Electric grape branch pruner

A technology of pruning machines and electric motors, which is applied in orchard operating machinery and gardening fields, can solve the problems of reducing the labor intensity of operators, and achieve the effects of improving pruning quality, light weight, and avoiding easy wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

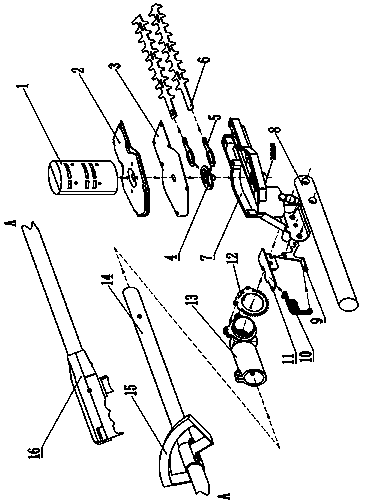

[0021] The structure and assembly of the electric grape branch pruning machine of this embodiment are as attached figure 1 shown.

[0022] In this embodiment, the motor 1 and the power transmission mechanism are assembled and connected with the simplest keyway structure, that is, the power output shaft of the motor and the transmission shaft of the power transmission mechanism are on the same axis, and the key head at the end of the power output shaft of the motor is inserted into the power transmission mechanism. In the groove of the drive shaft of the transmission mechanism.

[0023] See attached figure 1 , the power transmission mechanism of this embodiment is formed by upper cover 2, pressing plate 3, double crank shaft plate 4, upper and lower connecting rods 5 and housing 7, and the housing 7, pressing plate 3 and housing upper cover 2 combine the hyperbolic The shaft plate 4 and the upper and lower connecting rods 5 are axially limited, and the convex key at the end o...

Embodiment 2

[0029] In this embodiment, the power transmission mechanism, blade angle adjustment mechanism, extension bar and power control switch are the same as those in Embodiment 1, the difference is that the motor used in this embodiment is a composite motor with a gear transmission mechanism. It is a combination of ordinary DC brushed motor and variable speed gearbox.

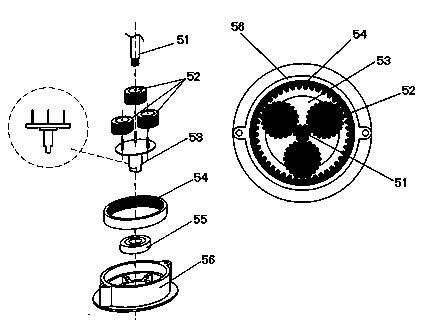

[0030] The composite motor structure of this embodiment is as attached image 3As shown, the composite motor is composed of three axial parts: a DC brushed motor, a cooling fan, and a gear box. The DC brushed motor is fixedly connected with the motor fixing plate 42, the gear box upper cover 43 and the gear box case 44 through the positioning pin 41 to form a whole. The reversing carbon brushes 34 of the motor, the cooling fan 35 and the gear box are all arranged along the axial direction of the motor rotor main shaft 31 . The cooling fan 35 is arranged on the top of the motor rotor main shaft 31 , and the motor rev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com