Automatic cleaning, spraying protection and drying machining equipment for thermal insulation composite board

A thermal insulation composite board, automatic cleaning technology, applied in the direction of coating, cleaning methods and tools, cleaning methods using tools, etc., can solve the problems of easy-to-break stone boards, large stone boards, and low manual operation efficiency, and achieve The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

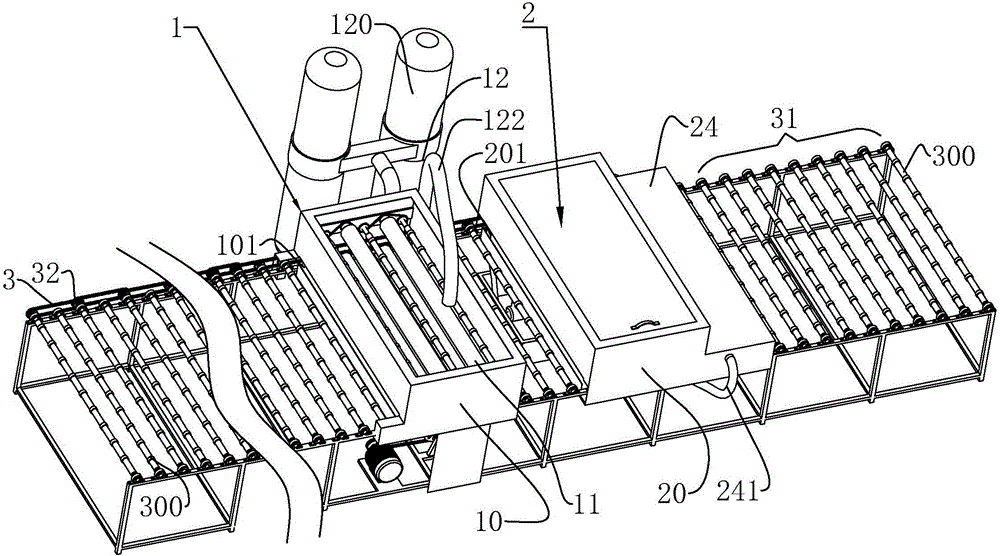

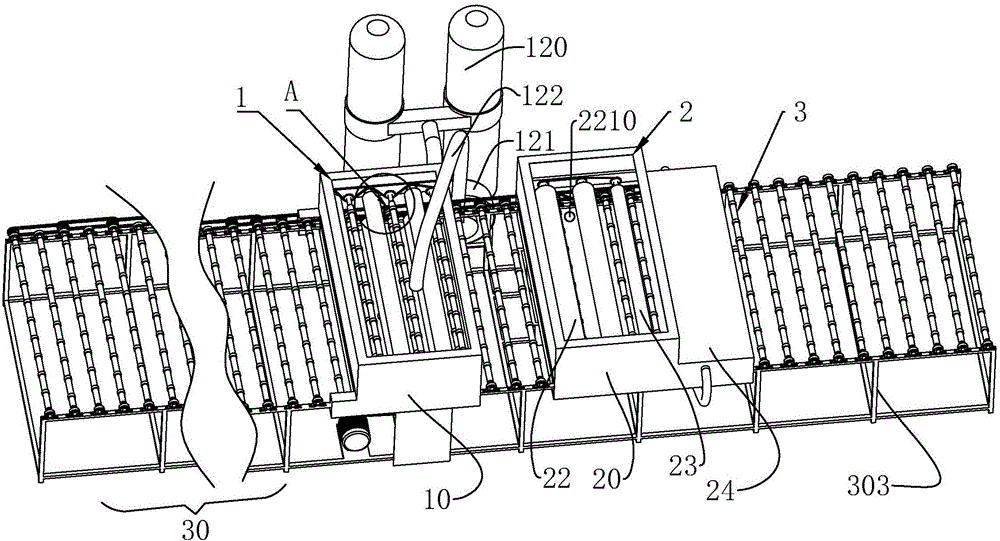

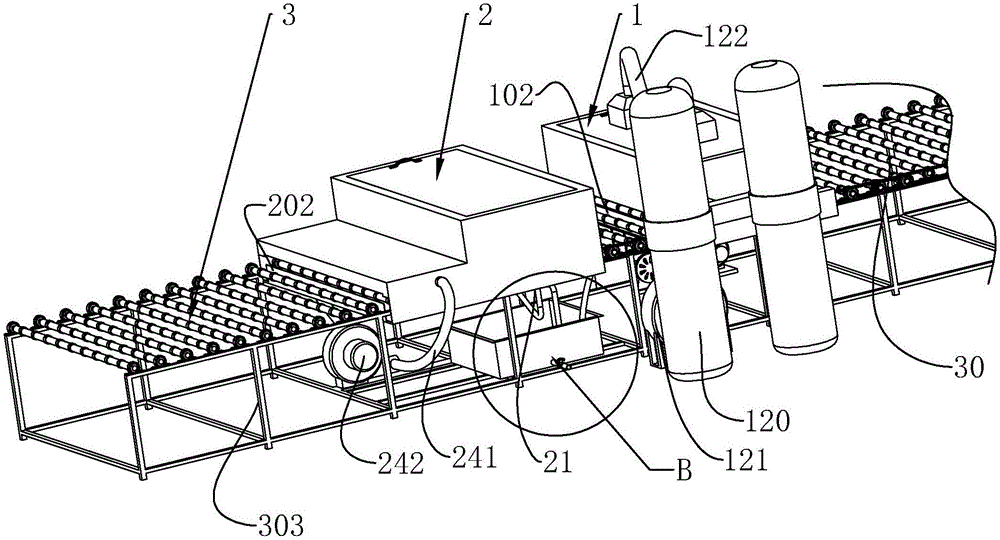

[0038] An automatic cleaning, coating protection, and drying processing equipment for thermal insulation composite boards, including a cleaning device 1, a protective liquid coating device 2, and a stone board conveying device 3 connecting the two and the feeding and discharging positions. Specifically,

[0039] The stone slab conveying device 3 includes three sections: the feeding section, where the stone slabs to be processed are placed (through vacuum handling, automatic feeding by manipulators, etc.); The covering device 2, the feeding section and the processing section together form the conveying section 30; the placing section 31 is connected with the processing section, and is used for temporarily storing the stone boards brought out by the processing section and having completed all the processing steps before cold pressing and compounding . Specifically, the slate conveying device 3 includes a frame supported on the ground and a number of conveying rollers 300 rotata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com