Method for improving precision of stepped components in laser spot-changing direct formation mode

A laser spot and laser technology, which is applied in the field of forming accuracy of wide components, can solve the problems of inconsistent growth height of the cladding layer, and achieve the effect of ensuring the forming quality and improving the forming accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

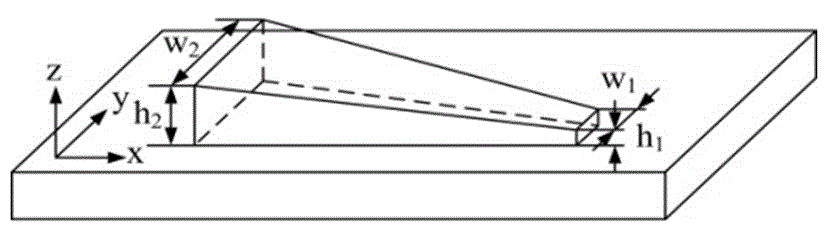

[0030] Embodiment one: see attached Figure 4 As shown in , it is a schematic diagram of the working principle of laser variable spot shaping. Based on the direct shaping of laser variable spots, this embodiment provides a method for improving the precision of components with unequal widths, including the following steps:

[0031] (1) Establish a three-dimensional forming part model with a computer, and process the model hierarchically through software to obtain the contour level information of the part;

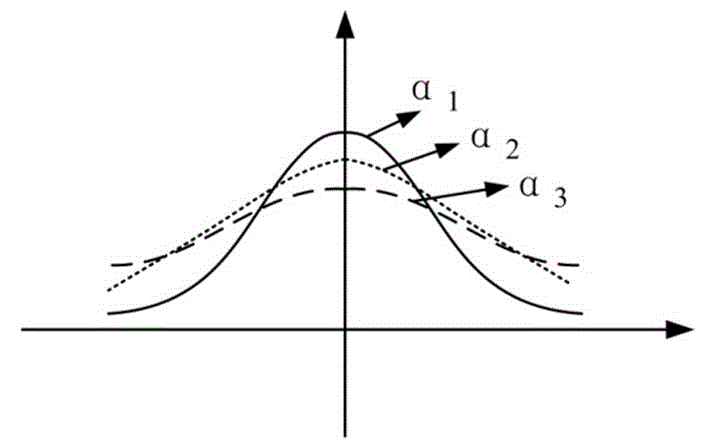

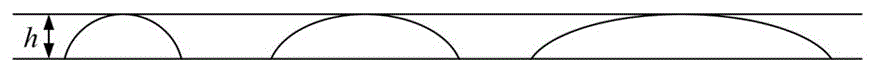

[0032] (2) See attached Figure 6 As shown, the driving device of the coaxial powder feeding nozzle is controlled, and the size of the laser spot is continuously adjusted in real time according to the size of the melting channel. During the process of laser spot change, the laser power, scanning speed and powder feeding amount are simultaneously adjusted for single-pass cladding. , measuring and obtaining the cross-sectional width and height data of a single cladding layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com