Improved diamond idler wheel trimmer

A diamond roller and dresser technology, applied in metal processing equipment, grinding machine parts, abrasive surface adjustment devices, etc., can solve the problems affecting the grinding performance of machine tools, uneven alternating force, short bearing life, etc. The effect of improving the quality of trimming, uniform force and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

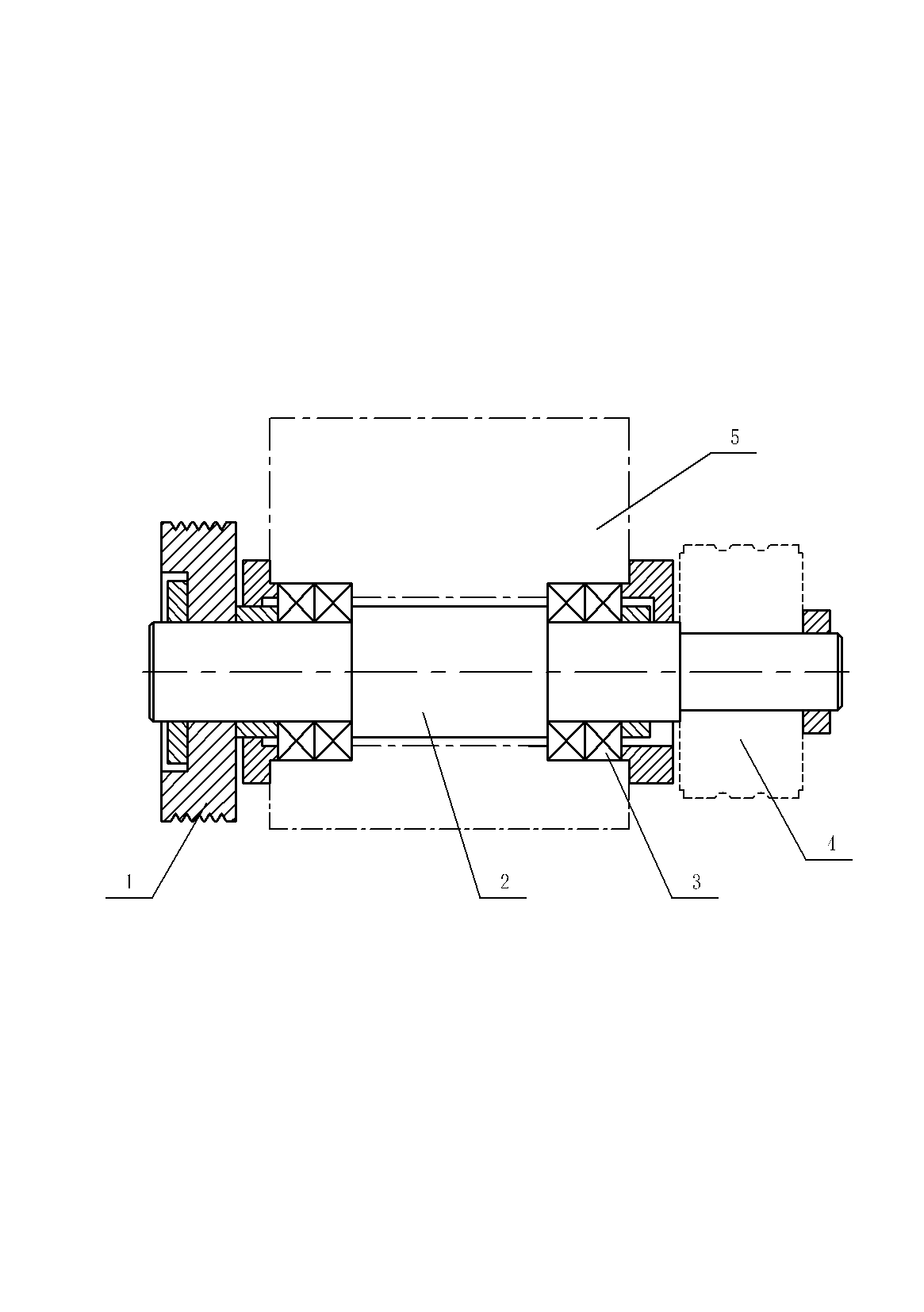

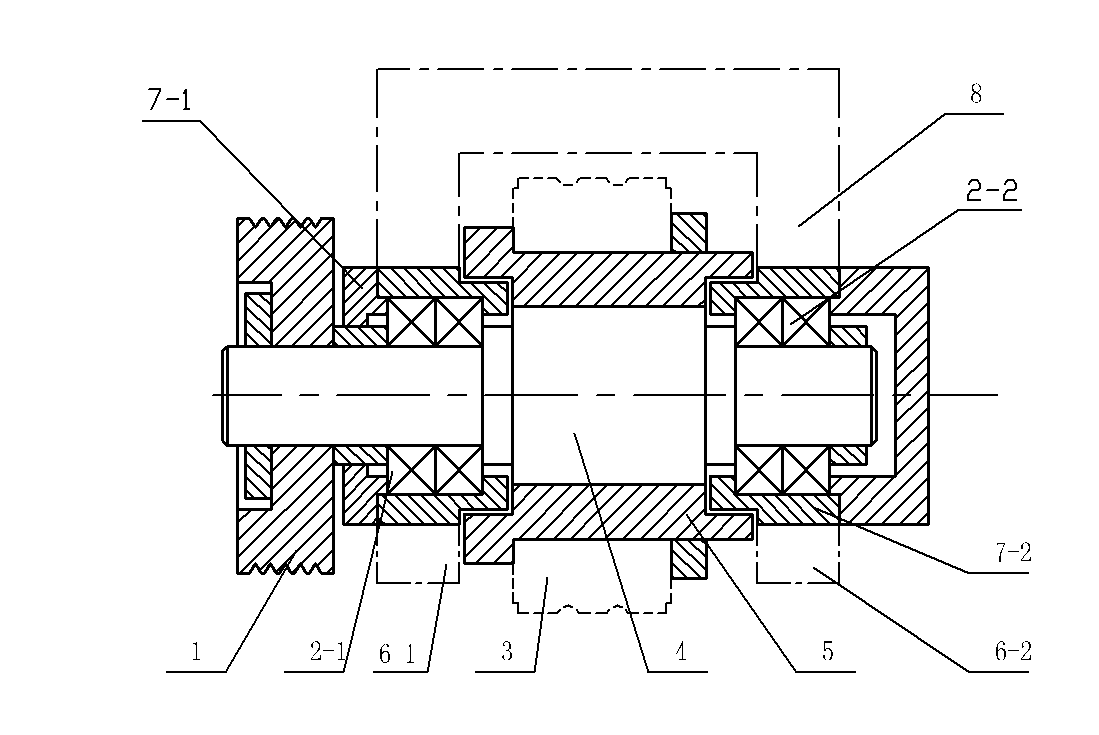

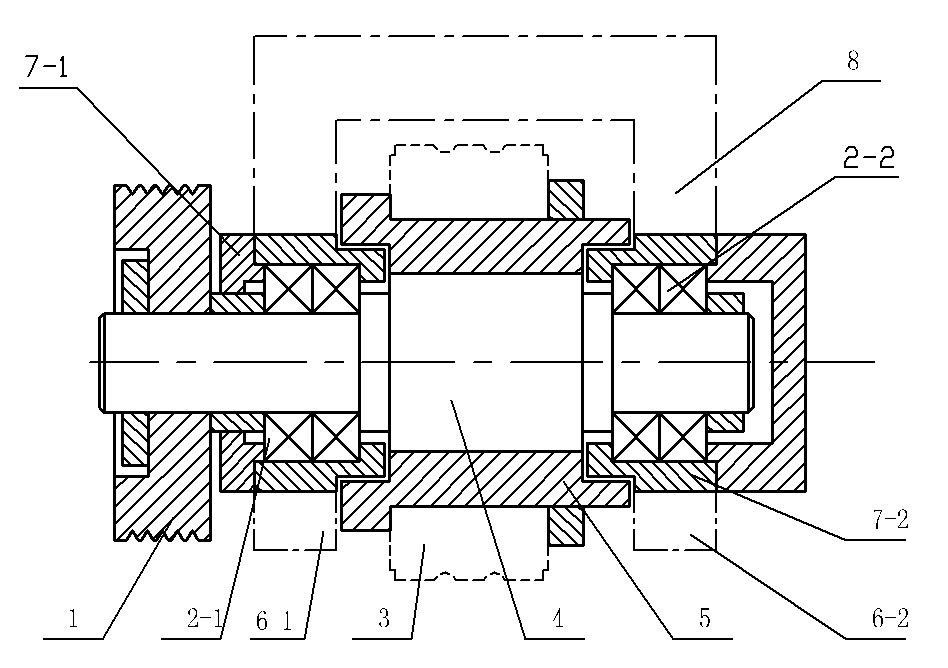

[0009] See figure 2 , the improved diamond roller dresser of the present invention includes a housing fixing device and a dressing rotary device. The dressing rotary device includes a main shaft 4, and the main shaft 4 passes through two gear bearings 2-1, 2-2, and bearing seats 7-1, 7-2, Rotationally installed on the housing fixing device, one end of the main shaft 4 is connected with the pulley 1, the housing fixing device includes a support 6, a housing 8, the main shaft 4 is fitted into the roller sleeve 5 with an interference fit, and the outer diameter of the roller sleeve 5 is larger than the bearing Outer diameter of seat 7-1,7-2, roller cover 5 is positioned between two gear bearings 2-1,2-2, diamond roller 3 is installed on the roller cover 5. The housing 8 covers the main shaft 4 and is matedly connected with the support 6 .

[0010] The main shaft 4 is rotated through the bearings 2-1, 2-2 at both ends of the roller sleeve 5, and the bearing housing 7-1, 7-2. Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com