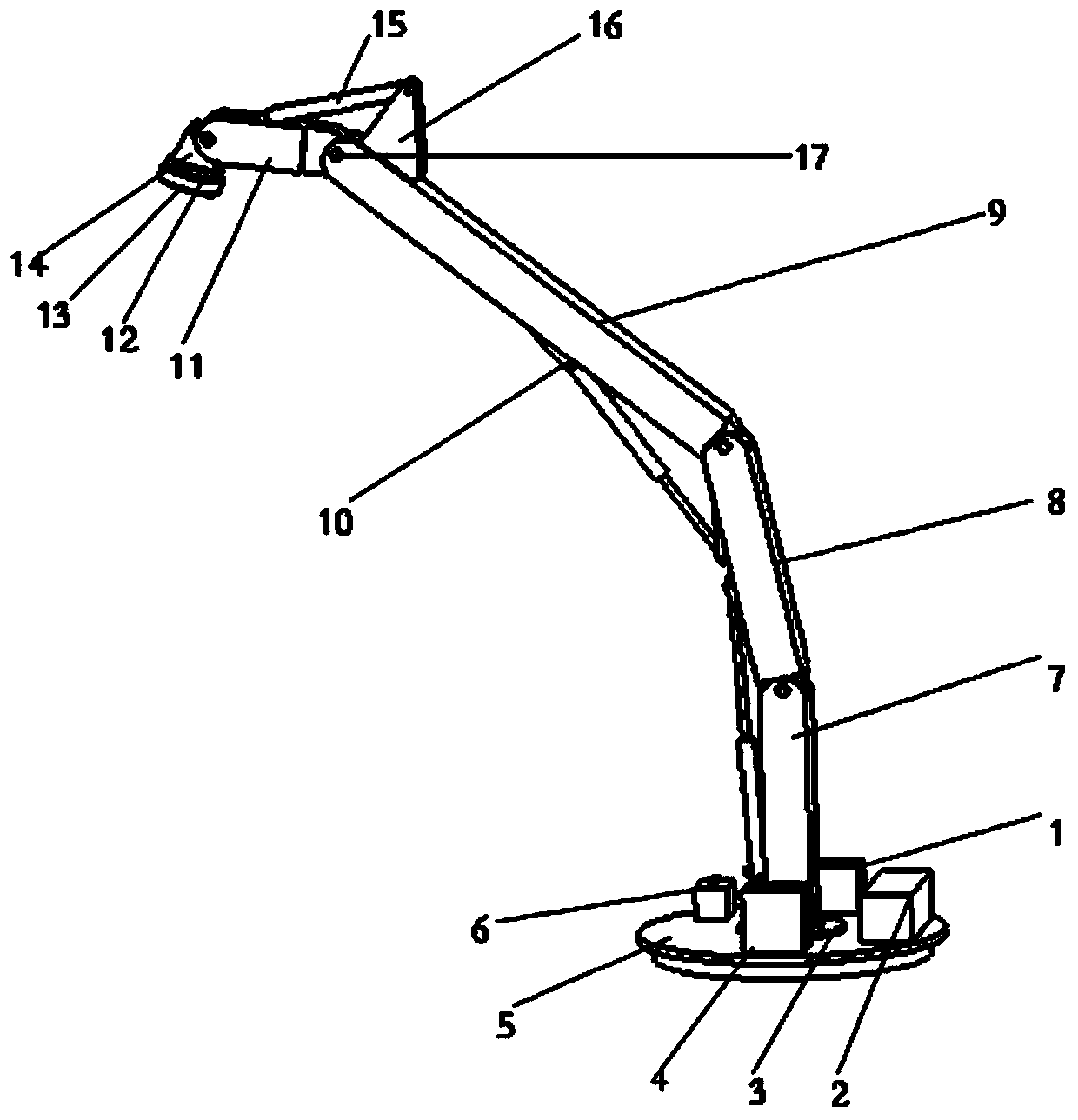

Arm type hedgerow trimmer

A hedge trimmer and arm-type technology, which is applied in the field of hedge trimming, can solve the problems of polluting gasoline engines, such as poor combustion efficiency, neatness, poor aesthetics, and low trimming work efficiency, and achieve convenient trimming operations, reasonable structural design, and improved trimming quality. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

