oxygen precipitates and / or nuclei, improves the recycling rate of the donor substrate.

Owner:SOITEC SA

High resistance silicon wafer and its manufacturing method

ActiveUS7397110B2Reduction in strengthPromote formationSemiconductor/solid-state device manufacturingSemiconductor devicesHigh resistanceHigh density

A high-resistance silicon wafer is manufactured in which a gettering ability, mechanical strength, and economical efficiency are excellent and an oxygen thermal donor is effectively prevented from being generated in a heat treatment for forming a circuit, which is implemented on the side of a device maker. A heat treatment for forming an oxygen precipitate nucleus is performed at 500 to 900° C. for 5 hours or more in a non-oxidizing atmosphere and a heat treatment for growing an oxygen precipitate is performed at 950 to 1050° C. for 10 hours or more on a high-oxygen and carbon-doped high-resistance silicon wafer in which resistivity is 100 Ωcm or more, an oxygen concentration is 14×1017 atoms / cm3 (ASTM F-121, 1979) or more and a carbon concentration is 0.5×1016 atoms / cm3 or more. By these heat treatments, a remaining oxygen concentration in the wafer is controlled to be 12×1017 atoms / cm3 (ASTM F-121, 1979) or less. Thus, there is provided a high-resistance, low-oxygen and high-strength silicon wafer in which resistivity is 100 Ωcm or more and an oxygen precipitate (BMD) having a size of 0.2 μm is formed so as to have high density of 1×104 / cm2 or more.

Owner:SUMITOMO MITSUBISHI SILICON CORP

Process for making silicon wafers with stabilized oxygen precipitate nucleation centers

A process for imparting controlled oxygen precipitation behavior to a single crystal silicon wafer. Specifically, prior to formation of the oxygen precipitates, the wafer bulk comprises dopant stabilized oxygen precipitate nucleation centers. The dopant is selected from a group consisting of nitrogen and carbon, and the concentration of the dopant is sufficient to allow the oxygen precipitate nucleation centers to withstand thermal processing, such as an epitaxial deposition process, while maintaining the ability to dissolve any grown-in nucleation centers.

Owner:SUNEDISON SEMICON LIMITED UEN201334164H

Arsenic and phosphorus doped silicon wafer substrates having intrinsic gettering

ActiveUS7485928B2Improve uniformityLow resistivityPolycrystalline material growthAfter-treatment detailsWaferingPhysical chemistry

Owner:GLOBALWAFERS CO LTD

Arsenic and phosphorus doped silicon wafer substrates having intrinsic gettering

ActiveUS20070105279A1Great wafer-to-wafer uniformityLow resistivityPolycrystalline material growthAfter-treatment detailsManufacturing technologyOxygen precipitates

Owner:GLOBALWAFERS CO LTD

Method for manufacturing silicon wafer method

ActiveUS7700394B2High strengthHeating fastPolycrystalline material growthAfter-treatment detailsFokker–Planck equationHigh intensity

