Urban green belt repairing robot

A green belt and robot technology, applied in the directions of manipulators, agricultural machinery and implements, equipment for trimming hedges, etc., can solve problems such as less intelligent trimming, and achieve the effect of intelligent trimming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

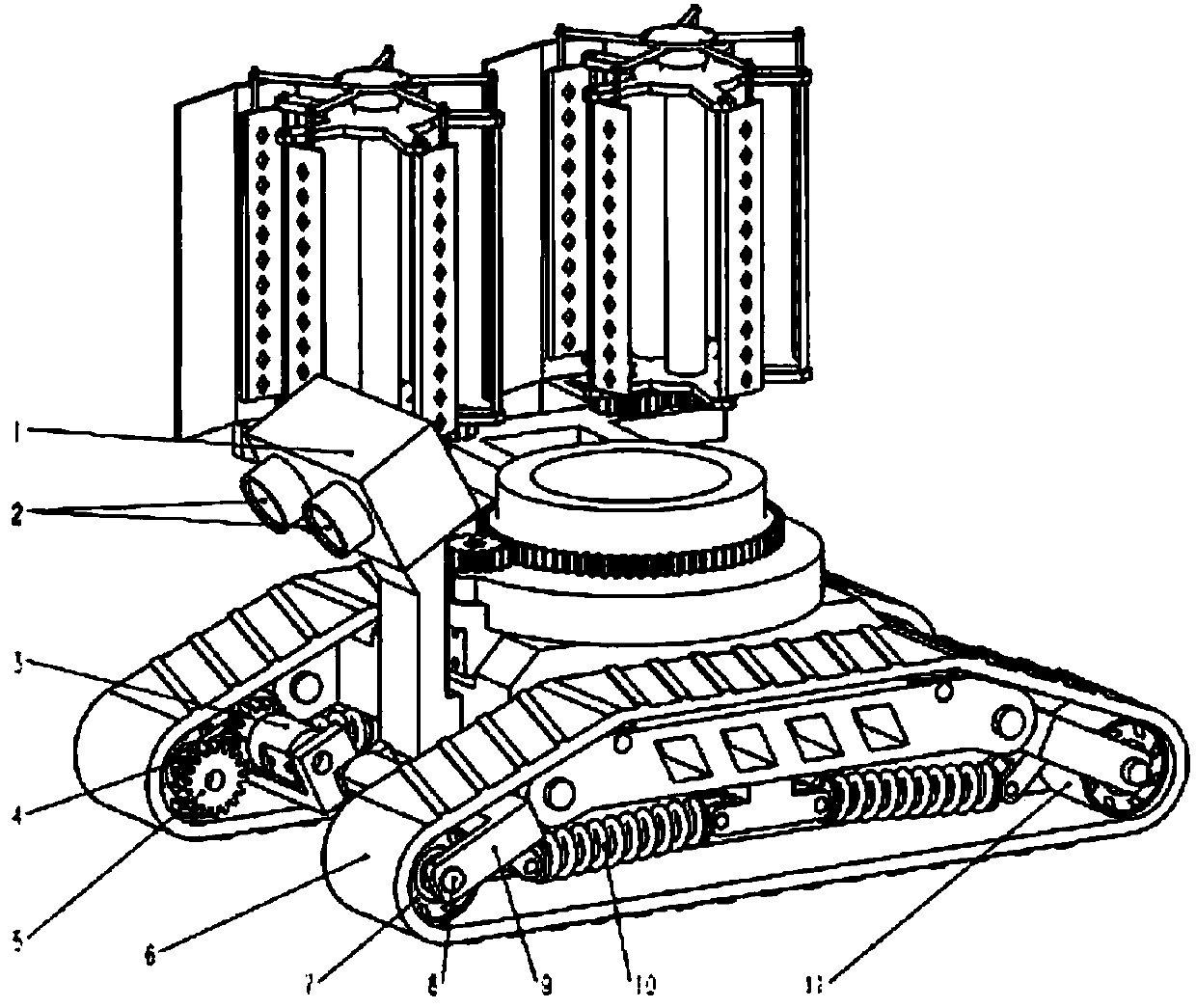

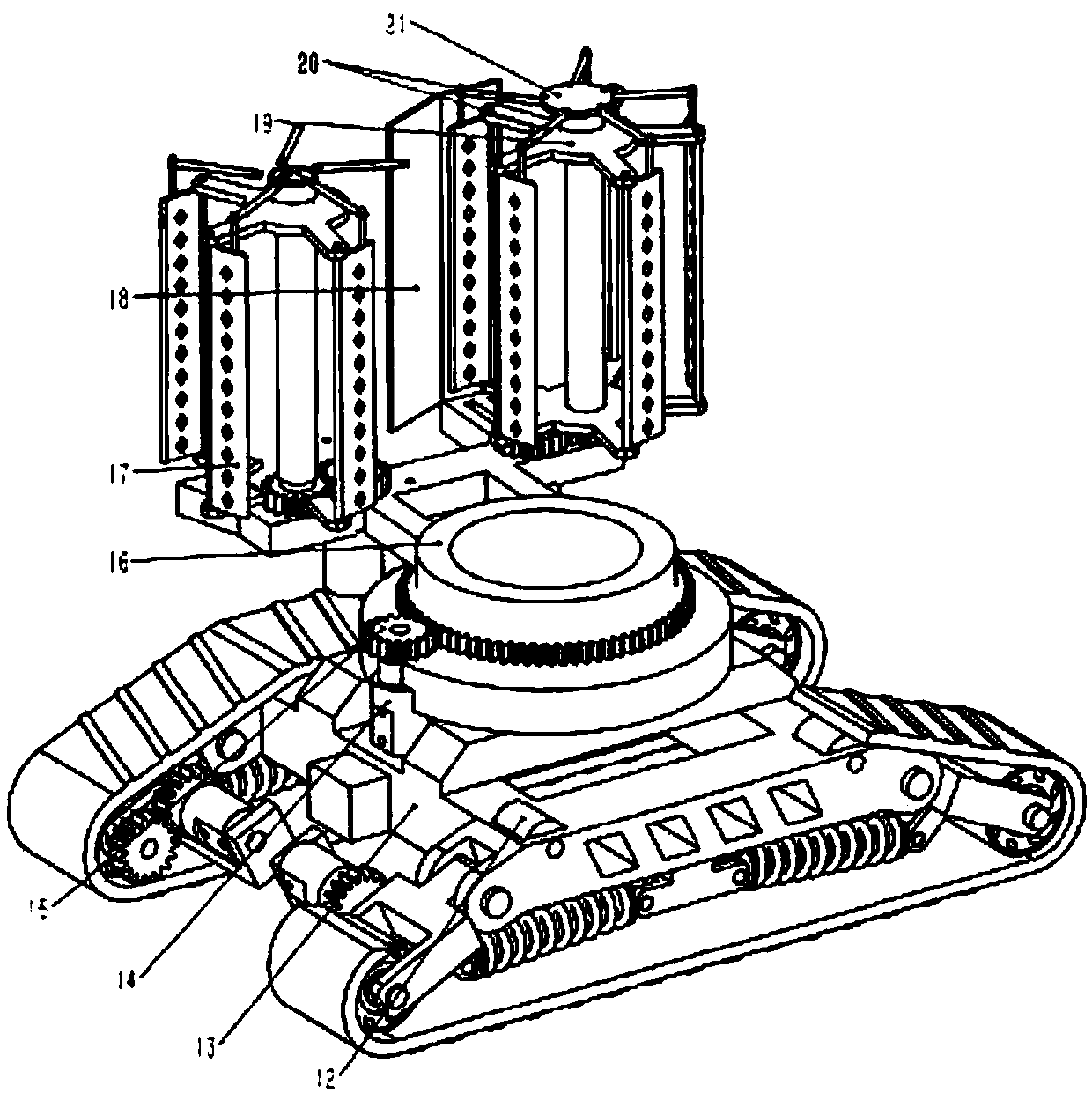

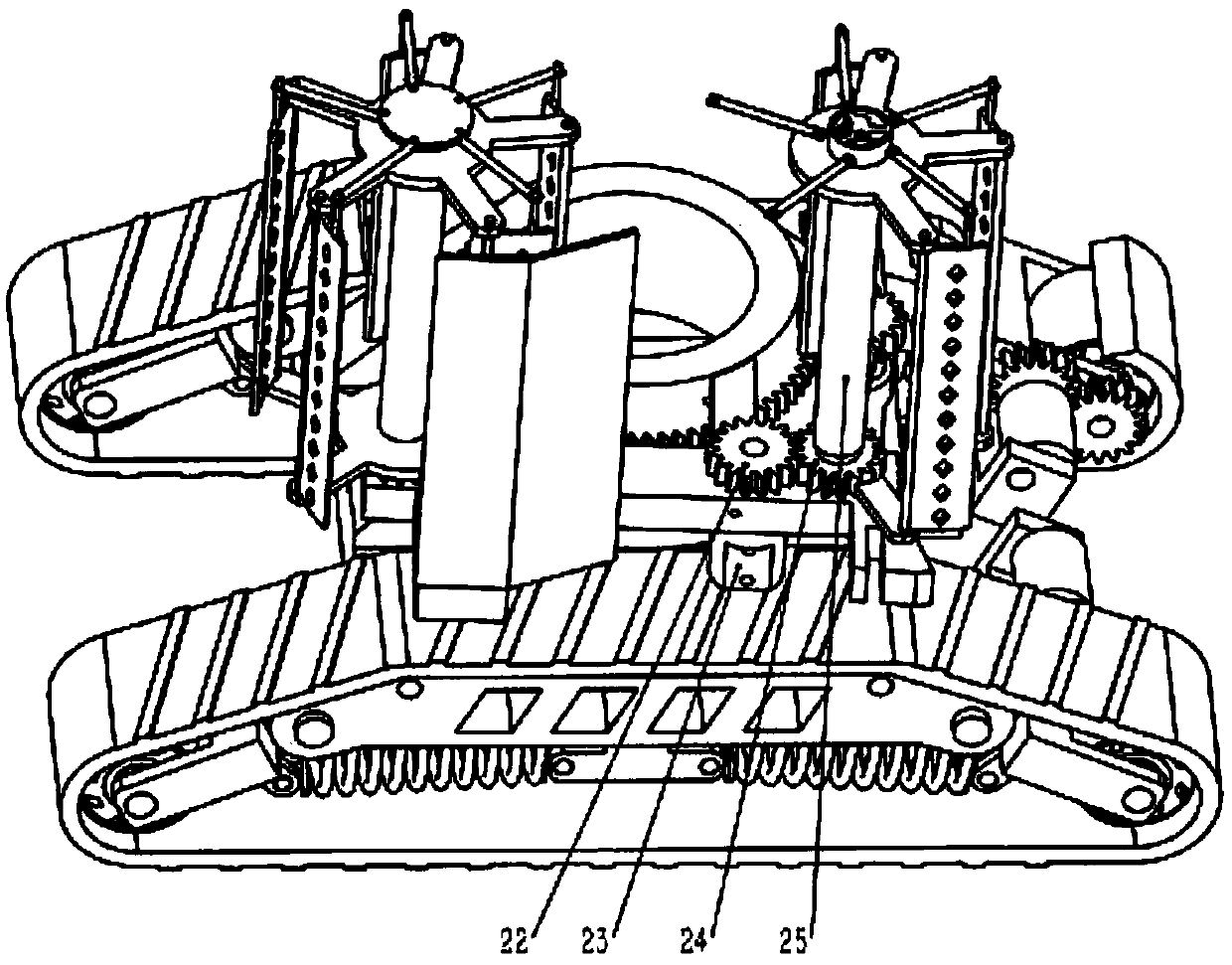

[0016] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 Shown, a kind of urban greening belt repair robot comprises intelligent controller 1, camera 2, crawler drive motor 3, crawler drive main gear 4, crawler drive secondary gear 5, crawler belt 6, crawler belt drive wheel 7, drive pin 8, Drive wheel frame 9, damping spring 10, driven wheel 11, supporting pulley 12, vehicle chassis 13, turntable drive motor 14, turntable drive gear 15, turntable tool holder 16, blade 17, blade plate 18, blade hanger 19. Blade pull rod 20, blade pull rod barrel 21, tool holder rotation drive gear 22, tool holder rotation drive motor 23, tool holder rotation driven gear 24, tool holder rotation shaft 25, inner ring gear 26, inner ring gear drive gear 27 . The intermediate gear 28 is characterized in that: the intelligent controller 1 is fixedly installed on the vehicle chassis 13, the camera 2 is fixedly installed on the intelligent controller 1, the crawler drive motor 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com