Saw blade polishing device capable of polishing swingingly

A technology of saw blades and swinging brackets, which is applied to tool trimming of sawing machines, metal sawing equipment, metal processing equipment, etc. It can solve the problems of poor cutting effect, blunt saw teeth, and unsatisfactory cutting effect, so as to reduce resistance, The effect of smoothing the sides of the sawtooth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The oscillating and sharpening saw blade sharpening device of the present invention will be further described below with reference to the accompanying drawings and embodiments.

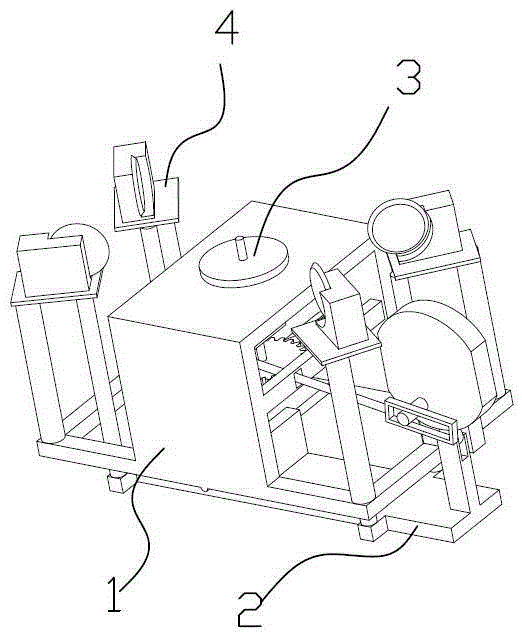

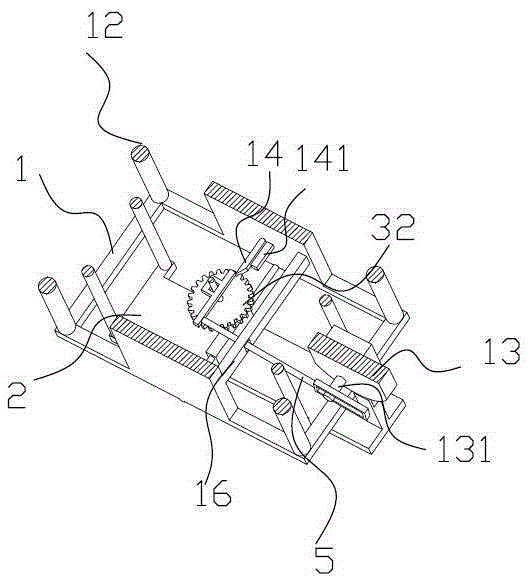

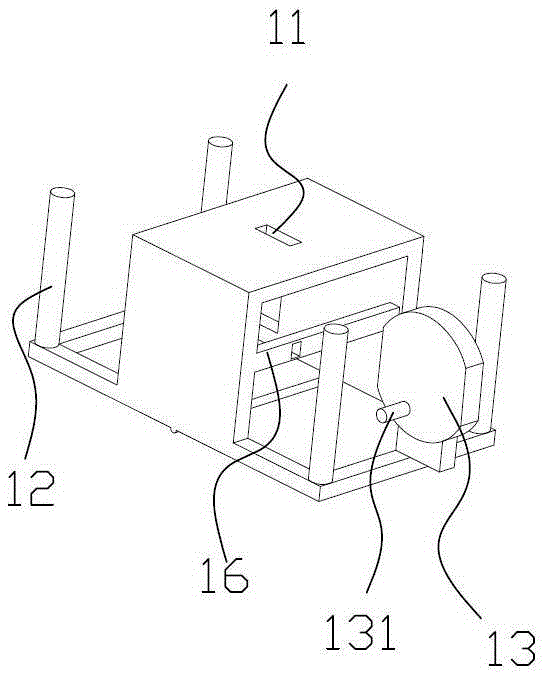

[0021] A saw blade sharpening device that can be shaken and sharpened, such as Figures 1 to 5 Shown, for sharpening the teeth of saw blades. Includes main frame, rocking frame, saw blade holder, and grinding motor. Specifically, a grinding platform extends upwards from the center of the main bracket, and the grinding platform is provided with a fixed disk rotation hole, and the fixed disk rotation hole is rectangular. The saw blade fixed disk is a circular flat plate structure, and its center is vertically extended along the upper and lower sides to extend the rotation axis. The rotation axis passes through the rotation hole of the fixed disk and is rotatably connected with the main bracket, and the rotation axis can be fixed Move in the disc rotation hole. A motor fixing column connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com