Bottom end stop for slide fastener

A code-stop and zipper technology, applied in the back-stop field to achieve excellent appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

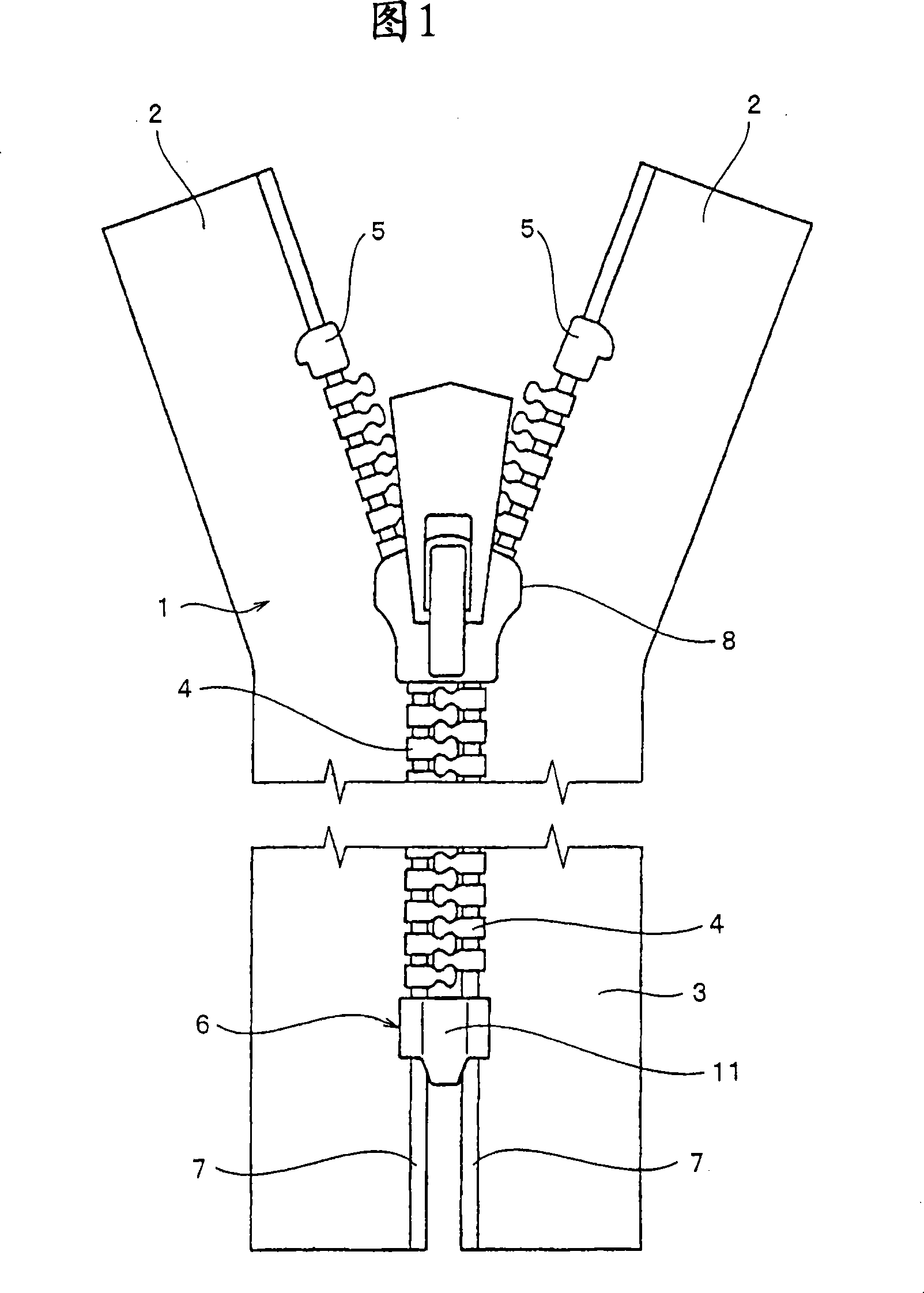

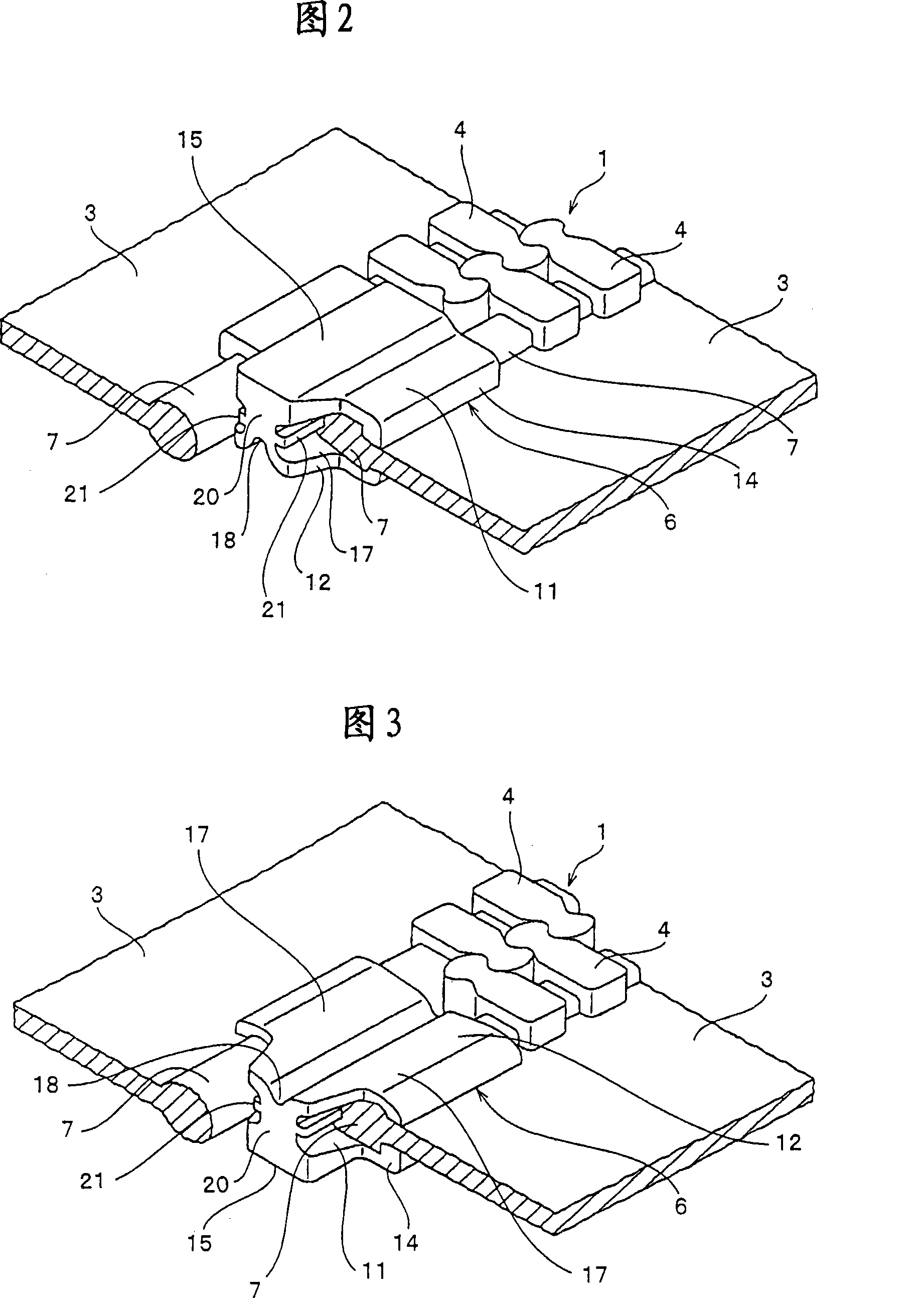

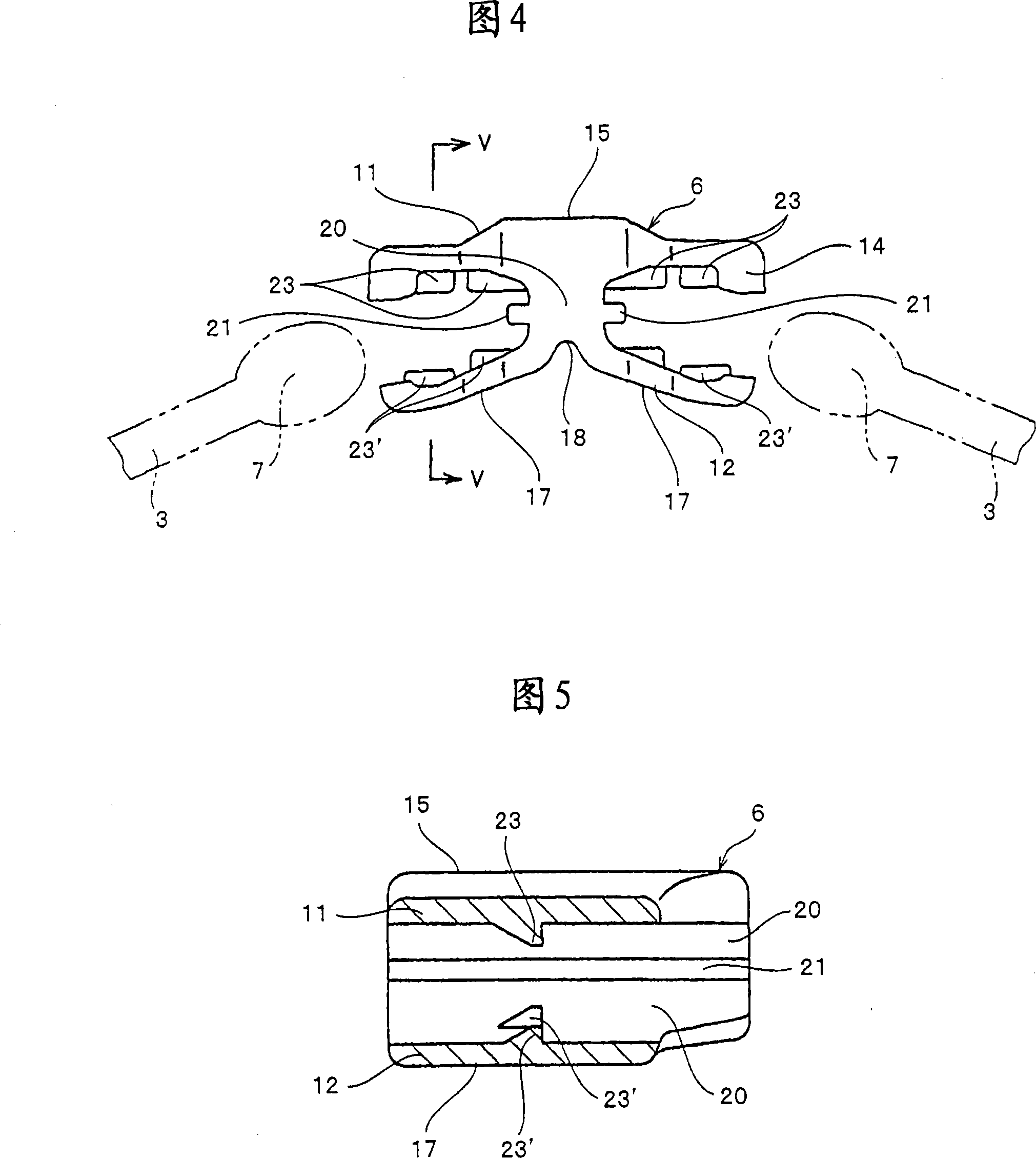

[0043] The bottom end stop 6 used in the slide fastener according to the first embodiment shown in FIGS. 1 to 6 is molded from a metal such as aluminum alloy or zinc alloy by a die-casting device. The bottom end stop 6 is formed by an upper plate 11 , a lower plate 12 and a base 20 . The upper plate 11 is formed such that its thickness increases continuously along the length direction of the slide fastener, thereby forming a raised portion 15 on the surface of the upper plate 