A method for reducing thermal conductivity of p-type ce-filled iron-based skutterudite thermoelectric materials

一种热电材料、方钴矿的技术,应用在新能源材料领域,能够解决低热导率、降低p型Ce填充铁基方钴矿热电材料热导率等问题,达到降低热导率、抑制声子输运、烧结致密度良好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

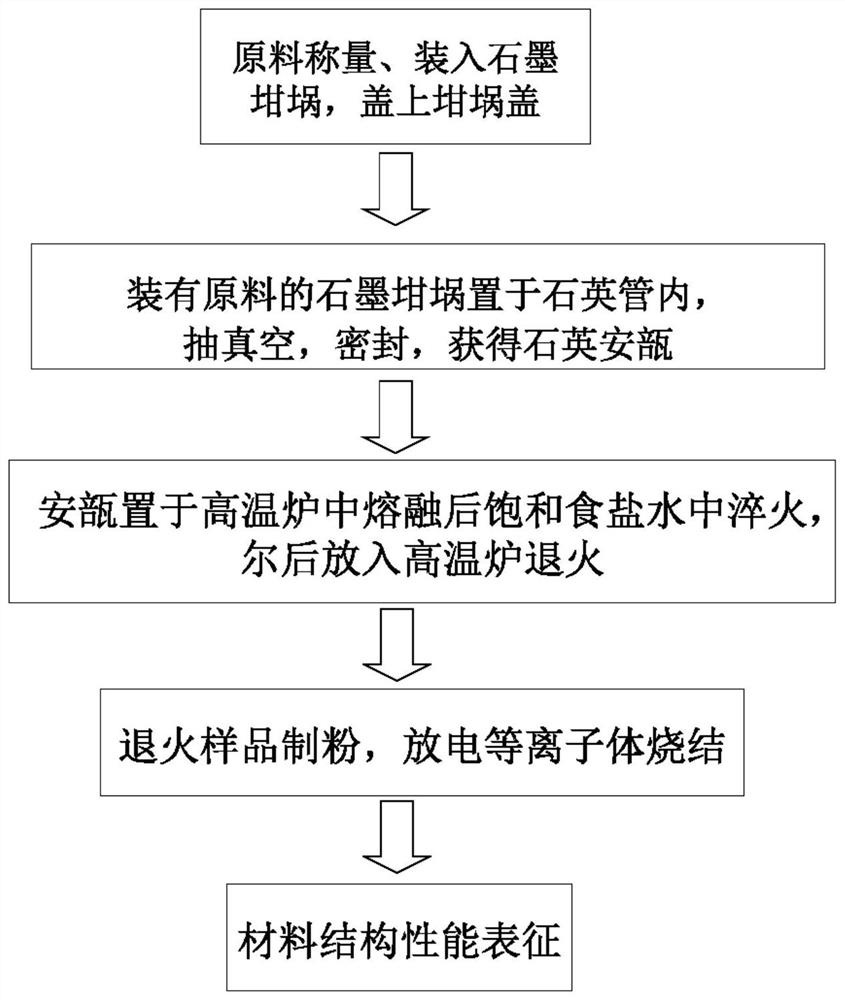

[0041] CE 1+x FE 4 SB 12 The optimization of CE element filling points consists of the following steps:

