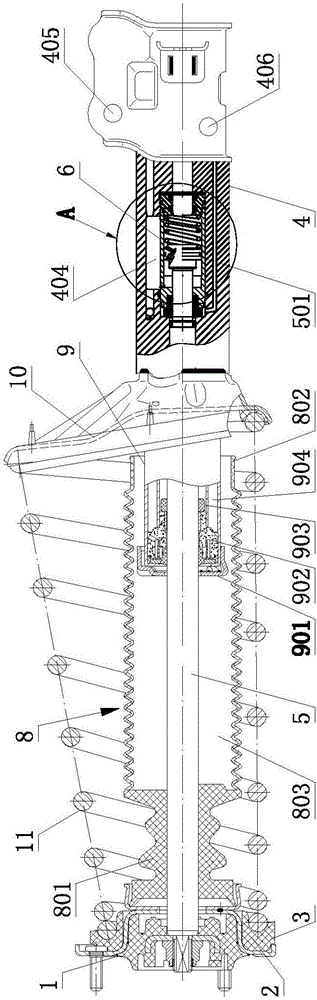

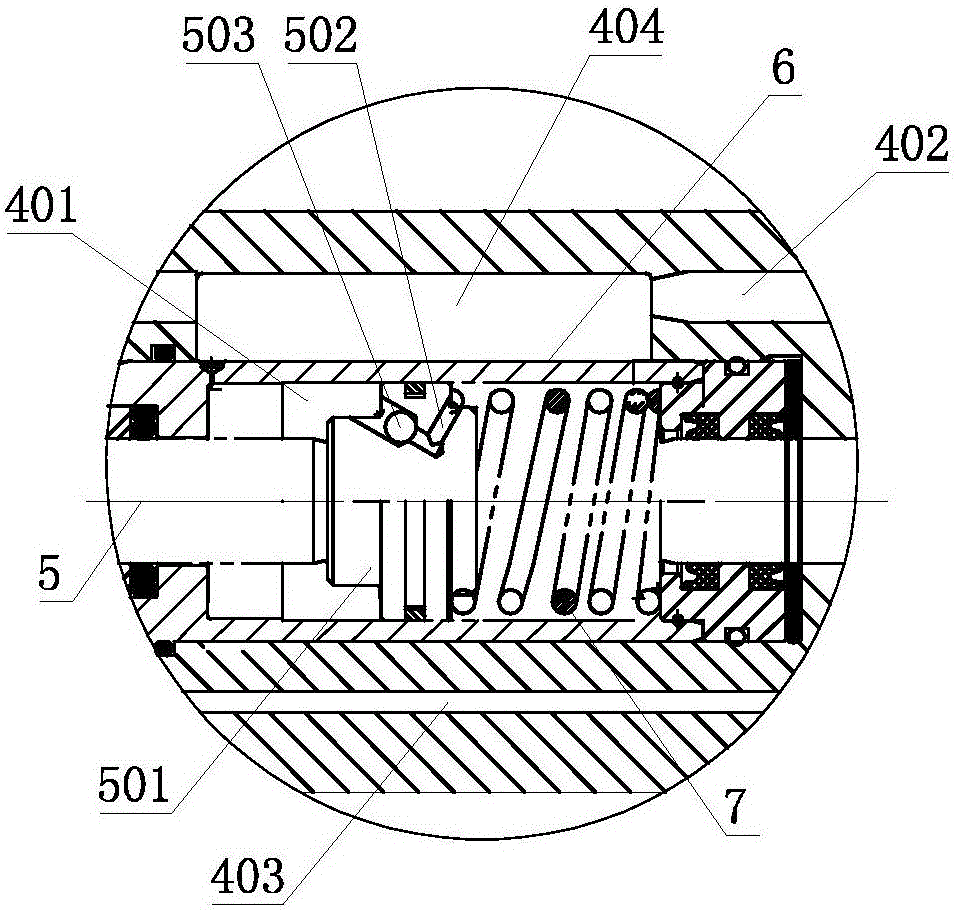

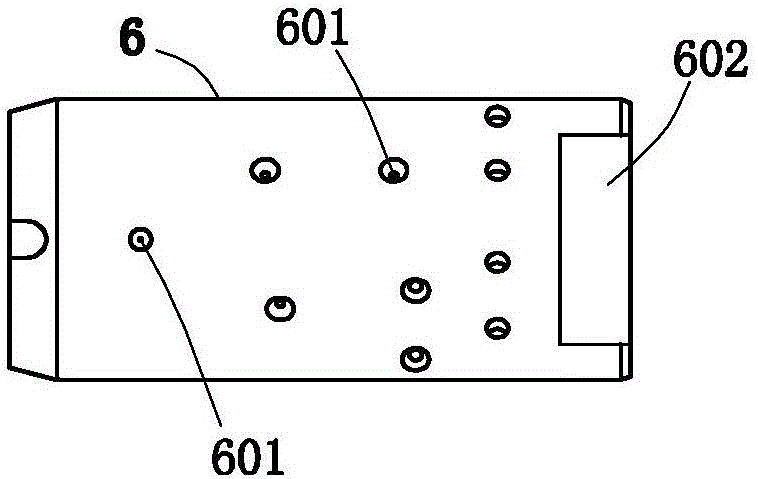

Automobile shock absorber

A technology for automobile shock absorbers and vehicles, applied in shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve the problem of short service life, poor shock absorption effect, and easy failure of shock absorber rebound ability. problems, to achieve the effect of simplifying the structure, facilitating maintenance, and reducing hydraulic components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0062]S1: Weigh 108 parts by mass of three-component composite elastic base material (composed of 100 parts by mass of nitrile rubber, 5 parts by mass of styrene-based thermoplastic elastomer (TPES) and 3 parts by mass of polyamide-based thermoplastic elastomer (TPAE) ), 1 part by mass of SiC whiskers with a length of 0.1-0.2mm, 2 parts by mass of dilaurate thiodipropionate, 0.1 part by mass of di-n-butyltin dilaurate, 0.3 parts by mass of ethylene-vinyl acetate copolymer ( EVA), 0.6 parts by mass of methacryloxypropyltrimethoxysilane, 1.2 parts by mass of 4,4'-diaminobicyclohexylmethane and 2 parts by mass of silicon dioxide powder with a particle size of 50-100nm;

[0063] S2: Add SiC whiskers, dilaurate thiodipropionate, ethylene-vinyl acetate copolymer (EVA), and methacryloxypropane with a total amount of 20% to the three-component composite elastic base material. Trimethoxysilane (0.12 parts by mass) and 4,4'-diaminobicyclohexylmethane (0.96 parts by mass) in a total amou...

preparation example 2

