A kind of interlayer matrix material and preparation method of diamond cutter head

A diamond cutter head and carcass material technology, which is applied in the field of interlayer carcass material and diamond cutter head preparation, can solve the problems of a large amount of labor costs, the incompressibility of iron sheet interlayers, and the inability to use multi-layer automatic cold pressing equipment, etc. , to reduce the price and cost, facilitate the sintering of the carcass, and improve the brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention also relates to a preparation method of a diamond cutter head, comprising the following steps:

[0031] Step 1, prepare the interlayer carcass material, weigh 85-65% Fe, 8-15% Zn, 5-20% Cu and 2-5% ALSi powder by mass percentage, and stir uniformly for 45-90 minutes to obtain a uniform mixture. The interlayer carcass material;

[0032] Step 2, in the multi-layer automatic cold press, load the interlayer carcass material, the first working layer mixture, and the second working layer mixture into the corresponding hoppers respectively;

[0033] Step 3, the first working layer mixture is sent into the cavity, using 200-400KG / cm 2 The first pressure is pre-pressed, and the pre-pressed first blank is left in the mold cavity, staying in a suitable position, and a cavity filled with the interlayer carcass material is reserved above the first blank;

[0034] Step 4: Feed the interlayer carcass material into the mold cavity, fill up the cavity reserved ab...

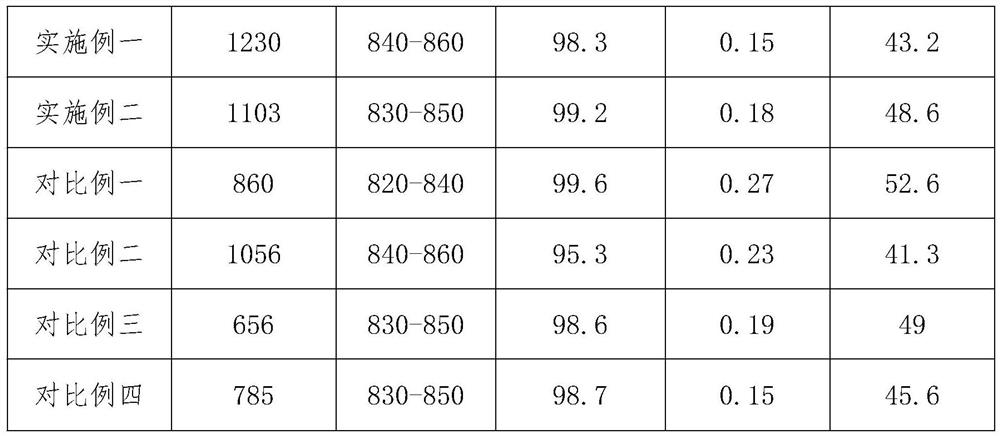

Embodiment 1

[0043] The preparation method of diamond cutter head in the present embodiment comprises the following steps:

[0044] Step 1: Prepare the interlayer carcass material, weigh 85% Fe, 8% Zn, 5% Cu and 2% ALSi powder by mass percentage, the powder particle size of the interlayer carcass material is 100-500 mesh, and the interlayer carcass The oxygen content of the material is 1500-3500PPM, and the three-dimensional mixer is used to uniformly stir for 45-90 minutes to obtain a uniformly mixed interlayer carcass material;

[0045] Step 2, in the multi-layer automatic cold press, load the interlayer carcass material, the first working layer mixture, and the second working layer mixture into the corresponding hoppers respectively;

[0046] Step 3, the first working layer mixture is sent into the cavity, using 200-400KG / cm 2 The first pressure is pre-pressed, and the pre-pressed first blank is left in the mold cavity, staying in a suitable position, and a cavity filled with the interla...

Embodiment 2

[0053] The preparation method of diamond cutter head in the present embodiment comprises the following steps:

[0054] Step 1: Prepare the interlayer carcass material, weigh 70% Fe, 15% Zn, 10% Cu and 5% ALSi powder by mass percentage, the powder particle size of the interlayer carcass material is 100-500 mesh, and the interlayer carcass The oxygen content of the material is 1500-3500PPM, and the three-dimensional mixer is used to uniformly stir for 45-90 minutes to obtain a uniformly mixed interlayer carcass material;

[0055] Step 2, in the multi-layer automatic cold press, load the interlayer carcass material, the first working layer mixture, and the second working layer mixture into the corresponding hoppers respectively;

[0056] Step 3, the first working layer mixture is sent into the cavity, using 200-400KG / cm 2 The first pressure is pre-pressed, and the pre-pressed first blank is left in the mold cavity, staying in a suitable position, and a cavity filled with the int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com