Preparation method of patterned polyethylene 4-thiol nickel thin film and device

A polyethylene tetrathiol and patterning technology, which is applied in the manufacture/processing of thermoelectric devices, and the material of the junction leads of thermoelectric devices, can solve the problems of difficult laser etching, plasma sputtering etching, hindering film growth, Difficulty and other problems, to achieve the effect of not easy lithography, easy preparation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

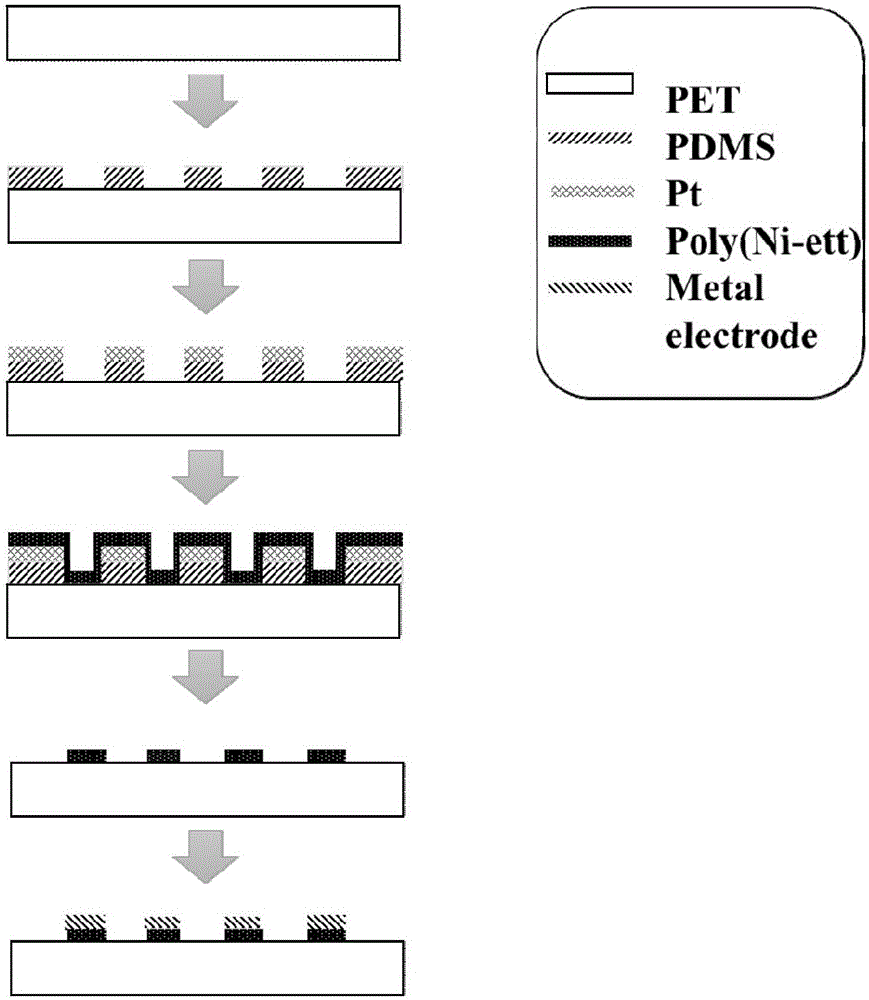

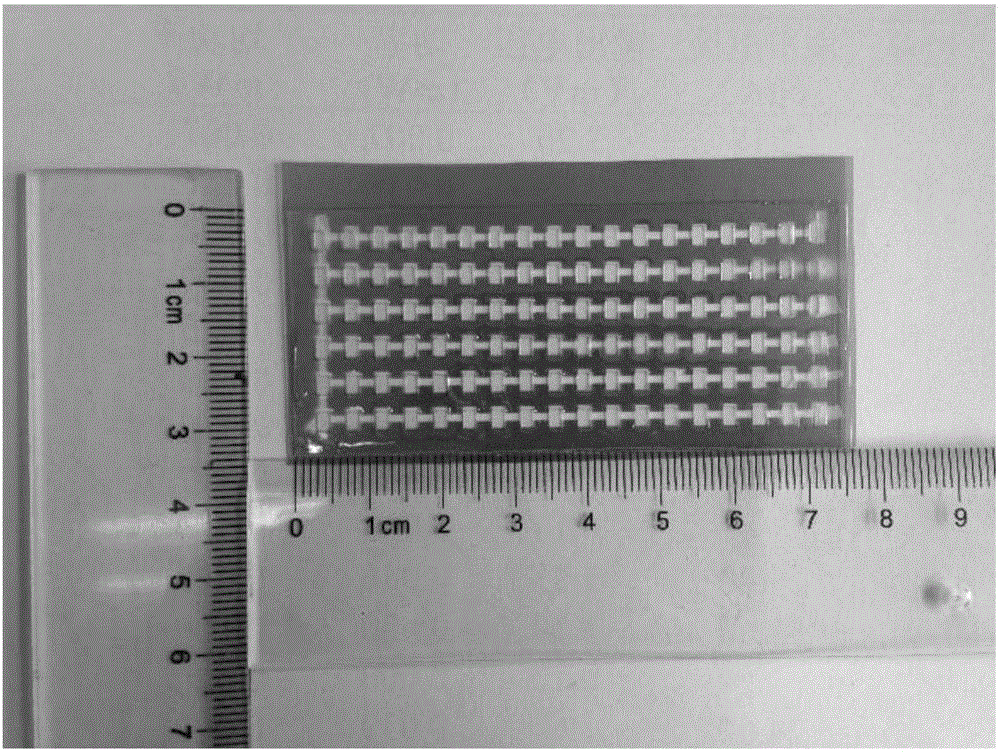

[0036]Example 1. Patterning of nickel polyethylene tetrathiol and preparation of N-type flexible devices

[0037] 1. Patterning of polyethylene tetramercaptan nickel

[0038] according to figure 1 Shown flow chart prepares the patterned polyethylene tetramercaptide nickel, concrete steps are as follows:

