Method for extracting perillaldehyde from perilla

A technology of perilla aldehyde and perilla, which is applied in the field of extraction, can solve the problems of complex chemical synthesis process, reduce the content of perillaldehyde, and the extraction effect is not good enough, so as to prolong the storage time, improve the quality and utilization rate, and improve the purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for extracting perillaldehyde from perilla, comprising the following steps:

[0035] (1) Pretreatment: Wash the perilla leaves and perilla calyxes in the flowering stage with water and grind to extract the juice, take the perilla juice, soak the remaining perilla residue with ethyl acetate with a material-to-liquid ratio of 1:3 for 2 hours, Take the soaking liquid and mix it with perilla juice, add 2% borax solution to the water-soluble rosmarinic acid, grind it thoroughly, evaporate and concentrate to half the volume of the previous solution, and then add the treated antioxidant to the perilla juice;

[0036] (2) Acidification and enzymolysis: first cellulase: pectinase: xylanase: xylosidase is made into compound enzyme, then trichoderma, actinomycetes and Bacillus sp. After mixing at a ratio of %, add 1.5mol / L glucose solution to make a complex microbial flora, then add the complex microbial flora and stir for 3 hours at a speed of 50rpm, add citric acid to t...

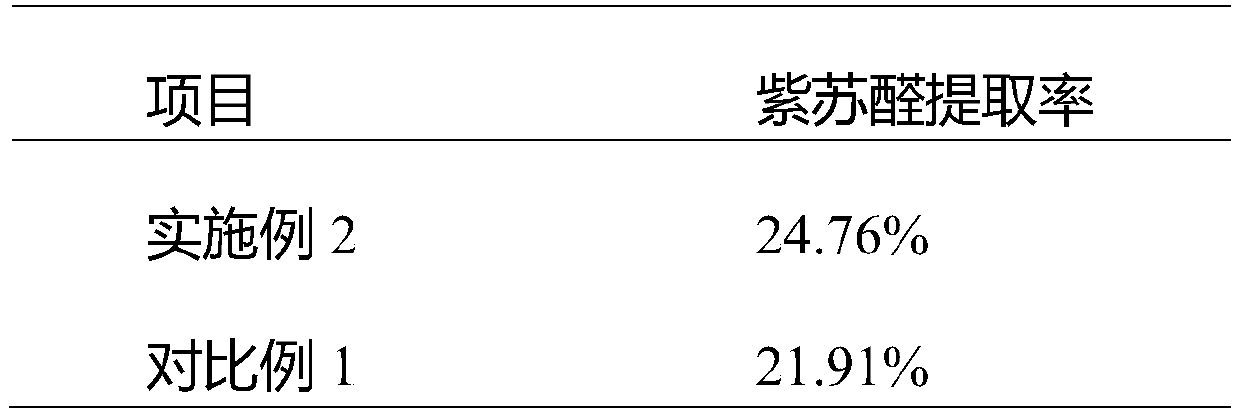

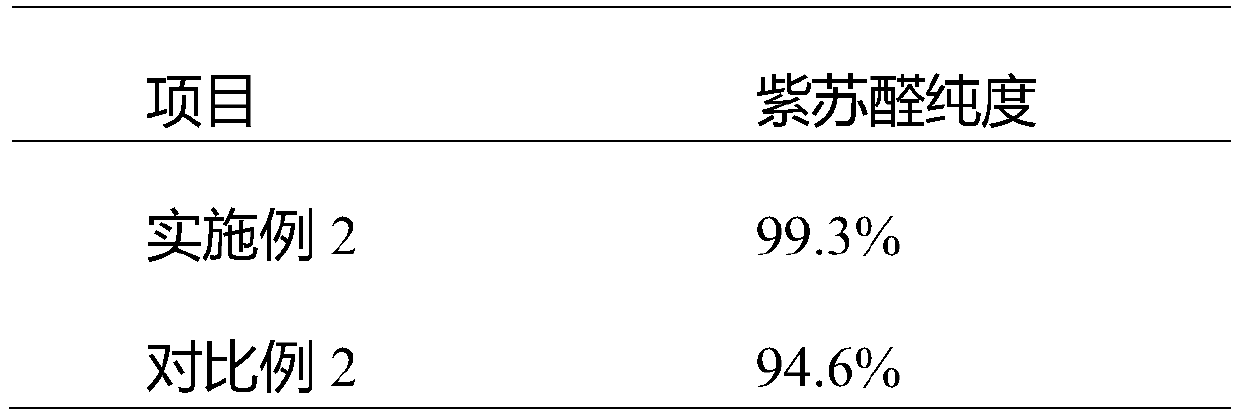

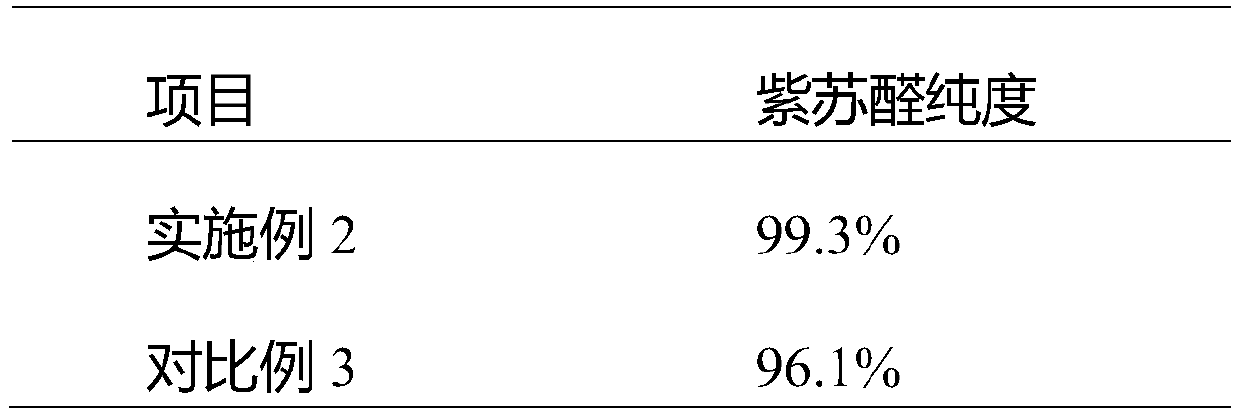

Embodiment 2

[0049] A method for extracting perillaldehyde from perilla, comprising the following steps:

[0050] (1) Pretreatment: Wash the perilla leaves and perilla calyxes in the flowering stage with water and grind to extract the juice, take the perilla juice, soak the remaining perilla residue with ethyl acetate with a material-to-liquid ratio of 1:3 for 2 hours, Take the soaking liquid and mix it with perilla juice, add 2% borax solution to the water-soluble rosmarinic acid, grind it thoroughly, evaporate and concentrate to half the volume of the previous solution, and then add the treated antioxidant to the perilla juice;

[0051] (2) Acidification and enzymolysis: first cellulase: pectinase: xylanase: xylosidase is made into compound enzyme, then trichoderma, actinomycetes and Bacillus sp. After mixing at a ratio of %, add 2.5mol / L glucose solution to make a complex microbial flora, then add the complex microbial flora and stir for 3 hours at a speed of 60rpm, add citric acid to t...

Embodiment 3

[0064] A method for extracting perillaldehyde from perilla, comprising the following steps:

[0065] (1) Pretreatment: wash the perilla leaves and perilla calyxes in the flowering stage with water and grind to extract the juice, take the perilla juice, soak the remaining perilla residue with ethyl acetate with a material-to-liquid ratio of 1:3 for 2 hours, Take the soaking liquid and mix it with perilla juice, add 2% borax solution to the water-soluble rosmarinic acid, grind it thoroughly, evaporate and concentrate to half the volume of the previous solution, and then add the treated antioxidant to the perilla juice;

[0066] (2) Acidification and enzymolysis: first cellulase: pectinase: xylanase: xylosidase is made into compound enzyme, then trichoderma, actinomycetes and Bacillus sp. After mixing at a ratio of %, add 1.5mol / L glucose solution to make a complex microbial flora, then add the complex microbial flora and stir for 3 hours at a speed of 70rpm, add citric acid to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com