Owner:SUMCO CORP

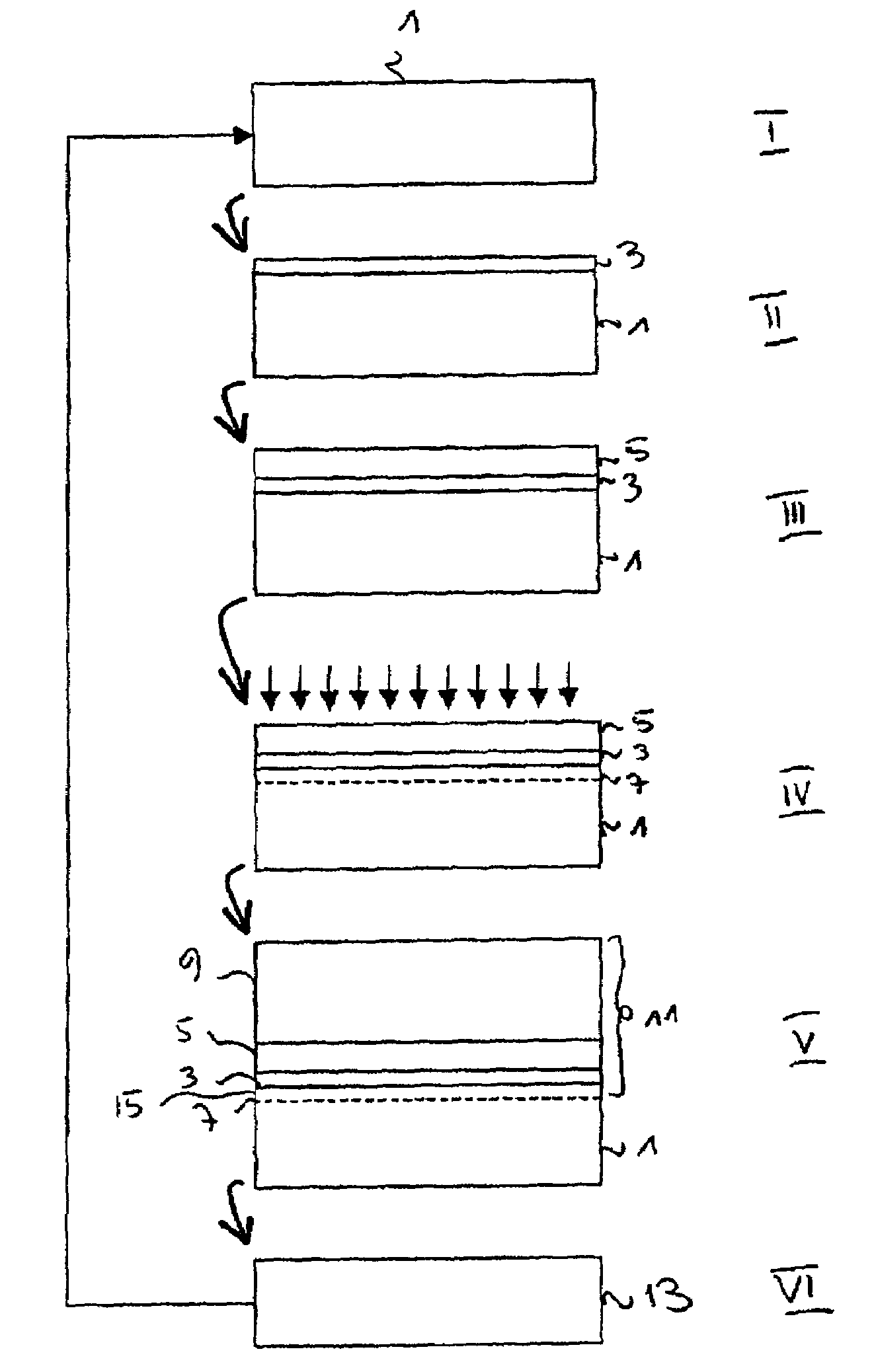

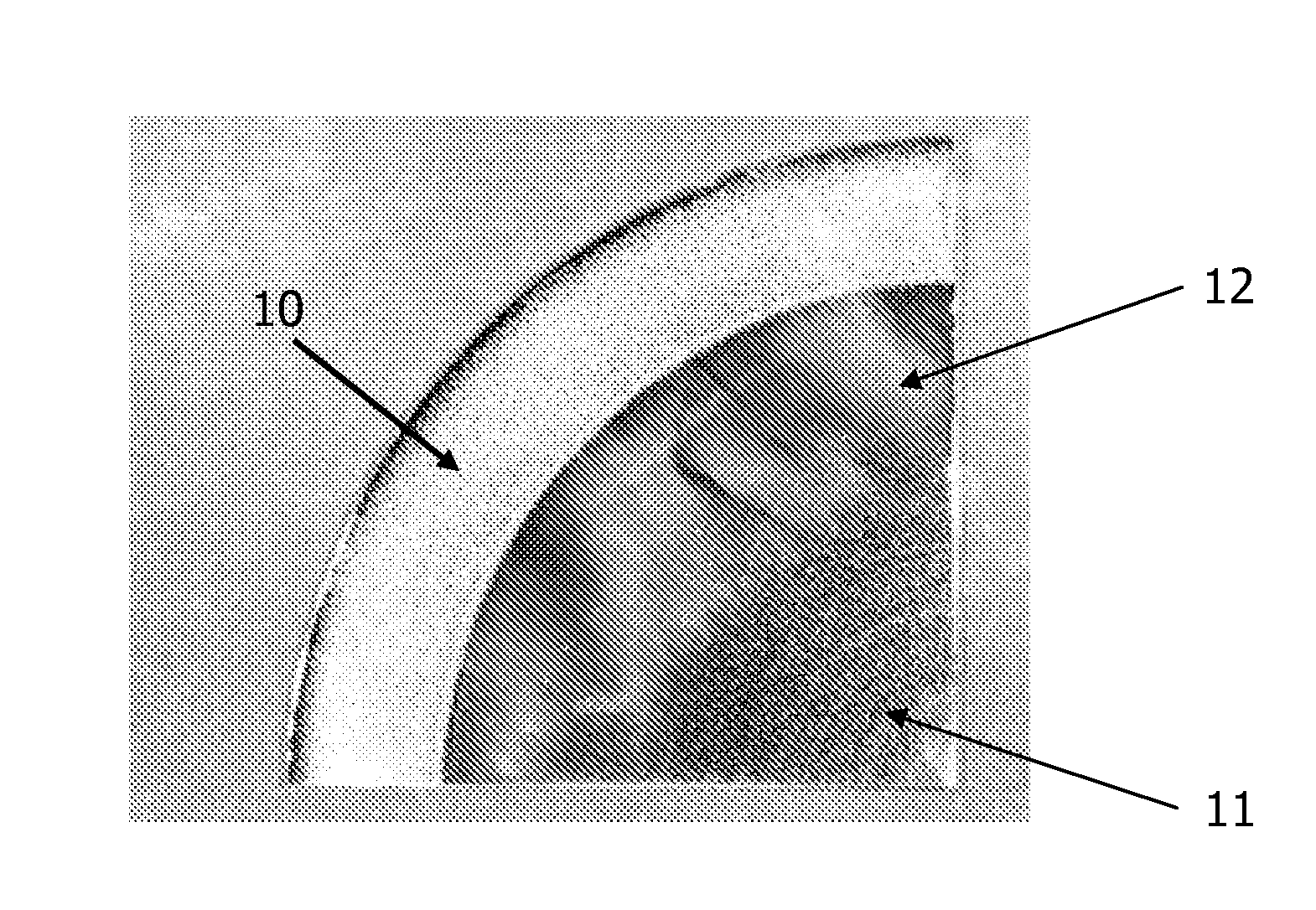

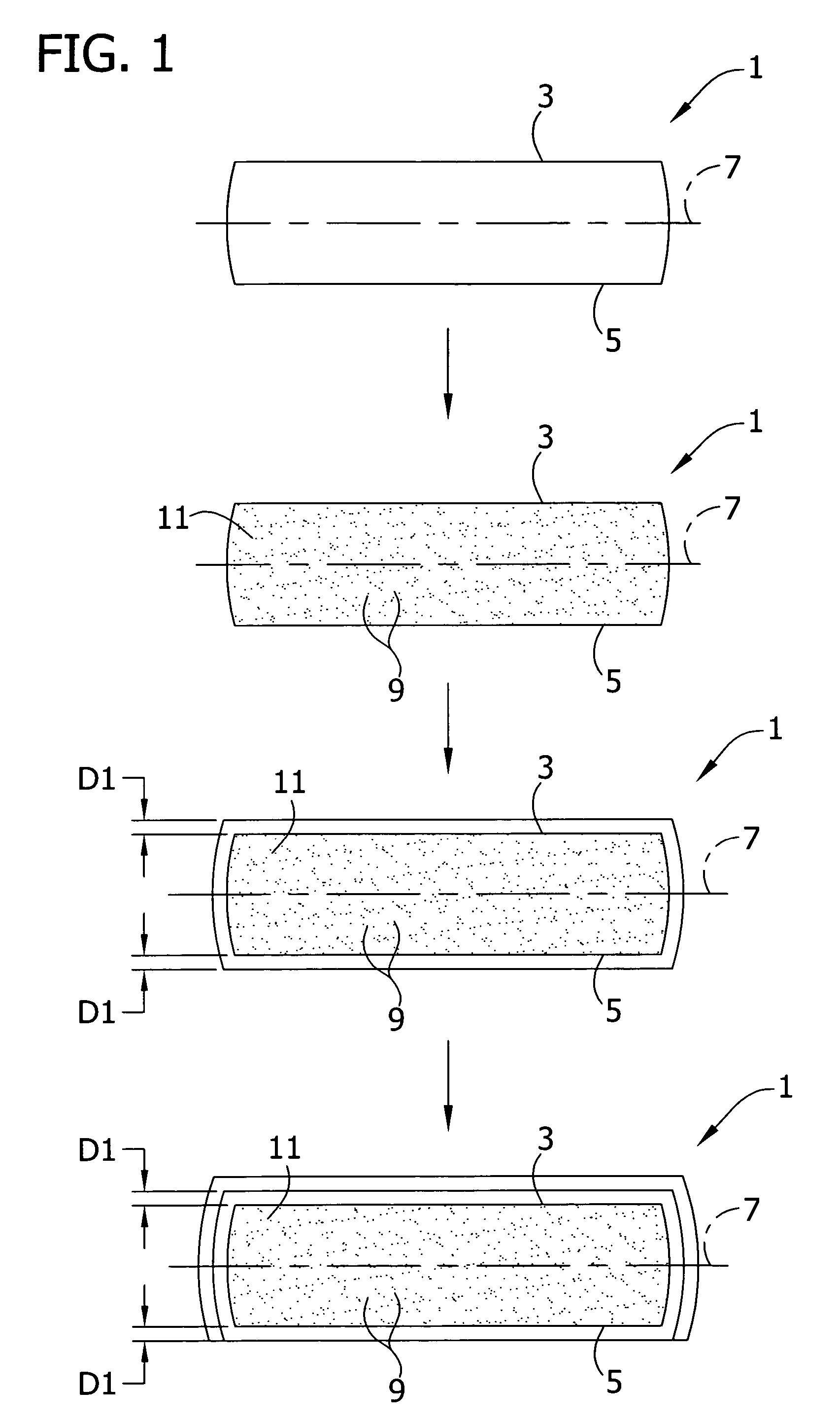

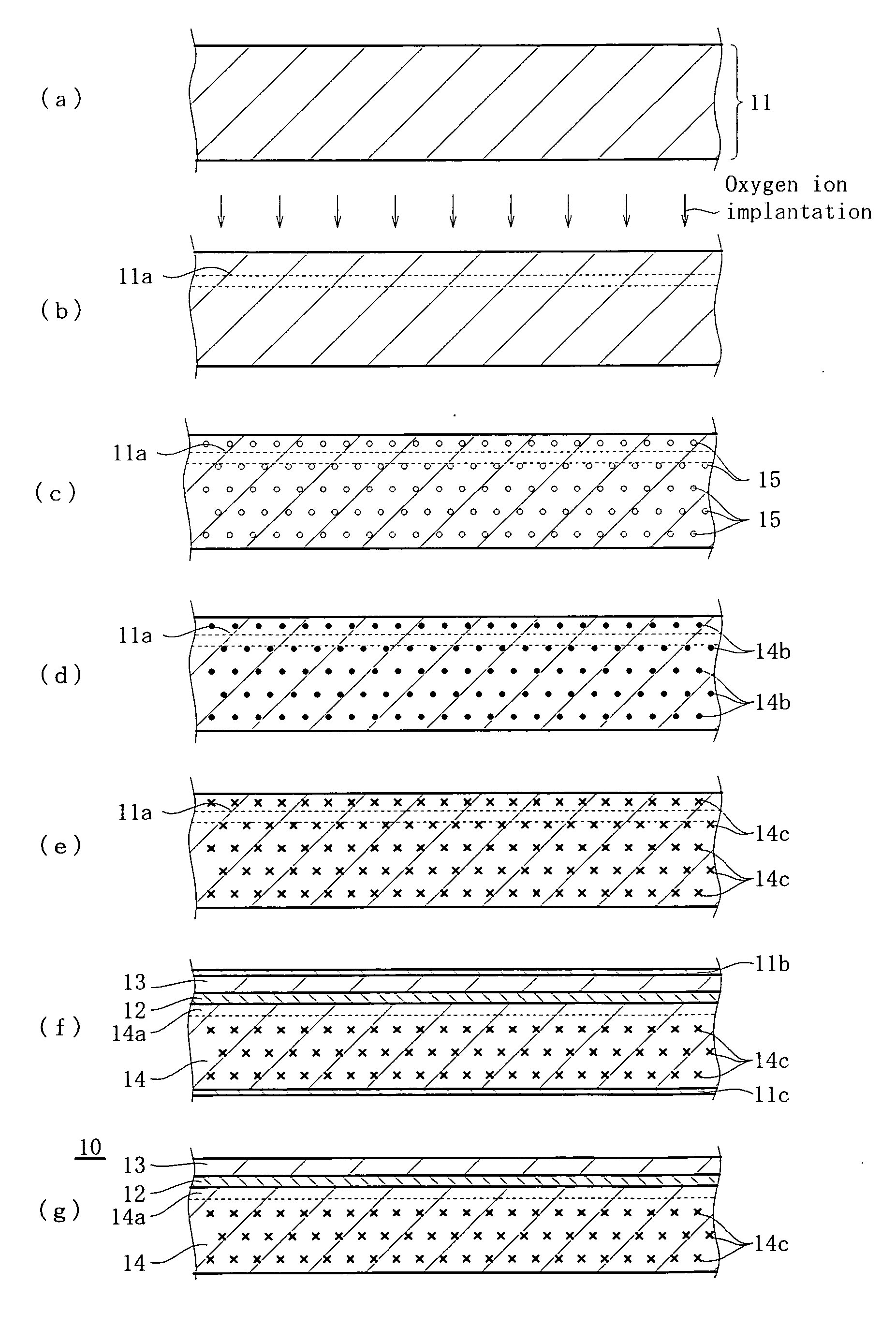

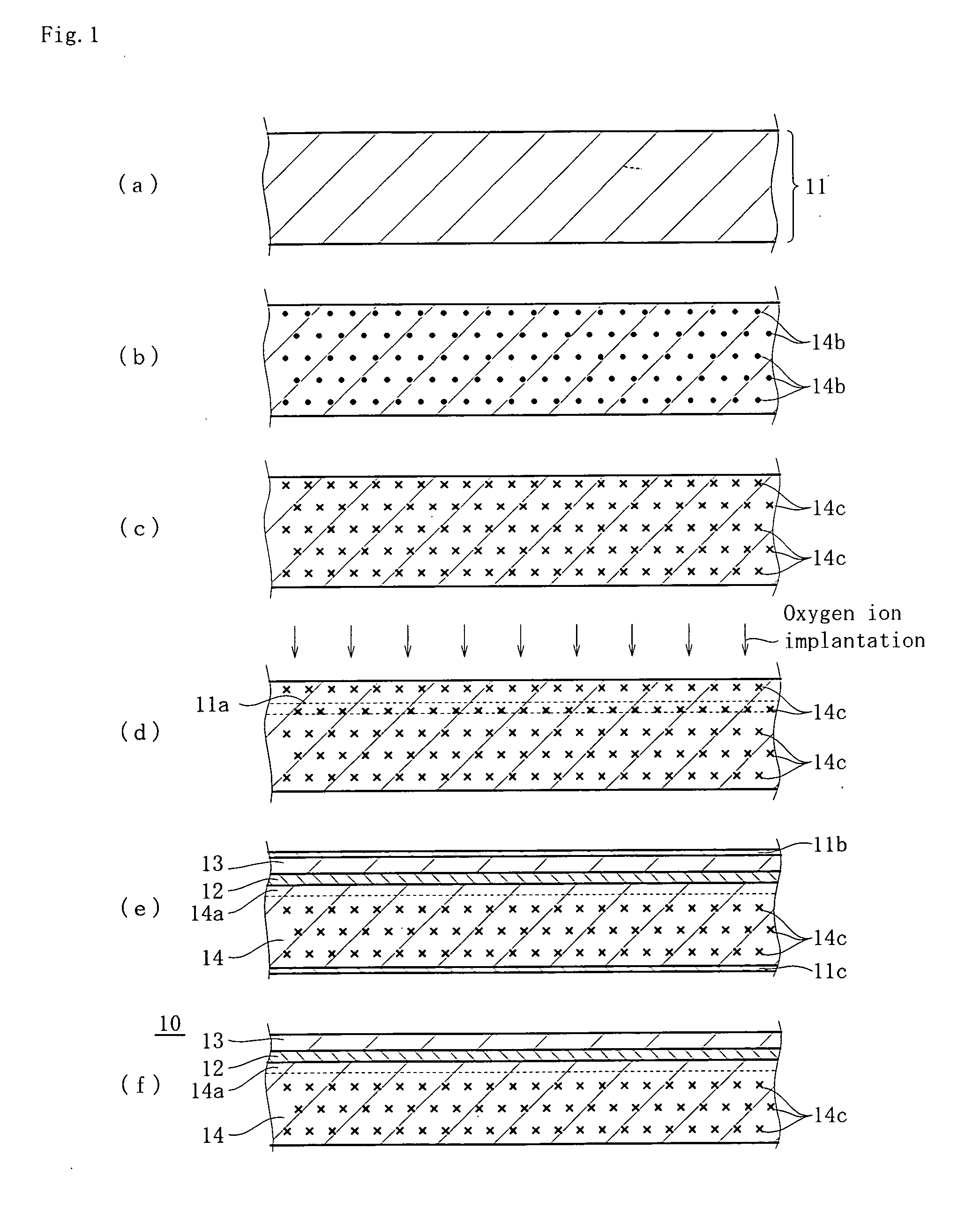

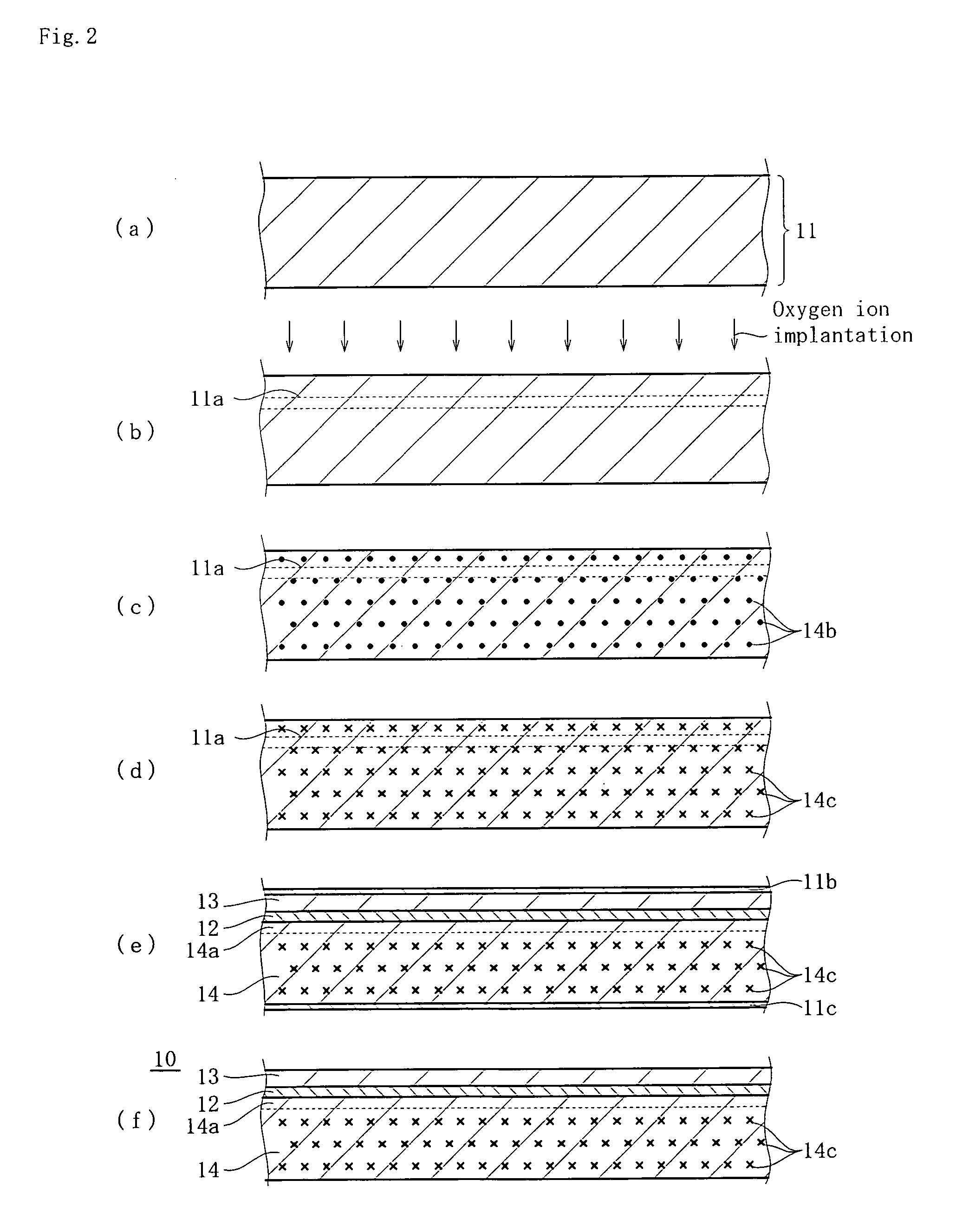

Method for Manufacturing Simox Substrate and Simox Substrate Obtained by the Method

InactiveUS20080044669A1Efficient captureDecrease heavy-metal capturing concentrationSolid-state devicesVacuum evaporation coatingPresent methodOxygen ions

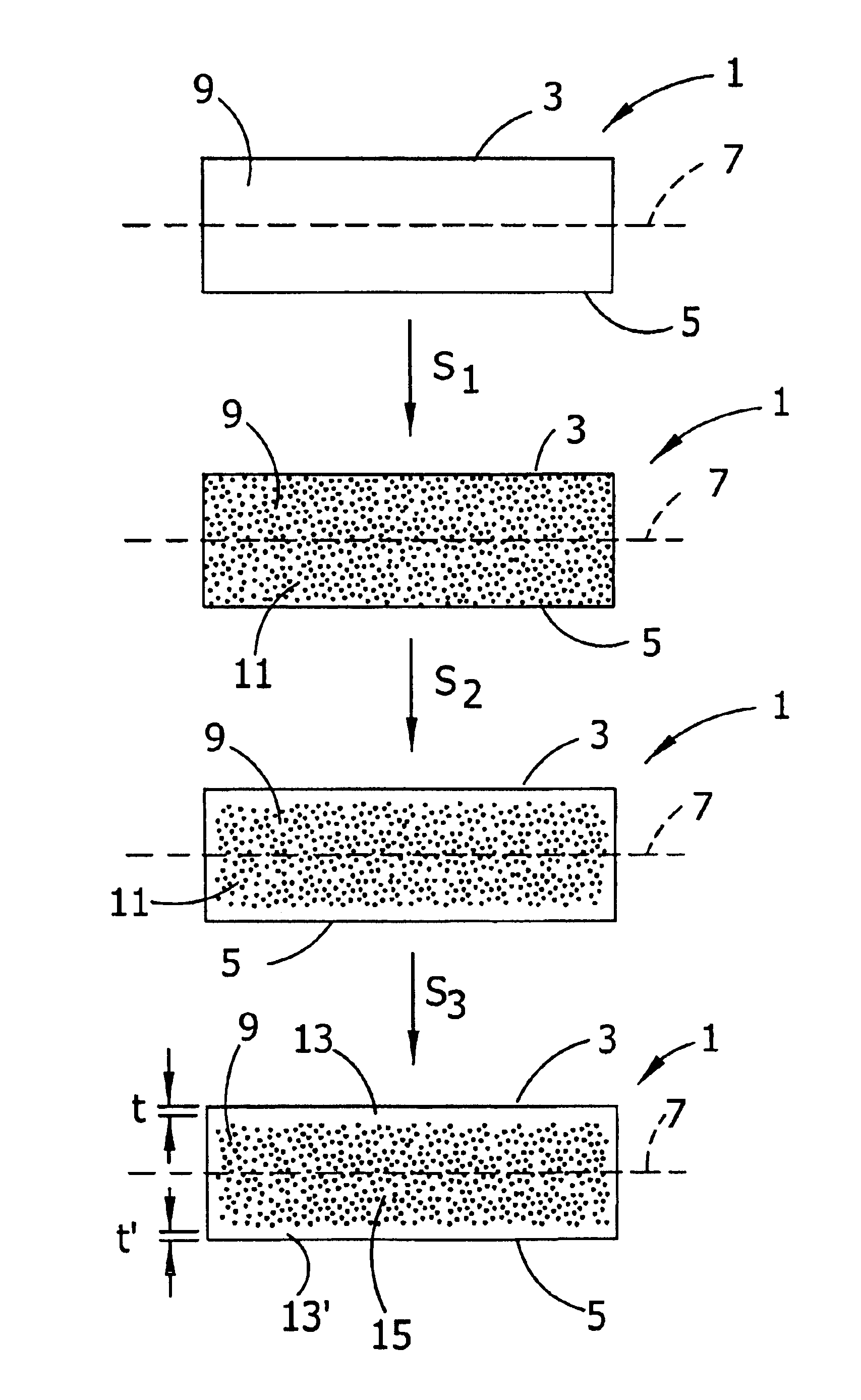

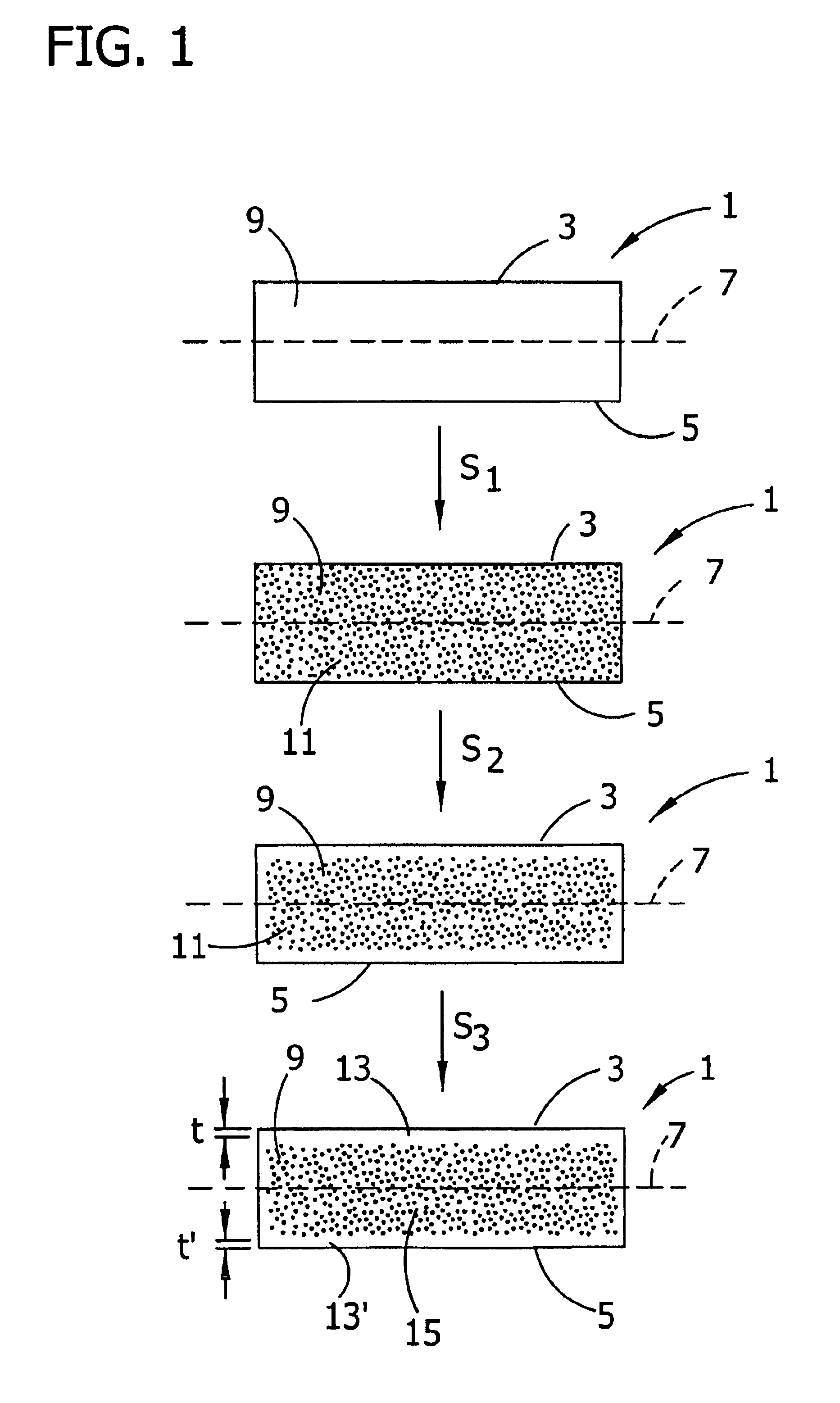

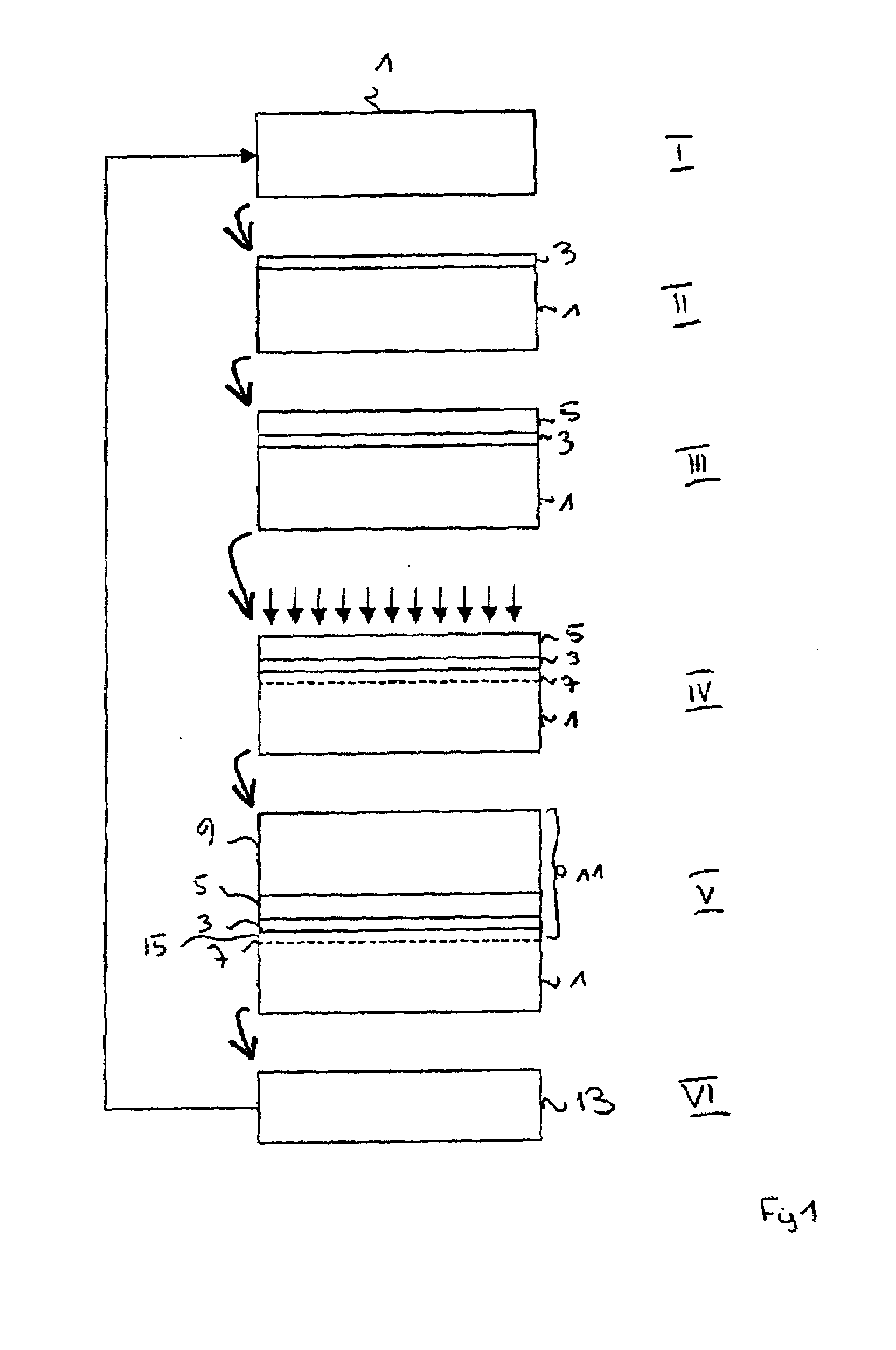

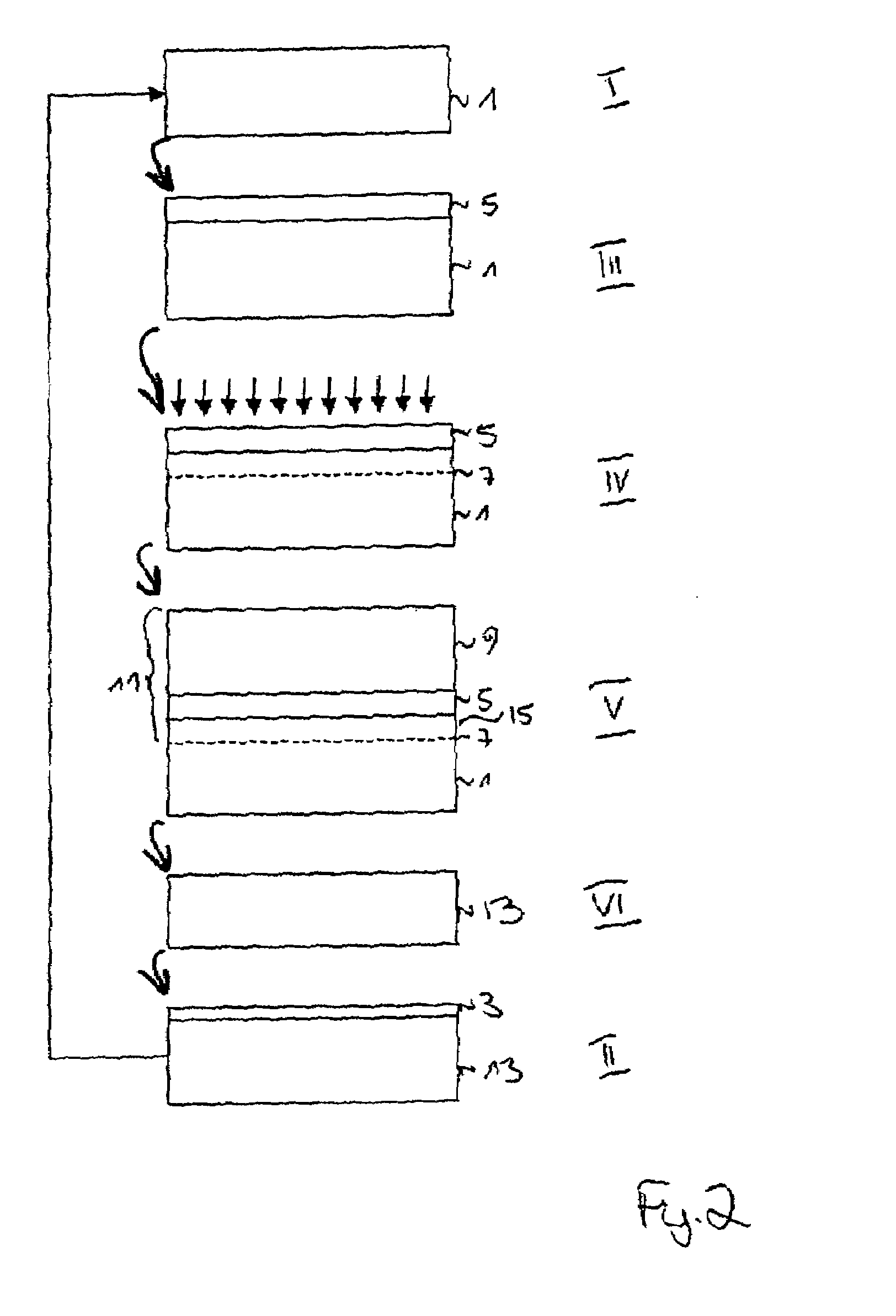

It is possible to efficiently capture heavy metal contamination due to ion implantation or high-temperature heat treatment in a bulk layer. It is characterized that the present method comprises: a step of implanting oxygen ions into a wafer 11; a step of applying first heat treatment to a wafer under a predetermined gas atmosphere at 1,300 to 1,390° C. and forming a buried oxide layer 12 and an SOI layer 13 by applying first heat treatment to a wafer at 1,300 to 1390° C.; a second heat treatment step in which a wafer before oxygen ions are implanted has an oxygen concentration of 9×1017 to 1.8×1018 atoms / cm3 (old ASTM) and a buried oxide layer is formed entirely or locally in the wafer to form oxygen precipitate nuclei 14b formed in the wafer before the oxygen ion implantation step or between the oxygen ion implantation step and the first heat treatment step; and a third heat treatment step of growing oxygen precipitate nuclei 14b formed in the wafer so as to be oxygen precipitates 14c.

