Trolley for pruning shrubs on two sides of municipal road

A technology of small carts and roads, which is applied to equipment for trimming hedges, devices for catching or killing insects, cutting tools, etc. It can solve the problems of unsafe manual trimming, high labor intensity, and slow speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

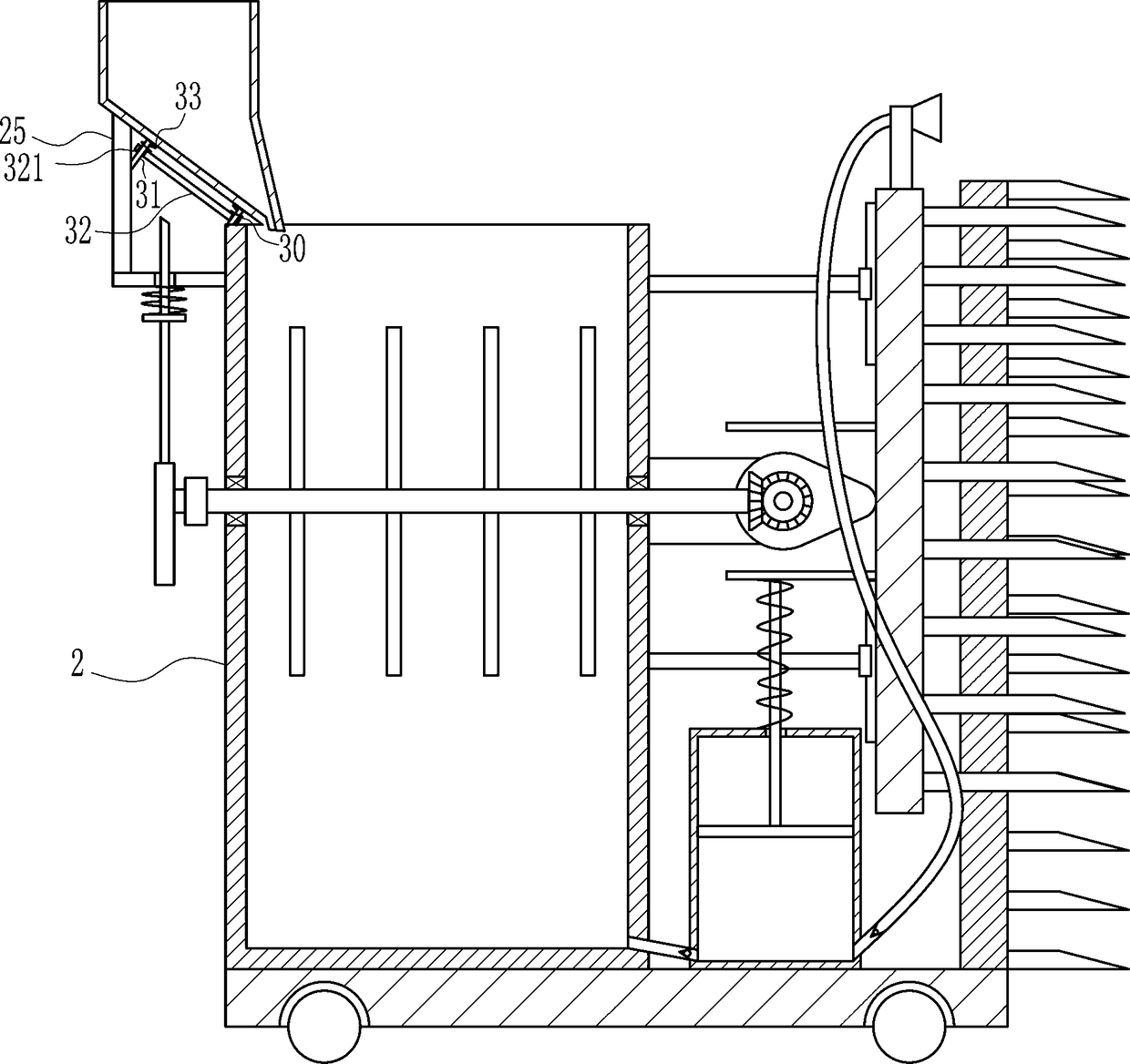

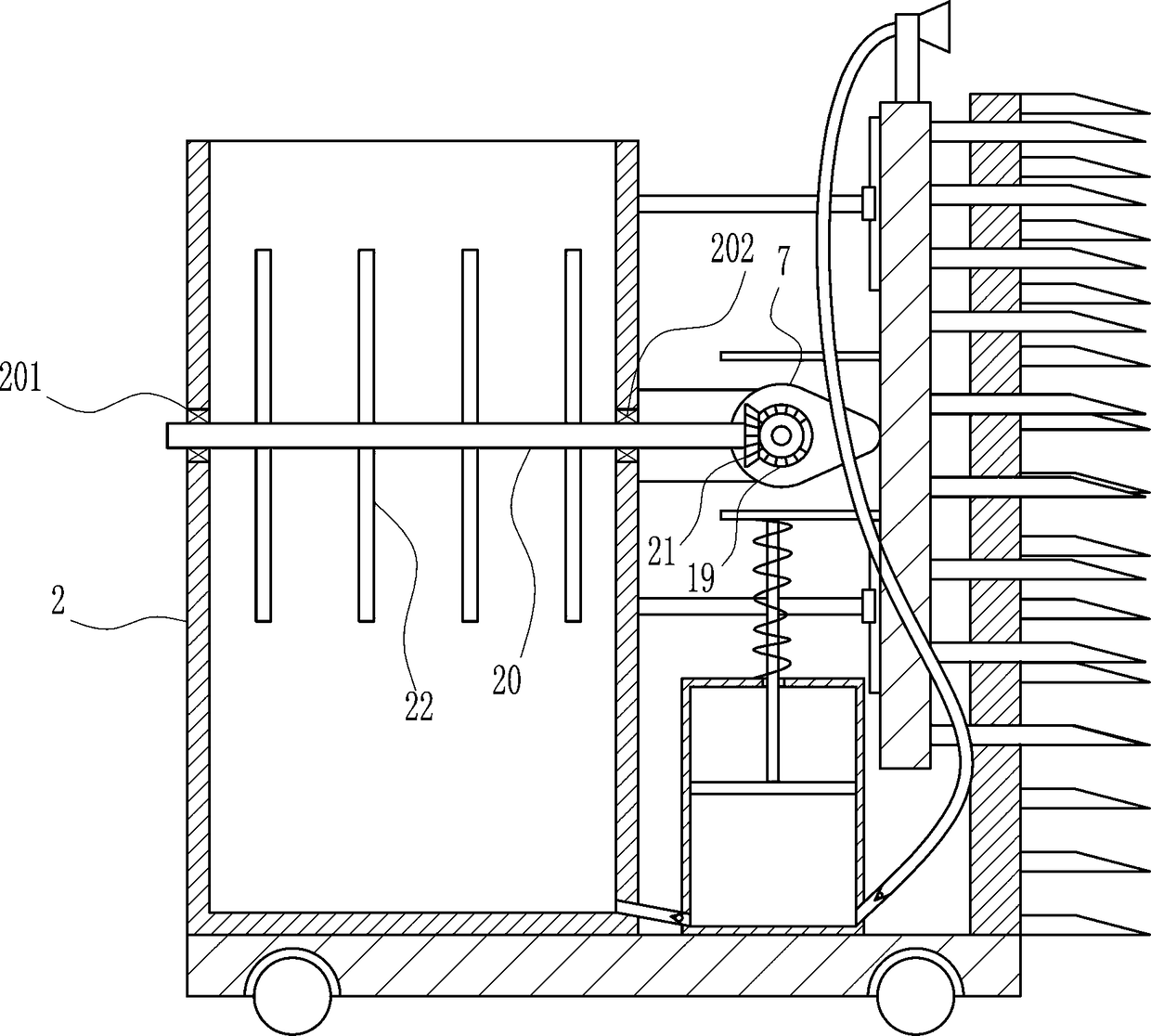

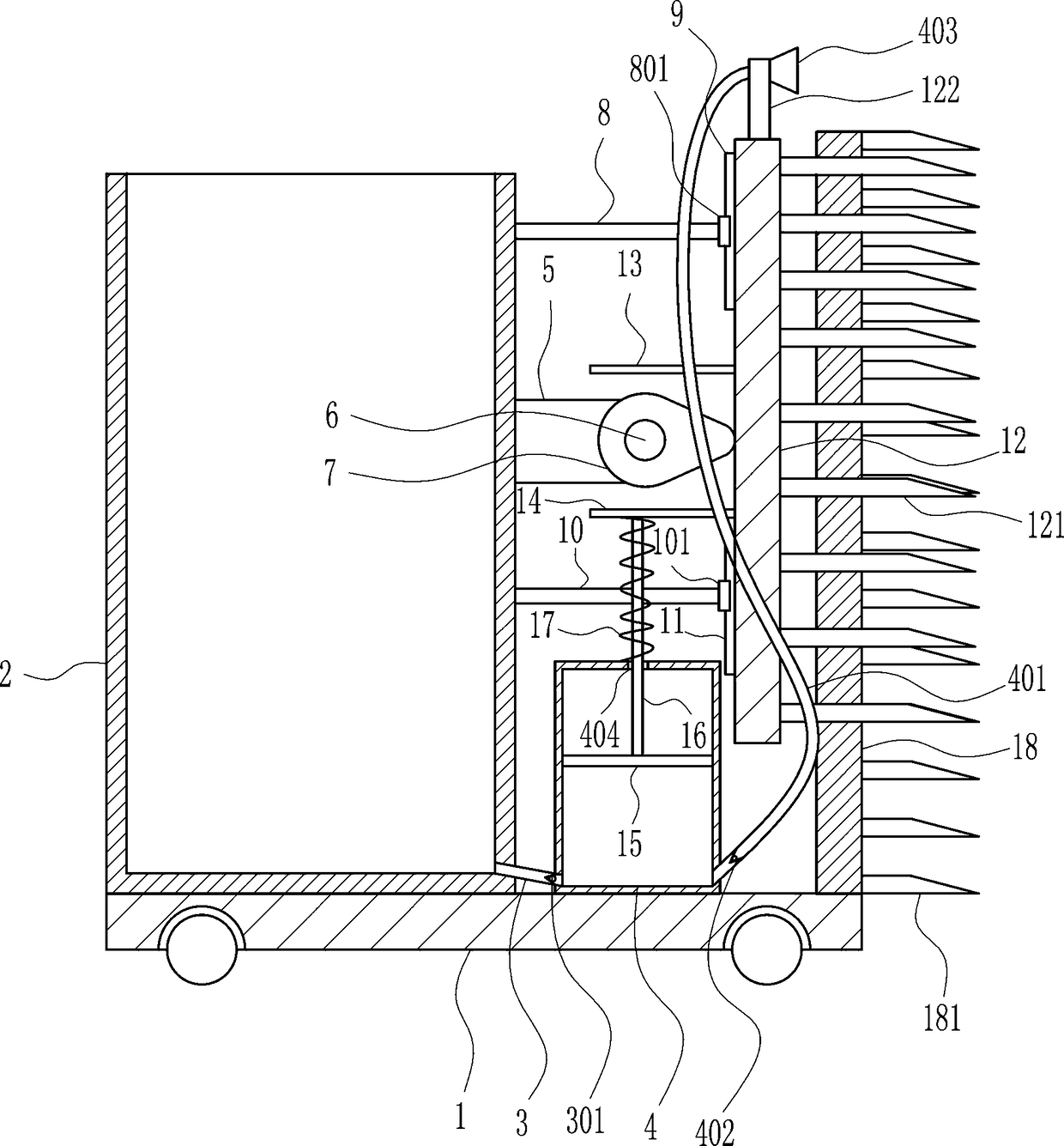

[0026] A kind of shrub pruning trolley on both sides of the municipal road, such as Figure 1-5 As shown, it includes a vehicle frame 1, a water tank 2, a water suction pipe 3, a first one-way valve 301, an extrusion box 4, a water outlet pipe 401, a second one-way valve 402, a nozzle 403, a fixed plate 5, a motor 6, the first A cam 7, the first support bar 8, the first slider 801, the first slide rail 9, the second support bar 10, the second slide block 101, the second slide rail 11, the first support plate 12, the first blade 121 , bracket 122, first top plate 13, second top plate 14, extrusion plate 15, first push rod 16, first spring 17, second support plate 18 and second blade 181 are