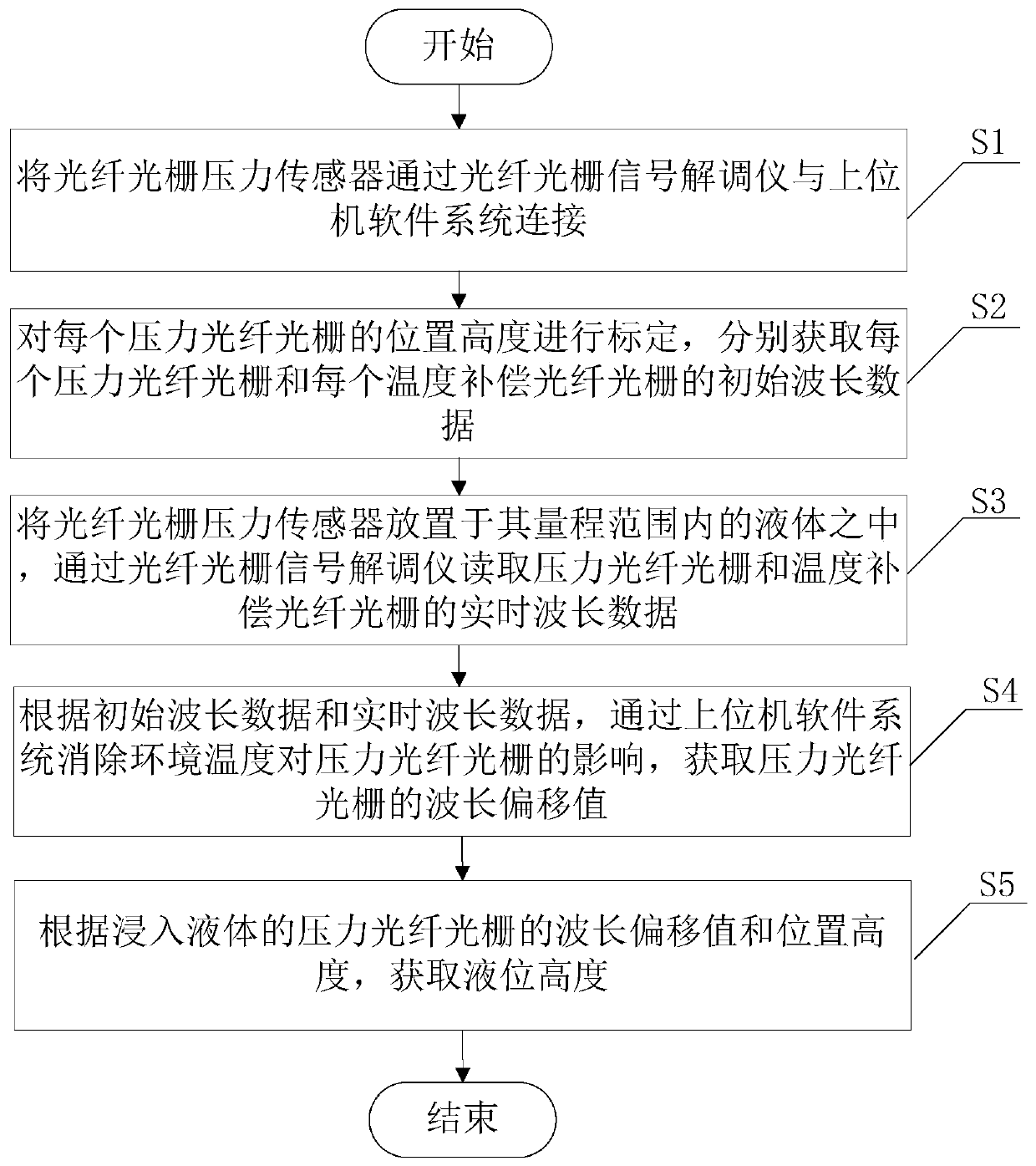

Fiber grating pressure sensor and using method thereof

A pressure sensor and fiber grating technology, applied in the field of data sensors, can solve the problems of insufficient pressure sensitivity and temperature compensation, and achieve the effects of enhanced sensitivity, small resilience and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific embodiments of the present invention are described below so that those skilled in the art can understand the present invention, but it should be clear that the present invention is not limited to the scope of the specific embodiments. For those of ordinary skill in the art, as long as various changes Within the spirit and scope of the present invention defined and determined by the appended claims, these changes are obvious, and all inventions and creations using the concept of the present invention are included in the protection list.

