Automatic quality detection and trimming device for gray cloth

A fabric and trimming technology, which is applied in the inspection of textile materials, textile and papermaking, spray/jet textile material processing, etc., can solve the problems of reducing the cost of fabric inspection, fabric waste, burrs, etc., to improve efficiency and quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

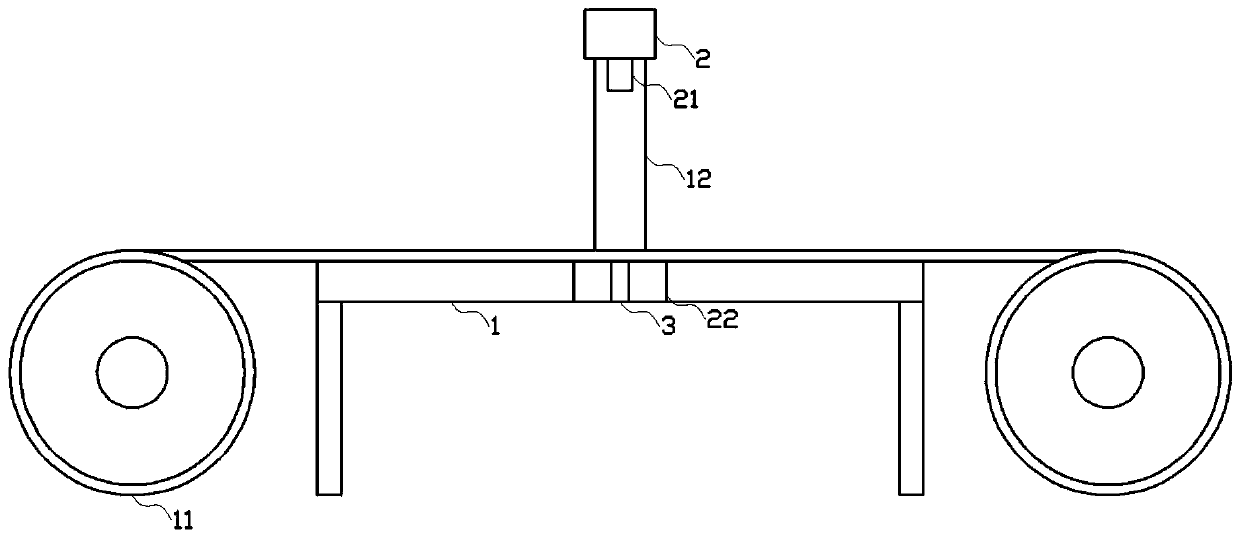

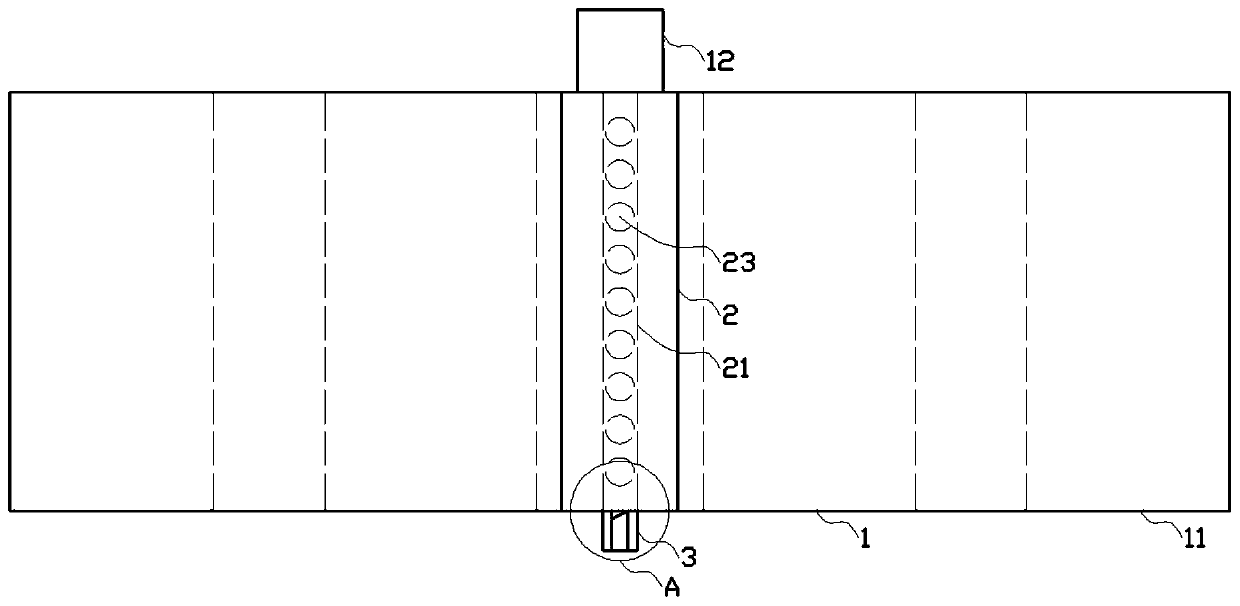

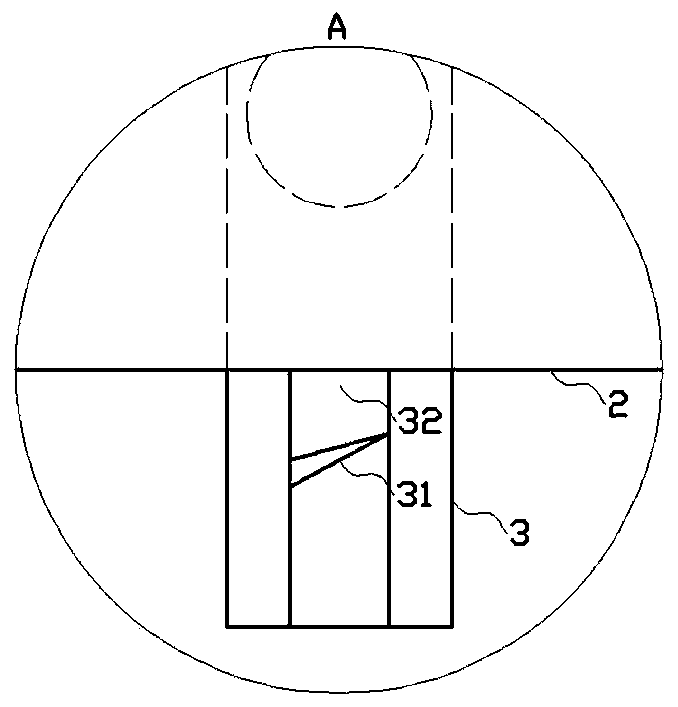

[0013] Such as figure 1 , figure 2 , image 3 As shown in the embodiment, the gray cloth automatic quality inspection and trimming device is a device that detects the edge of the gray cloth by infrared, adjusts the position of the trimming tool in time, and avoids the waste of cloth under the purpose of ensuring trimming; at the same time, it can A device that monitors and marks the defects of the gray cloth at the automatic detection point, which greatly improves the efficiency and accuracy of defect detection. It includes a transmission module 1, a detection module 2 and a trimming module 3; the transmission module 1 includes a conveying frame, The conveying rack is provided with a support plate 12, and the two ends of the support plate 12 are provided with a drive roller 11, and the top of the drive roller 11 is on the same plane as the top of the support pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com