11 . The surface of the raised portion 15 is flat, and when the bottom stop 6 is formed, decorations such as letters, marks, and patterns are expressed by engraving or in post-processing.

[0044] Both sides of a raised portion 15 formed in the middle of the upper plate 11 extend flatly to the left and right, and flanges 14 are formed on both sides of the raised portion so that the flanges 14 are bent downward at right angles to the upper plate 11 . Decorations such as letters, marks, and patterns may be...

no. 2 approach

[0052] The bottom end stop 6 for a slide fastener according to the second embodiment shown in FIG. 7 is formed of an upper plate 11 , a lower plate 12 and a base 20 , and the surface of the upper plate 11 is flat. The flange 14 is formed by bending both side ends at right angles, and the surface of the upper plate 11 is formed in such a configuration that decorations such as letters, marks, and patterns can be expressed. A groove portion 18 having a circular cross section is concavely formed in the middle of the rear surface of the lower plate 12 in the left-right direction, and arm portions 17 are formed on the right and left sides of the groove portion 18 so that the arm portion 17 is formed from the groove portion. 18 in a row. The base 20 is provided to connect the upper plate 11 and the lower plate 12 in a vertical direction, and a protrusion 21 is formed on a side surface of the base 20 to reinforce the base 20 .

[0053] The bottom end stop 6 has a square shape in plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com