Window film edge cutting machine with adjustable cutter body

An adjustable, edge-cutting machine technology, used in thin material processing, metal processing, sending objects, etc., can solve problems such as high efficiency, uneven corners of window film, and uneven cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

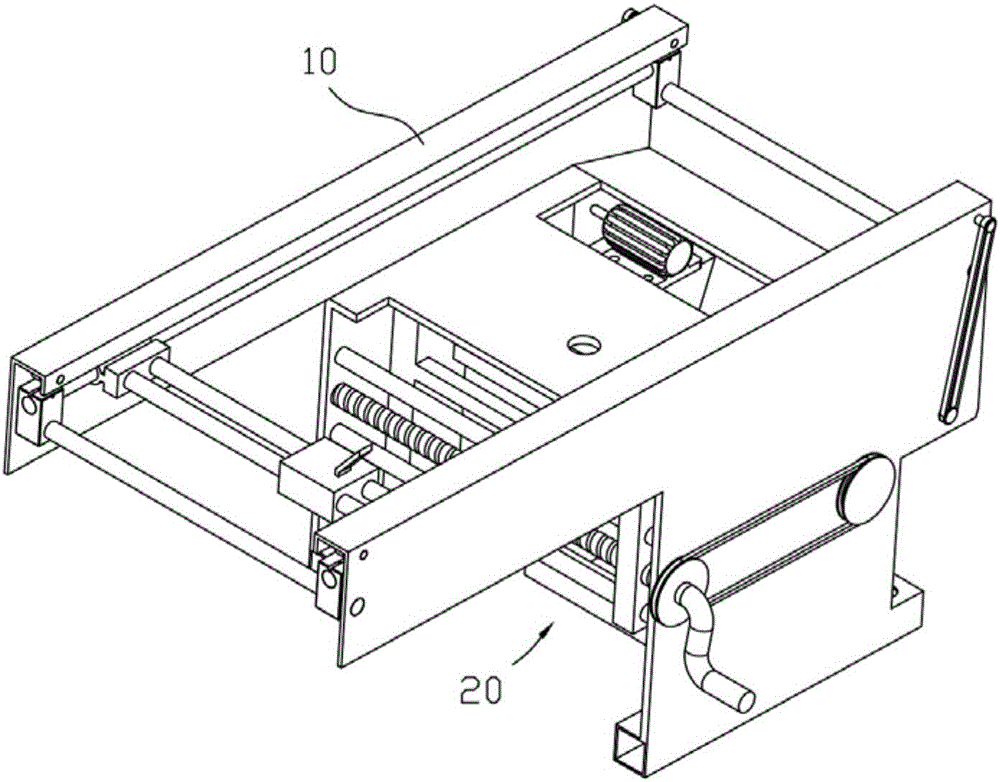

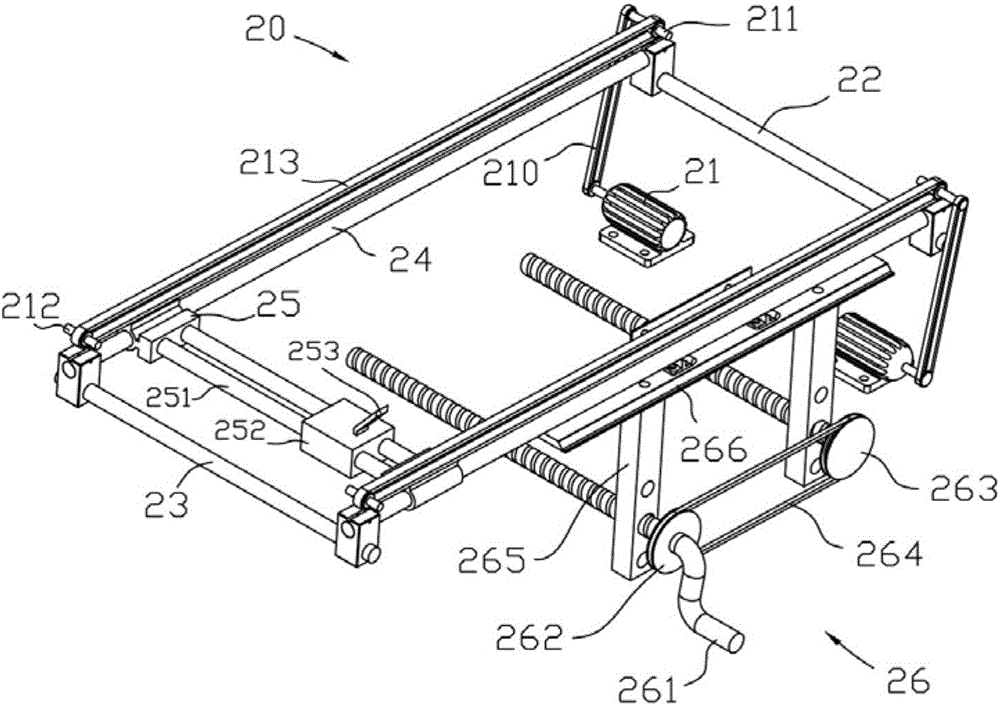

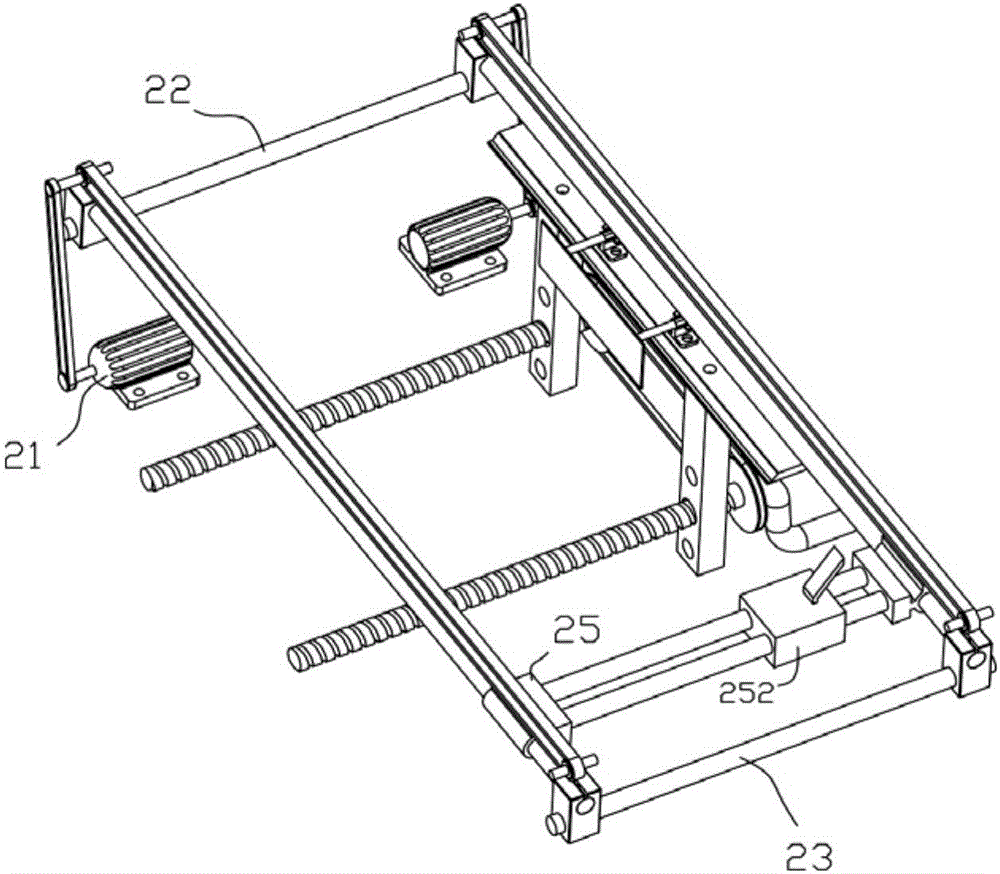

[0023] Such as Figure 1 to Figure 4 As shown, a window film trimming machine with an adjustable knife body includes a frame 10 and a rotating assembly 20, and the rotating assembly 20 includes a front fixed rod 22, a rear fixed rod 23 and a middle fixed rod 24, and the front fixed rod Between the rod 22 and the rear fixed rod 23, two intermediate fixed rods 24 are connected; two motors 21 are arranged below the front fixed rod 22, and each motor 21 is connected with the front rotating shaft 211 by a belt 210, and the front rotating shaft 211 It is connected with the rear rotating shaft 212 through the conveyor belt 213 .

[0024] The rotating assembly 20 also includes a cutting assembly 26, the cutting assembly 26 includes a handle 261, the handle 261 is connected to a driving pulley 262, and the driving pulley 262 is connected to a driven pulley 263 through a timing belt 264, Both the driving pulley 262 and the driven pulley 263 are connected with the screw rod 267, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com