Owner:SUMCO CORP

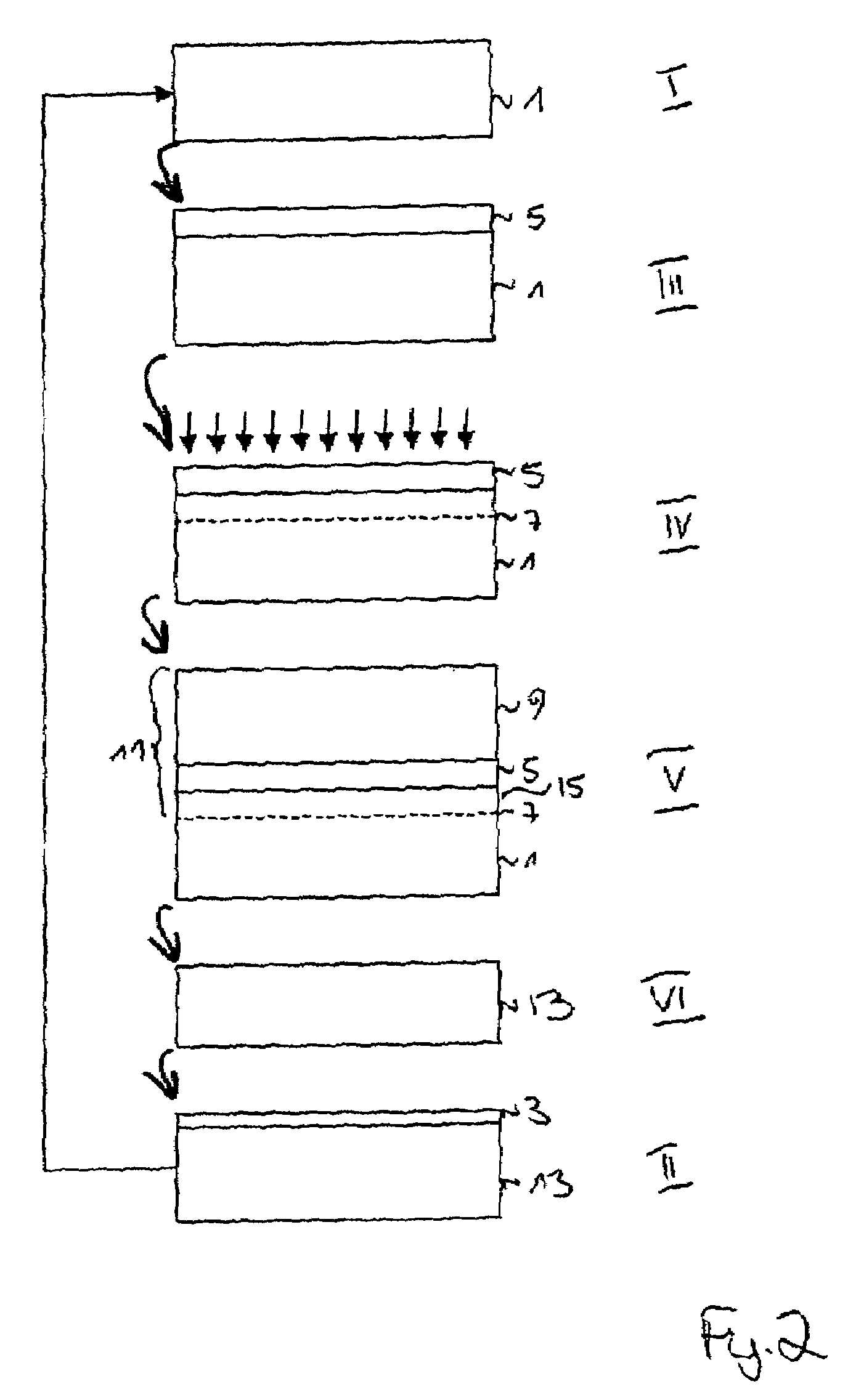

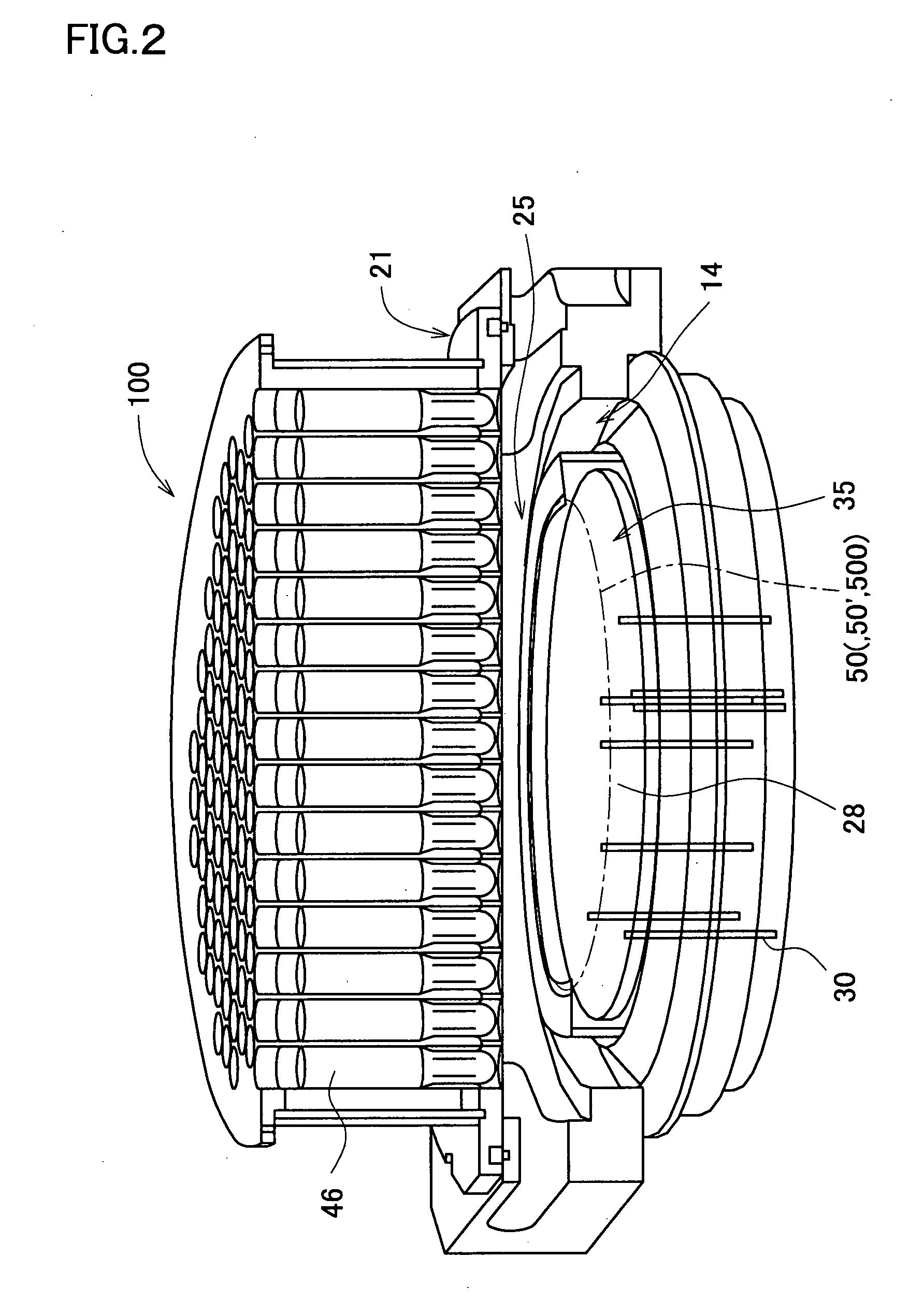

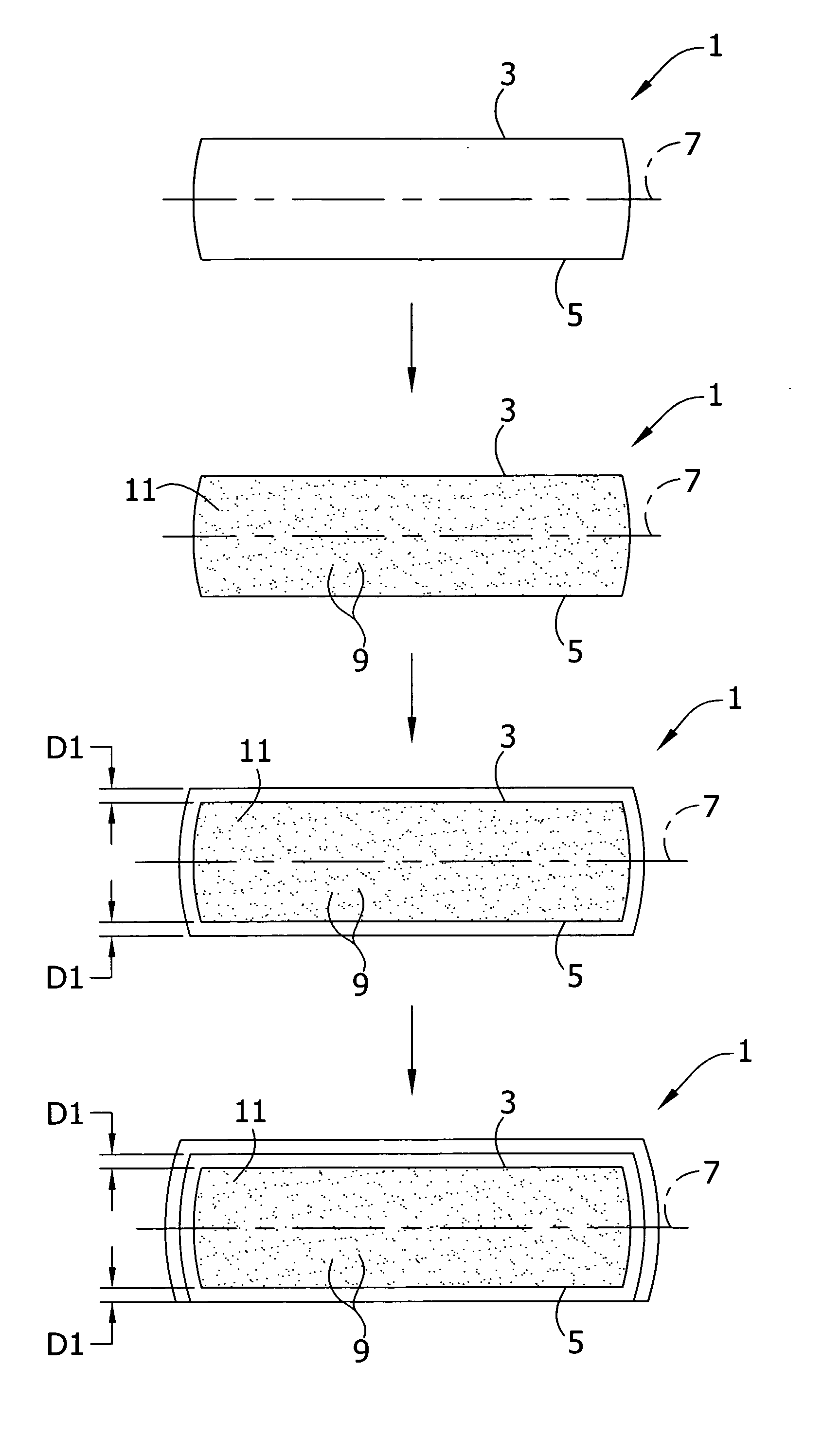

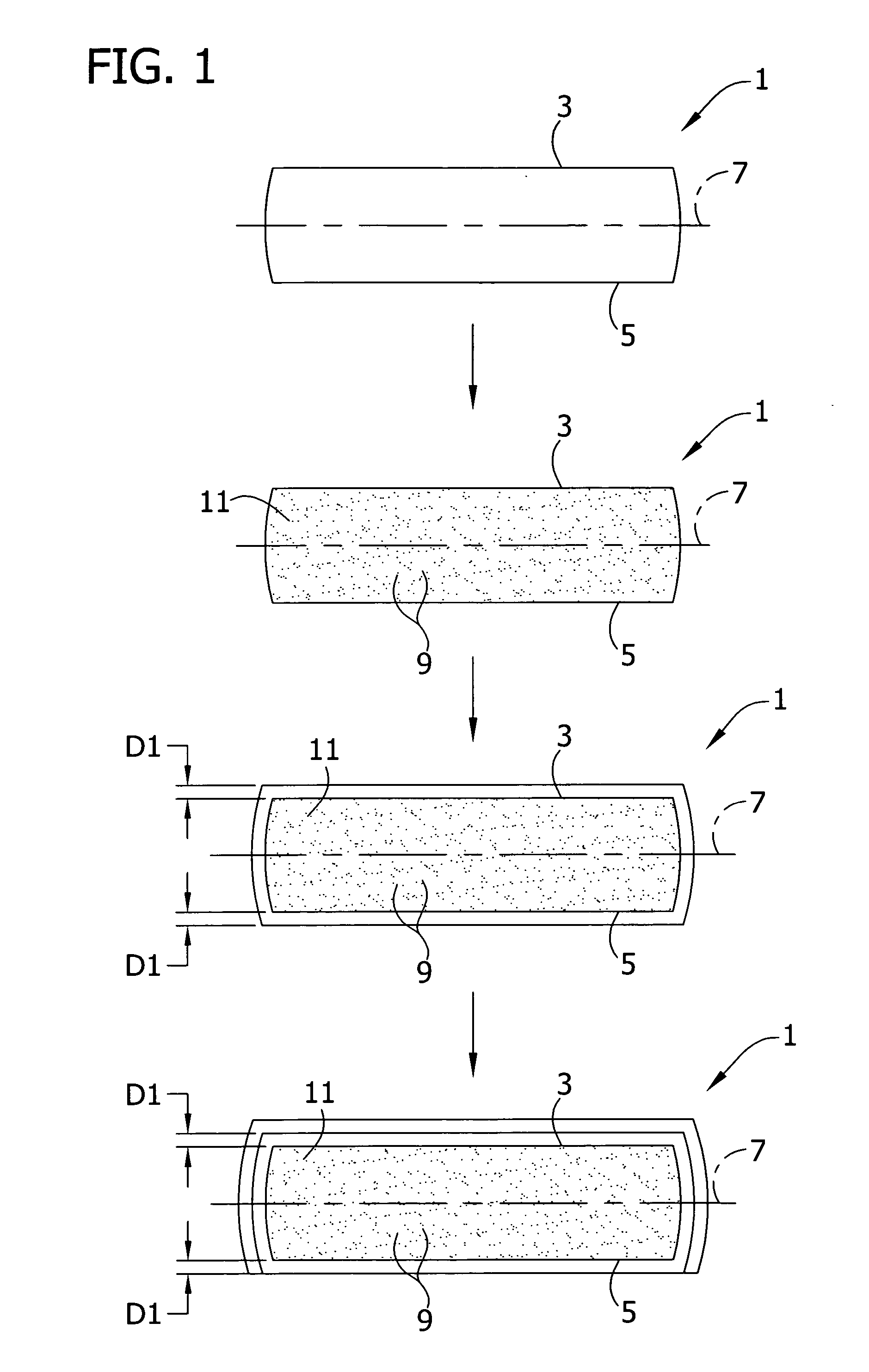

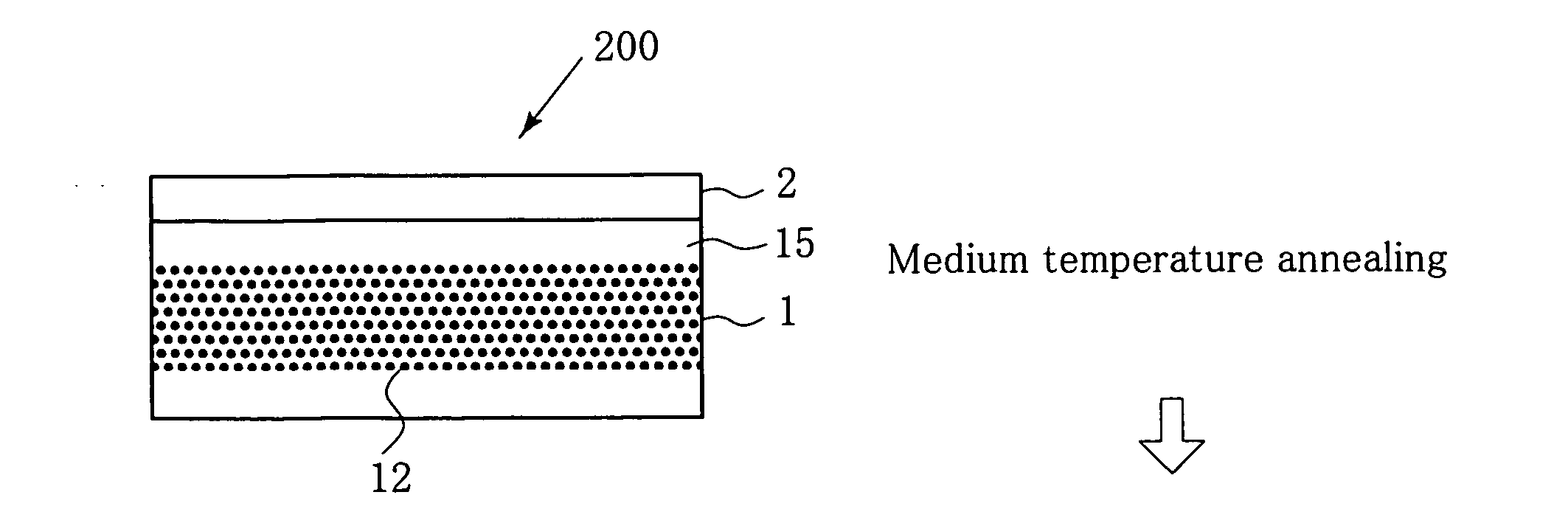

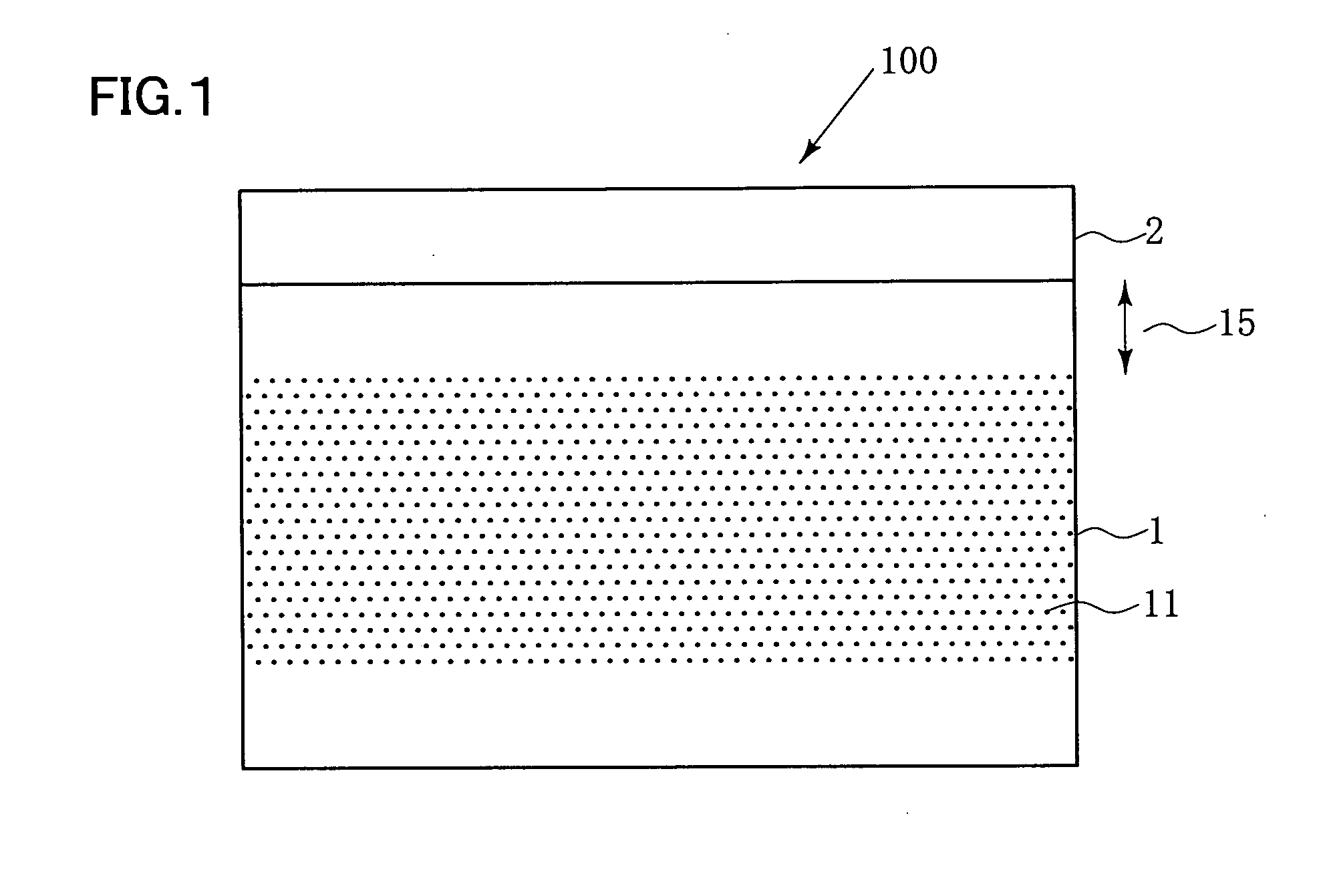

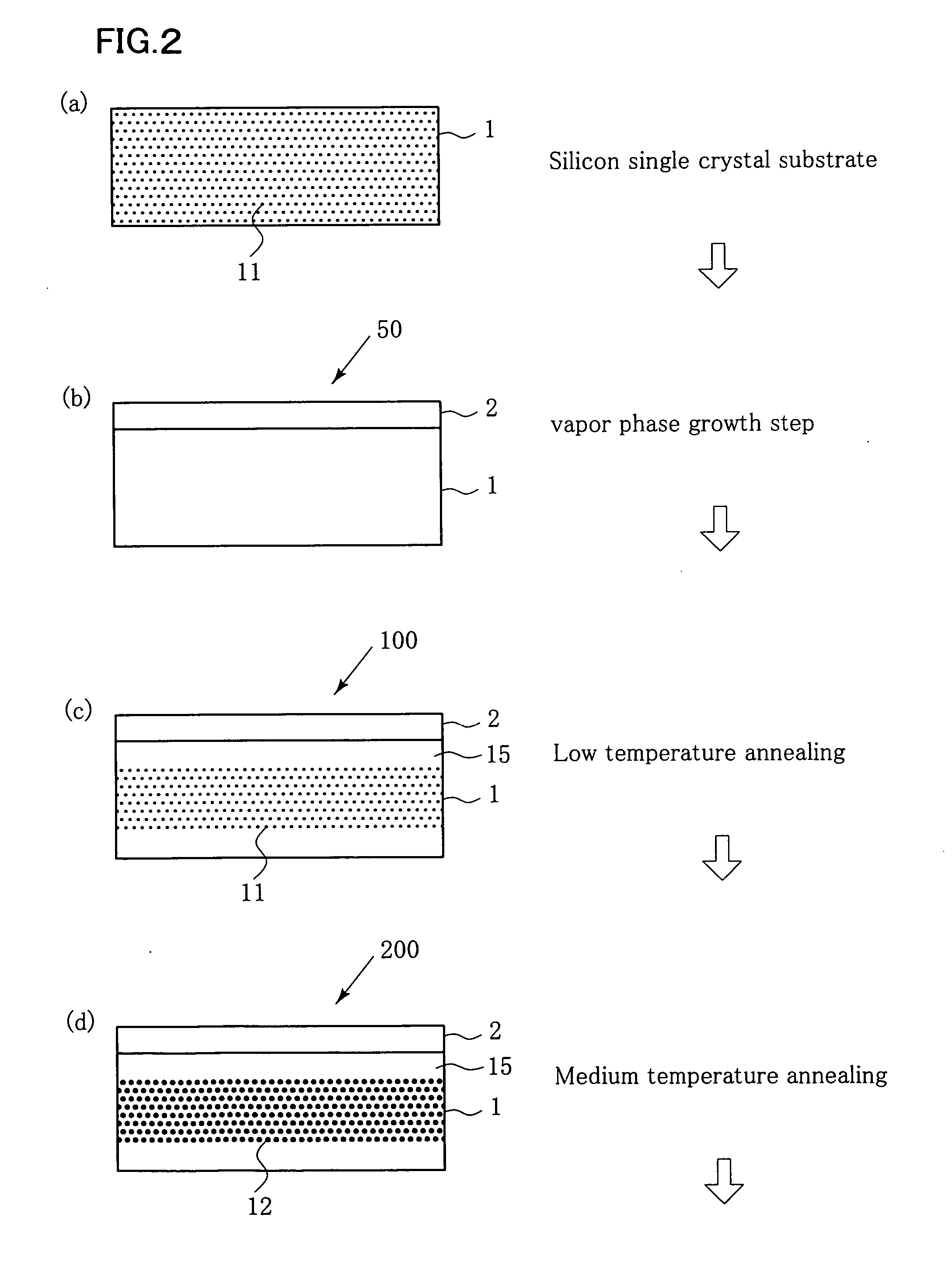

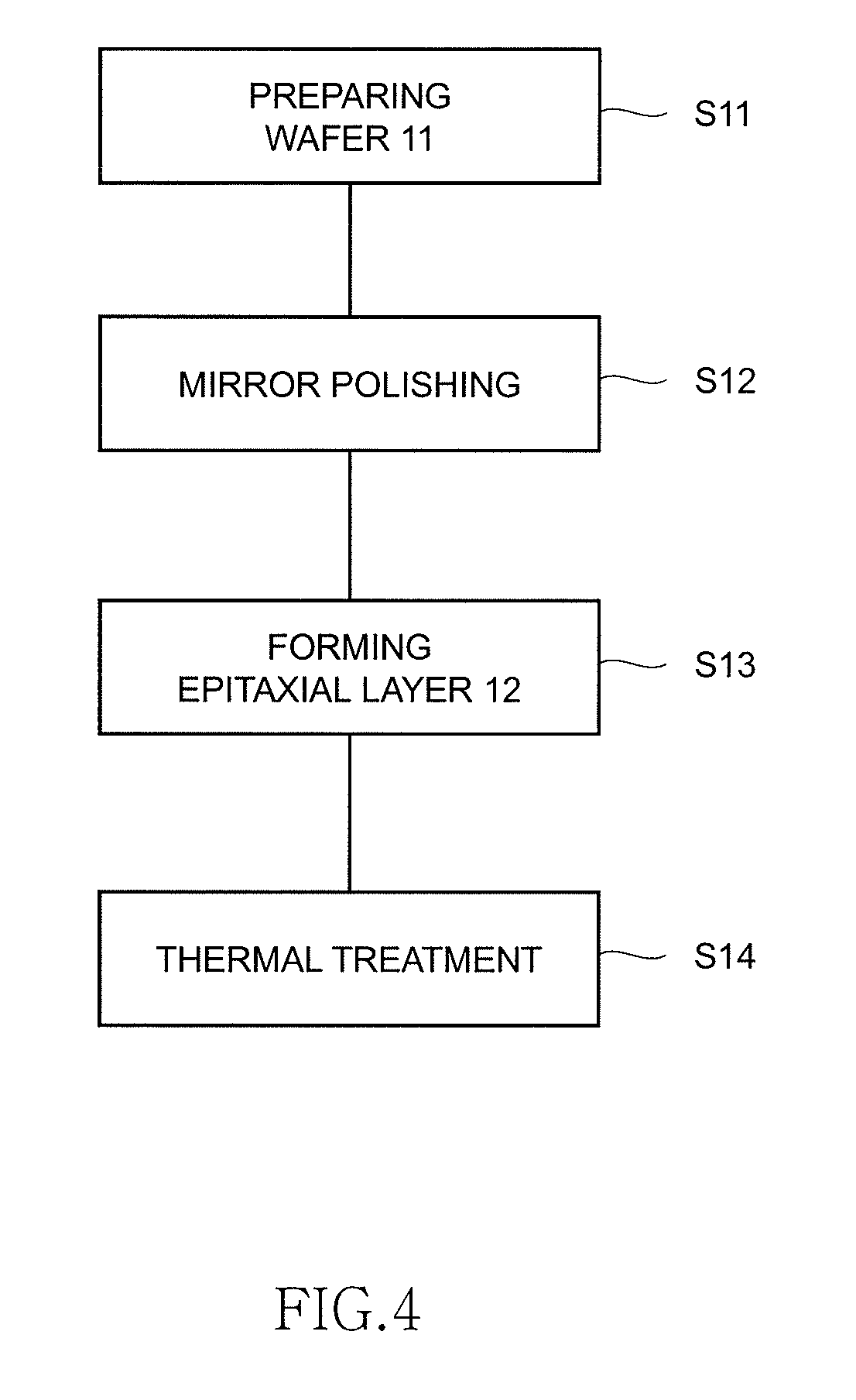

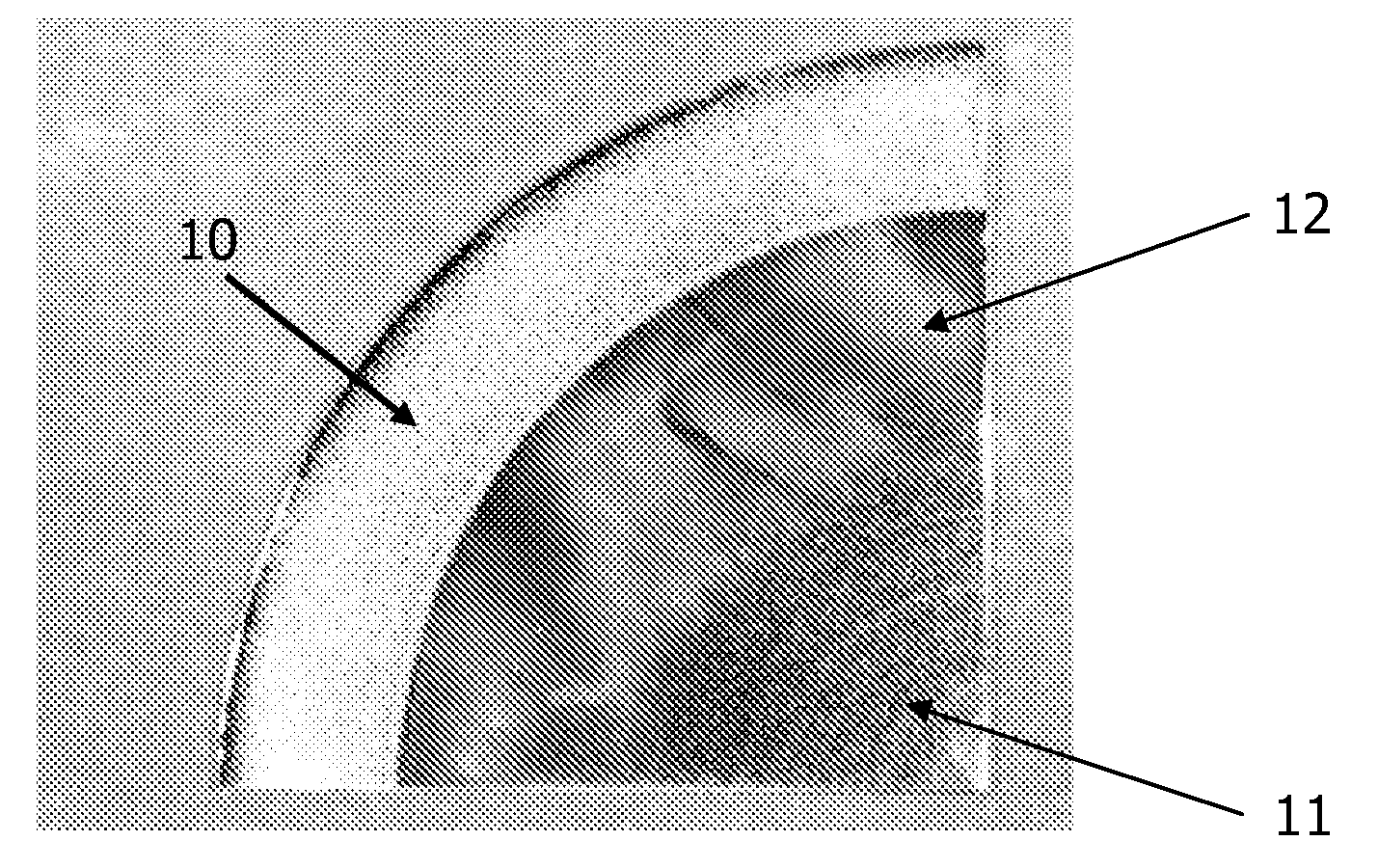

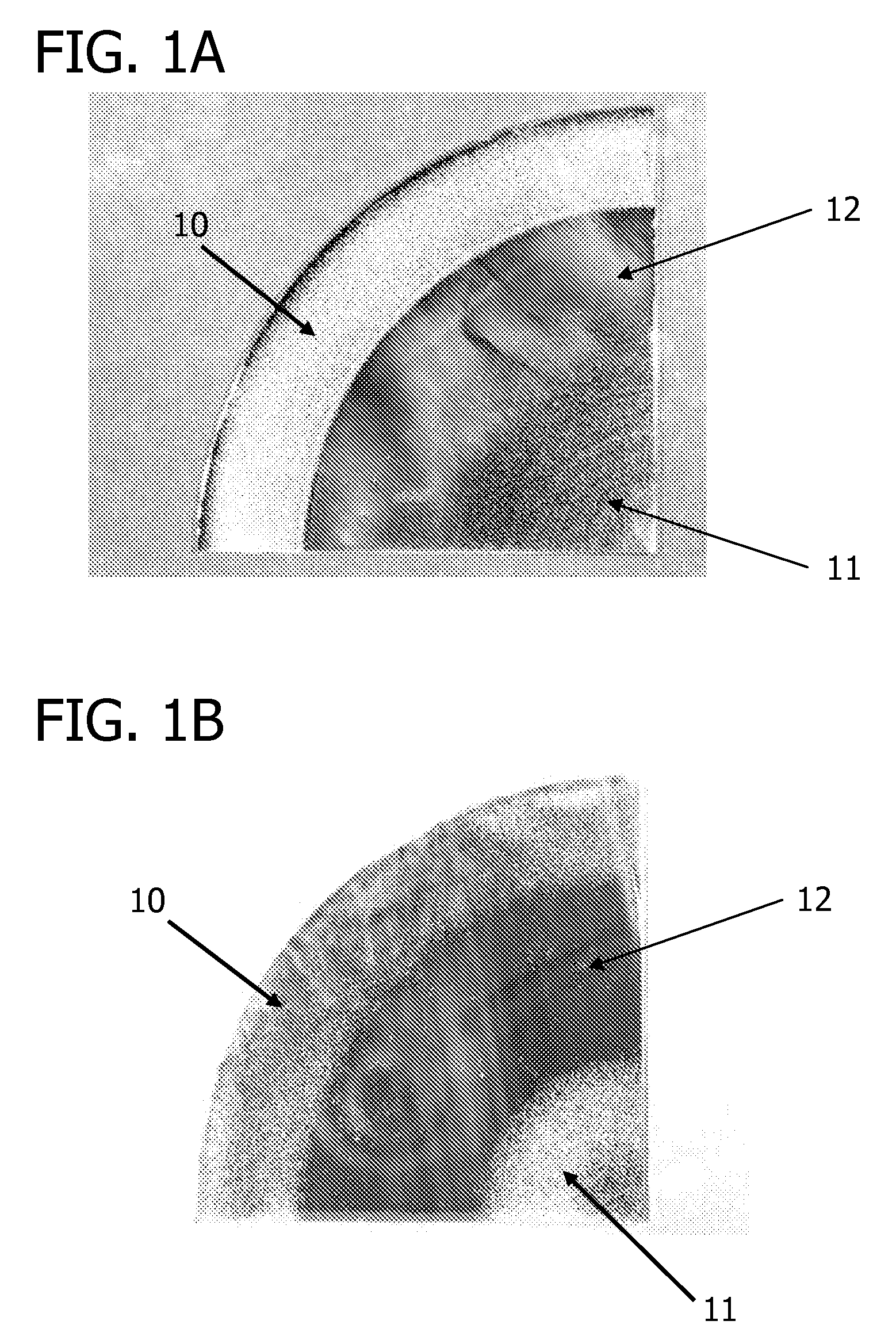

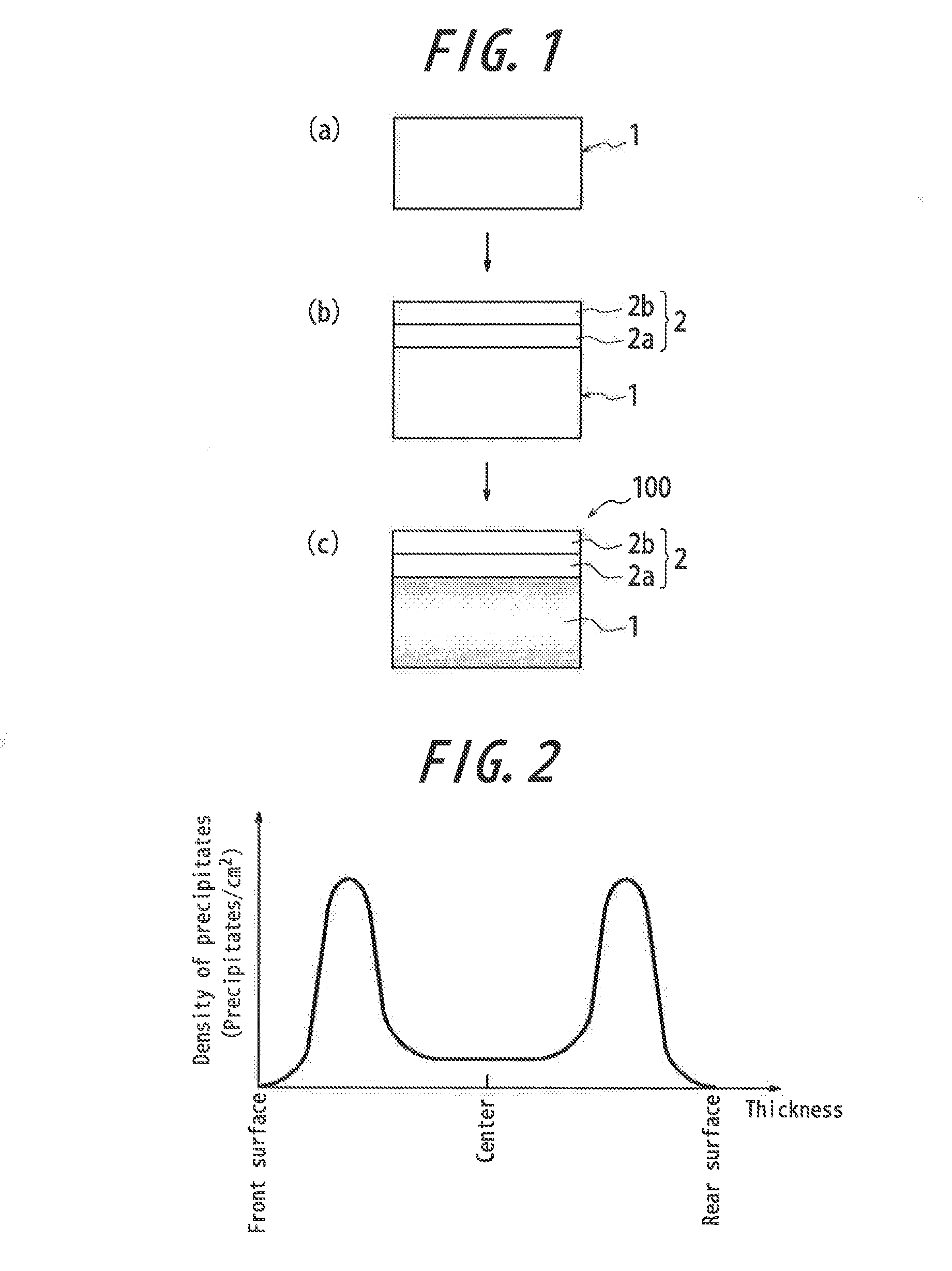

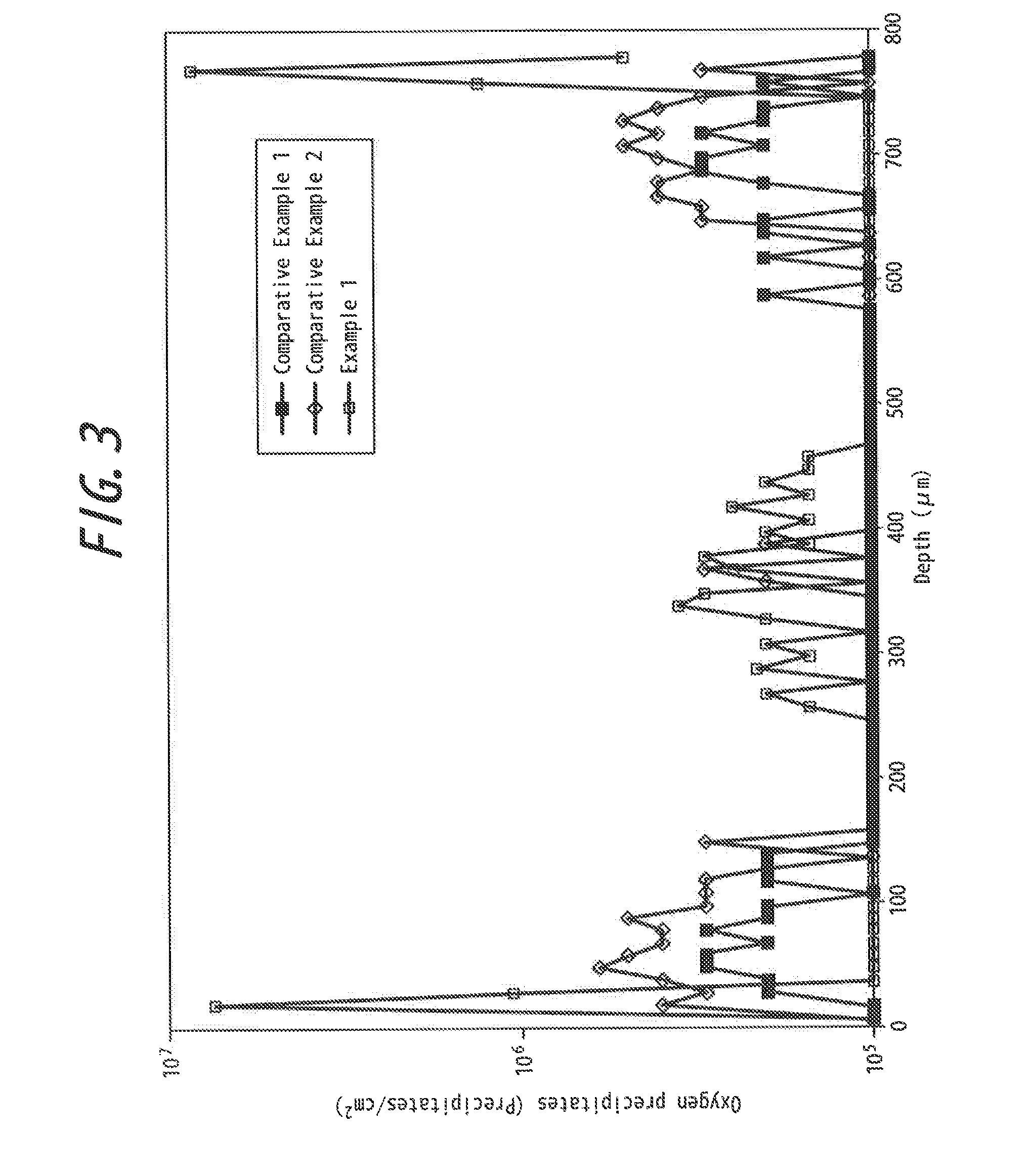

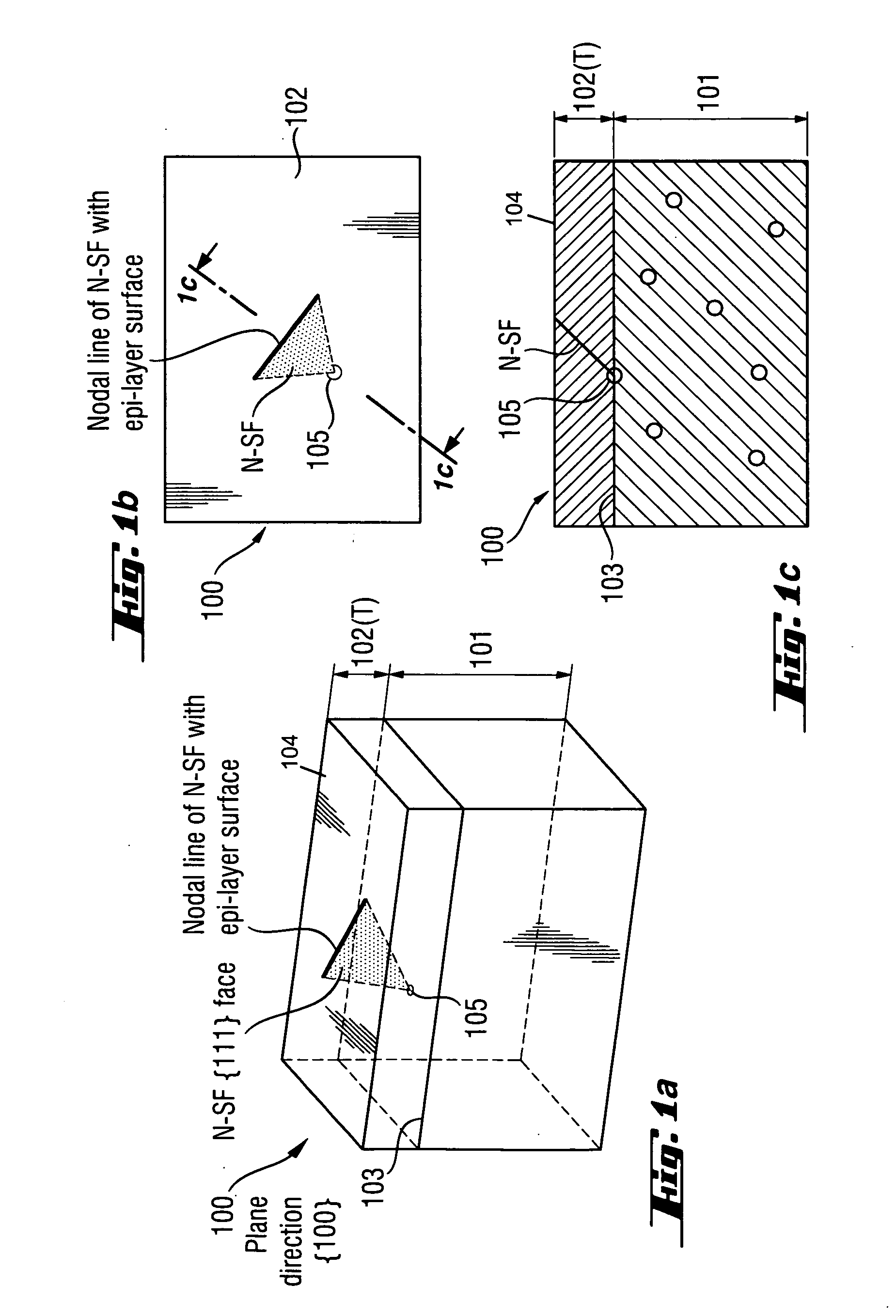

Silicon Epitaxial Wafer And Manufacturing Method Thereof

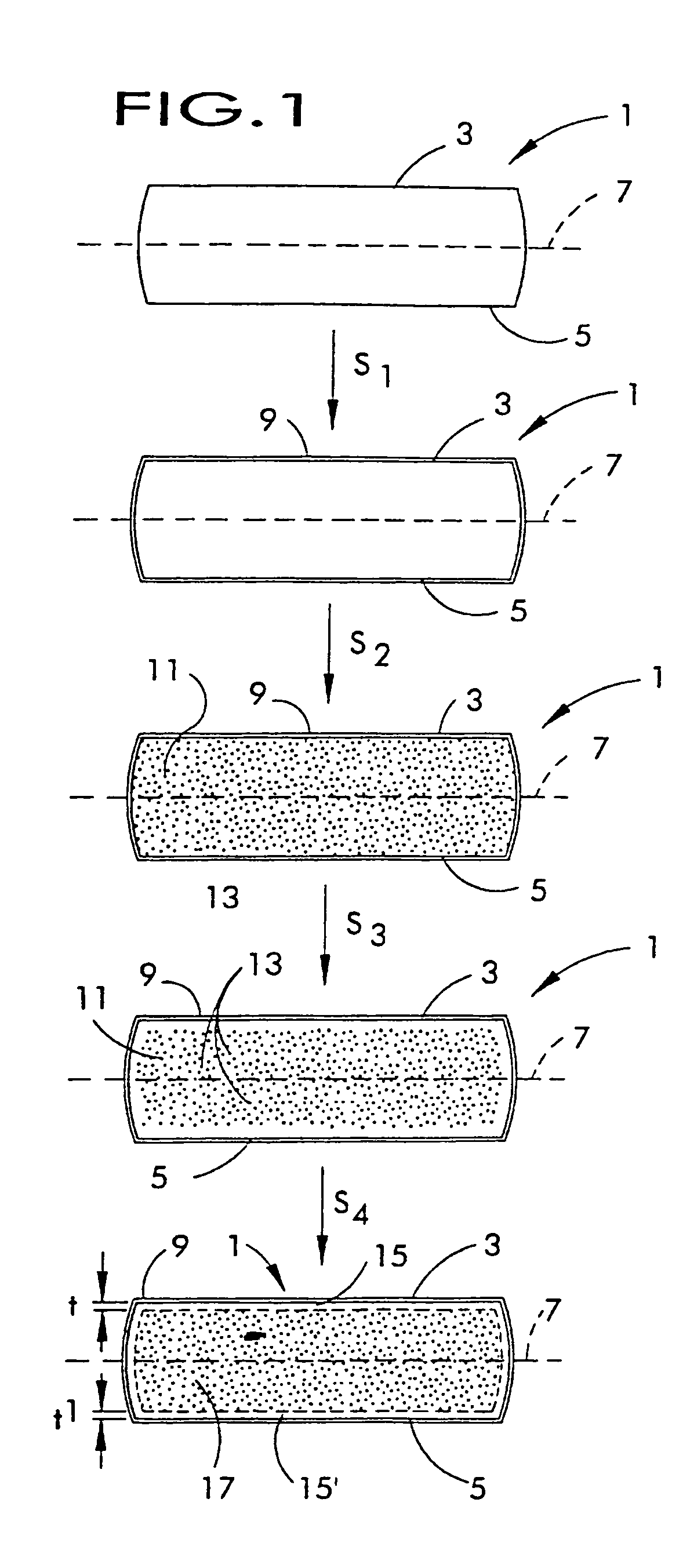

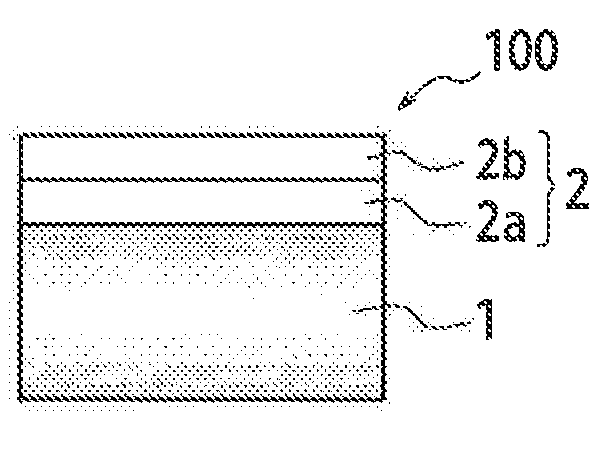