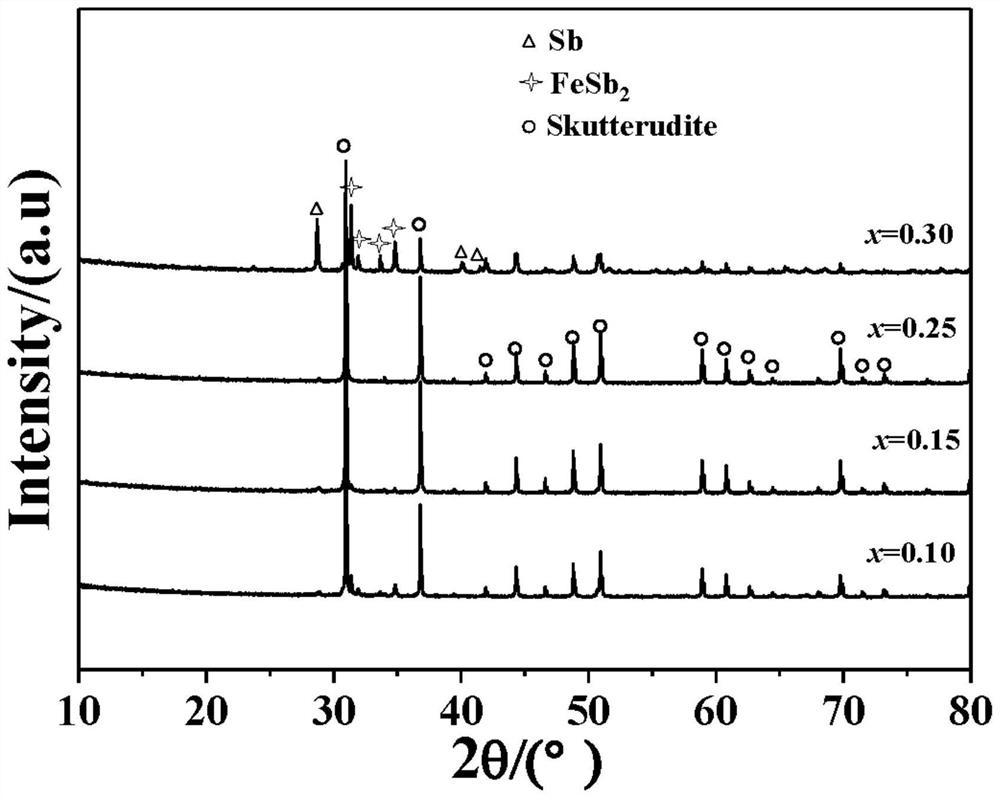

[0042](1) The initial raw material with high pure CE (99.9 % block), Fe (99 % powder) and SB (99.999 % powder), according to the chemical measurement ratio CE CE 1+x FE 4 SB 12 (X = 0.10, 0.15, 0.25 and 0.30) Implit.

[0043] (2) Mix the raw materials by hand by 10 minutes to mix it evenly. Then place the mixed powder into a clean graphite pupa; seal the graphite pupa in the quartz tube under the condition of the vacuum less than 0.1MPa, put it in the program control the temperature and melt furnace, slowly hear the heating to 1100 ° C. At this temperature, the vacuum is vacuum at this temperature. After 10 hours of melting, the melt was placed in saturated salt water and quenched to get the CE 1+x FE 4 SB 12 Casting; put the quartz -containing quenching casting blocks in the high temperature furnace at 675 ° C for 168h, and the samples of the annealing were manually grinded i...

Embodiment 2

[0045] (1) The initial raw material with high pure CE (99.9 % block), Fe (99 % powder) and SB (99.999 % powder), according to the chemical measurement ratio CE CE 1.25 FE 4 SB 12 Illects.

[0046] (2) Mix the raw materials by hand by 10 minutes to mix it evenly. Then place the mixed powder into a clean graphite pupa; seal the graphite pupa in the quartz tube under the condition that the vacuum is less than 0.1MPa, and place it in the procedure to control the warm melting furnace. After 10 hours of melting, the melt was placed in saturated salt water and quenched to get the CE 1.25 FE 4 SB 12 Casting; put the quartz -containing quenching casting blocks in the high temperature furnace at 675 ° C for 168h, and the samples of the annealing were manually grinded into fine powder.

[0047] (3) The annealing powder after the optimization of the step (2) obtained by the optimization score is burned with a discharge plasma sintering method in the vacuum. The sintering temperature is 500 ° ...

Embodiment 3

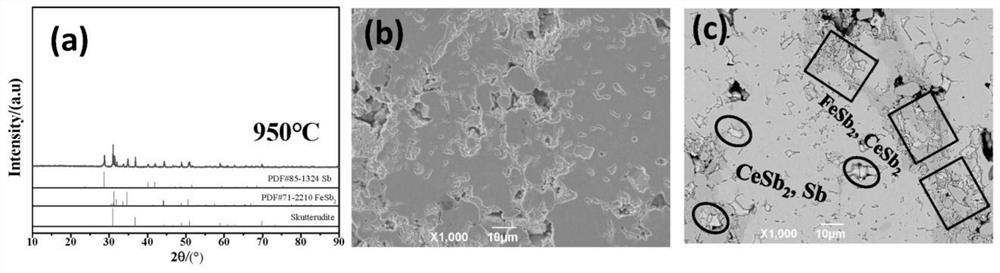

[0050] In this embodiment, the method of reducing the heat guidance rate of the CE -type CE -filled iron -filled iron -filled iron -filled cobalt mine thermal power material, except for changes in quenching temperature, the remaining preparation methods are the same as the embodiment 2, the quenching temperature increases to 1000 ° C.

[0051] The results of the powder X-ray diffraction analysis of the sarcasm show that the main phase of the sintering body is a cobalt mines, which contains more FESB 2 In the sb impurities, such as Figure 5 A shown. Compared with Example 2, impurities have decreased slightly. The BEI diagram of the light surface and EDS energy spectrum are the same as the XRD analysis results, such as Figure 5 C shown in. The SEI diagram of the light surface shows that the surface of the sample is relatively flat, and there are a small amount of hole structure, such as Figure 5 b.

[0052] The thermal conductivity of the block material after the SPS sintering was t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com