Backlight assembling structure of vehicle-mounted display screen

A technology for assembling structure and display screen, applied in the directions of optics, nonlinear optics, instruments, etc., can solve the problems of affecting the display effect of the display screen, poor force MURA, uneven brightness of the display, etc., to avoid weight and flatness problems, Solve the problem of rainbow pattern and avoid the effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

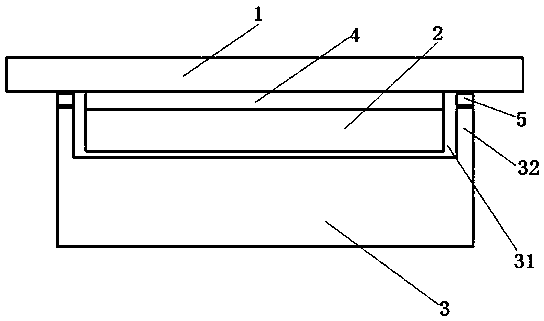

[0023] A backlight assembly structure of a vehicle-mounted display of the present invention, such as figure 1 As shown: it includes a cover structure 1, a display screen 2 and a display backlight 3. A groove 31 matching the display screen 2 is arranged in the display screen backlight 3, and the display screen 2 is installed in the groove 31 and connected with the groove 31 is provided with a gap, the upper surface of the display screen 2 is closely and fully bonded to the lower surface of the cover structure 1 through the first adhesive layer 4, and the upper surface of the groove frame 32 of the groove 31 of the display screen backlight 3 passes through the first adhesive layer 4. The second adhesive layer 5 is in close contact with the lower surface of the cover plate structure 1 .

[0024] Wherein, the first adhesive layer 4 is an OCA optical adhesive layer, and the thickness range of the OCA optical adhesive layer is 0.5-0.1 mm; the second adhesive layer 5 is an OCA optica...

Embodiment 2

[0028] The difference between this embodiment and Embodiment 1 lies in the cover plate structure 1 .

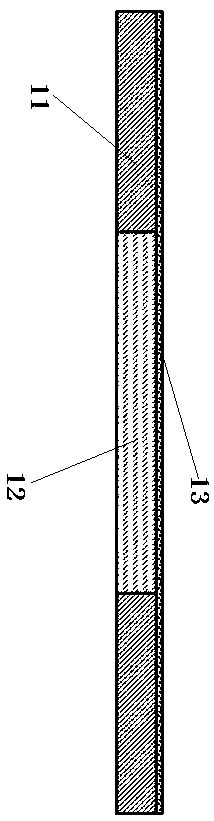

[0029] In this embodiment, the cover plate structure 1 is as figure 2 Shown:

[0030] The cover plate structure 1 includes a cover plate 11 and a transparent panel 12, the transparent panel 12 is set in the cover plate 11, the transparent panel 12 corresponds to the window of the display screen 2; a diaphragm is pasted on the upper surface of the cover plate 11 13; the diaphragm 13 is a FILM diaphragm. Wherein, the thickness of the transparent panel 12 is the same as that of the cover plate 11, and the transparent panel 12 includes a PC plate and a PMMA plate; the cover plate 11 is an IML cover plate, and the transparent panel 12 is set in the cover plate 11, that is, the transparent panel 12 is injected into the IML. in the cover.

[0031] In this embodiment, a transparent panel 12 corresponding to the window of the display screen 2 is placed in the cover plate 11. Since...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com