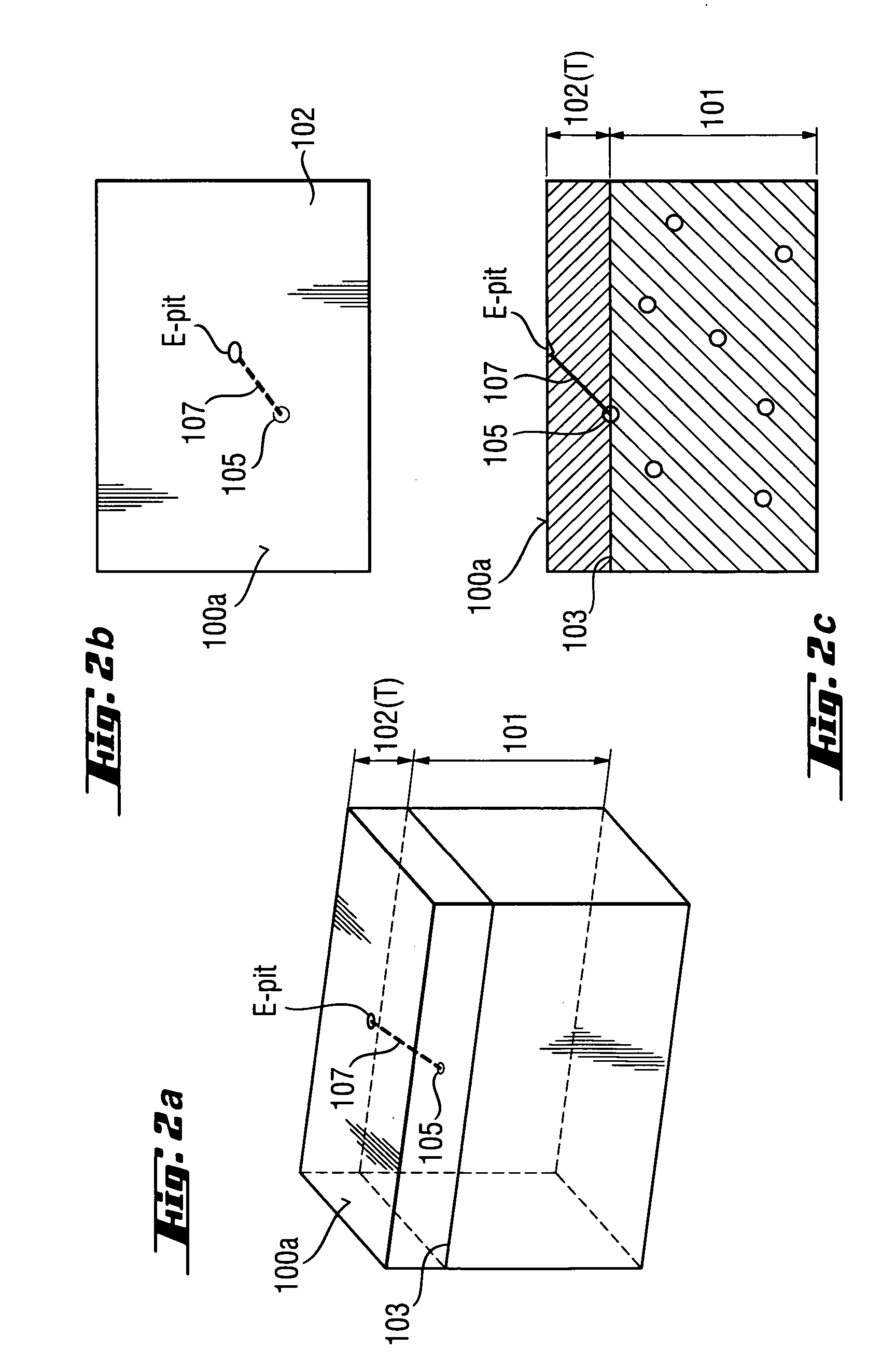

InactiveUS20080038526A1High possibility of rapid increase in deformationAvoid deformationPolycrystalline material growthAfter-treatment detailsSingle crystal substrateSingle crystal

A silicon epitaxial wafer 100 formed by growing a silicon epitaxial layer 2 on a silicon single crystal substrate 1, produced by a CZ method, and doped with boron so that a resistivity thereof is in the range of 0.009 Ω·cm or higher and 0.012 Ω·cm or lower. The silicon single crystal substrate 1 has a density of the oxygen precipitation nuclei of 1×1010 cm−3 or higher. A width of a no-oxygen-precipitation-nucleus-forming-region 15, formed between the silicon epitaxial layer 2 and the silicon single