Passive-type strip steel edge grinding device suitable for finishing machine set

A technology for finishing unit and strip steel edge, which is applied in the field of metallurgy, can solve the problems of non-adjustable grinding force, inflexible device, inability to adapt to changes in strip steel specifications, etc., so as to improve the quality of trimming and solve process problems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

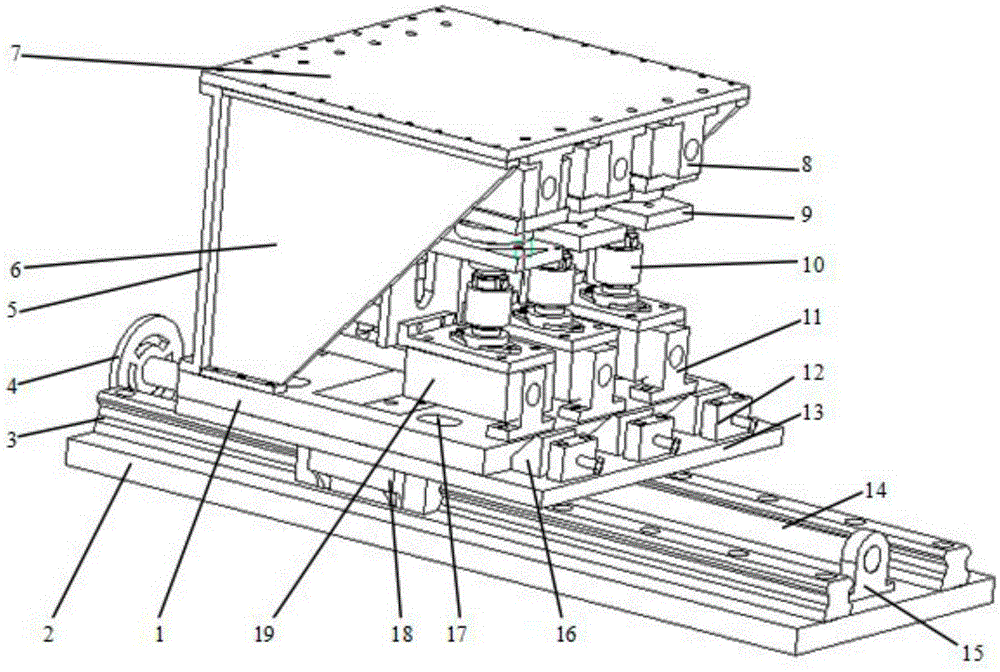

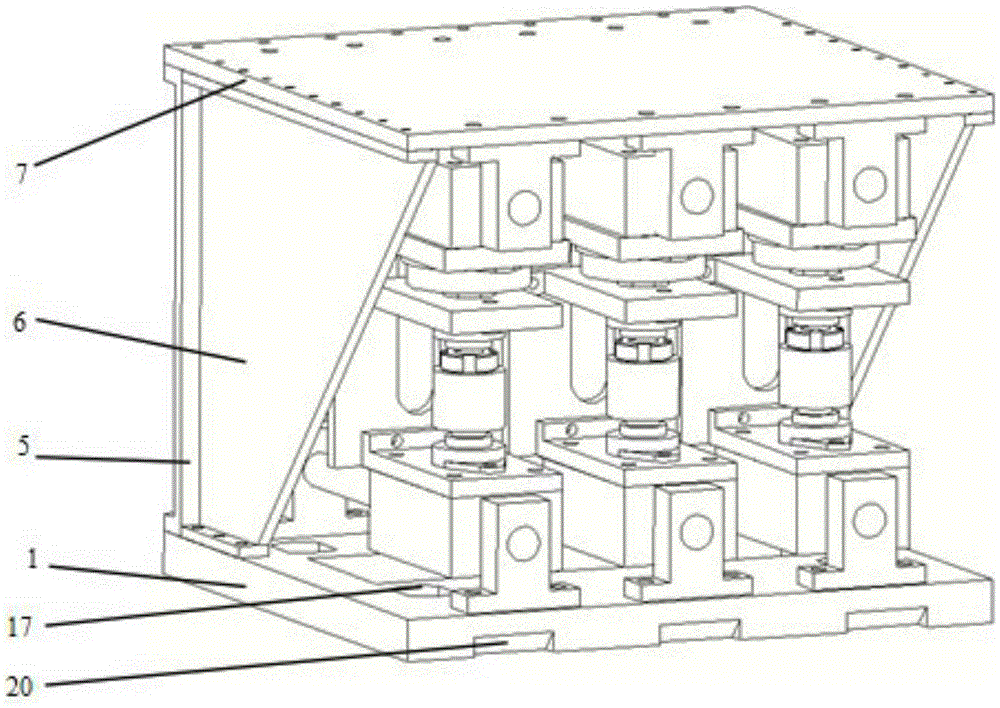

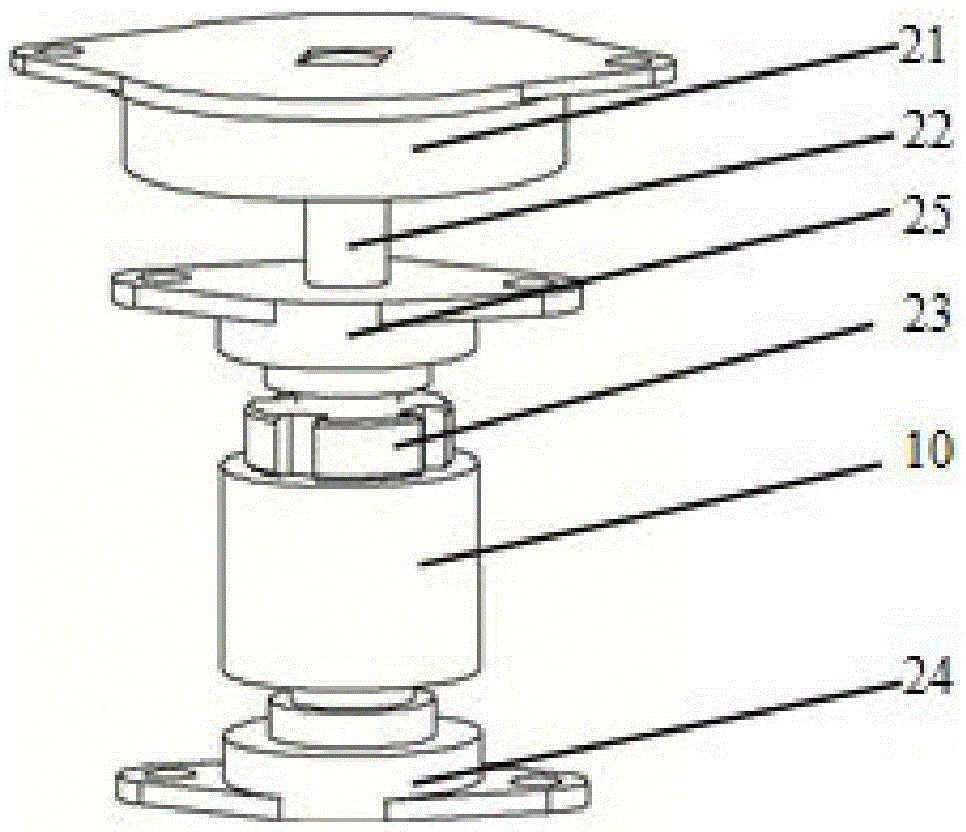

[0030] exist figure 1 In the schematic diagram of the passive strip edge grinding device suitable for the finishing unit shown, the grinding mechanism and the follower mechanism are arranged in the box frame, and the bottom of the box frame is fixedly connected with the feeding mechanism; figure 2 As shown, one end of the box bottom plate 1 and the box top plate 7 in the box frame is fixedly connected by the box back plate 5 to form a box frame. Box ribs 6; 3 groups of milling mechanisms arranged in a row are arranged in the box frame; four waist grooves 17 arranged equally on the circumference are arranged on the box bottom plate, and one end bottom of the box bottom plate is open An angle adjustment track 20 parallel to the above-mentioned pressing and grinding mechanism is provided; image 3 As shown, the grinding wheel 10 in the grinding mechanism is fixedly connected to one end of the grinding wheel shaft 22 through a lock nut 23, and the other end of the grinding wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com