Plate shearing machine with trimming device

A shearing machine and edge trimming technology, which is applied in the direction of shearing devices, machine tools suitable for grinding the edge of workpieces, and attachments of shearing machines, etc. It can solve the problems of affecting the use of workpieces, uneven shearing, time-consuming and laborious, etc. , to achieve the effect of improving trimming efficiency, ensuring cutting quality and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

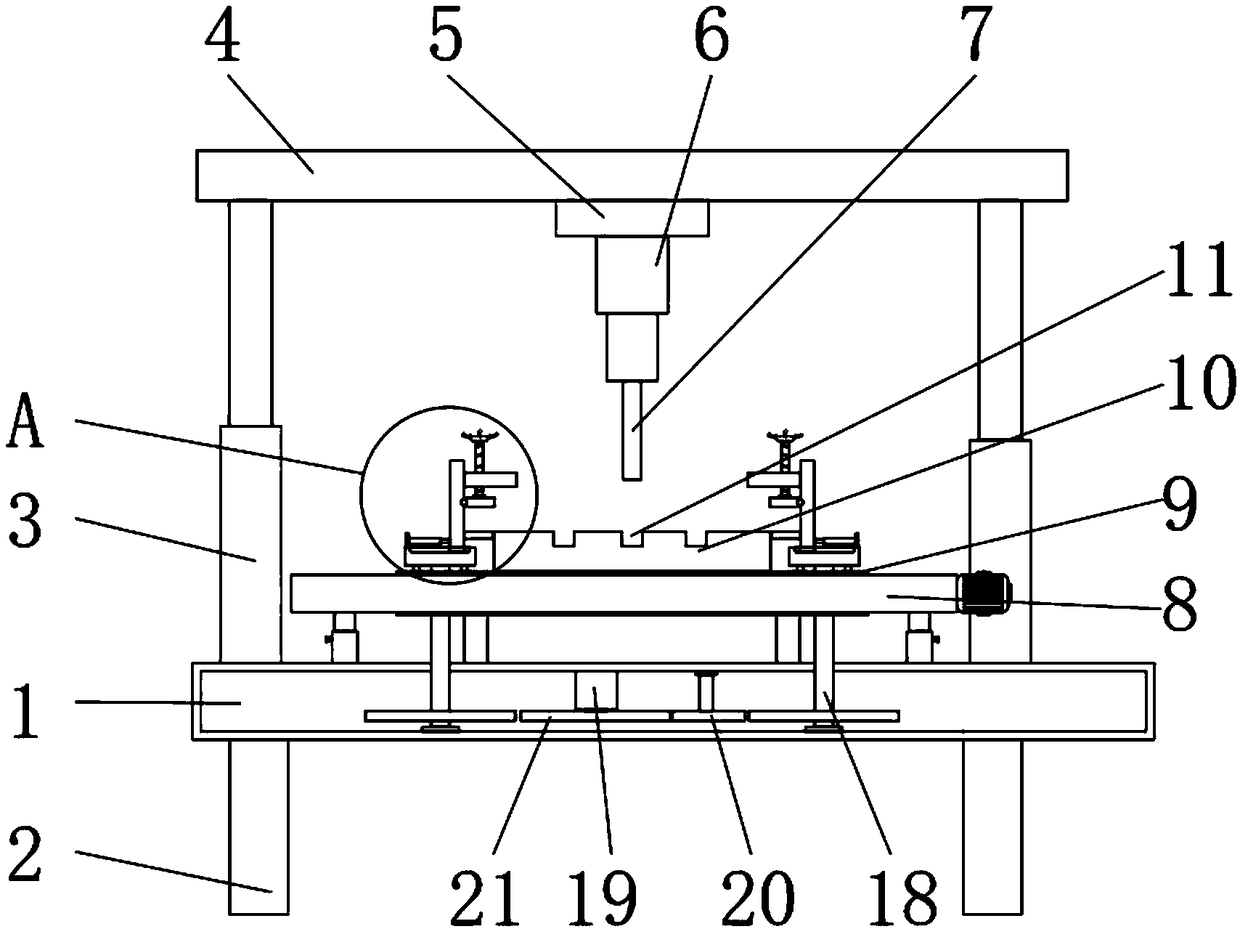

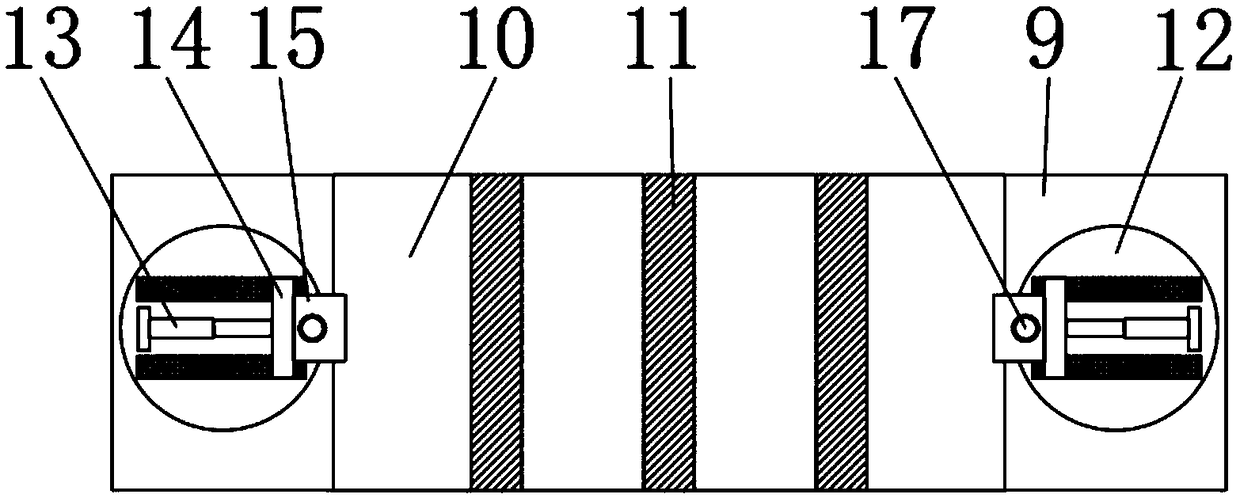

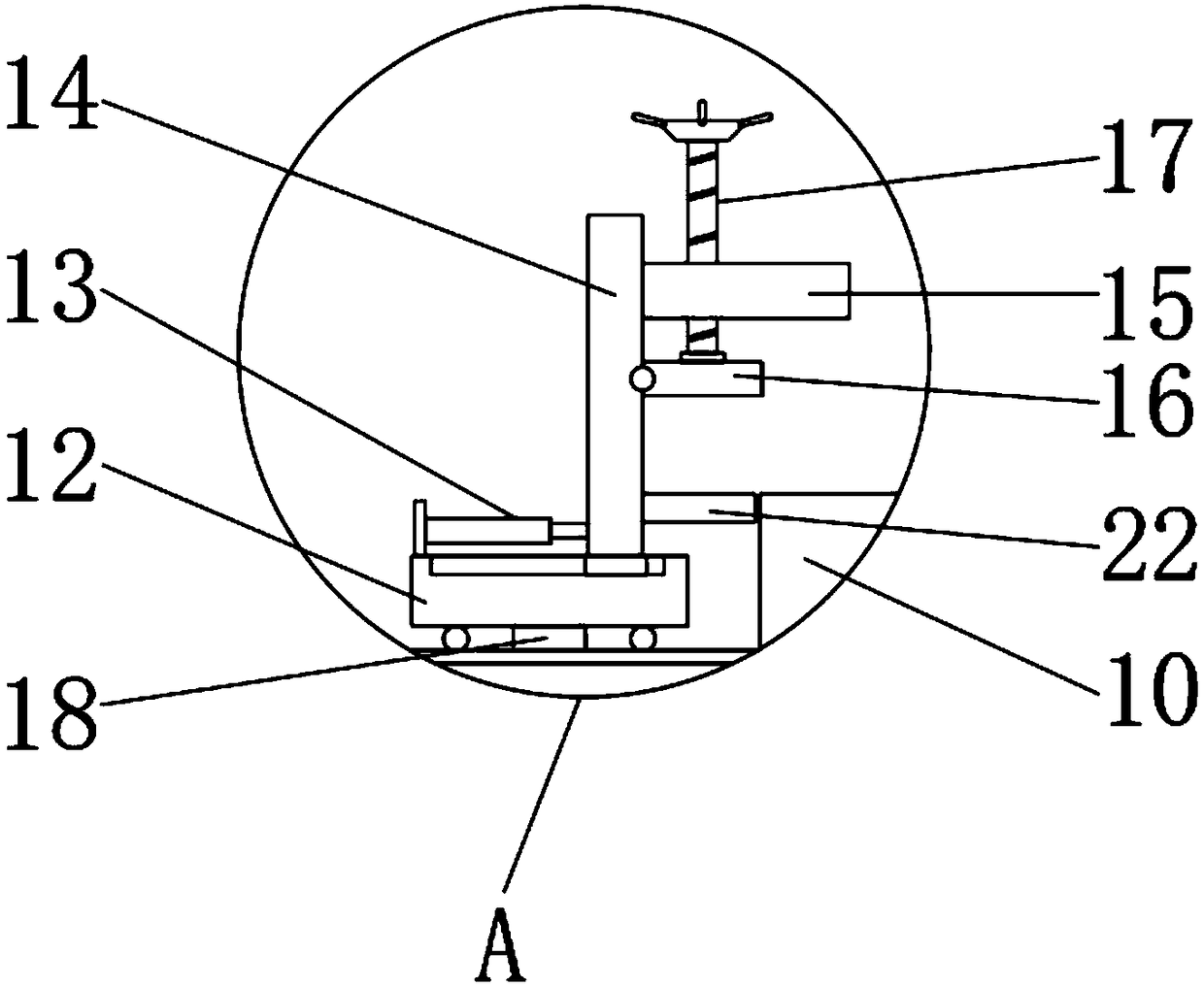

[0028] Embodiment: When in use, the plate workpiece is placed on the shear placement plate 10, and according to the length of the plate, start the electric telescopic rod 13 to shorten and extend to adjust the position of the support plate 10, so that the left and right sides of the bottom of the plate workpiece are located on the supporting plate 22 top, turn the screw rod 17 to drive the fixed plate 16 downward, fix the plate workpiece through the fixed plate 16 and the supporting plate 22, adjust the adjusting rod 81 to adjust the mounting block 82 to the designated position, and then move the moving block 5 and the moving guide rail 4. The upper blade 7 is adjusted to the position corresponding to the shear groove 11, and the hydraulic telescopic rod 3 is started to drive the moving guide rail 4 downward, so that the upper blade 7 cuts the plate workpiece downward. After the cutting is completed, the hydraulic telescopic rod 3 is started to drive Move the guide rail 4 upwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com