substrate 1, is in the range of more than 0 μm and less than 10 μm. Thereby, provided is a silicon epitaxial wafer using a boron doped p+ CZ substrate, wherein a formed width of no-oxygen-precipitation-nucleus-forming-region is reduced sufficiently, and oxygen precipitates can be formed having a density sufficient enough to exert an IG effect.

Owner:SHIN-ETSU HANDOTAI CO LTD

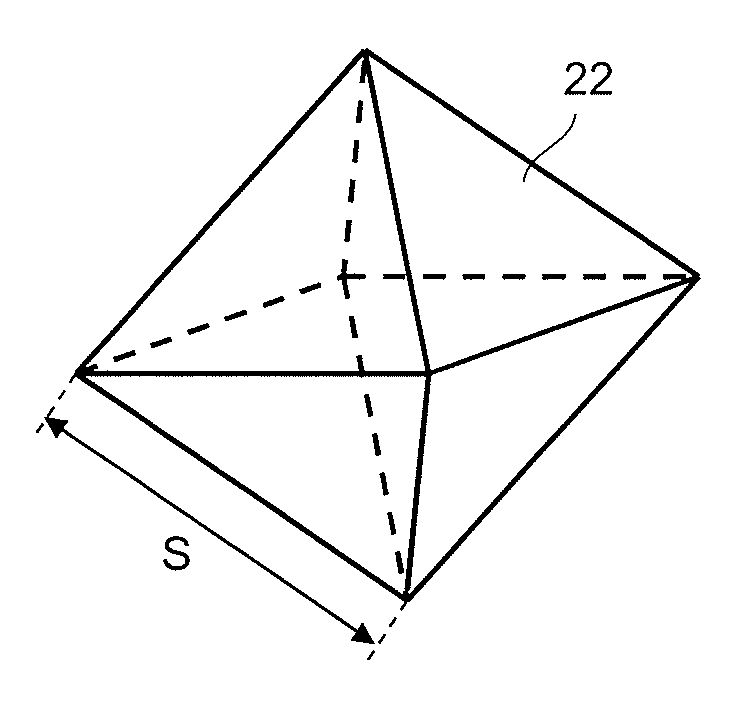

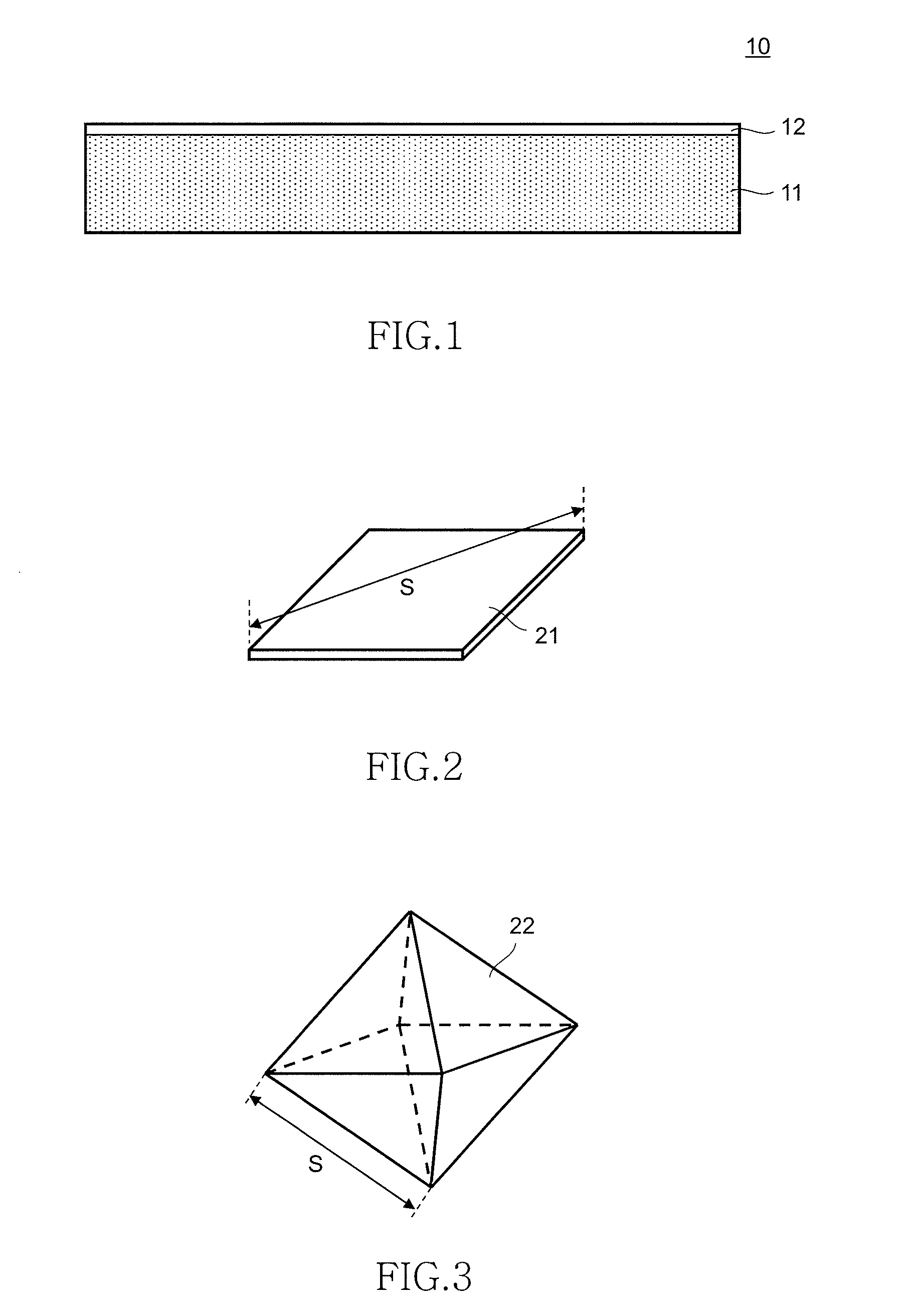

Silicon wafer and method of manufacturing thereof, and method of manufacturing semiconductor device

ActiveUS20120306052A1Avoid misalignmentAvoid it happening againSemiconductor/solid-state device manufacturingSemiconductor devicesNitrogenOxygen precipitates