[0066] S1: Weigh 112 parts by mass of three-component composite elastic base material (composed of 100 parts by mass of nitrile rubber, 10 parts by mass of styrene thermoplastic elastomer (TPES) and 2 mass parts of polyamide thermoplastic elastomer (TPAE) ), 2 parts by mass of SiC whiskers with a length of 0.1-0.2mm, 1 part by mass of dilaurate thiodipropionate, 0.3 parts by mass of di-n-butyltin dilaurate, 0.2 parts by mass of ethylene-vinyl acetate copolymer ( EVA), 0.9 parts by mass of methacryloxypropyltrimethoxysilane, 1 part by mass of 4,4'-diaminobicyclohexylmethane and 3 parts by mass of silicon dioxide powder with a particle size of 50-100nm;

[0067] S2: Add SiC whiskers, dilaurate thiodipropionate, ethylene-vinyl acetate copolymer (EVA), and methacryloxypropane in a total amount of 30% to the three-component composite elastic base material. Trimethoxysilane (0.27 parts by mass) and 4,4'-diaminobicyclohexylmethane (0.7 parts by mass) in a total amount of 70%, and the...

preparation example 3

[0070] S1: Weigh 110 parts by mass of three-component composite elastic base material (composed of 100 parts by mass of nitrile rubber, 7.5 parts by mass of styrene-based thermoplastic elastomer (TPES) and 2.5 parts by mass of polyamide-based thermoplastic elastomer (TPAE) ), 1.5 parts by mass of SiC whiskers with a length of 0.1-0.2mm, 1.5 parts by mass of dilaurate thiodipropionate, 0.2 parts by mass of di-n-butyltin dilaurate, 0.25 parts by mass of ethylene-vinyl acetate copolymer ( EVA), 0.8 parts by mass of methacryloxypropyltrimethoxysilane, 1.1 parts by mass of 4,4'-diaminobicyclohexylmethane and 2.5 parts by mass of silicon dioxide powder with a particle size of 50-100nm;

[0071] S2: Add SiC whiskers, dilaurate thiodipropionate, ethylene-vinyl acetate copolymer (EVA), and methacryloxypropane in a total amount of 25% to the three-component composite elastic base material. Trimethoxysilane (0.2 parts by mass) and 4,4'-diaminobicyclohexylmethane (0.825 parts by mass) in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com