Thermoforming and edge-cutting integrated technique and mold of high-duty steel part

A technology of high-strength steel and high-strength steel plate, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc. , single and other problems, to achieve the effect of shortening the production cycle, high quality trimming, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

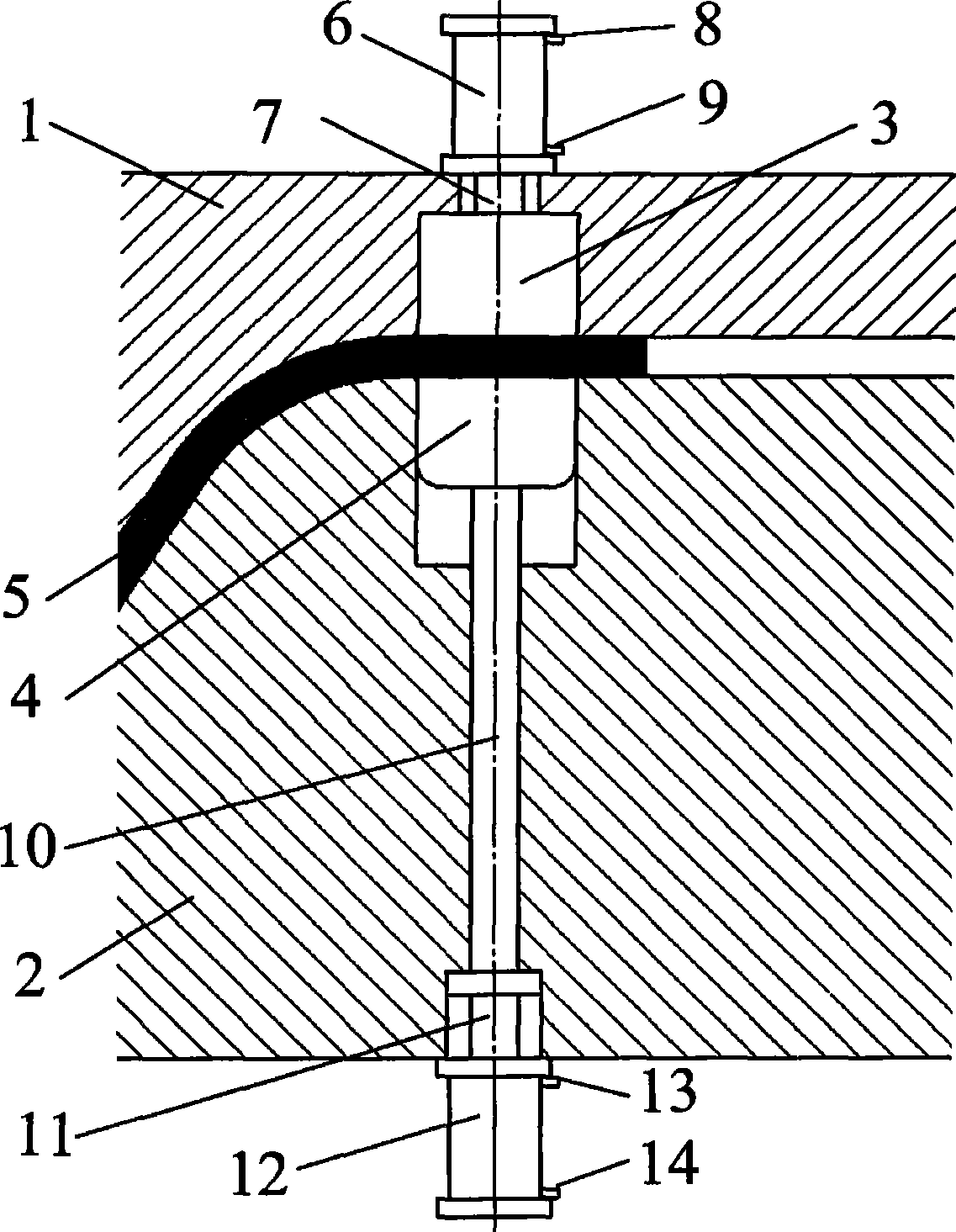

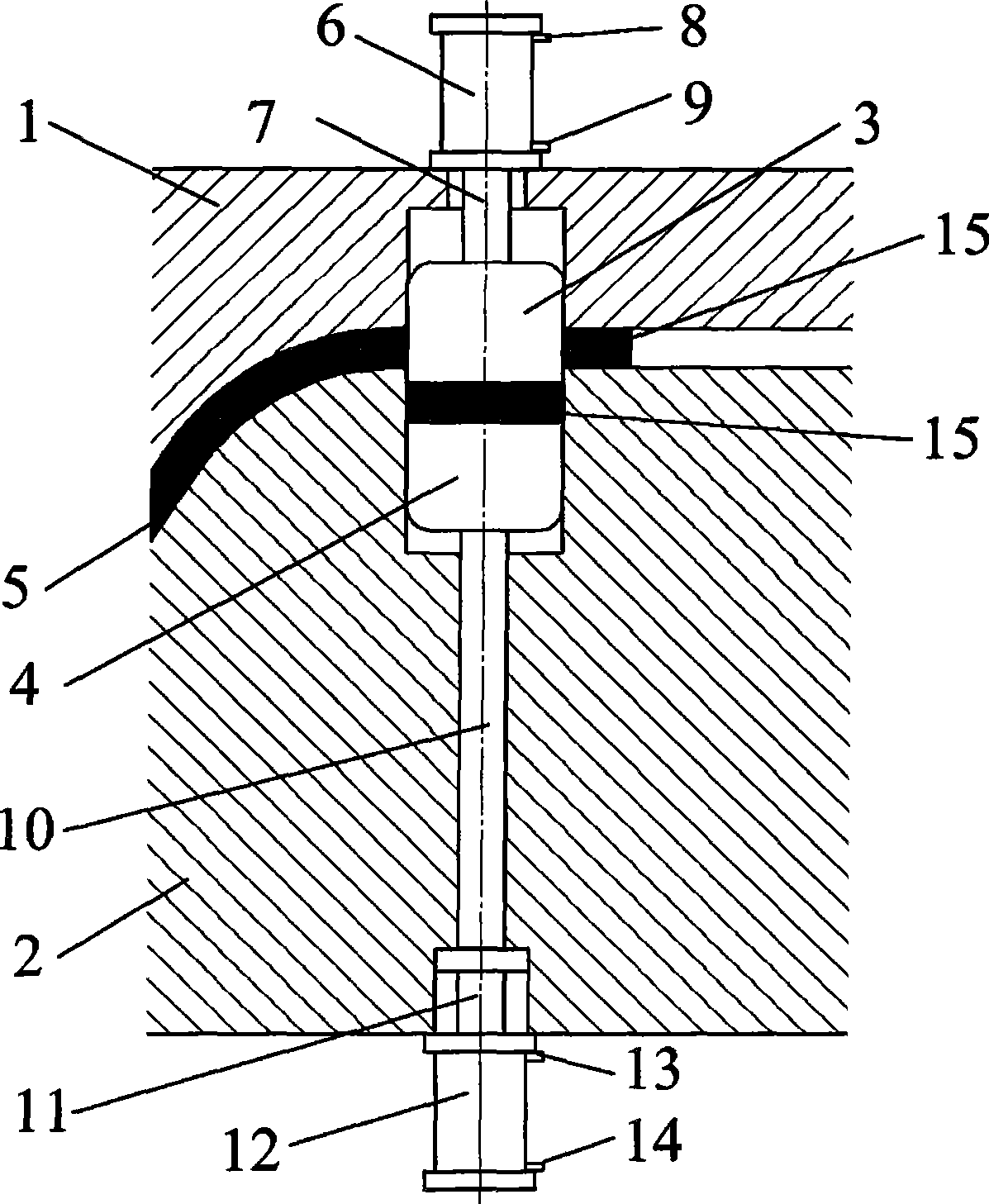

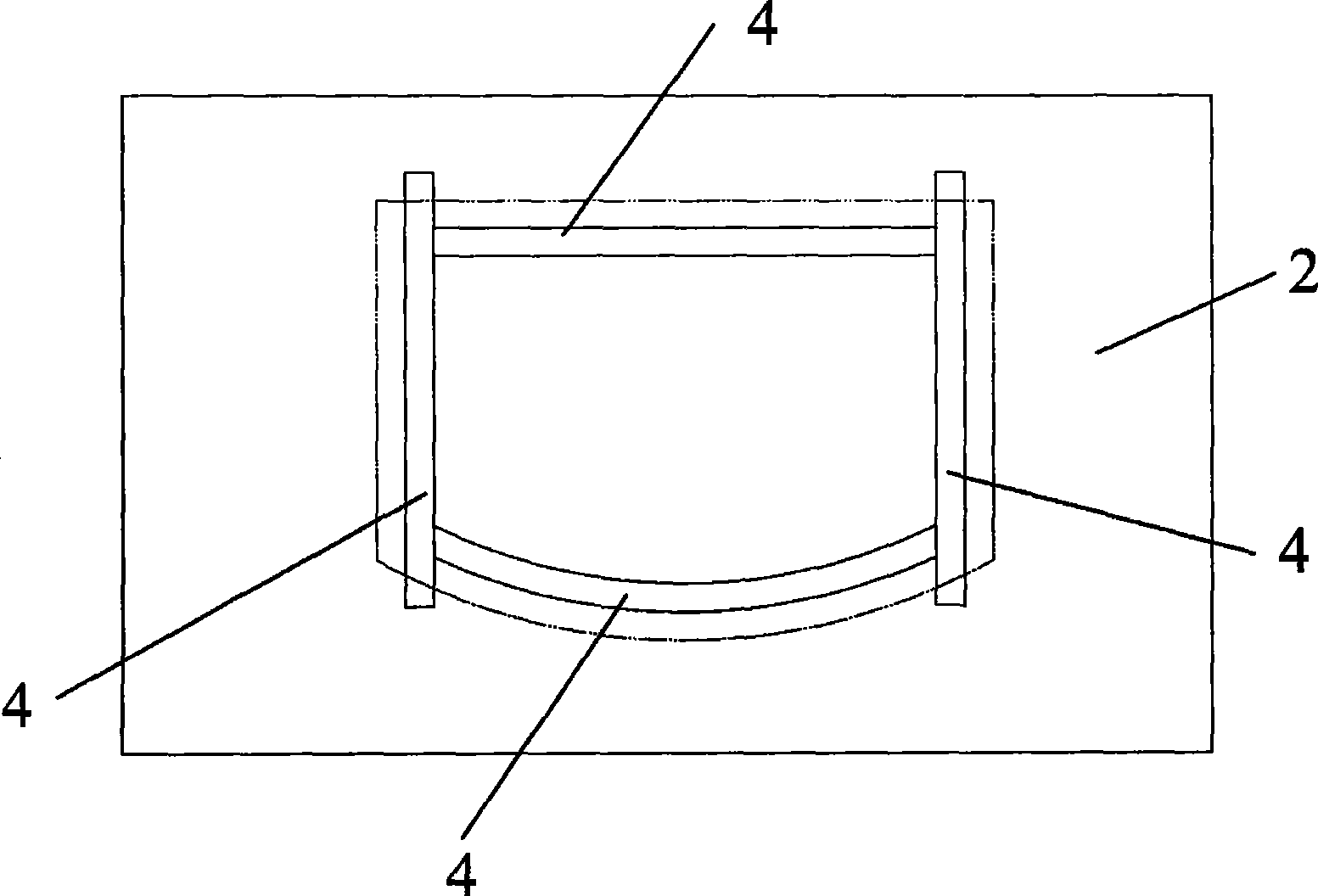

[0023] The thermal forming trimming integrated process of high-strength steel parts of the present invention, firstly, corresponding trimming tools are arranged on the upper mold and the lower mold of the thermoforming mold of high-strength steel parts, and oil cylinders or air cylinders are installed on the molds. , the piston rod of the oil cylinder or cylinder is rigidly connected with the trimming tool. The process of this process is that the sheet heated to the austenitic state is placed on the lower mold of the thermoforming mold → driven by the press, the upper and lower molds are closed to complete the thermoforming of the part → the oil cylinder or air cylinder in the mold drives the trimming tool to move , complete the edge trimming→introduce cooling medium into the cooling water channel inside the mold to cool the mold to realize the quenching of high-strength parts. The formed waste → Driven by the press, the upper and lower molds are opened, and the waste formed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com