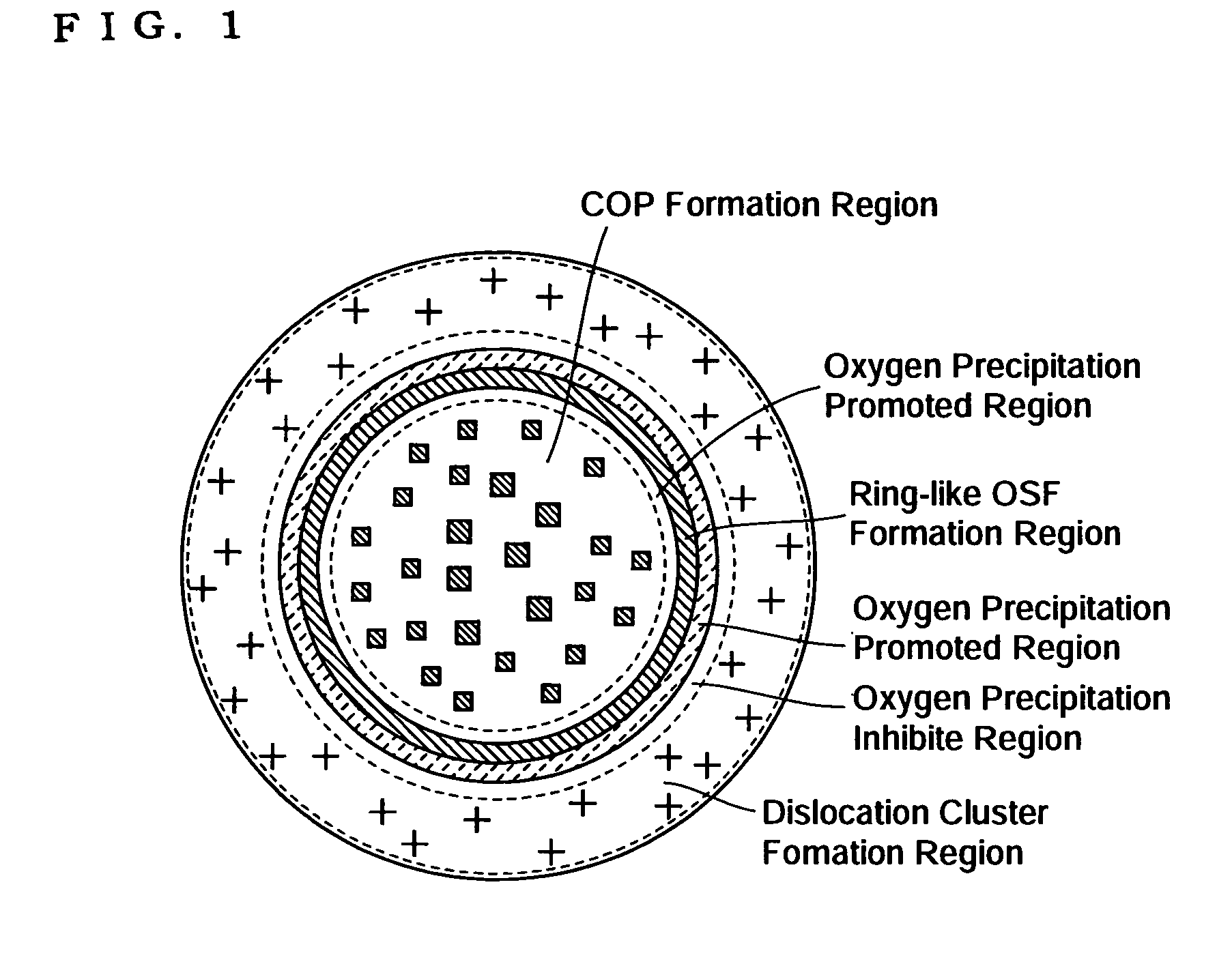

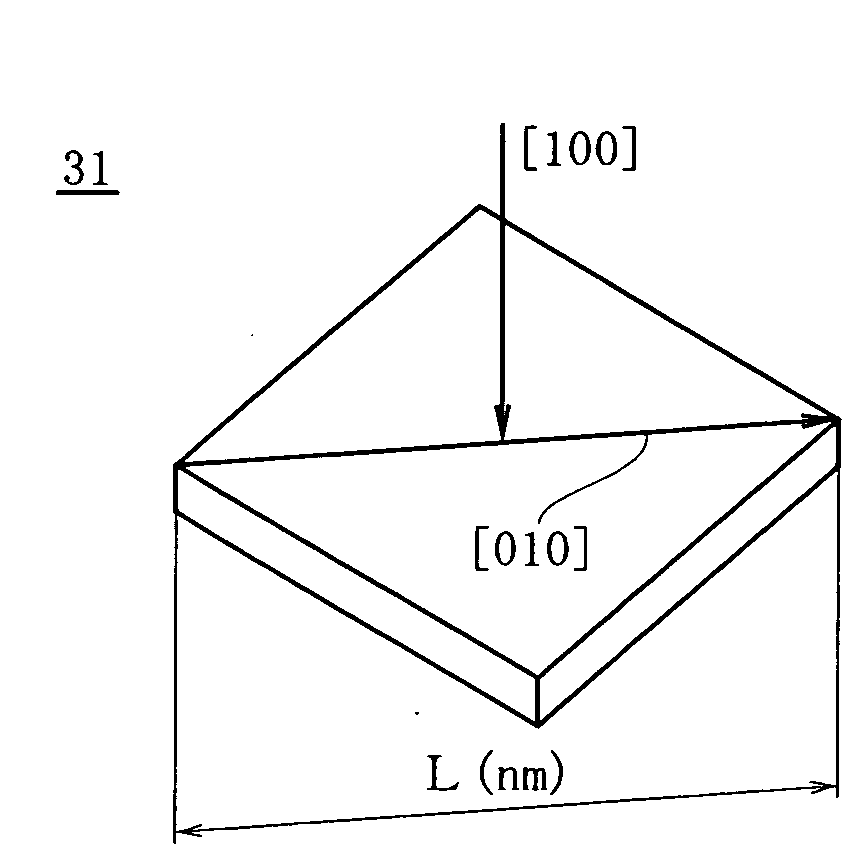

An object of the present invention is to provide an epitaxial wafer on which dislocation is preventable even when a LSA treatment is performed in device processes. An epitaxial wafer according to the present invention includes a wafer 11 whose nitrogen concentration is 1×1012 atoms / cm3 or more or whose specific resistance is 20 mΩ·cm or less by boron doping, and an epitaxial layer 12 provided on the wafer 11. On the wafer 11, if a thermal treatment is performed at 750° C. for 4 hours and then at 1,000° C. for 4 hours, polyhedron oxygen precipitates grow predominantly over plate-like oxygen precipitates. Therefore, in the device processes, plate-like oxygen precipitates cannot be easily formed. As a result, even when the LSA treatment is performed after various thermal histories in the device processes, it is possible to prevent the dislocation, which is triggered by oxygen precipitates, from generating.

Owner:SUMCO CORP

Silicon material with controlled agglomerated point defects and oxygen clusters induced by the lateral surface

ActiveUS20070269361A1Polycrystalline material growthSemiconductor/solid-state device manufacturingChemical physicsWafering

The present invention relates to a single crystal silicon ingot or wafer wherein the lateral incorporation effect of intrinsic point defects has been manipulated such that the formation of agglomerated intrinsic point defects and / or oxygen precipitate clusters in a ring extending radially inward from about the lateral surface of the ingot segment is limited.

Owner:GLOBALWAFERS CO LTD

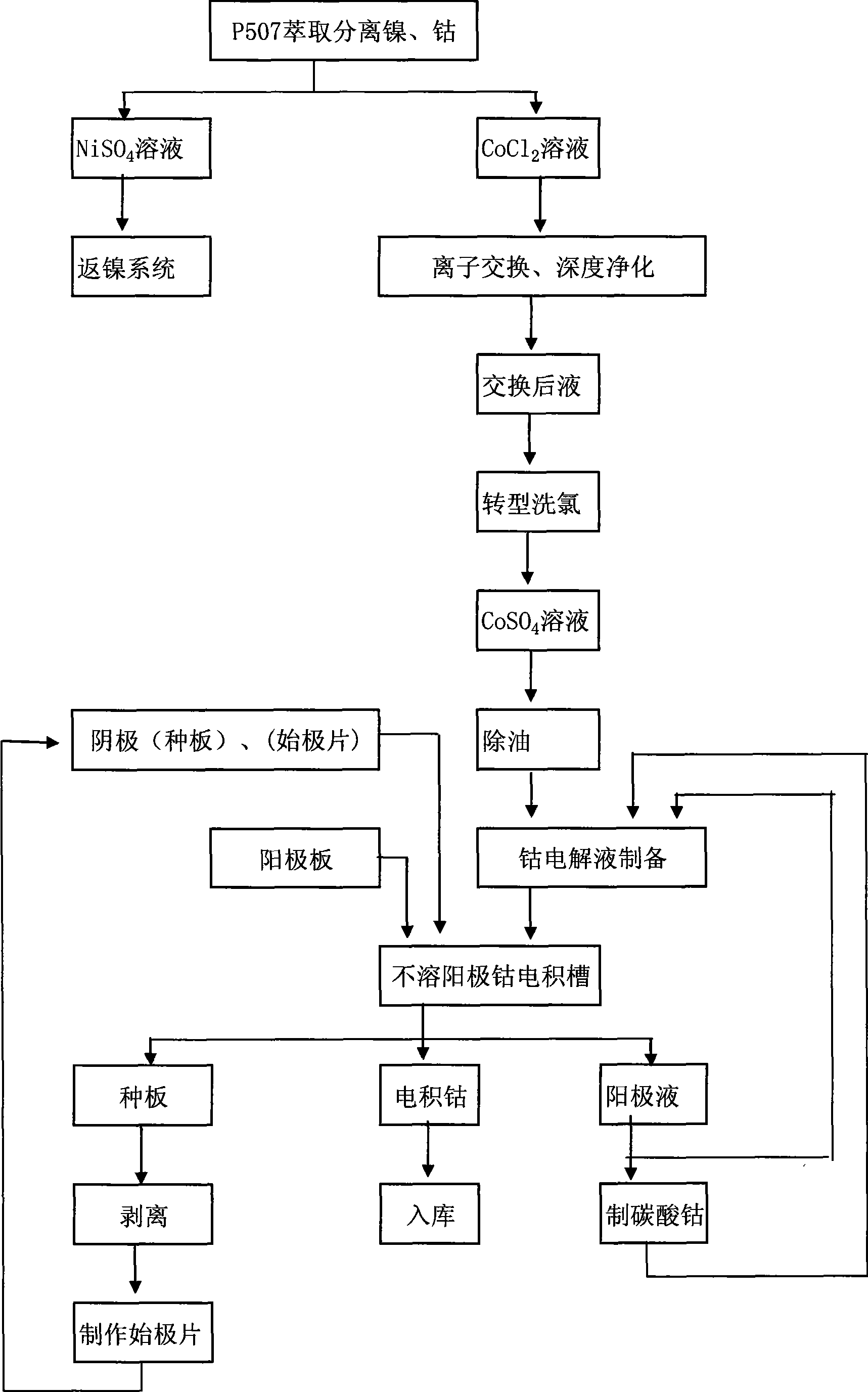

Method for producing electrodeposited cobalt by non-hydrochloric acid electrolyte

ActiveCN101532095AReduced surface swellingAvoid bringing inPhotography auxillary processesProcess efficiency improvementPhysical chemistryPhysical approach

The invention relates to a method for producing electrodeposited cobalt, which belongs to the technical field of production methods of the electrodeposited cobalt. The method for producing the electrodeposited cobalt by a non-hydrochloric acid electrolyte is characterized in that the method comprises the steps of: the preparation of a CoCl2 solution, extraction and transformation, dechlorination, the removal of an organic substance by a physical method, the preparation of a cobalt electrolyte, and the production of the electrodeposited cobalt. The method adds an acid fog inhibitor into the electrolyte to ensure that the expansive force on the surface of the electrolyte is reduced and oxygen precipitated by an anode smoothly passes through the liquid level so as to prevent acid from being brought into production field. The method effectively improves work environment and prevent the pollution to the ambient environment. The method for producing the electrodeposited cobalt by the non-hydrochloric acid electrolyte, due to adopting solution transformation and chlorine washing processes, ensures that Cl<-> in the electrolyte is lower than 0.1g.l<-1>, and basically meets the requirement of no precipitation of chlorine gas during the electrodeposition.

Owner:YANTAI KAISHI IND CO LTD

Process for preparing a stabilized ideal oxygen precipitating silicon wafer

ActiveUS20050005841A1Heating fastPolycrystalline material growthAfter-treatment detailsFree zoneSingle crystal

The present invention is directed to a single crystal Czochralski-type silicon wafer, and a process for the preparation thereof, which has a non-uniform distribution of stabilized oxygen precipitate nucleation centers therein. Specifically, the peak concentration is located in the wafer bulk and a precipitate-free zone extends inward from a surface.

Owner:GLOBALWAFERS CO LTD

Suppression of Oxygen Precipitation in Heavily Doped Single Crystal Silicon Substrates

This invention generally relates to a process for suppressing oxygen precipitation in epitaxial silicon wafers having a heavily doped silicon substrate and a lightly N-doped silicon epitaxial layer by dissolving existing oxygen clusters and precipitates within the substrate. Furthermore, the formation of oxygen precipitates is prevented upon subsequent oxygen precipitation heat treatment.

Owner:MEMC ELECTONIC MATERIALS INC

Process for making silicon wafers with stabilized oxygen precipitate nucleation centers

A process for imparting controlled oxygen precipitation behavior to a single crystal silicon wafer. Specifically, prior to formation of the oxygen precipitates, the wafer bulk comprises dopant stabilized oxygen precipitate nucleation centers. The dopant is selected from a group consisting of nitrogen and carbon, and the concentration of the dopant is sufficient to allow the oxygen precipitate nucleation centers to withstand thermal processing, such as an epitaxial deposition process, while maintaining the ability to dissolve any grown-in nucleation centers.

Owner:SUNEDISON SEMICON LIMITED UEN201334164H

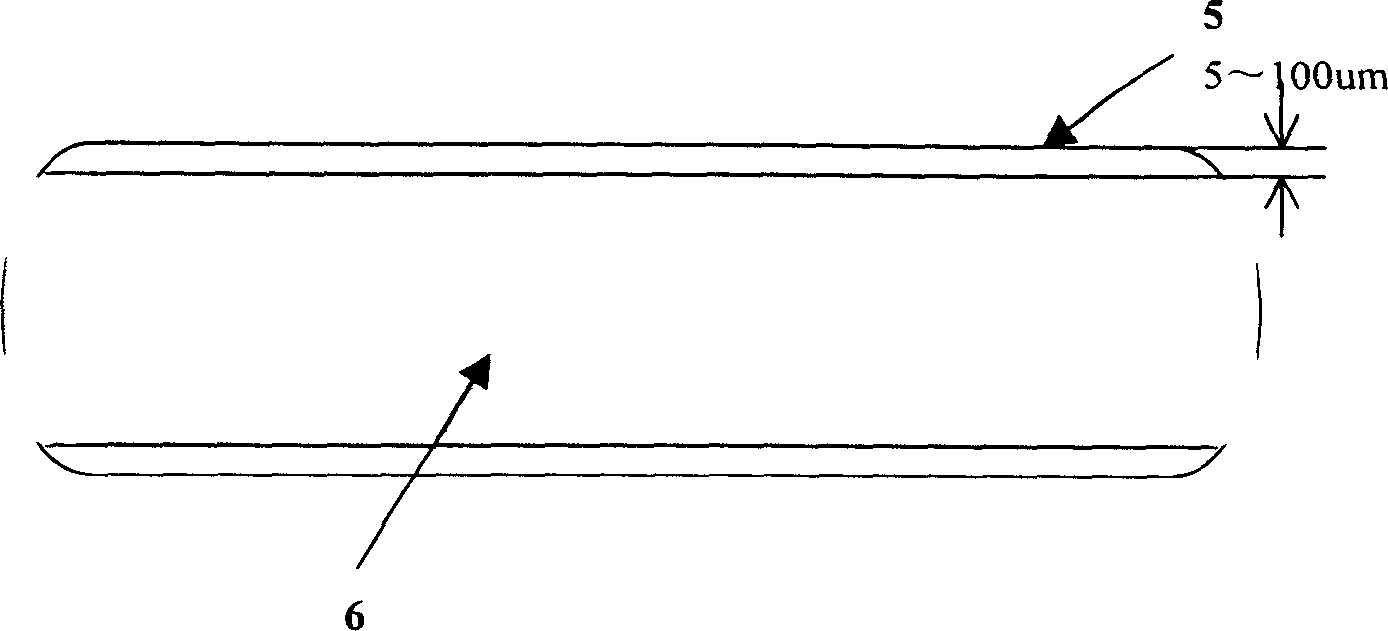

Rapid thermal process for silicon sheet capable of obtaining denuded zone and product thereof

ActiveCN1838388AImprove eliminationMeet the requirements of getteringSemiconductor/solid-state device manufacturingHeat treatedOxygen

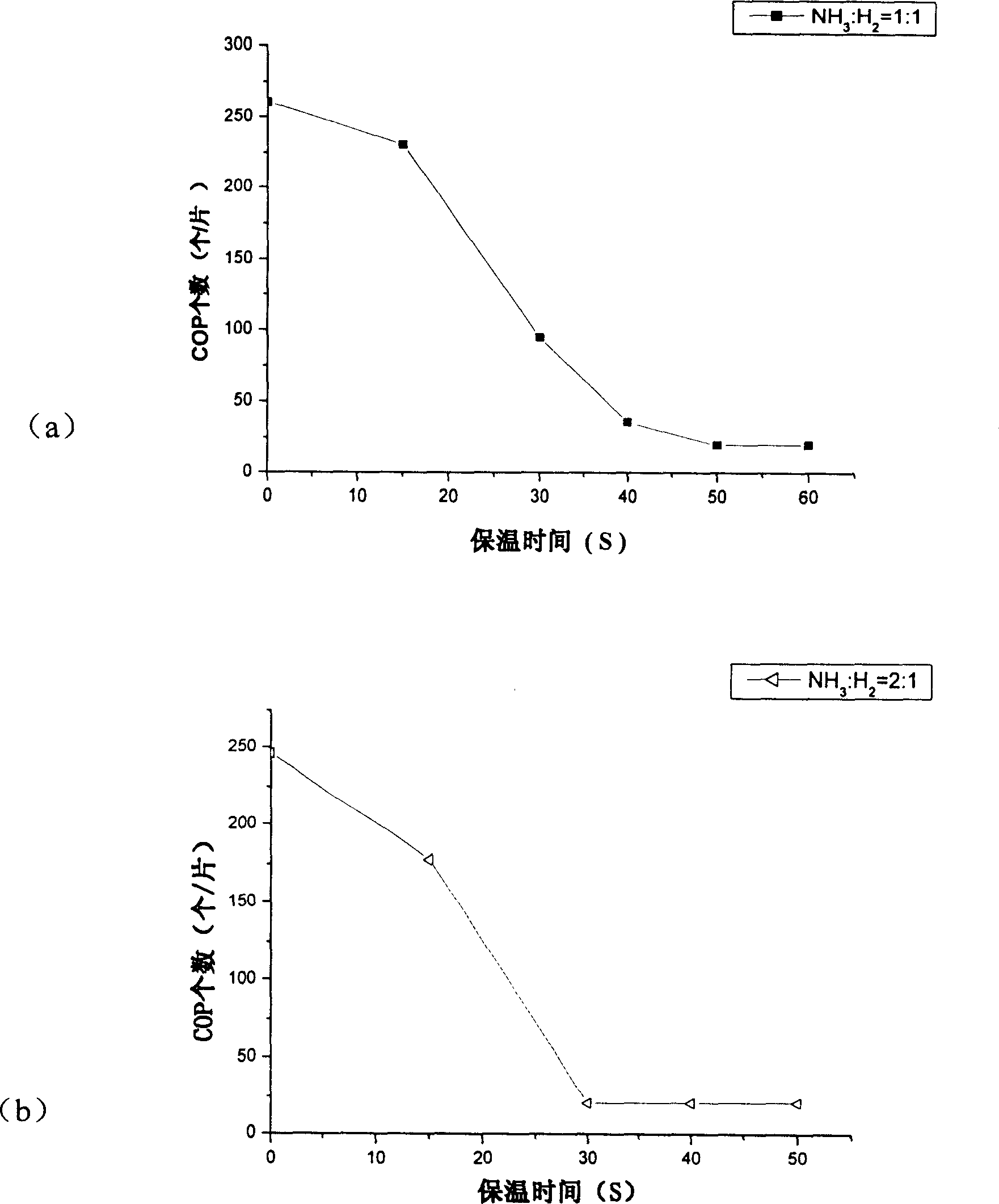

This invention relates to a silicon fast heat process technology for obtaining clear area and its product. The method includes: (1) in Ar / NH3 / H2 or N2 / NH3 / H2, heating silicon sheet up to 1150- 1250DEG.,then keeping the temperature of the silicon sheet under 1150-1250DEG., then lowering temperature by 20-100DEG. / S speed to normal temperature; (2)anneal by regular method ; (3) heat processing by regular method to obtain the silicon sheet with clear area. This technology can control the thickness of the clear area between 5-40 mum, under which the technology can improve the oxygen deposition density of the impurity absorbing area and lower COP density of the surface.

