Electrolytic polishing solution and electrolytic polishing process used for additive manufacturing of titanium alloy fatigue specimen

An electrolytic polishing and additive manufacturing technology, applied in the field of electrolytic polishing process, can solve the problems of complex composition of titanium alloy fatigue samples and poor polishing process stability, and achieve the effects of fast polishing speed, easy operation and simple production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] For ease of understanding, the technical solutions of the present invention are further specifically described below in conjunction with the accompanying drawings and through embodiments:

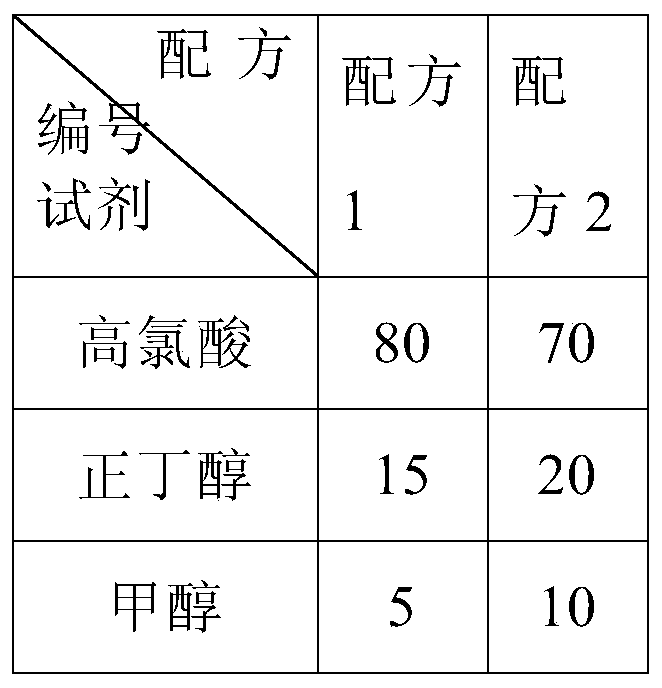

[0019] An electrolytic polishing solution for additively manufacturing titanium alloy fatigue samples, the polishing solution is prepared by volume fraction of 5-10% perchloric acid, 15-30% n-butanol and 60-80% methanol.

[0020] Methanol, perchloric acid and n-butanol were chemically pure or analytically pure reagents.

[0021] The electrolytic polishing process for the additive manufacturing of titanium alloy fatigue samples, the specific implementation steps are as follows:

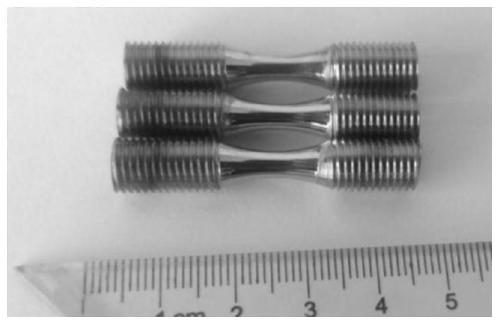

[0022] 1. Coarse grinding of samples: Additively manufactured Ti6Al4V alloy fatigue samples (with a maximum diameter of length 50mm) for metallographic sandpaper grinding, sandpaper models are 280 mesh, 400 mesh, 600 mesh, 800 mesh and 1200 mesh. Wash surface and blow dry.

[0023] 2. Prepare electrolytic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com