a tio 2 Doped uo 2 ‑10wt%gd 2 o 3 Burnable poison and its preparation method

A UO2 and mixed solution technology, applied in the field of TiO2-doped UO2-10wt% Gd2O3 combustible poison and its preparation, can solve the problems of reducing the sintering density, grain size and thermal conductivity of the combustible poison, and achieve good purity and crystal structure , Low sintering temperature and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

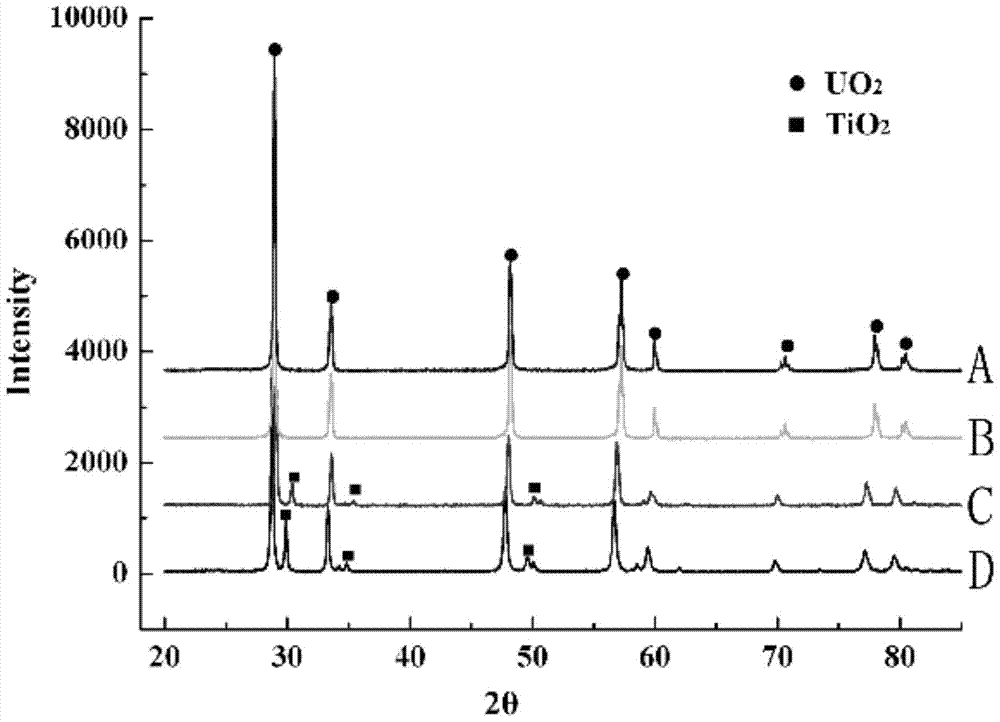

Embodiment 1

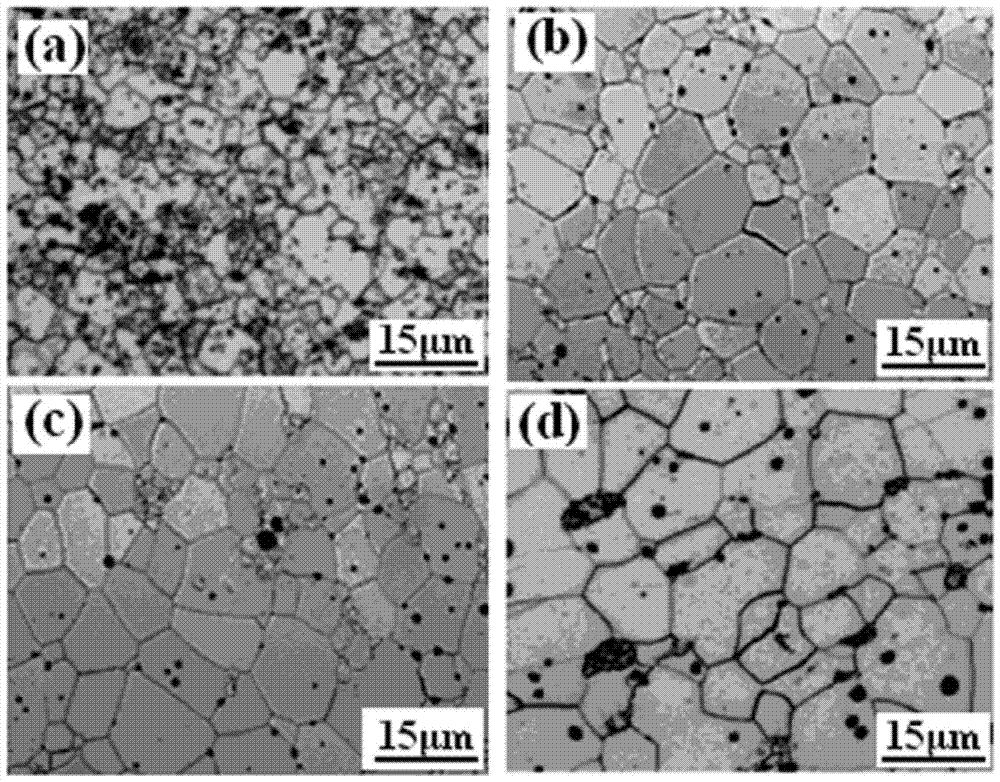

[0049] In the first step, nuclear-grade pure U 3 o 8 Drying at 350°C for 2.5h, the Gd with a purity of 99.9% 2 o 3 The powder was dried at 550°C for 2h. Press UO 2 -10wt%Gd 2 o 3 Gd in burnable poison 2 o 3 The mass fraction accounted for is 89.95g UO 2 Powder (89.95wt%), 10g Gd 2 o 3 Put the powder (10wt%) into the dissolving tank, add a certain amount of deionized water to it, and add an appropriate amount of concentrated nitric acid to dissolve under rapid stirring conditions. After dissolving for 25 minutes, filter out the insoluble matter to form UO 2 (NO 3 ) 2 and Gd(NO 3 ) 3 homogeneously mixed solution.