fixedly connected on the left part of the vehicle frame 1 top There is a water tank 2, the lower part of the right side of the water tank 2 is provided with a water suction pipe 3, and the upper part of the vehicle frame 1 is fixedly connected with an extrusion box 4. 4. The lower part of t...

Embodiment 2

[0028] A kind of shrub pruning trolley on both sides of the municipal road, such as Figure 1-5 As shown, it includes a vehicle frame 1, a water tank 2, a water suction pipe 3, a first one-way valve 301, an extrusion box 4, a water outlet pipe 401, a second one-way valve 402, a nozzle 403, a fixed plate 5, a motor 6, the first A cam 7, the first support bar 8, the first slider 801, the first slide rail 9, the second support bar 10, the second slide block 101, the second slide rail 11, the first support plate 12, the first blade 121 , bracket 122, first top plate 13, second top plate 14, extrusion plate 15, first push rod 16, first spring 17, second support plate 18 and second blade 181 are fixedly connected on the left part of the vehicle frame 1 top There is a water tank 2, the lower part of the right side of the water tank 2 is provided with a water suction pipe 3, and the upper part of the vehicle frame 1 is fixedly connected with an extrusion box 4. 4. The lower part of t...

Embodiment 3

[0031] A kind of shrub pruning trolley on both sides of the municipal road, such as Figure 1-5 As shown, it includes a vehicle frame 1, a water tank 2, a water suction pipe 3, a first one-way valve 301, an extrusion box 4, a water outlet pipe 401, a second one-way valve 402, a nozzle 403, a fixed plate 5, a motor 6, the first A cam 7, the first support bar 8, the first slider 801, the first slide rail 9, the second support bar 10, the second slide block 101, the second slide rail 11, the first support plate 12, the first blade 121 , bracket 122, first top plate 13, second top plate 14, extrusion plate 15, first push rod 16, first spring 17, second support plate 18 and second blade 181 are fixedly connected on the left part of the vehicle frame 1 top There is a water tank 2, the lower part of the right side of the water tank 2 is provided with a water suction pipe 3, and the upper part of the vehicle frame 1 is fixedly connected with an extrusion box 4. 4. The lower part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com