[0039] (1) Preparation of patterned polyethylene tetrathiol nickel film template:

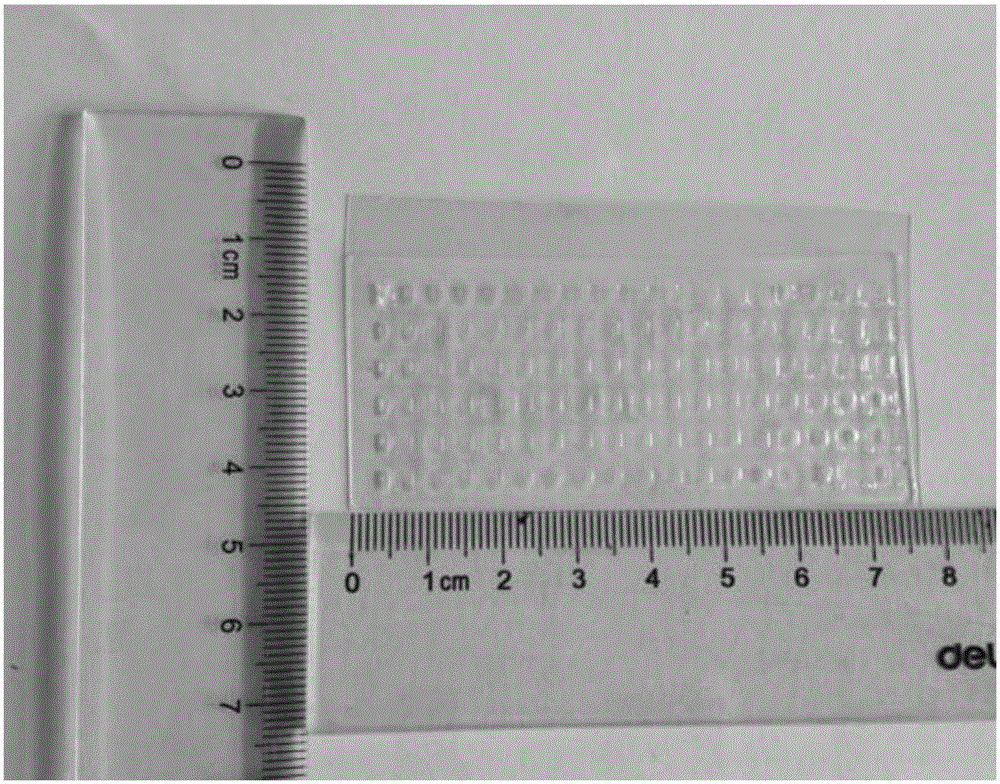

[0040] 1-1) According to the pre-designed pattern (6*18 rectangles of 2*3mm, the distance between each rectangle is 2mm), pattern the PDMS coating on the substrate PET surface to obtain a polymer template; the uncovered PDMS coating on the substrate The blank part of the layer forms the pattern, the specific steps are as follows:

[0041] Use the glue dispenser (2400, EFD) to program, design 6*18 rectangles of 2*3mm, the distance between each rectangle is 2mm, under the condition of gas pressure 30psi, movement speed 1mm / s, draw the rectangle with room temperature vulcanized silicone rubber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com