[0038] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

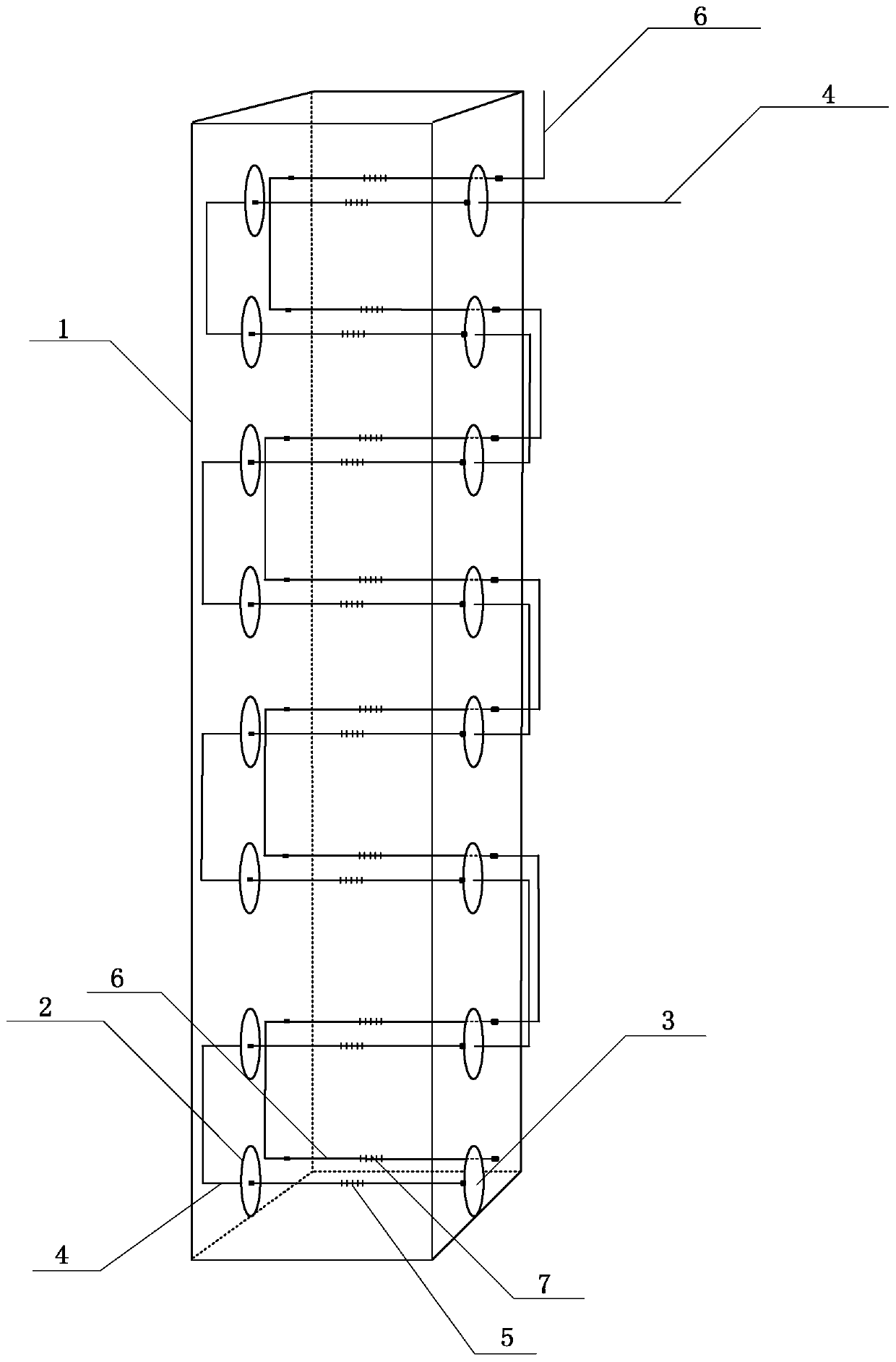

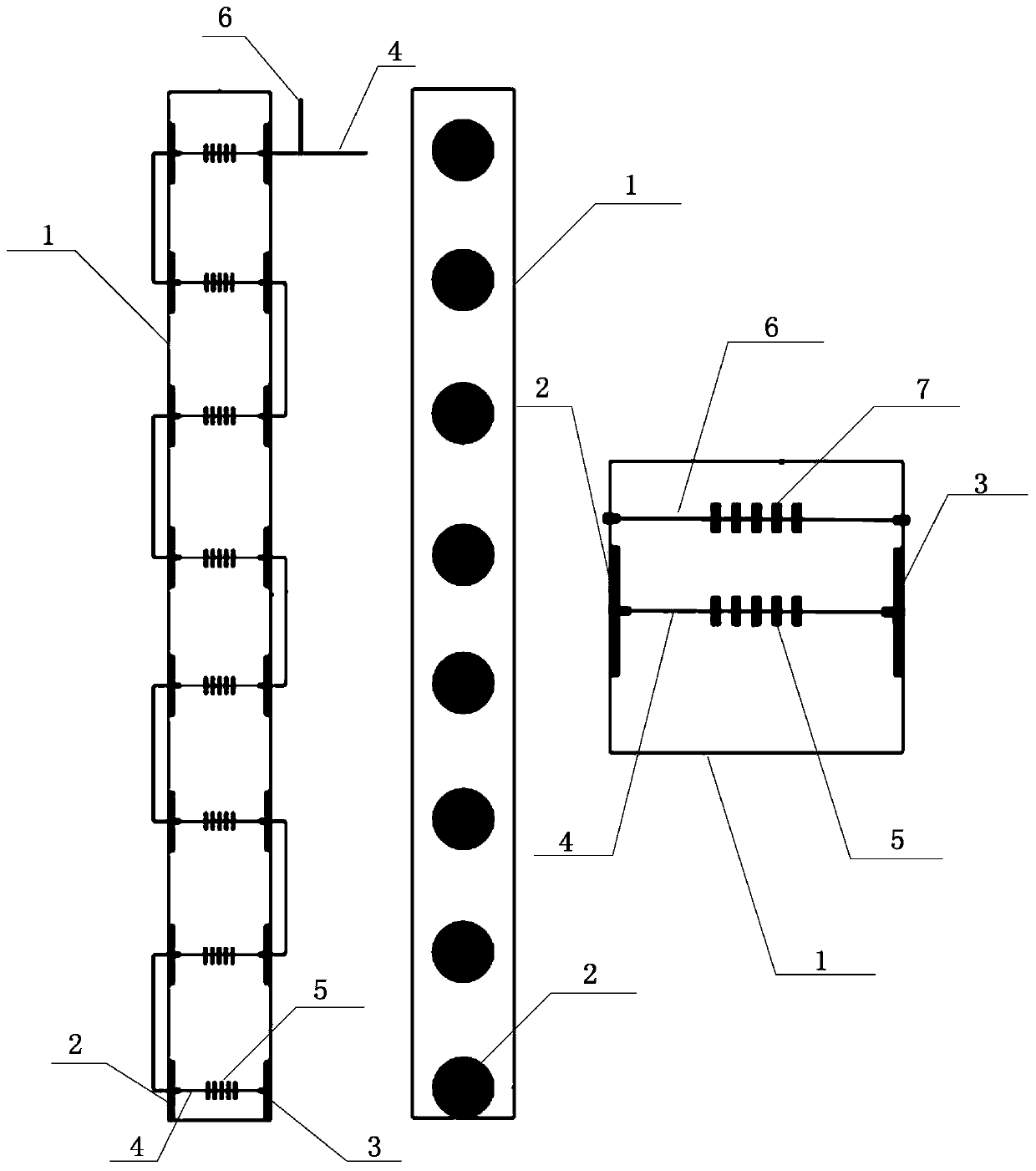

[0039] Such as figure 1 and figure 2 Commonly shown, a fiber grating pressure sensor includes a housing 1 and a pressure optical fiber 4. The housing 1 is a cuboid with a cavity, and the center line of one side is provided with N first round holes at equal intervals. Each of the first round holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com