Heating system for single crystal furnace

A heating system and single crystal furnace technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., to achieve the effect of reducing temperature difference, reducing heat convection, and reducing oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

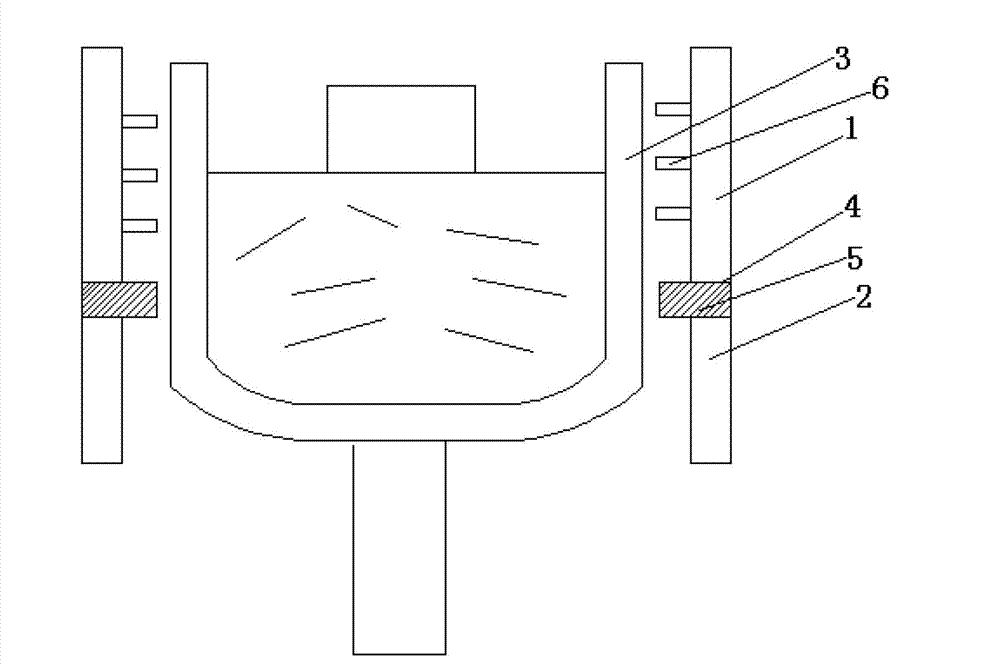

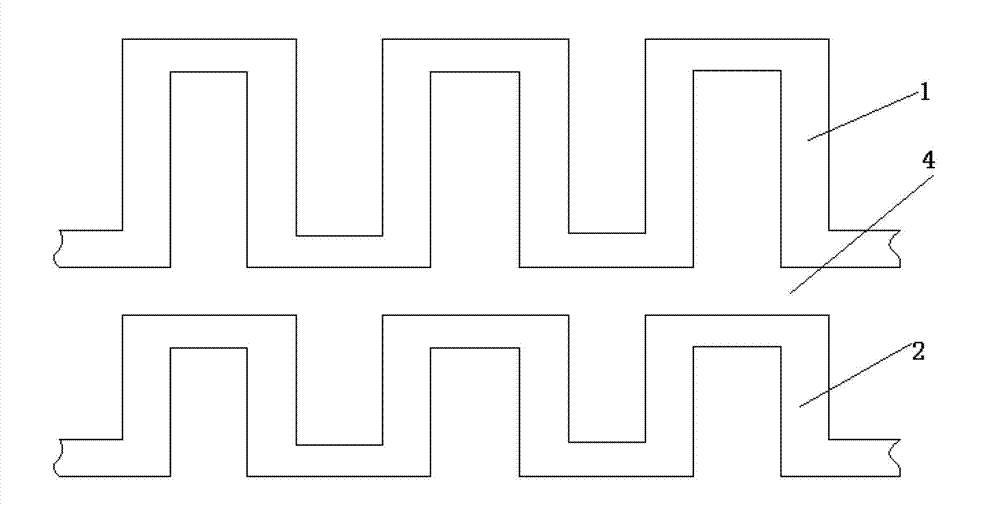

[0015] Referring to the accompanying drawings, the single crystal furnace heating system includes an upper heater 1 and a lower heater 2 placed in the furnace body. The upper heater 1 and the lower heater 2 are respectively facing the upper and lower parts of the crucible 3. The upper heater and the lower heater The heaters are respectively connected with a power system, the upper heater 1 and the lower heater 2 are respectively in a square wave shape, there is a gap 4 between the lower end of the upper heater 1 and the upper end of the lower heater, and the upper heater 1 is larger than the lower heater 2 Vertical height, a heat shield 5 is arranged in the gap between the lower end of the upper heater and the upper end of the lower heater. Electrically connected to the control unit of the power supply system of the upper heater and the lower heater; several anti-convection plates 6 are respectively fixed on the inner walls of the upper heater and the lower heater, and the anti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com