Stepping full-automatic weeding machine

A weeding machine, fully automatic technology, applied in the fields of harvesters, agricultural machinery and implements, agriculture, etc., can solve the problems of hidden safety hazards and increased workload, and achieve the effect of improving the quality of trimming, improving efficiency, and simple and single power system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

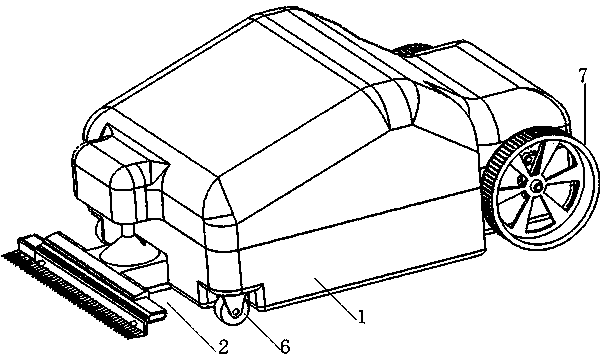

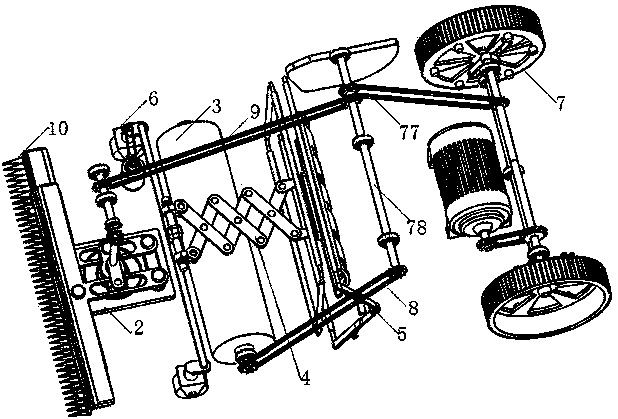

[0039] Attached below figure 1 —9 Describe the technical solution of the present invention.

[0040] The present invention includes a machine housing 1. A grass cutting device 2 is provided at the front of the machine housing 1, a weed pick-up device 3, a weed compression device 4, and a weed packing device 5 are provided inside, and a steering wheel device 6 is provided at the bottom. , Motorized wheel device 7, after the mowing device 2 trims the weeds, the weeds are collected by the weed picking device 3, and the weeds are packed by the weed compression device 4 and the weed packing device 5. The weeder is driven by the motor wheel The device 7 is driven forward, and the weed lifting device 3 is driven by the three-stage conveyor belt 8 to work, the grass cutting device 2 is driven by the second-stage conveyor belt 9 to work, and the direction is adjusted by the steering wheel device 6.

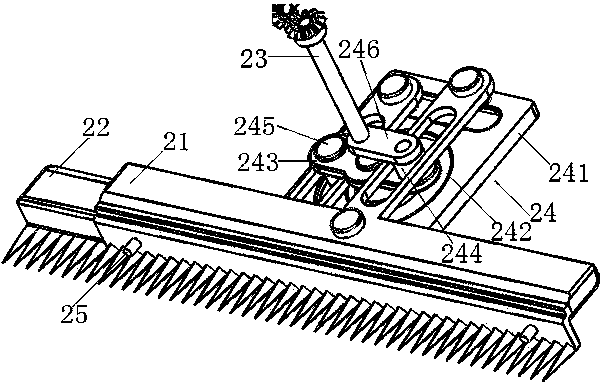

[0041] Among them, the mowing device 2 includes an upper knife holder 21 and a lower knife...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com