Deburring device for TB tyre side surface

A deburring and tire technology, applied in the field of tire manufacturing, can solve the problems of substandard trimming quality, unevenness, and irregular tire side curve, so as to improve the trimming quality, ensure the removal effect, and improve the trimming efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

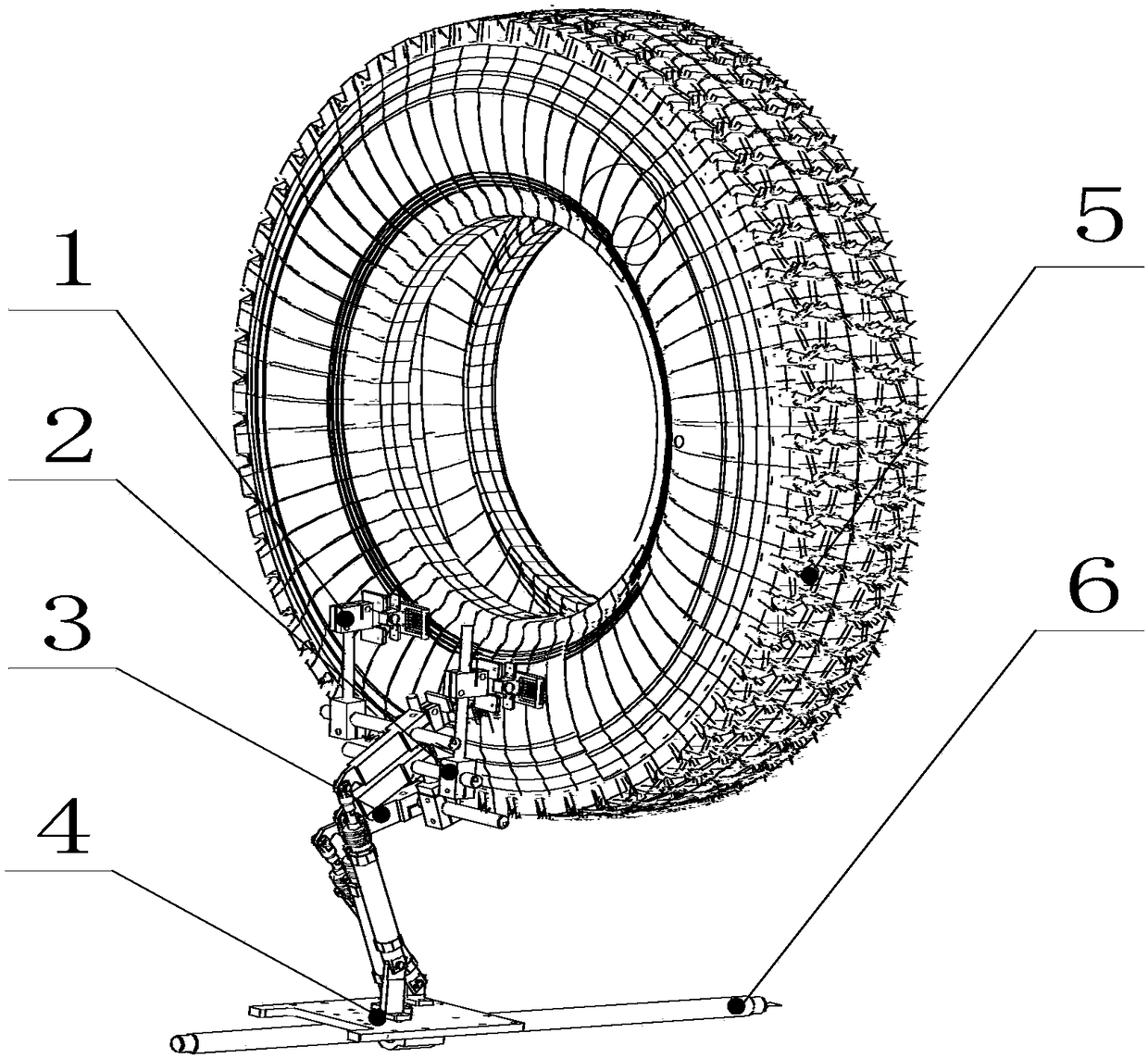

[0024] figure 1 For a complete schematic diagram of the TB tire side deburring device, the trimming tool mechanisms 1, 2, and 3 are all installed on the frame translation assembly 4, and placed on both sides of the tire 5 (the tire 5 is positioned by the clamping and rotating device and It can be driven by the ball screw on the frame translation component 4 to move along the ball screw guide rail, and each trimming tool is spaced at a certain distance in the horizontal and vertical directions, which can prevent the tool and the mechanism. Interference and collision occur between them and affect the operation of the machine.

