Laser grinding wheel trimming device with double tangential liquid column flows and trimming method thereof

A laser dressing and grinding wheel technology, used in abrasive surface adjustment devices, parts of grinding machine tools, grinding/polishing equipment, etc., can solve problems such as micro-cracks, and achieve the purpose of inhibiting movement, reducing the influence of residual heat, and inhibiting the effect of energy accumulation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

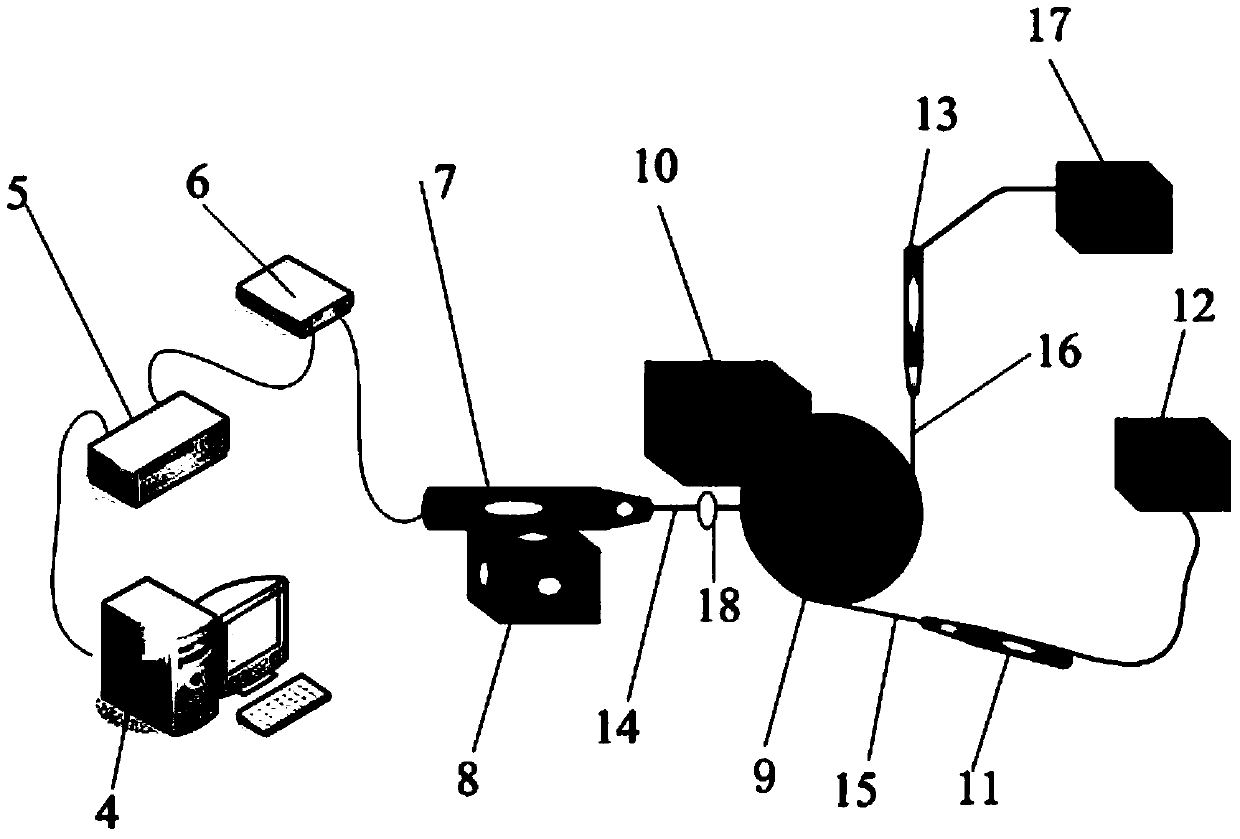

[0023] The following will be attached image 3 The specific technical solution of the present invention is described in detail.

[0024] Such as image 3 As shown, the laser dressing device for grinding wheels with dual tangential liquid column flows according to the present invention includes computer control equipment 4, control operation platform 5, fiber laser 6, laser ablation head 7, three-dimensional mobile platform 8, super hard Abrasive grinding wheel 9, grinding machine 10, lower tangential water pipe 11, lower tangential liquid column pressure controller 12, right tangential water pipe 13, laser beam 14, lower tangential liquid column flow 15, right tangential liquid column flow 16, right cut To the liquid column pressure controller 17, focus lens 18 and so on.

[0025] The super-abrasive grinding wheel 9 is installed on the controllable grinder 10. The grinder 10 drives the grinding wheel to rotate. The laser ablation head 7 is fixed on the three-dimensional moving plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com