Owner:GRINM SEMICONDUCTOR MATERIALS CO LTD

Silicon annealed wafer and silicon epitaxial wafer

ActiveUS7273647B2Improve temperature distributionShorten the timePolycrystalline material growthAfter-treatment detailsSingle crystalOxygen precipitates

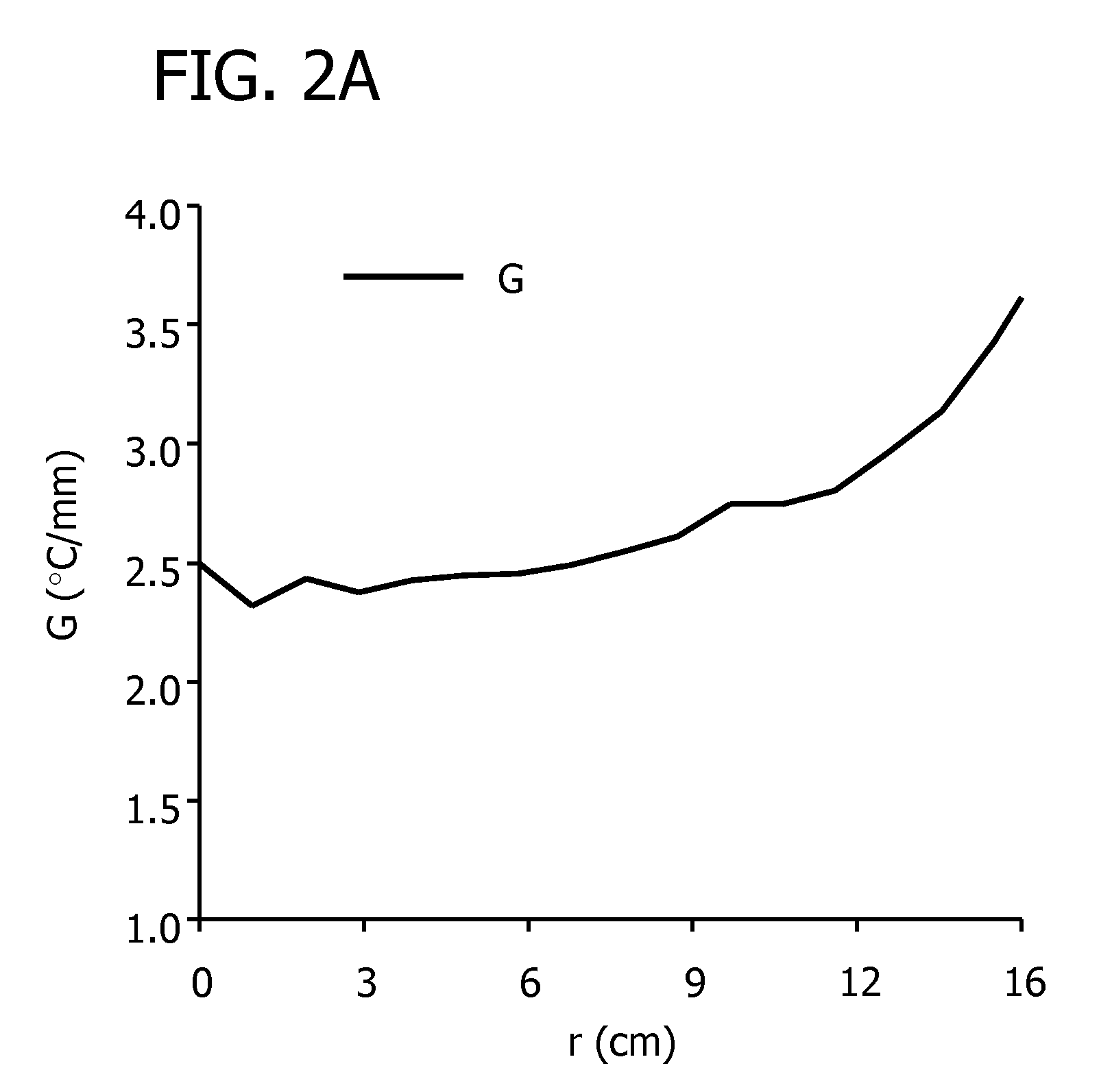

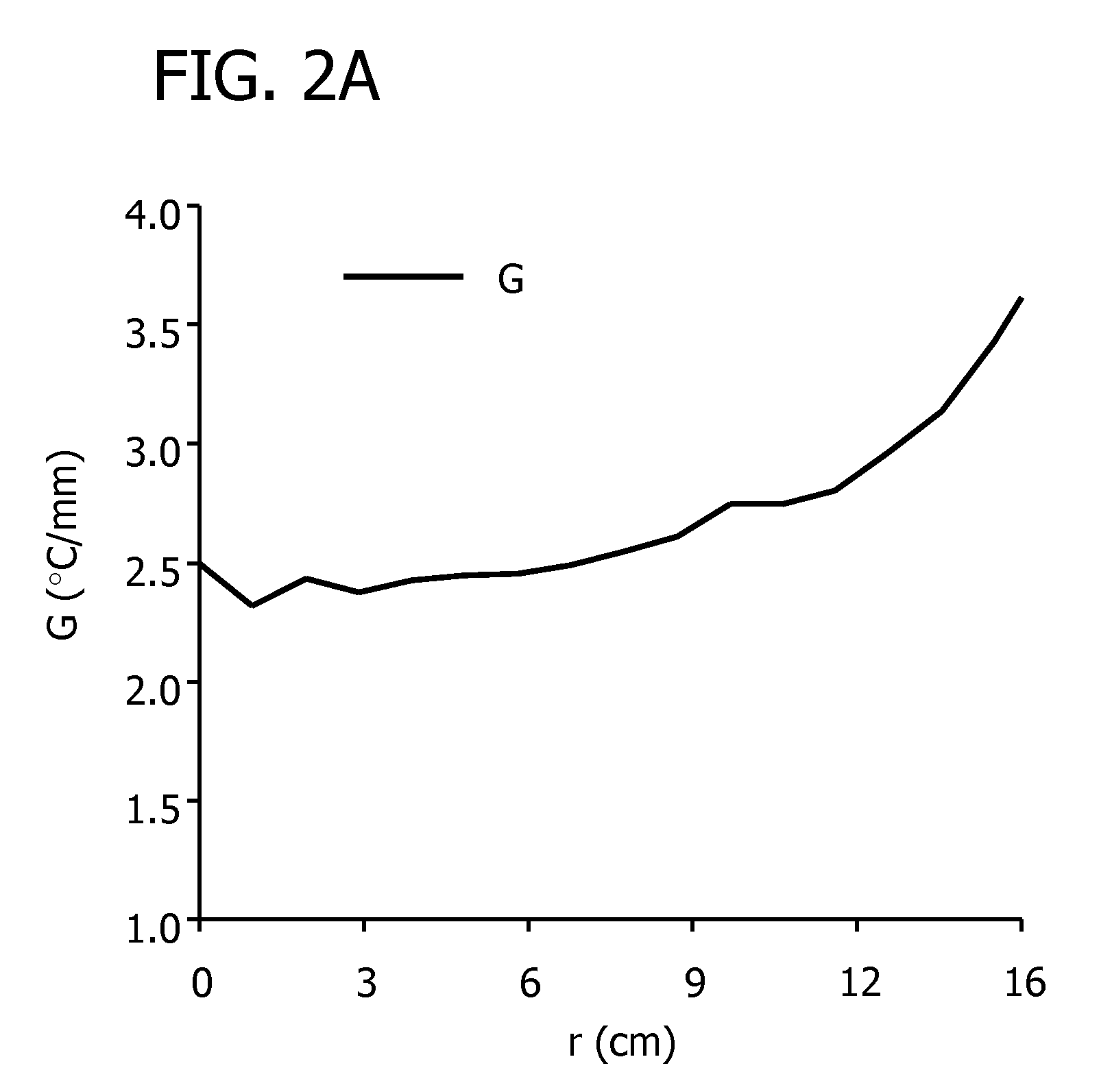

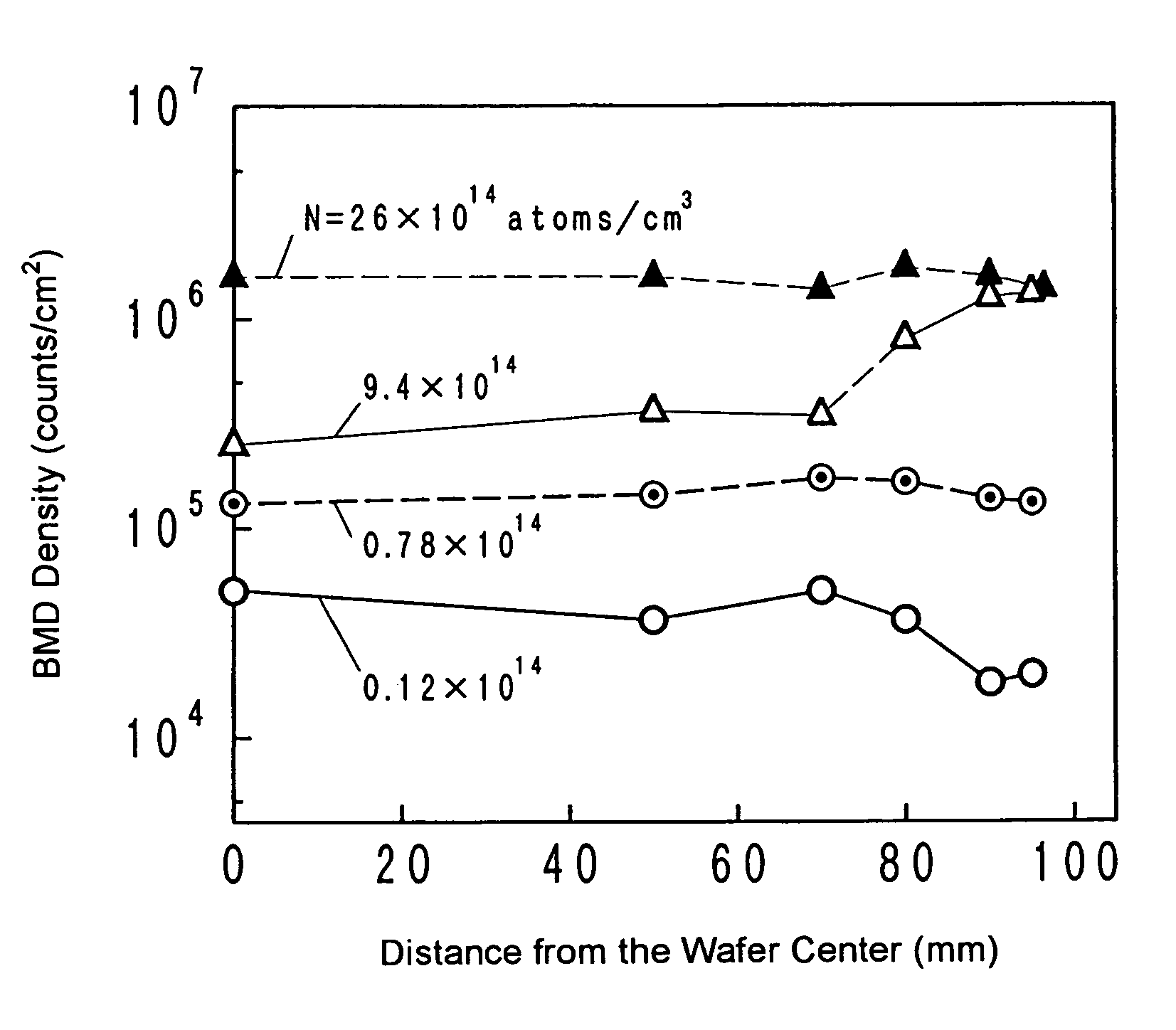

A silicon annealed wafer having a sufficient thick layer free from COP defects on the surface, and a sufficient uniform BMD density in the inside can be produced by annealing either a base material wafer having nitrogen at a concentration of less than 1×1014 atoms / cm3, COP defects having a size of 0.1 μm or less in the highest frequency of occurrence and no COP defects having a size of 0.2 μm or more, oxygen precipitates at a density of 1×104 counts / cm2 or more, and BMDs (oxygen precipitates), where the ratio of the maximum to the minimum of the BMD density in the radial direction of the wafer is 3 or less, or a base material wafer grown at specific average temperature gradients within specific temperature ranges and specific cooling times for a single crystal at a nitrogen concentration of less than 1×1014 atoms / cm3, employing the Czochralski method. Moreover, a silicon epitaxial wafer having very small defects and a uniform BMD distribution in the inside can be formed by growing an epitaxial layer on the surface of either the first type base material wafer or the second type base material wafer. Both the silicon annealed wafer and the silicon epitaxial wafer greatly reduce the rate of producing defective devices, thereby enabling the device productivity to be enhanced.

Owner:SUMITOMO MITSUBISHI SILICON CORP

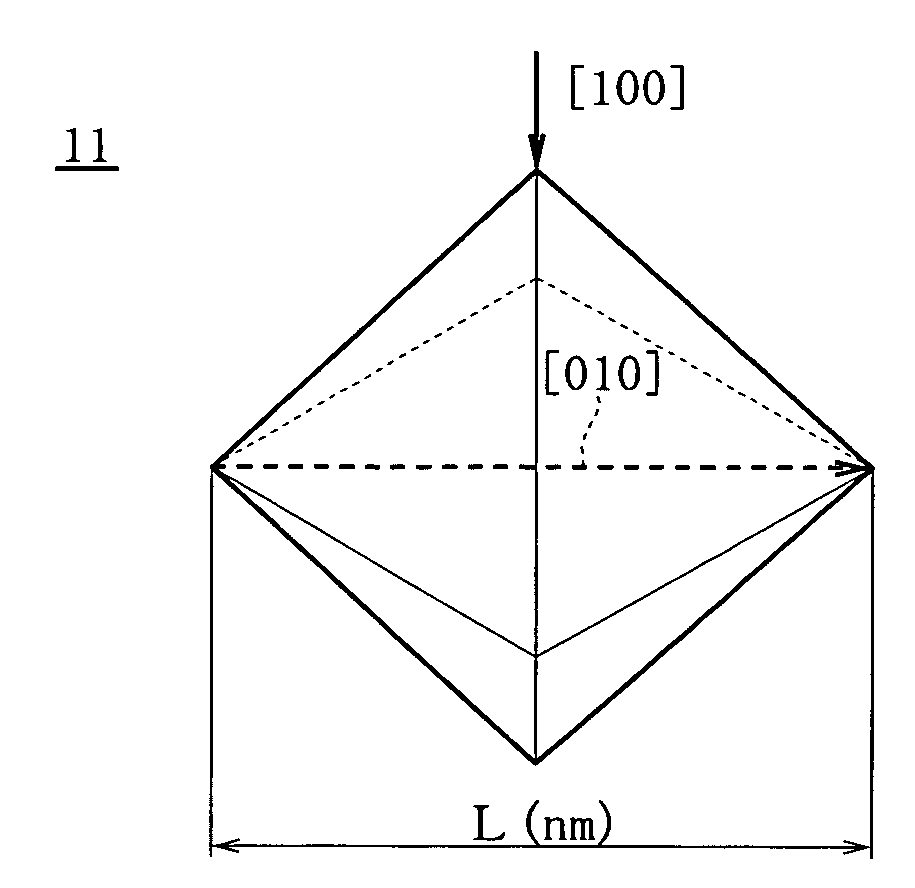

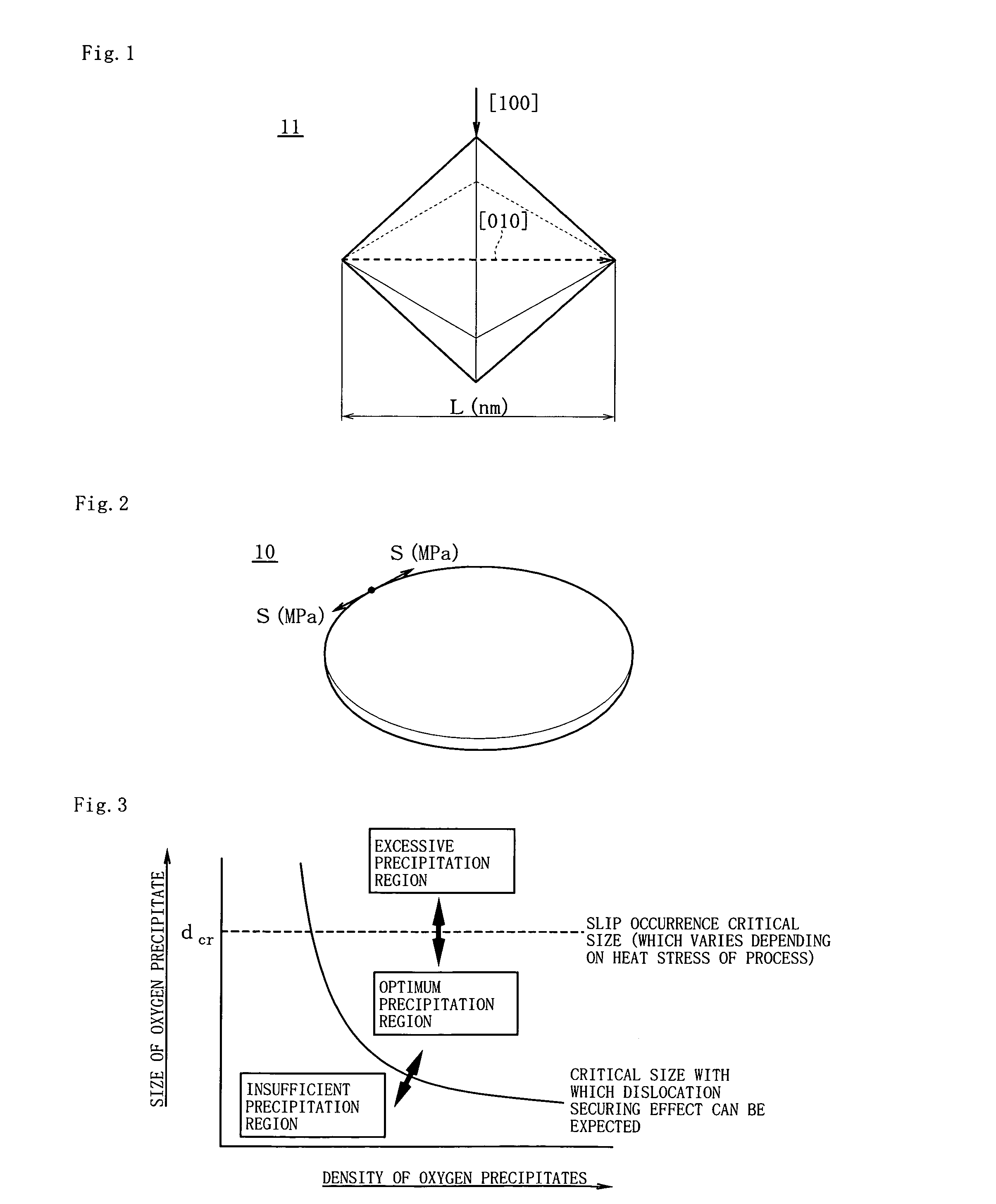

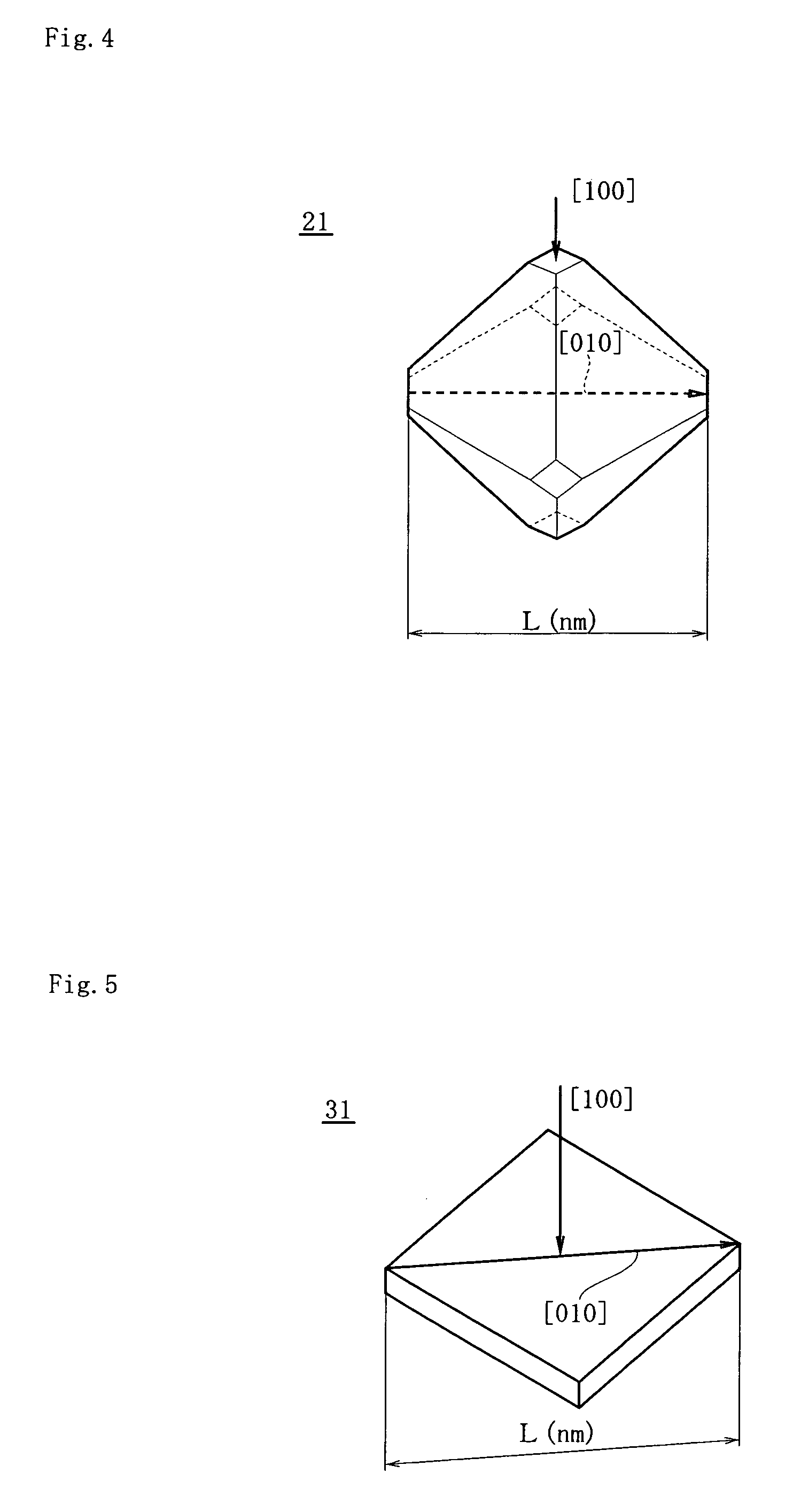

Method for Manufacturing Silicon Wafer and Silicon Wafer Manufactured by this Method