[0050] with TiO 2 Accounting for the mass ratio of the prepared combustible poison is calculated as (0.05)wt%, take 0.22g tetrabutyl titanate (TBT) and put it into a beaker, add a certain amount of deionized water to it, under rapid stirring conditions, After adding an appropriate amount of concentrated nitric acid to dissolve, a stable titanium sol s...

Embodiment 2

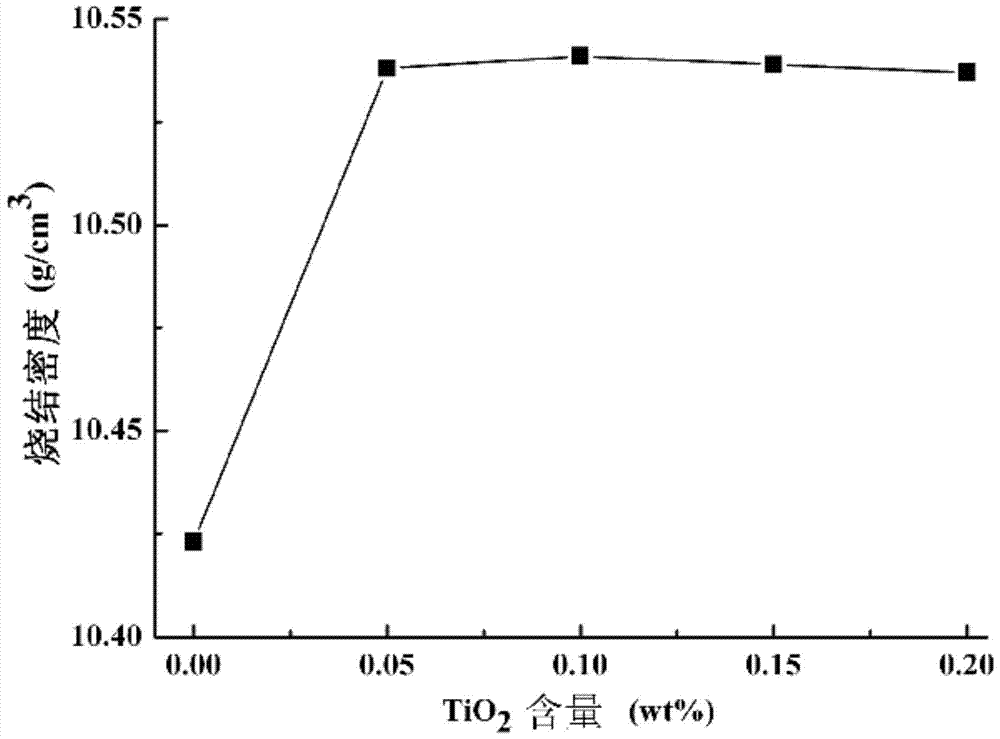

[0056] Adopt the same method as embodiment 1 to prepare TiO 2 doped UO 2 -10wt%Gd 2 o 3 Burnable poison, its difference with embodiment 1 is: TiO 2 The content accounting for the burnable poison is 0.1wt%, and the corresponding amount of tetrabutyl titanate taken by weighing is 0.45g, UO 2 The powder was 89.9 g (89.9 wt%).

[0057] The theoretical density of the burnable poison prepared above is not lower than 95% T.D., the grain size is 15.5 μm, and the thermal conductivity is 0.054W / (cm.°C).

Embodiment 3

[0059] Adopt the same method as embodiment 1 to prepare TiO 2 doped UO 2 -10wt%Gd 2 o 3 Burnable poison, its difference with embodiment 1 is: TiO 2 The content accounting for the burnable poison is 0.15wt%, and the corresponding amount of tetrabutyl titanate is 0.67g, UO 2 The powder was 89.85 g (89.85 wt %).

[0060] The theoretical density of the burnable poison prepared above is not lower than 95% T.D., the grain size is 15.6 μm, and the thermal conductivity is 0.055 W / (cm.° C.).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com