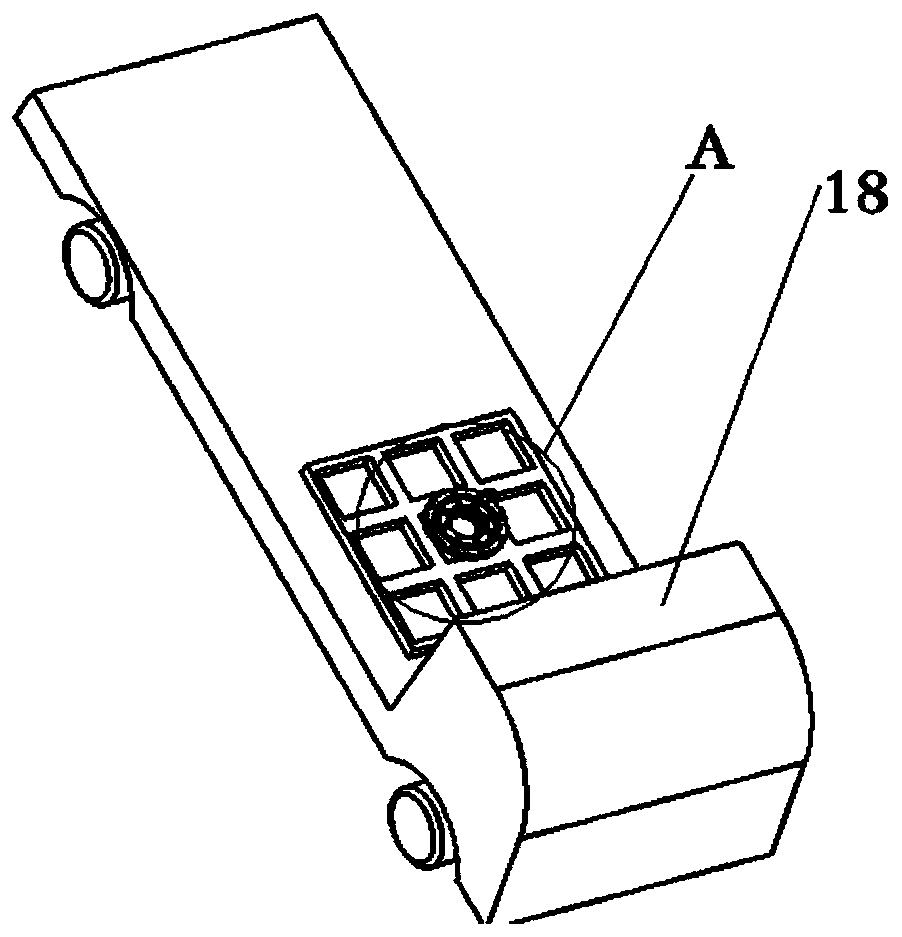

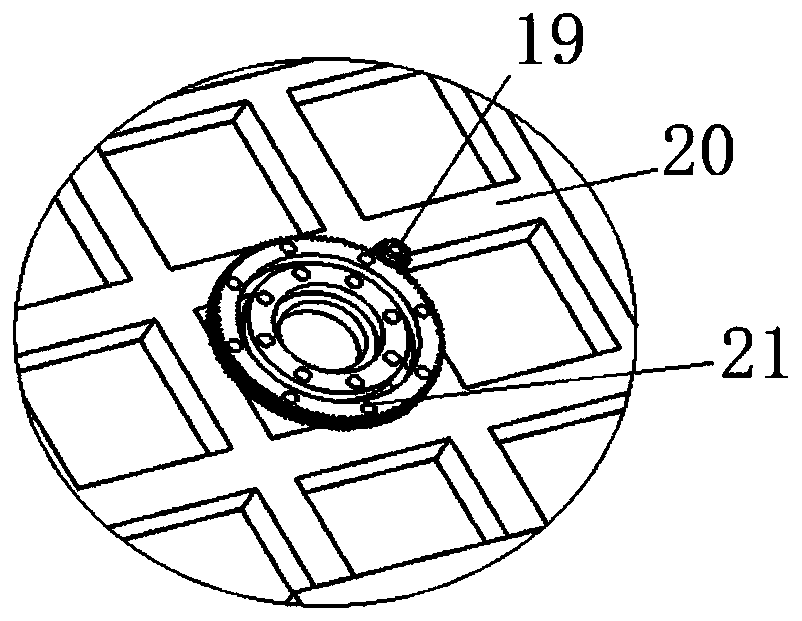

[0037] The rotation of the slewing platform 5 is driven by the slewing support 21 fixed on the chassis carrying vehicle 18. The slewing support 21 is set on the fixed square frame 20. The slewing support 21 adopts external tooth contact ball bearings. The number of teeth of the drive gear 19 meshes. Wherein the drive gear 19 is connected and matched with the transmission shaft of the drive motor 22 through a key, and the drive gear 19 is driven to rotate by the rotation of the drive motor 22, so that the slewing bearing 21 meshing with it rotates accordingly, and the slewing support 21 is connected with the slewing platform 5 through a connecting shaft On the fixed plate 3, the slewing support 21 rotates, and the slewing platform 5 and the devices arranged on the platform also rotate thereupon. Each device arranged on the slewing platform 5 includes a hydraulic oil tank 1 that provides hydraulic oil for the hydraulic cylinder system, a battery 6 that provides the power source ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com