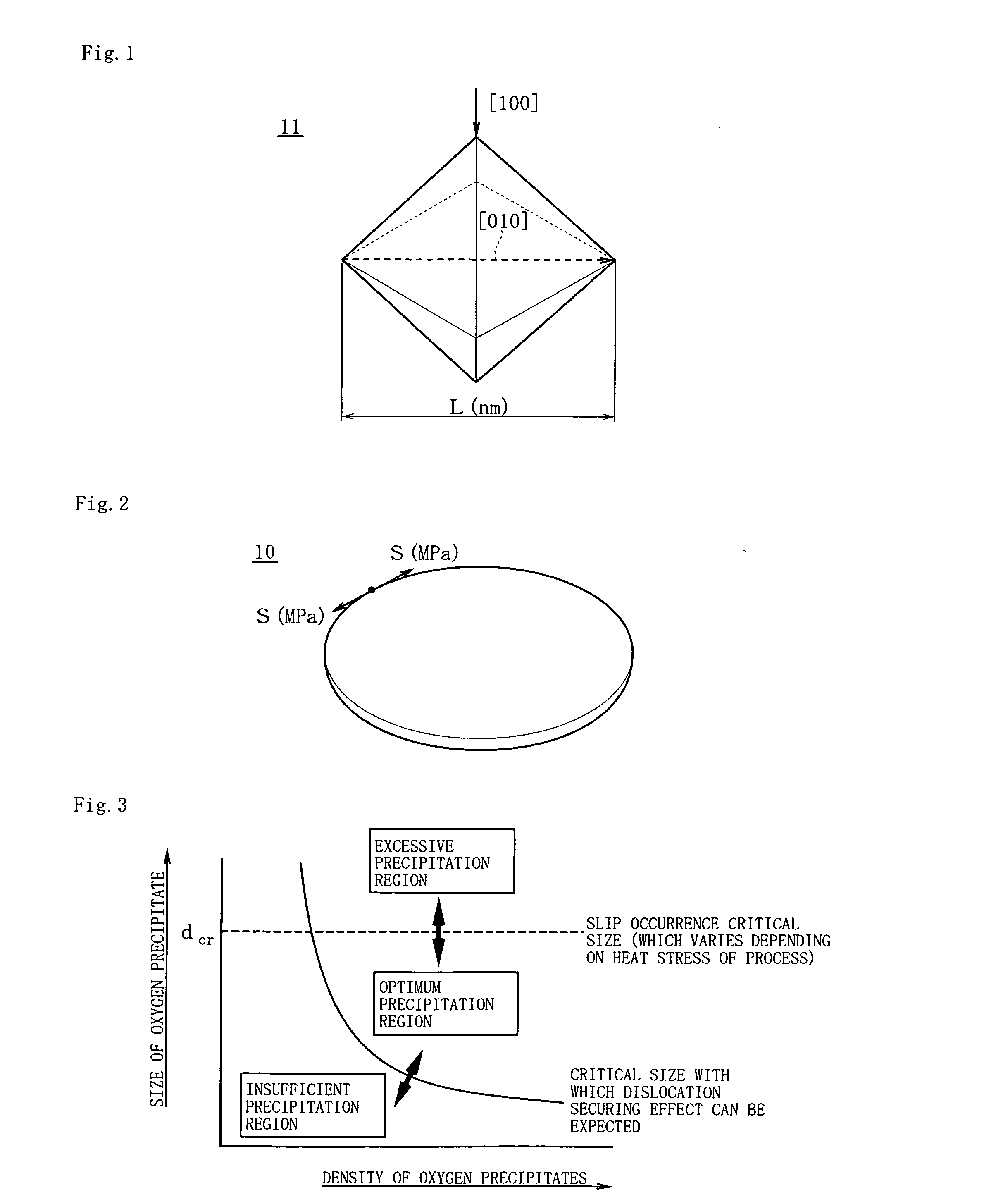

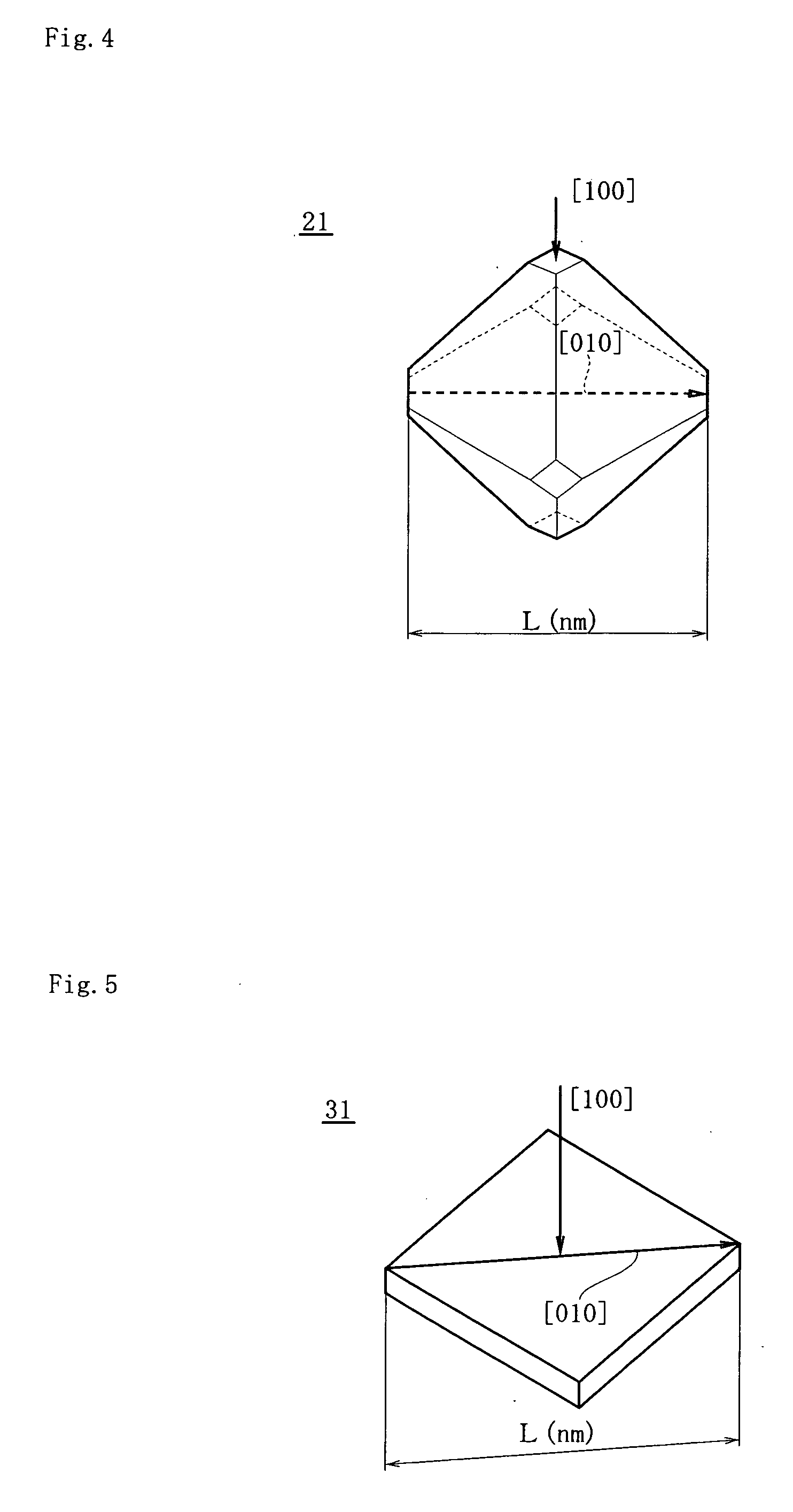

ActiveUS20080118424A1High strengthPrevent slippingPolycrystalline material growthAfter-treatment detailsFokker–Planck equationVolumetric Mass Density

There is obtained a silicon wafer which has a large diameter, where no slip generated therein in a wide range of a density of oxygen precipitates even though a heat treatment such as SLA or FLA is applied thereto, and which has high strength.First, by inputting as input parameters combinations of a plurality of types of oxygen concentrations and thermal histories set for manufacture of a silicon wafer a Fokker-Planck equation is solved to calculate each of a diagonal length L and a density D of oxygen precipitates in the wafer after a heat treatment step to form the oxygen precipitates (11) and immediately before a heat treatment step of a device manufacturing process is calculated. Then, a maximum heat stress S acting in a tangent line direction of an outer peripheral portion of the wafer in the heat treatment step of the device manufacturing process is calculated based on a heat treatment furnace structure and a heat treatment temperature used in the heat treatment step of the device manufacturing process, and then an oxygen concentration or the like satisfying the following Expression (1) is determined:12000×D−0.26≦L≦51000×S−1.55 (1)

Owner:SUMCO CORP

Epitaxial substrate and method for producing same

InactiveUS20110300371A1Suppressing metal contaminationReduce generationAfter-treatment detailsLayered productsDopantSurface layer

Owner:SUMCO CORP

Epitaxial wafer and method for producing epitaxial wafers

ActiveUS20070178668A1Reliably producedQuality improvementPolycrystalline material growthLiquid-phase epitaxial-layer growthNitrogenSingle crystal

This disclosure is aimed at providing a method for producing an epitaxial wafer allowing uniform occurrence of oxygen precipitate in a substrate plane in the radial direction in a base plate and excelling in the crystal quality of an epi-layer. A method for the production of an epitaxial wafer, characterized by using as a substrate a base plate of nitrogen- and carbon-added silicon single crystal having a nitrogen concentration of 5×1014 to 5×1015 atoms / cm3 and a carbon concentration of 1×1016 to 1×1018 atoms / cm3, having a crystal growth condition during the production of silicon single crystal in a range in which the whole surface of substrate becomes an OSF region, and being pulled at a cooling speed of not less than 4° C. / minute between 1100 and 1000° C. during the growth of crystal, and depositing the silicon single crystal layer on the surface of the substrate by the epitaxial method.

Owner:SILTRONIC AG

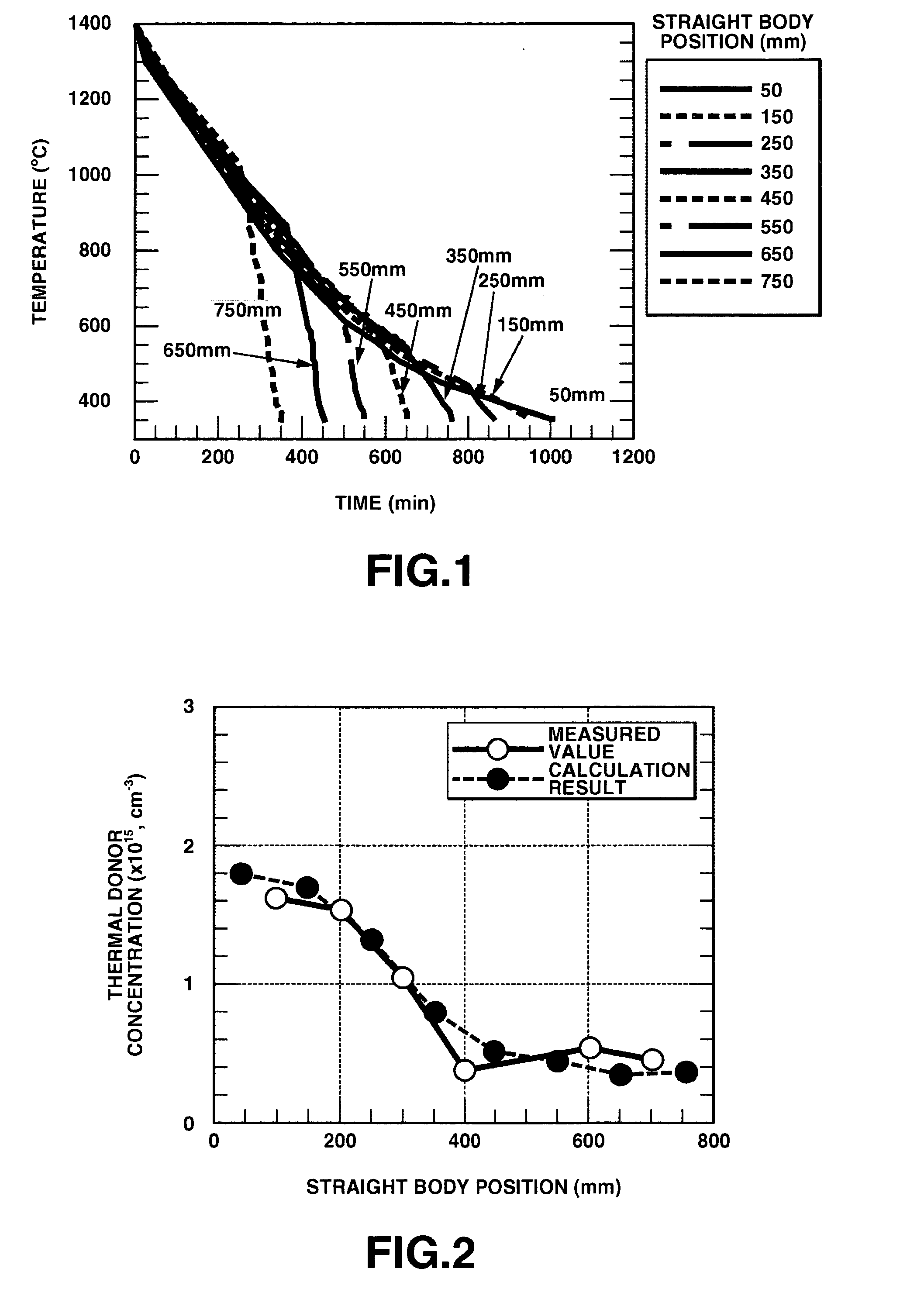

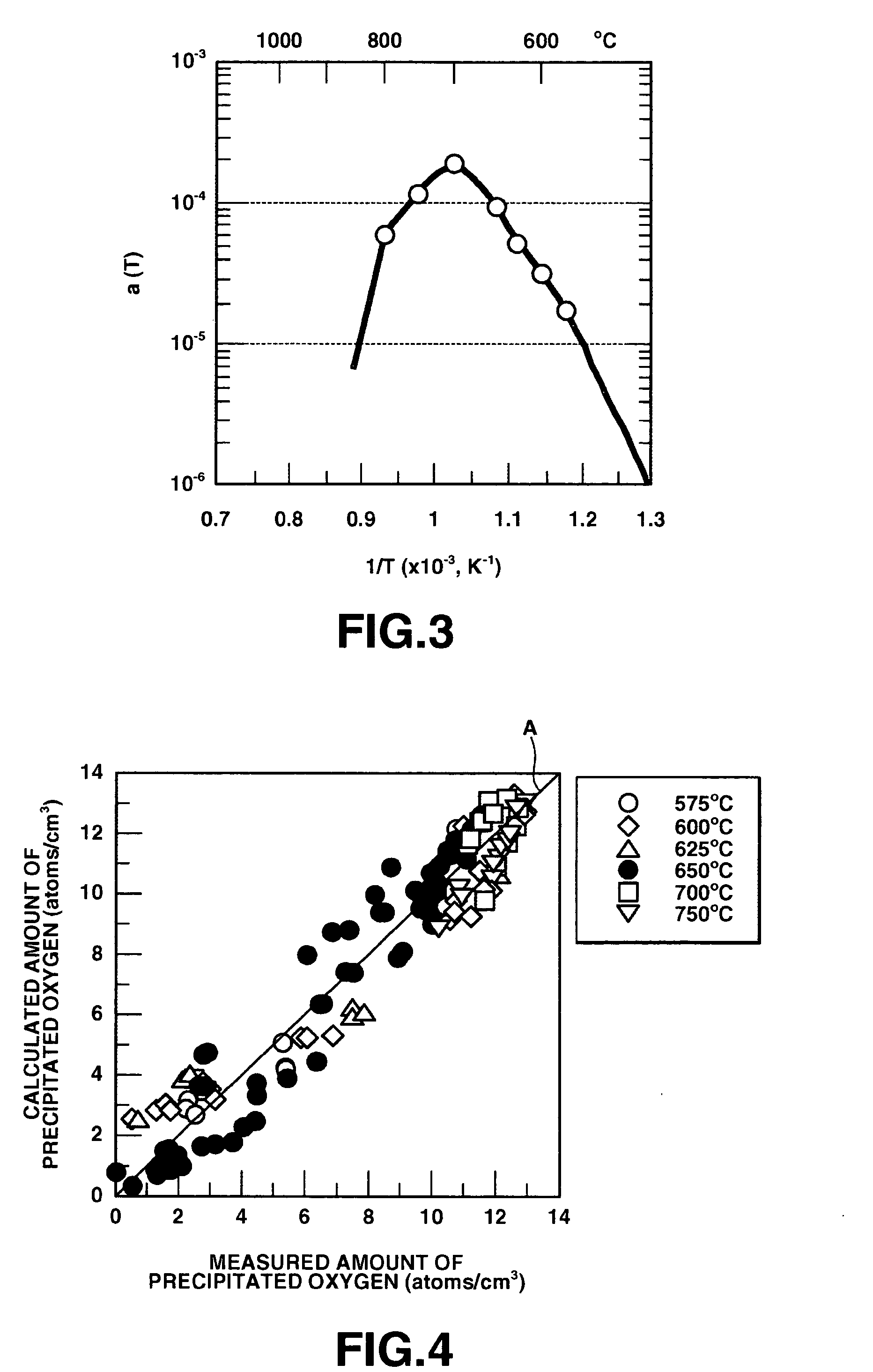

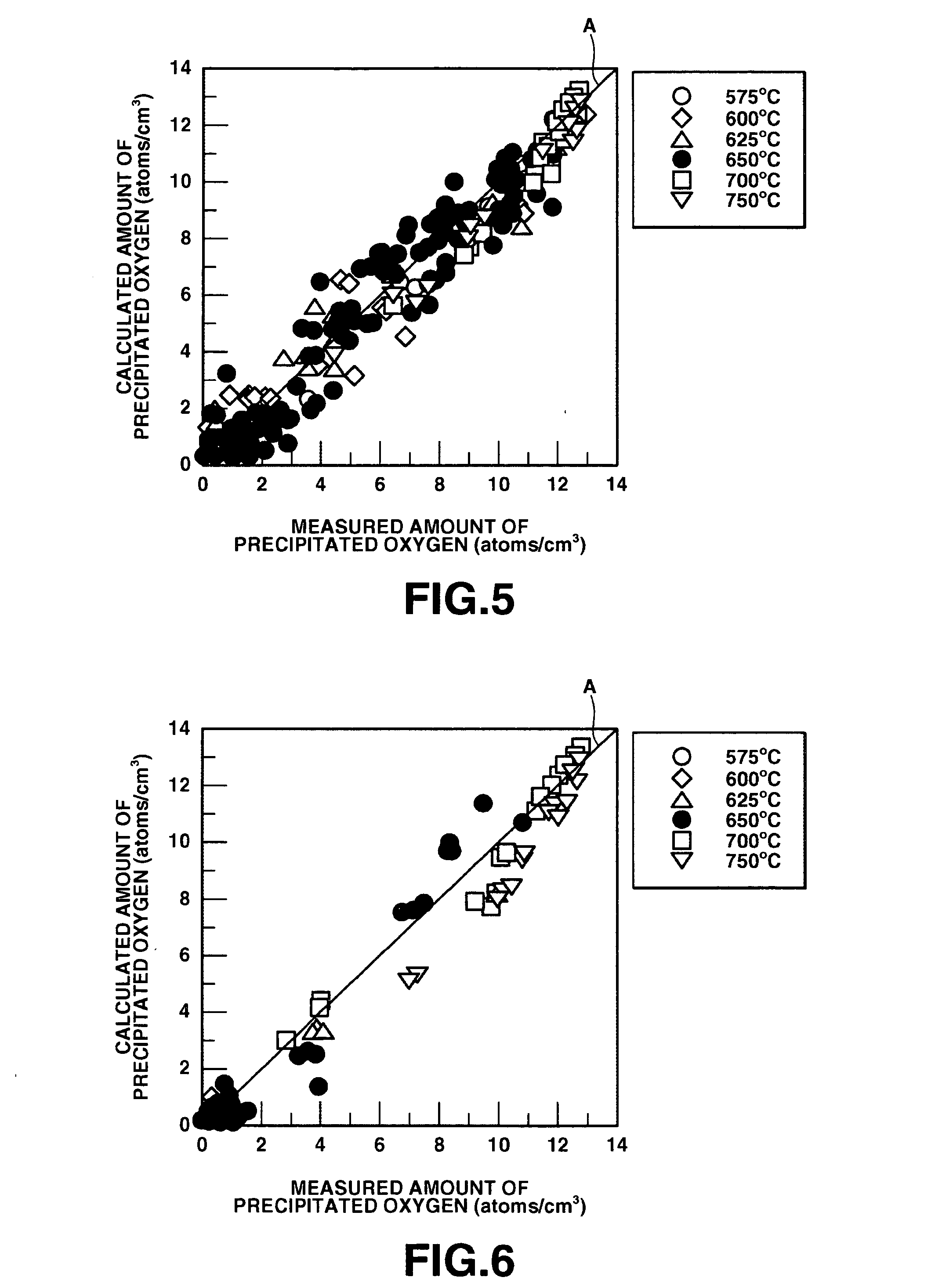

Method for predicting precipitation behavior of oxygen in silicon single crystal, method for determining production parameter of silicon single crystal, and storage medium for storing program for predicting precipitation behavior of oxygen in silicon single crystal

ActiveUS20090210166A1Reliable calculationImprove reliabilityPolycrystalline material growthAfter-treatment detailsSingle crystalNucleation

By specifying an initial oxygen concentration in a silicon single crystal and a concentration of thermal donors produced according to a thermal history from 400° C. to 550° C. that the silicon single crystal undergoes during crystal growth, a nucleation rate of oxygen precipitates produced in the silicon single crystal while the silicon single crystal is subjected to a heat treatment is determined. Further, by specifying the heat treatment condition of the silicon single crystal, an oxygen precipitate density and an amount of precipitated oxygen under a given heat treatment condition are predicted by calculation.

Owner:SUMCO TECHXIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com