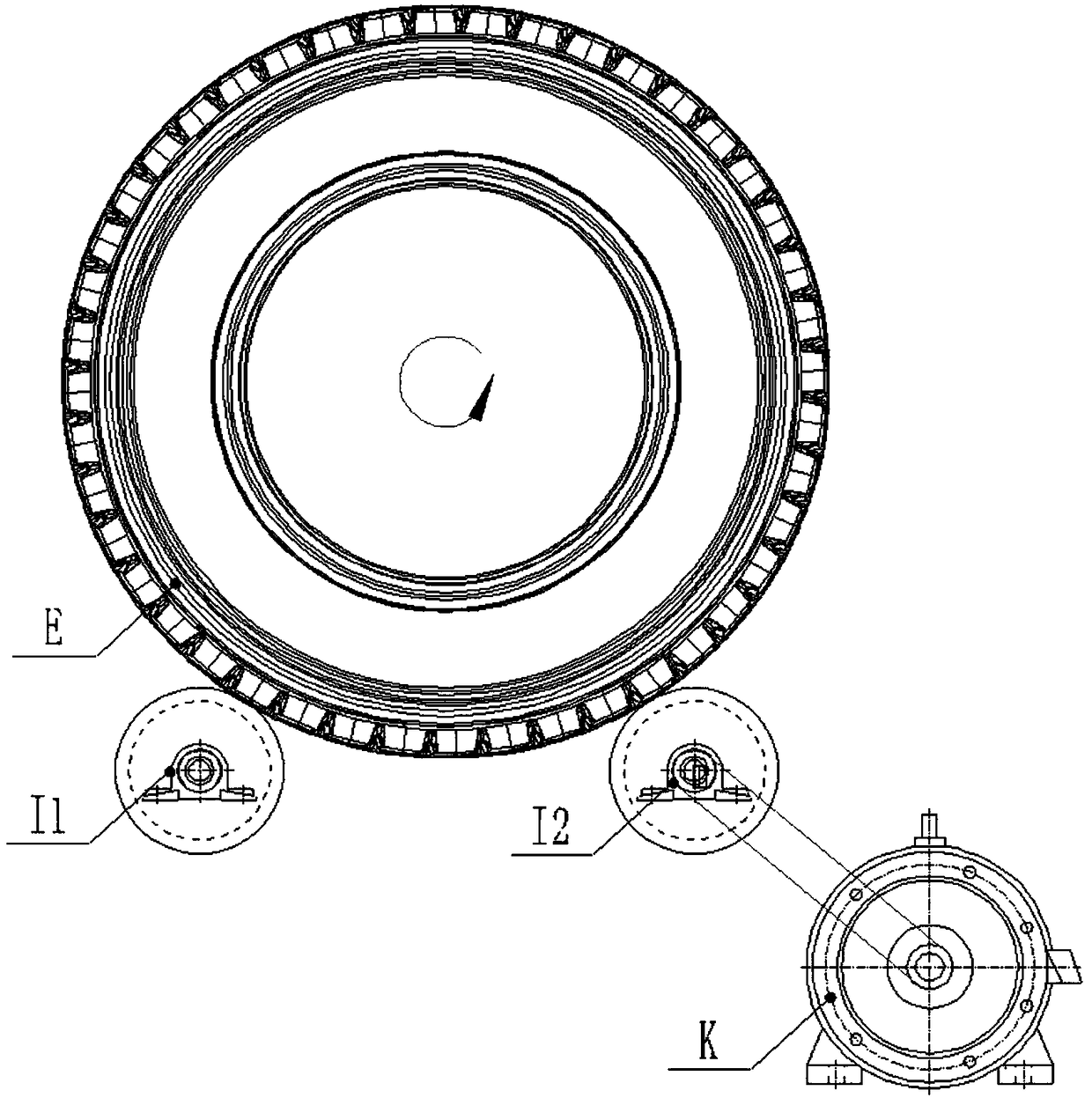

[0025] figure 2 It is a schematic diagram of a tire clamping and rotating device, wherein the tire clamping and rotating device is composed of rollers I1 and I2, a driving motor K, a pulley, and a belt. The drive motor K is connected with the first pulley through a key, the roller I2 (drive roller) is connected with the first pulley through a key, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com