High quality polyurethane foaming system for refrigerators and refrigerator based on the same

A rigid polyurethane and polyurethane technology is applied in the field of thermal insulation of low-temperature storage equipment, which can solve the problems such as the inability to meet the technical requirements of thin-walled products, the deterioration of thermal insulation performance of the foam layer, and the insufficient flow of foam raw materials, so as to avoid fire hazards. , Improve thermal insulation performance, good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

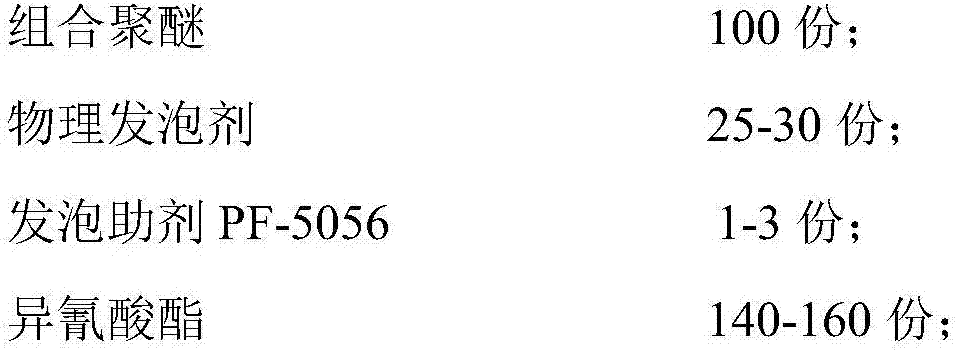

[0028] The composition of each raw material of the polyurethane foaming system of the present embodiment by mass parts is:

[0029]

[0030] Utilize the polyurethane foaming system of present embodiment, the step of making the insulation rigid polyurethane foam in the refrigerator cabinet is as follows:

[0031] 1) Under the condition of the material temperature of 20°C, mix the combined polyether, physical foaming agent HFC-245fa and foaming aid according to the ratio to obtain the mixed white material;

[0032] 2) Under the condition of the material temperature of 20°C, put the isocyanate into the premixing tank and stir evenly to obtain the black material;

[0033] 3) Under the condition of the material temperature of 20°C, mix the black material and the mixed white material according to the ratio through a high-pressure foaming machine, and quickly inject them into the refrigerator box to be foamed;

[0034] 4) The mold temperature of the refrigerator box to be foamed ...

Embodiment 2

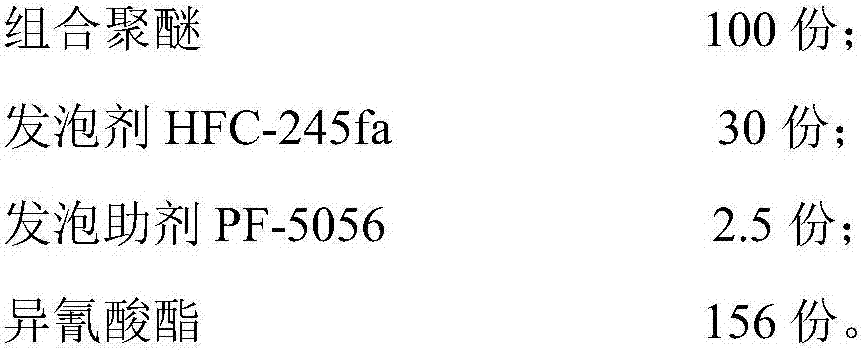

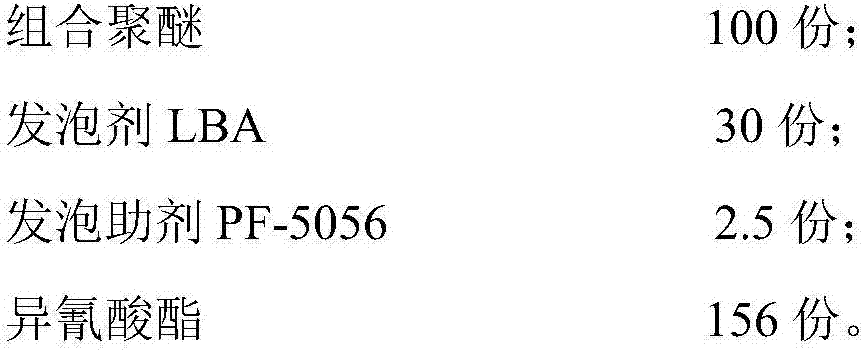

[0037] The composition of each raw material of the polyurethane foaming system of the present embodiment by mass parts is:

[0038]

[0039] Utilizing the polyurethane foaming formula of this embodiment, the method for manufacturing the heat-insulating rigid polyurethane foam in the refrigerator cabinet is the same as that of Example 1.

[0040] After the foam box was cooled to room temperature, the rigid polyurethane foam in the box was taken out, and its related properties were tested. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com